ASTM D5354-95

(Test Method)Standard Test Method for Determination of Total Active Ingredients in Sulfonated and Sulfated Oils

Standard Test Method for Determination of Total Active Ingredients in Sulfonated and Sulfated Oils

SCOPE

1.1 This test method covers the determination of the total active ingredients in a sample of sulfonated or sulfated oil, or both, as it exists in the original sample by extracting the undecomposed sulfonated or sulfated fat and other fatty matter over an acidified concentrated salt solution. Free alkali or alkali bound as soap is not included. This test method was derived from Test Methods D500.

Note 1—In the case of sulfated oils only, this determination may also be estimated by calculation (see 6.3), as it is equivalent to the sum of the desulfated fatty matter and neutralized organically combined sulfuric anhydride.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

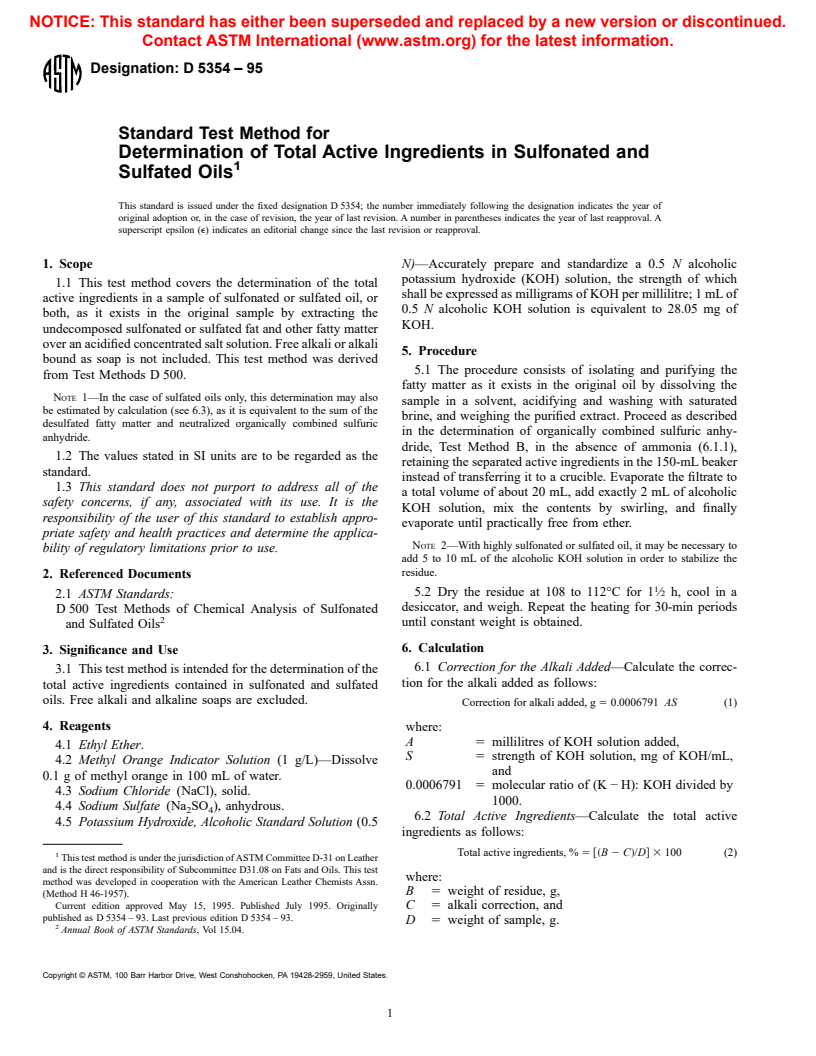

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5354 – 95

Standard Test Method for

Determination of Total Active Ingredients in Sulfonated and

Sulfated Oils

This standard is issued under the fixed designation D 5354; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope N)—Accurately prepare and standardize a 0.5 N alcoholic

potassium hydroxide (KOH) solution, the strength of which

1.1 This test method covers the determination of the total

shall be expressed as milligrams of KOH per millilitre; 1 mL of

active ingredients in a sample of sulfonated or sulfated oil, or

0.5 N alcoholic KOH solution is equivalent to 28.05 mg of

both, as it exists in the original sample by extracting the

KOH.

undecomposed sulfonated or sulfated fat and other fatty matter

over an acidified concentrated salt solution. Free alkali or alkali

5. Procedure

bound as soap is not included. This test method was derived

5.1 The procedure consists of isolating and purifying the

from Test Methods D 500.

fatty matter as it exists in the original oil by dissolving the

NOTE 1—In the case of sulfated oils only, this determination may also

sample in a solvent, acidifying and washing with saturated

be estimated by calculation (see 6.3), as it is equivalent to the sum of the

brine, and weighing the purified extract. Proceed as described

desulfated fatty matter and neutralized organically combined sulfuric

in the determination of organically combined sulfuric anhy-

anhydride.

dride, Test Method B, in the absence of ammonia (6.1.1),

1.2 The values stated in SI units are to be regarded as the

retaining the separated active ingredients in the 150-mL beaker

standard.

instead of transferring it to a crucible. Evaporate the filtrate to

1.3 This standard does not purport to address all of the

a total volume of about 20 mL, add exactly 2 mL of alcoholic

safety concerns, if any, associated with its use. It is the

KOH solution, mix the contents by swirling, and finally

responsibility of the user of this standard to establish appro-

evaporate until practically free from ether.

priate safety and health practices and determine the applica-

NOTE 2—With highly sulfonated or sulfated oil, it may be necessary to

bility of regulatory limitations prior to use.

add 5 to 10 mL of the alcoholic KOH solution in order to stabilize the

residue.

2. Referenced Documents

5.2 Dry the residue at 108 to 112°C for 1 ⁄2 h, cool in a

2.1 ASTM Standards:

desiccator, and weigh. Repeat the heating for 30-min periods

D 500 Test Methods of Chemical Analysis of Sulfonated

until constant weight is obtained.

and Sulfated Oils

6. Calculation

3. Significance and Use

6.1 Correction for the Alkali Added—Calculate the correc-

3.1 This test method is intended for the determination of the

tion for the alkali added as follows:

total active ingredients contained in sulfonated and sulfated

oils. Free alkali and alkaline soaps are excluded.

Correction for alkali added, g 5 0.0006791 AS (1)

4. Reagents

where:

A 5 millilitres of KOH solution added,

4.1 Ethyl Ether.

S 5 strength of KOH solution, mg o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.