ASTM D6653/D6653M-13

(Test Method)Standard Test Methods for Determining the Effects of High Altitude on Packaging Systems by Vacuum Method

Standard Test Methods for Determining the Effects of High Altitude on Packaging Systems by Vacuum Method

SIGNIFICANCE AND USE

4.1 Packaged products transported via the feeder aircraft network are liable to experience altitudes as high as 5 791 m [19 000 ft].4 When exposed to these high altitude conditions, products or packaging systems, or a combination thereof, may be affected negatively by the resultant pressure differential.

4.2 These test methods are suitable for evaluating the effect of high altitude on packaging systems.

4.3 These test methods are suitable for package or product, or both, development and engineering.

4.4 Other test methods, such as Test Methods D3078, D4991 and D5094, test for leakage of packaging systems by vacuum method and are applicable for testing the effects of high altitude.

SCOPE

1.1 These test methods determine the effects of pressure differential when packaged products are transported via certain modes of transport, such as feeder aircraft or ground over high mountain passes. The results of these tests are intended to be used for qualitative purposes.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6653/D6653M − 13

Standard Test Methods for

Determining the Effects of High Altitude on Packaging

1

Systems by Vacuum Method

This standard is issued under the fixed designation D6653/D6653M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E122 Practice for Calculating Sample Size to Estimate,With

Specified Precision, the Average for a Characteristic of a

1.1 These test methods determine the effects of pressure

Lot or Process

differential when packaged products are transported via certain

2.2 Other:

modes of transport, such as feeder aircraft or ground over high

Altitude-pressuretablesbasedontheUnitedStatesStandard

mountain passes. The results of these tests are intended to be

3

Atmospheres

used for qualitative purposes.

1.2 The values stated in either SI units or inch-pound units

3. Terminology

are to be regarded separately as standard. The values stated in

3.1 Definitions—Terms and definitions used in these test

each system may not be exact equivalents; therefore, each

methods may be found in Terminology D996.

system shall be used independently of the other. Combining

3.2 Definition of Term:

values from the two systems may result in non-conformance

with the standard. 3.2.1 feeder aircraft, n—small, potentially nonpressurized

aircraft used to transport express air packages to remote areas.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

4.1 Packaged products transported via the feeder aircraft

priate safety and health practices and determine the applica-

network are liable to experience altitudes as high as 5 791 m

bility of regulatory limitations prior to use.

4

[19 000 ft]. When exposed to these high altitude conditions,

2. Referenced Documents products or packaging systems, or a combination thereof, may

2 be affected negatively by the resultant pressure differential.

2.1 ASTM Standards:

D996 Terminology of Packaging and Distribution Environ-

4.2 These test methods are suitable for evaluating the effect

ments of high altitude on packaging systems.

D3078 Test Method for Determination of Leaks in Flexible

4.3 These test methods are suitable for package or product,

Packaging by Bubble Emission

or both, development and engineering.

D4169 Practice for Performance Testing of Shipping Con-

4.4 Other test methods, such as Test Methods D3078,

tainers and Systems

D4991 and D5094, test for leakage of packaging systems by

D4332 Practice for Conditioning Containers, Packages, or

vacuum method and are applicable for testing the effects of

Packaging Components for Testing

high altitude.

D4991 Test Method for Leakage Testing of Empty Rigid

Containers by Vacuum Method

5. Apparatus

D5094 Test Methods for Gross Leakage of Liquids from

5.1 Vacuum Chamber—Any suitable chamber capable of

Containers with Threaded or Lug-Style Closures

withstanding approximately one atmosphere pressure differen-

tial fitted with a flat-vacuum-tight cover or equivalent chamber

1

These test methods are under the jurisdiction of ASTM Committee D10 on

providing the same functional capabilities, such as an altitude

Packaging and is the direct responsibility of Subcommittee D10.21 on Shipping

chamber.

Containers and Systems - Application of Performance Test Methods.

Current edition approved Jan. 15, 2013. Published February 2013. Originally

approved in 2001. Last previous edition approved in 2010 as D6653/D6653M – 01

3

(Reapproved 2010). DOI: 10.1520/D6653_D6653M-13. Available from http://naca.larc.nasa.gov/reports/1936/naca-report-538/.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Basedonfieldtestinganalysis.SeeSingh,S.P.,Singh,J.,Stallings,J.,Burgess,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM G., and Saha, K., “Measurement andAnalysis of Temperature and Pressure in High

Standards volume information, refer to the standard’s Document Summary page on Altitude Air Shipments,” Journal of Packaging Technology and Science, Vol. 23,

the ASTM website. Issue 1, pp. 35 – 46, December 2009.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6653/D6653M − 13

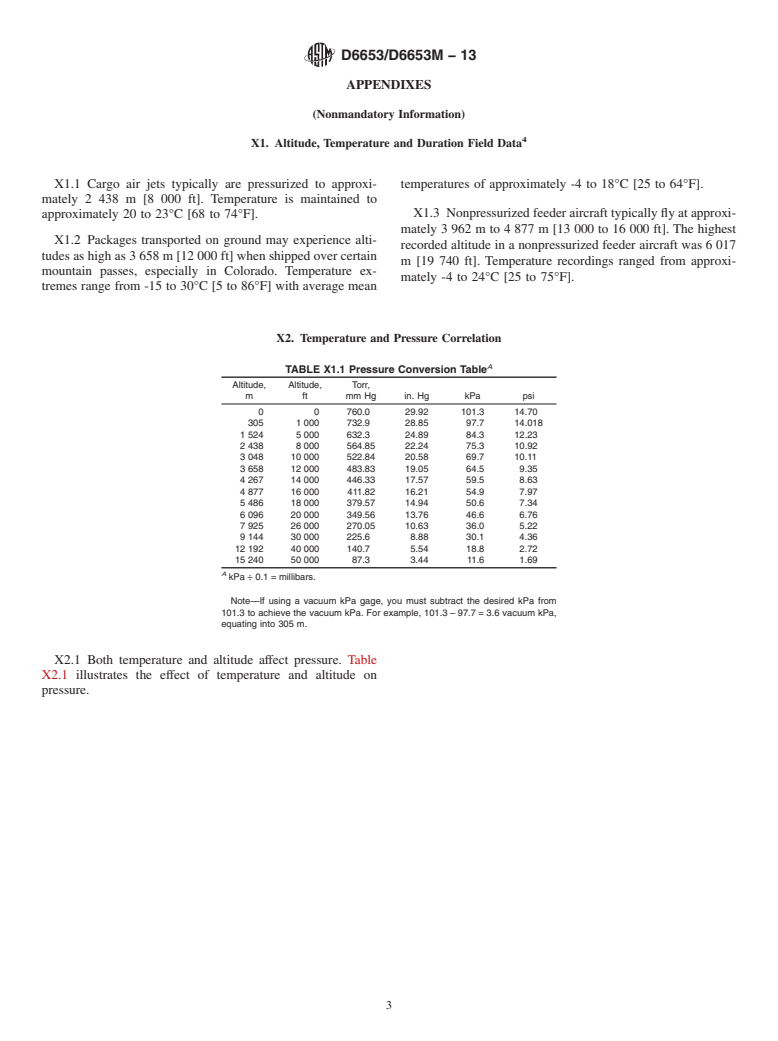

5.2 Vacuum Gage, Inlet Tube from a Source of Vacuum and damage level acceptances, or other criteria (see Appendix X1

Outlet Tube to the Atmosphere, shall be sealed to the chamber. and Table X2.1 for guidance).

The inlet and outlet tubes shall be

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D6653/D6653M − 01 (Reapproved 2010) D6653/D6653M − 13

Standard Test Methods for

Determining the Effects of High Altitude on Packaging

1

Systems by Vacuum Method

This standard is issued under the fixed designation D6653/D6653M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Units information was corrected editorially in March 2011.

1. Scope

1.1 These test methods determine the effects of pressure differential when packaged products are transported via certain modes

of transport, such as feeder aircraft or ground over high mountain passes. The results of these tests are intended to be used for

qualitative purposes.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D996 Terminology of Packaging and Distribution Environments

D3078 Test Method for Determination of Leaks in Flexible Packaging by Bubble Emission

D4169 Practice for Performance Testing of Shipping Containers and Systems

D4332 Practice for Conditioning Containers, Packages, or Packaging Components for Testing

D4991 Test Method for Leakage Testing of Empty Rigid Containers by Vacuum Method

D5094 Test Methods for Gross Leakage of Liquids from Containers with Threaded or Lug-Style Closures

E122 Practice for Calculating Sample Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or

Process

2.2 Other:

3

Altitude-pressure tables based on the United States Standard Atmospheres

3. Terminology

3.1 Definitions—Terms and definitions used in these test methods may be found in Terminology D996.

3.2 Definition of Term:

3.2.1 feeder aircraft, n—small, potentially nonpressurized aircraft used to transport express air packages to remote areas.

1

These test methods are under the jurisdiction of ASTM Committee D10 on Packaging and is the direct responsibility of Subcommittee D10.21 on Shipping Containers

and Systems - Application of Performance Test Methods.

Current edition approved Oct. 1, 2010Jan. 15, 2013. Published March 2011February 2013. Originally approved in 2001. Last previous edition approved in 20062010 as

D6653 – 01D6653/D6653M – 01 (Reapproved 2006).2010). DOI: 10.1520/D6653_D6653M-01R10E01.10.1520/D6653_D6653M-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from http://naca.larc.nasa.gov/reports/1936/naca-report-538/.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6653/D6653M − 13

4. Significance and Use

4.1 Packaged products transported via the feeder aircraft network are liable to experience altitudes as high as 5 791 m [19 000

4

ft]. When exposed to these high altitude conditions, products or packaging systems, or a combination thereof, may be affected

negatively by the resultant pressure differential.

4.2 These test methods are suitable for evaluating the effect of high altitude on packaging systems.

4.3 These test methods are suitable for package or product, or both, development and engineering.

4.4 Other test methods, such as Test Methods D3078, D4991 and D5094, test for leakage of packaging systems by vacuum

method and are applicable for testing the effects of high altitude.

5. Apparatus

5.1 Vacuum Chamber—Any suitable chamber capable of withstanding approximately one atmosphere pressure differential fitted

with a flat-vacuum-tight cover or equivalent chamber providing the same functional capabilities, such as an altitude chamber.

5.2 Vacuum Gage, Inlet Tube from a Source of Vacuum and Ou

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.