ASTM A952/A952M-02(2022)

(Specification)Standard Specification for Forged Grade 80 and Grade 100 Steel Lifting Components and Welded Attachment Links

Standard Specification for Forged Grade 80 and Grade 100 Steel Lifting Components and Welded Attachment Links

ABSTRACT

This specification covers forged alloy steel lifting components and welded coupling and master links for Grade 80 and Grade 100 alloy chain slings. The steel materials shall be melt processed either by electric process or oxygen blown process. The steel shall be fully killed and shall conform to the required austenitic grain size. Product analysis shall be performed on and the steel specimens shall conform to the required chemical compositions of nickel, chromium, molybdenum, phosphorus and sulfur. Proof tests shall be performed and the materials shall conform to the required values of working load and breaking force. Deformation test, breaking force test and fatigue test shall be performed on the steel materials.

SCOPE

1.1 This specification covers the requirements for forged alloy steel lifting components and welded coupling and master links for Grade 80 and Grade 100 alloy chain slings as described in Specification A906/A906M.

1.2 Two grades of components and welded links are covered:

1.2.1 Grade 80.

1.2.2 Grade 100.

1.3 This specification is a performance standard. Other standards apply to use of these products. Some of these standards are: OSHA 1910.184, ASME B30.9, and ASME B30.10.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A952/A952M −02 (Reapproved 2022)

Standard Specification for

Forged Grade 80 and Grade 100 Steel Lifting Components

and Welded Attachment Links

This standard is issued under the fixed designationA952/A952M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A391/A391M Specification for Grade 80 Alloy Steel Chain

A751 Test Methods and Practices for Chemical Analysis of

1.1 This specification covers the requirements for forged

Steel Products

alloy steel lifting components and welded coupling and master

A906/A906M Specification for Grade 80 and Grade 100

links for Grade 80 and Grade 100 alloy chain slings as

Alloy Steel Chain Slings for Overhead Lifting

described in Specification A906/A906M.

A973/A973M Specification for Grade 100Alloy Steel Chain

1.2 Two grades of components and welded links are cov-

E4 Practices for Force Calibration and Verification of Test-

ered:

ing Machines

1.2.1 Grade 80.

E44 Definitions for Terms Relating to Heat Treatment of

1.2.2 Grade 100.

Metals (Withdrawn 1993)

1.3 This specification is a performance standard. Other E165/E165M Practice for Liquid Penetrant Testing for Gen-

eral Industry

standards apply to use of these products. Some of these

standards are: OSHA 1910.184, ASME B30.9, and ASME E709 Guide for Magnetic Particle Testing

B30.10.

2.2 Other Standards:

OSHA 1910.184 Slings

1.4 The values stated in either inch-pound units or SI units

ASME B30.9 Slings

are to be regarded separately as standard. Within the text, the

ASME B30.10 Hooks

SI units are shown in brackets. The values stated in each

system are not necessarily exact equivalents; therefore, to

3. Terminology

ensure conformance with the standard, each system shall be

used independently of the other, and values from the two 3.1 Definitions of Terms Specific to This Standard:

systems shall not be combined.

3.1.1 breaking force, minimum—the minimum force in

pounds or newtons at which the component has been found by

1.5 This international standard was developed in accor-

verification testing to break when a constantly increasing force

dance with internationally recognized principles on standard-

was applied in direct tension. This test is a manufacturer’s

ization established in the Decision on Principles for the

design verification test and shall not be used as criteria for

Development of International Standards, Guides and Recom-

service.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

3.1.2 chain sling—an assembly consisting of alloy steel

chain joined to upper and lower end components for attaching

2. Referenced Documents

loads to be lifted by a crane or lifting machine.

2.1 ASTM Standards:

3.1.3 coupling link—a link fitted to the end of the chain to

A29/A29M SpecificationforGeneralRequirementsforSteel

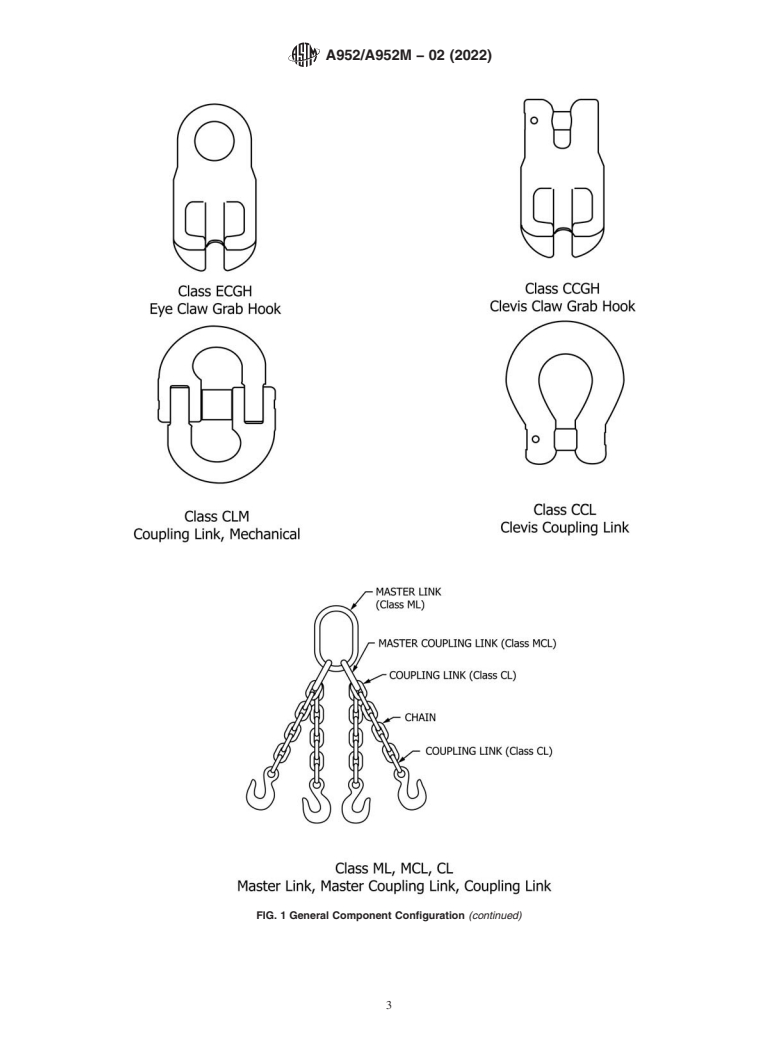

connect to another component of the sling. See Fig. 1.

Bars, Carbon and Alloy, Hot-Wrought

3.1.4 master link—alinkusedasanupperendcomponentof

a chain sling and by means of which the sling may be attached

to a crane or other device. See Fig. 1.

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.27 on Steel Chain.

Current edition approved March 1, 2022. Published March 2022. Originally The last approved version of this historical standard is referenced on

approved in 1996. Last previous edition approved in 2016 as A952/ www.astm.org.

A952M–02(2016). DOI: 10.1520/A0952_A0952M-02R22. Available from Occupational Safety and Health Administration (OSHA), 200

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Constitution Ave., NW, Washington, DC 20210, http://www.osha.gov.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Society of Mechanical Engineers (ASME), ASME

Standards volume information, refer to the standard’s Document Summary page on International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

the ASTM website. www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A952/A952M−02 (2022)

FIG. 1 General Component Configuration

A952/A952M−02 (2022)

FIG. 1 General Component Configuration (continued)

A952/A952M−02 (2022)

3.1.5 master coupling link (secondary or intermediate 5.1.8 Acceptance of inspection by purchaser, if required.

link)—a link used on three and four leg slings to connect the

5.1.9 Supplementary requirements, if required.

legs to a master link. See Fig. 1.

NOTE 1—Component size and working load limits are based on Grade

3.1.6 proof test—a quality control tensile test applied to

80 and Grade 100 alloy steel chain nominal sizes. See Specifications

components for the purpose of verifying manufacturing and A391/A391M and A973/A973M.

material quality. It is the minimum force in pounds or newtons

which the component has withstood at the time it left the 6. Materials

producer, under a test in which a constantly increasing force

6.1 Quality—The selection of the type of steel is left to the

has been applied in direct tension. Proof test loads are a

judgment of the manufacturer provided the material meets the

manufacturingintegritytestandshallnotbeusedascriteriafor

requirements set forth in 6.2 and 6.3.

service.

6.2 Melting Process—The steel used shall be produced by

3.1.7 traceability code—a series of letters, or numbers, or

an electric process or by an oxygen blown process. The steel

both, marked on a component which enables its manufacturing

shall be fully killed and have an austenitic grain size of 5 or

history, including identity of the steel heat, to be traced.

finer.

3.1.8 working load limit (WLL)—the maximum combined

6.3 Chemical Requirements:

static and dynamic load in pounds or kilograms that shall be

6.3.1 The alloy steel used shall contain at least two of the

applied in direct tension to the component.

three alloying agents in the minimum percentages as listed

4. Classification below:

Nickel 0.40 % minimum

4.1 Only Grade 80 and Grade 100 components are covered

Chromium 0.40 % minimum

under this specification.

Molybdenum 0.15 % minimum

4.2 Sixteen classes of components are covered under this

6.3.2 The phosphorous and sulfur content of the steel shall

specification. The general configuration on these components

not exceed 0.025 % for each element.

are shown in Fig. 1.

6.3.3 Product Analysis—The steel used may be analyzed by

4.2.1 Class EGH—Eye Grab Hook.

the purchaser and shall conform to the requirements of 6.3.1

4.2.2 Class CGH—Clevis Grab Hook.

and 6.3.2 subject to the product analysis tolerances specified in

4.2.3 Class ESH—Eye Sling Hook.

Specification A29/A29M. Test samples may be taken from

4.2.4 Class CSH—Clevis Sling Hook.

rods, bars, or finished product.

4.2.5 Class EFH—Eye Foundry Hook.

6.3.4 Chemical analysis of material covered by this speci-

4.2.6 Class CFH—Clevis Foundry Hook.

fication for referee purposes shall be in accordance with Test

4.2.7 Class CLM—Coupling Link, Mechanical.

Methods and Practices A751.

4.2.8 Class ESLH—Eye Self-Locking Hook.

4.2.9 Class CSLH—Clevis Self-Locking Hook.

7. Manufacture

4.2.10 Class ECGH—Eye Claw Grab Hook.

7.1 The body of all components shall be forged hot in one

4.2.11 Class CCGH—Clevis Claw Grab Hook.

piece, with the exception of Class ML, MCL, and CL link

4.2.12 Class ML—Master Link.

components.

4.2.13 Class MCL—Master Coupling Link.

4.2.14 Class CL—Coupling Link.

7.2 Excess metal flash shall be cleanly removed, leaving the

4.2.15 Class CCL—Clevis Coupling Link.

surface free from sharp edges.

4.2.16 Class OTH—Specialty components may be required

7.3 Class ML, MCL, and CL link components may be

for certain applications.

manufactured using the electric welding, gas welding, or

4.3 For the classes listed in 4.2, an “S” prefix denotes a

forging process.

component with a swivel joint.

7.4 Ancillary components such as load pins, latches,

5. Ordering Information

bearings, and springs need not be forged components.

5.1 It shall be the responsibility of the purchaser to specify

7.5 Welding shall not be used to repair forged components.

all requirements that are necessary for material ordered under

Grindingofsurfacediscontinuitiesmaybecarefullyperformed

this specification. Such requirements to be considered include,

aslongasnodimensionisalteredoutsideofthemanufacturer’s

but are not limited to, the following:

dimensions and tolerances for that component. All ground

5.1.1 Product to conform to Specification A952 or Specifi-

areas must blend in smoothly with the surface.

cation A952M and year of issue.

7.6 Heat Treatment—After forging or welding is completed,

5.1.2 Nominal size of component, in. [mm] (see Note 1).

each load bearing component shall be heat treated before

5.1.3 Grade of component.

applying the proof test. Heat treatment shall include quenching

5.1.4 Class of component.

and tempering as defined in Definitions E44.

5.1.5 Quantity of components.

5.1.6 Finish, if required. 7.7 After heat treatment, furnace scale shall be removed

5.1.7 Certification, if required. from the component.

A952/A952M−02 (2022)

TABLE 2 Mechanical Requirements for Grade 100 Single Leg

8. Performance Requirements

Components

8.1 Proof Test—All components shall be proof tested as

Nominal Size Working Load Proof Test, min Breaking Force,

required in accordance with 8.1.1 through 8.1.5.All tests shall

Limit, max min

be performed on equipment certifiable to Practices E4.

in. mm lb kg lbkNlbkN

8.1.1 All components used on single legs of slings shall be

⁄32 5.5 2700 1220 5400 23.8 10 800 47.6

⁄32 7.0 4300 1950 8600 38.5 17 200 77

tested to at least the proof test load prescribed in Table 1 for

⁄16 8.0 5700 2600 11 400 51 22 800 102

Grade 80 components and Table 2 for Grade 100 components.

⁄8 10.0 8800 4000 17 600 79 35 200 158

8.1.2 All components to which two legs of a sling are 1

⁄2 13.0 15 000 6800 30 000 134 60 000 268

attached shall be proof tested to at least a load equal to four ⁄8 16.0 22 600 10 300 45 200 201 90 400 402

⁄4 20.0 35 300 16 000 70 600 315 141 200 630

times the working load limit of the r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.