ASTM A906/A906M-02(2010)

(Specification)Standard Specification for Grade 80 and Grade 100 Alloy Steel Chain Slings for Overhead Lifting

Standard Specification for Grade 80 and Grade 100 Alloy Steel Chain Slings for Overhead Lifting

ABSTRACT

This specification covers requirements and method of rating and testing for alloy chain slings. Only component parts compatible with alloy chain shall be used. Sling assembled by welding shall be fabricated by the electric or gas welding process, or both. The material shall undergo proof test to meet the prescribed mechanical requirements. Several grades of alloy chain sling shall conform to the specified working load limit values.

SCOPE

1.1 This specification covers the requirements and method of rating and testing for alloy chain slings. Slings shall be assembled using components manufactured in accordance with Specification A391/A391M for Grade 80 chain, A973/A973M for Grade 100 chain, and A952/A952M for other components. This specification covers welded and mechanically assembled slings.

1.2 This specification does not cover slings used at elevated temperatures (above 400°F [200°C]), in harmful or corrosive environmental conditions or for applications such as nonsymmetrical legs or loading.

1.3 This specification is a performance and assembly specification. Other standards, such as OSHA 1910.184, ASME B30.9, and ASME B30.10, apply to the use of the products in this specification.

1.4 The values stated in either inch-pound units or SI units shall be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore each system shall be used independently of the other, without combining values in any way.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A906/A906M −02(Reapproved 2010)

Standard Specification for

Grade 80 and Grade 100 Alloy Steel Chain Slings for

Overhead Lifting

This standard is issued under the fixed designationA906/A906M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Other Standards:

OSHA 1910.184

1.1 This specification covers the requirements and method

ASME B30.9Slings

of rating and testing for alloy chain slings. Slings shall be

ASME B30.10Hooks

assembledusingcomponentsmanufacturedinaccordancewith

Specification A391/A391M for Grade 80 chain, A973/A973M

3. Terminology

for Grade 100 chain, and A952/A952M for other components.

3.1 Definitions:

This specification covers welded and mechanically assembled

slings. 3.1.1 chain sling—an assembly consisting of alloy steel

chain or chains joined to suitable upper and lower fittings,

1.2 This specification does not cover slings used at elevated

according to the provisions of this specification, for attaching

temperatures (above 400°F [200°C]), in harmful or corrosive

loads to be lifted by a crane or lifting machine.

environmental conditions or for applications such as nonsym-

metrical legs or loading. 3.1.2 coupling link—a link fitted to the end of the chain to

connect to another component of the sling. See Fig. 1.

1.3 This specification is a performance and assembly speci-

3.1.3 master coupling link (secondary or intermediate

fication. Other standards, such as OSHA 1910.184, ASME

link)—a link used on three and four leg slings to connect the

B30.9, andASME B30.10, apply to the use of the products in

legs to a master link. See Fig. 1.

this specification.

3.1.4 master link—a link used as the upper end component

1.4 The values stated in either inch-pound units or SI units

of a chain sling and by means of which the sling is attached to

shallberegardedseparatelyasstandard.Withinthetext,theSI

a crane or other lifting machine. See Fig. 1.

units are shown in brackets. The values stated in each system

are not exact equivalents; therefore each system shall be used

3.1.5 overhead lifting—that process of lifting which would

independently of the other, without combining values in any

elevateafreelysuspendedloadtosuchapositionthatdropping

way.

theloadwouldpresentapossibilityofbodilyinjuryorproperty

damage.

2. Referenced Documents

3.1.6 proof test—a term designating a quality control test

2.1 ASTM Standards:

applied to a sling or to components of a sling. It is the

A391/A391MSpecification for Grade 80 Alloy Steel Chain

minimum force in pounds or newtons which the sling and

A952/A952MSpecification for Forged Grade 80 and Grade

components have withstood under a test in which a constantly

100 Steel Lifting Components and Welded Attachment

increasing force has been applied in direct tension.

Links

3.1.7 length (reach)—the distance from the bearing point of

A973/A973MSpecificationforGrade100AlloySteelChain

the upper end fitting to the bearing point of the lower end

fitting. See Fig. 1.

3.1.8 sling angle—that angle measured between the hori-

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

zontal plane and the leg (legs) of the sling. See Tables 1-3.

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

A01.27 on Steel Chain.

Current edition approved April 1, 2010. Published May 2010. Originally

approved in 1991. Last previous edition approved in 2002 as A906/A906M – 02.

DOI: 10.1520/A0906_A0906M-02R10. Available from Occupational Safety and Health Administration (OSHA), 200

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Constitution Ave., NW, Washington, DC 20210, http://www.osha.gov.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Society of Mechanical Engineers (ASME), ASME

Standards volume information, refer to the standard’s Document Summary page on International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

the ASTM website. www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A906/A906M−02 (2010)

FIG. 1Chain Sling Major Components

TABLE 1 Chain and Single Leg Grade 80 Sling WLL Data

5.1.1 Conformance to ASTM designation A906 or A906M

and year of issue,

5.1.2 Size of sling in inches [millimetres],

5.1.3 Grade of sling,

5.1.4 Typeofsling(s)asdesignatedbythesymbolsdepicted

in Table 7, if possible,

5.1.5 Quantity ordered,

5.1.6 Reach of sling(s),

5.1.7 Sling angle, and

5.1.8 Certification of proof test(s), if required.

Grade 80 Chain Size Single Leg WLL (max)

in. mm lb kg

6. Manufacture

⁄32 5.5 2100 950

⁄32 7 3500 1600

6.1 Assembly:

⁄16 8 4500 2000

6.1.1 Only component parts compatible with alloy chain

⁄8 10 7100 3200

1 shall be used.

⁄2 13 12 000 5400

⁄8 16 18 100 8200 6.1.2 Slingsassembledbyweldingshallbefabricatedbythe

⁄4 20 28 300 12 800

electric or gas welding process, or both.

⁄8 22 34 200 15 500

6.1.3 Mechanically assembled slings shall be assembled in

1 26 47 700 21 600

1 ⁄4 32 72 300 32 800

accordance with component manufacturer’s recommendations.

6.1.4 Components shall be assembled so as to ensure free

articulation of the sling.

3.1.9 working load limit (WLL)—the maximum load which

7. Mechanical Requirements

a sling is designed to support in direct tension without shock

7.1 Proof Test:

loading at a designated sling angle of lift.

7.1.1 All components of a sling, either individually or as an

assembly, shall be proof tested as required in 7.1.2 – 7.1.4.

4. Classification

7.1.2 The proof test load for single leg slings and compo-

4.1 There are two grades of chain slings covered under this

nents attached to single legs shall be twice the working load

specification. The size of a sling is denoted by the size of the

limit for the size and grade chain.

chain used in its manufacture. The grade of a sling is denoted

7.1.3 The proof test load for components attached to two

by the lowest grade component used in its manufacture.

legsofaslingshallbefourtimestheworkingloadlimitforthe

4.1.1 Grade 80.

size and grade chain.

4.1.2 Grade 100.

7.1.4 Theprooftestloadforcomponentsattachedtothreeor

fourlegsofaslingshallbesixtimestheworkingloadlimitfor

5. Ordering Information

the size and grade chain.

5.1 It shall be the responsibility of the purchaser to specify 7.1.5 All sling components shall withstand the proof test

all requirements that are necessary for material ordered under load without loss of integrity or detrimental dimensional

this specification. Such requirements to be considered include, changes. Components that do not withstand the proof test shall

but are not limited to, the following: be discarded.

A906/A906M−02 (2010)

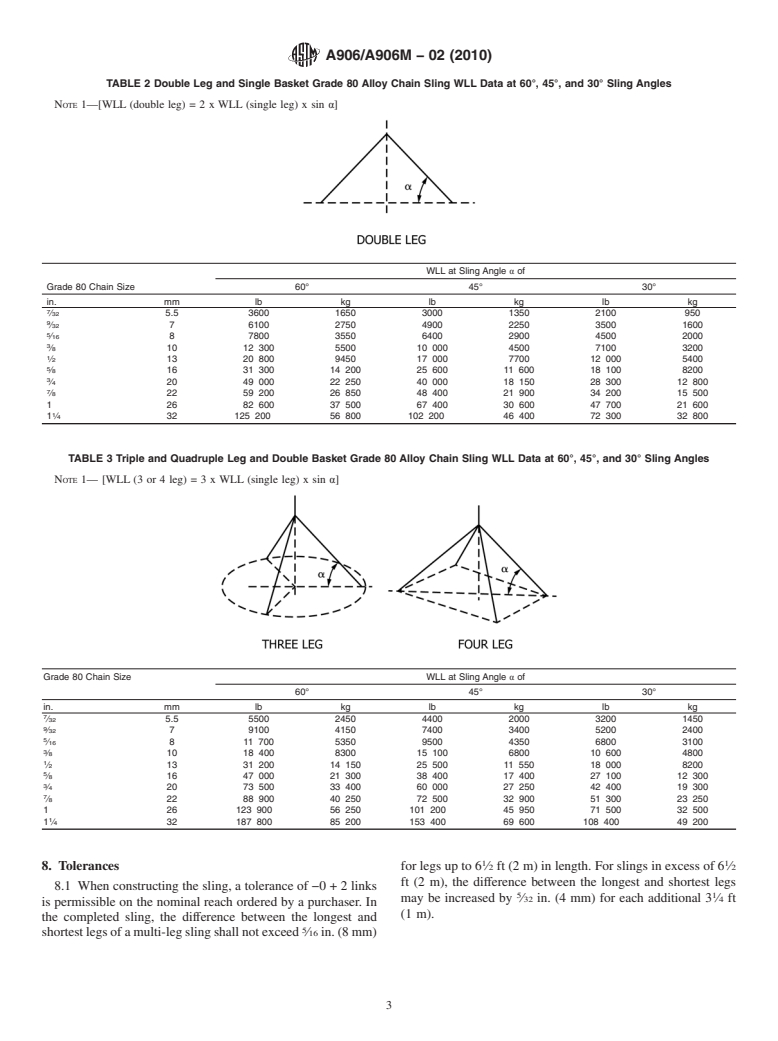

TABLE 2 Double Leg and Single Basket Grade 80 Alloy Chain Sling WLL Data at 60°, 45°, and 30° Sling Angles

NOTE 1—[WLL (double leg)=2xWLL (single leg) x sin α]

WLL at Sling Angle α of

Grade 80 Chain Size 60° 45° 30°

in. mm lbkglbkglbkg

⁄32 5.5 3600 1650 3000 1350 2100 950

⁄32 7 6100 2750 4900 2250 3500 1600

⁄16 8 7800 3550 6400 2900 4500 2000

⁄8 10 12 30

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.