ASTM D7359-08

(Test Method)Standard Test Method for Total Fluorine, Chlorine and Sulfur in Aromatic Hydrocarbons and Their Mixtures by Oxidative Pyrohydrolytic Combustion followed by Ion Chromatography Detection (Combustion Ion Chromatography-CIC)

Standard Test Method for Total Fluorine, Chlorine and Sulfur in Aromatic Hydrocarbons and Their Mixtures by Oxidative Pyrohydrolytic Combustion followed by Ion Chromatography Detection (Combustion Ion Chromatography-CIC)

SIGNIFICANCE AND USE

The total fluorine, chlorine and sulfur contained in aromatic hydrocarbon matrices can contribute to emissions, be harmful to many catalytic chemical processes, and lead to corrosion. This test method can be used to determine total sulfur and halogens aromatic hydrocarbon matrices, in finished products and can be used for compliance determinations when acceptable to a regulatory authority using performance based criteria.

SCOPE

1.1 This test method covers the individual determination of total fluorine, chlorine and sulfur in aromatic hydrocarbons and their mixtures. Samples containing 0.1 to 50 mg/kg of each element can be analyzed.

1.2 This method can be applied to sample types outside the range of the scope by dilution of the sample in an appropriate solvent to bring the total concentrations of fluorine, chlorine and sulfur within the range covered by the test method. However, it is the responsibility of the analyst to verify the solubility of the sample in the solvent and that the diluted sample results conform to the precision and accuracy of the method.

1.3 In determining the conformance of the test results using this method to applicable specifications, results shall be rounded off in accordance with the rounding-off method of Practice E 29.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Section 8.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7359 − 08

StandardTest Method for

Total Fluorine, Chlorine and Sulfur in Aromatic

Hydrocarbons and Their Mixtures by Oxidative

Pyrohydrolytic Combustion followed by Ion

Chromatography Detection (Combustion Ion

Chromatography-CIC)

This standard is issued under the fixed designation D7359; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D6809 Guide for Quality Control and Quality Assurance

Procedures for Aromatic Hydrocarbons and Related Ma-

1.1 This test method covers the individual determination of

terials

totalfluorine,chlorineandsulfurinaromatichydrocarbonsand

E29 Practice for Using Significant Digits in Test Data to

their mixtures. Samples containing 0.1 to 50 mg/kg of each

Determine Conformance with Specifications

element can be analyzed.

2.2 Other Documents:

1.2 This method can be applied to sample types outside the

OSHA Regulations, 29 CFR paragraphs 1910.1000 and

range of the scope by dilution of the sample in an appropriate

1910.1200

solvent to bring the total concentrations of fluorine, chlorine

and sulfur within the range covered by the test method.

3. Summary of Test Method

However, it is the responsibility of the analyst to verify the

3.1 A sample of known weight or volume is placed into a

solubility of the sample in the solvent and that the diluted

sample boat and introduced at a controlled rate into a high

sample results conform to the precision and accuracy of the

temperature combustion tube. There the sample is combusted

method.

in an oxygen rich pyrohydrolytic environment. The gaseous

1.3 In determining the conformance of the test results using

by-products of the combusted sample are trapped in an

this method to applicable specifications, results shall be

absorption medium where the hydrogen halides (HX) formed

rounded off in accordance with the rounding-off method of -

during combustion disassociate into their respective ions, X

Practice E29.

while the sulfur oxides (SO ) formed are further oxidized to

X

2-

1.4 The values stated in SI units are to be regarded as

SO in the presence of an oxidizing agent. An aliquot of

standard. No other units of measurement are included in this known volume of the adsorbing solution is then automatically

standard. injected into an ion chromatograph (IC) by means of a sample

injectionvalve.Thehalideandsulfateanionsareseparatedinto

1.5 This standard does not purport to address all of the

individualelutionbandsontheseparatorcolumnoftheIC.The

safety concerns, if any, associated with its use. It is the

conductivity of the eluent is reduced with an anion suppression

responsibility of the user of this standard to establish appro-

device prior to the ion chromatograph’s thermal conductivity

priate safety and health practices and determine the applica-

detector, where the anions of interest are measured. Quantifi-

bility of regulatory limitations prior to use. See Section 8.

cation of the fluorine, chlorine and sulfur in the original

2. Referenced Documents

combusted sample is achieved by first calibrating the system

with a series of standards containing known amounts of

2.1 ASTM Standards:

fluorine, chlorine and sulfur and then analyzing unknown

D1193 Specification for Reagent Water

samples under the same conditions as the standards. The

combined system of pyrohydrolytic combustion followed by

This test method is under the jurisdiction of ASTM Committee D16 on

Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of

ionchromatographicdetectionisreferredtoasCombustionIon

Subcommittee D16.04 on Instrumental Analysis.

Chromatography (CIC).

Current edition approved Oct. 15, 2008. Published November 2008. DOI:

10.1520/D7359-08.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

Standards volume information, refer to the standard’s Document Summary page on 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

the ASTM website. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7359 − 08

4. Significance and Use bustion by-products (HX and SO2) are absorbed. The Gas

Adsorption Unit rinses the gas lines and adsorption tube with

4.1 The total fluorine, chlorine and sulfur contained in

TypeIreagentwater(7.2)priortosamplecombustionandafter

aromatic hydrocarbon matrices can contribute to emissions, be

the absorption solution is injected into the Ion Chromatograph

harmful to many catalytic chemical processes, and lead to

to minimize cross contamination from the previous analysis.

corrosion. This test method can be used to determine total

sulfur and halogens aromatic hydrocarbon matrices, in finished 6.8 Gas-Tight Sampling Syringe, capable of accurately de-

products and can be used for compliance determinations when

livering 10 to 80 µL of standard or sample.

acceptable to a regulatory authority using performance based

6.9 Pyrohydrolytic Combustion Tube made of quartz and

criteria.

constructed such that when the sample is combusted in the

presence of humidified oxygen, the by-products of combustion

5. Interferences

are swept into the humidified pyrohydrolytic combustion zone.

5.1 Substances that co-elute with the anions of interest will

The inlet end shall allow for the stepwise introduction and

interfere. A high concentration of one anion can interfere with

advancement of a sample boat into the heated zone and shall

other constituents if their retention times are close enough to

have a side arm for the introduction of the humidified carrier

affect the resolution of their peak.

gas and oxygen. The pyrohydrolytic combustion tube must be

of ample volume, and have a heated zone with quartz wool or

6. Apparatus

other suitable medium providing sufficient surface area so that

6.1 Autosampler (Optional), capable of accurately deliver-

the complete pyrohydrolytic combustion of the sample is

ing 10 to 80 µL of sample into the sample boat. The

ensured.

autosampler may be used as long as the accuracy and perfor-

6.10 Humidifier Delivery System, capable of delivering

mance of the method is not degraded.

Type 1 reagent water (7.2) to the combustion tube at a

NOTE 1—Multiple rinsing with clean solvent between sample injections

controlled rate sufficient to provide a pyrohydrolytic environ-

and/or sampling between different sample vials to minimize carryover

ment.

contamination from previous samples is recommended. A solvent flush

from a vial separate from the solvent wash, providing clean, uncontami-

6.11 Ion Chromatograph (IC) , equipped with:

nated solvent may also be used. These features may be used as long as

6.11.1 High Performance inert PEEK-

they do not degrade the performance and accuracy of the method.

(polyetheretherketone) flow path system is required.

6.2 Balance, analytical, with sensitivity to 0.0001 g.

6.11.2 High Pressure eluent pump, capable of delivering

6.3 Boat Inlet System—Thesystemprovidesasamplingport

0.0 to 5 mL/min (without eluent generator; 0.1 to 3 mL/min

for the introduction of liquid and solid samples into the sample

(with eluent generator), in 0.01 mL/min increments. Flow rate

boat and is connected to the inlet of the Pyrohydrolytic

accuracy of <1 % of the set value and precision of <2 % is

Combustion Tube. The system is swept by a humidified inert

required.

carrier gas and shall be capable of allowing the quantitative

6.11.3 ConductivityDetector,capableofanoperatingrange

delivery of the material to be analyzed into the pyrohydrolytic

of 0 to 15 000 µS with a linearity correlation coefficient of

oxidation zone at a controlled and repeatable rate.

0.999 and %RSD <5 % at 800 µS. Detector cell constructed of

6.4 Boat Inlet Cooler (Optional)—Sample volatility and

PEEK and capable of maintaining an operating temperature of

injection volume may require an apparatus capable of cooling 30 to 55°C.

the sample boat prior to sample introduction. Thermoelectric

6.11.4 Injection valve, 2 position electrically actuated with

coolers (peltier) or recirculating refrigerated liquid devices are

wetted component material of PEEK (polyetheretherketone).

strongly recommended. Switching sample boats between each

6.11.5 Anion Separator Column AS11HC (4x250mm) or

analysis may prove effective, provided sample size is not too

equivalent, with sufficient capacity for disparate analyte con-

large.

centrations and constructed of PEEK. Capacity of >290

µEquivalents/column with alkanol quartenary ammonium

6.5 Flow Control—The apparatus must be equipped with

functional groups.

flow controllers capable of maintaining a constant supply and

6.11.6 Guard Column AG11HC (4X50mm) or equivalent,

flow of oxygen and argon gas.

packedwithsamematerialforprotectionoftheanionseparator

6.6 Furnace which can maintain a minimum temperature of

column and constructed of PEEK.

900°C.

6.11.7 Post-Column Chemical Suppression Device, capable

6.7 Gas Adsorption Unit, having an adsorption tube of

of reducing the absolute conductivity of eluent concentrations

either 10 or 20 mL which is automatically filled with a known

ofupto200mMKOH(orNaOH).Deliveryofhydroniumions

volume of absorption solution by a built-in burette or other

for suppression by electrolysis of recycled eluent through a

similardevice.TheGasAdsorptionUnitisinterfacedtotheIon

cation exchange membrane.

Chromatograph and injects an aliquot of the adsorption solu-

tion into the Ion Chromatograph after the sample is combusted

and the by-products of combustion are absorbed. The Gas

Many different companies manufacture automatic ion chromatographs. Consult

Adsorption Unit rinses out the gas lines with Type I reagent

the manufacturer for details in setup and operation. Other systems may be used as

water (7.2) from the pyrohydrolytic combustion tube after the

long as precision is shown to be as good as or better than the precision in the

completion of the sample combustion to ensure all the com- method.

D7359 − 08

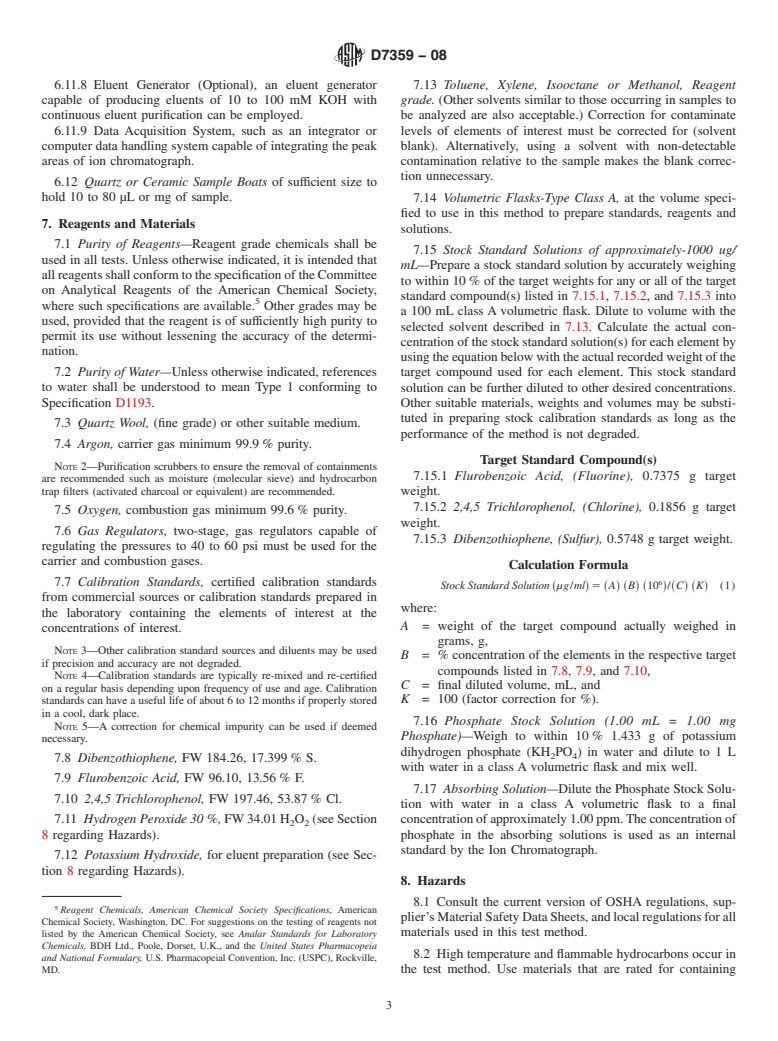

6.11.8 Eluent Generator (Optional), an eluent generator 7.13 Toluene, Xylene, Isooctane or Methanol, Reagent

capable of producing eluents of 10 to 100 mM KOH with grade. (Other solvents similar to those occurring in samples to

continuous eluent purification can be employed. be analyzed are also acceptable.) Correction for contaminate

6.11.9 Data Acquisition System, such as an integrator or levels of elements of interest must be corrected for (solvent

computer data handling system capable of integrating the peak blank). Alternatively, using a solvent with non-detectable

areas of ion chromatograph. contamination relative to the sample makes the blank correc-

tion unnecessary.

6.12 Quartz or Ceramic Sample Boats of sufficient size to

hold 10 to 80 µL or mg of sample. 7.14 Volumetric Flasks-Type Class A, at the volume speci-

fied to use in this method to prepare standards, reagents and

7. Reagents and Materials

solutions.

7.1 Purity of Reagents—Reagent grade chemicals shall be

7.15 Stock Standard Solutions of approximately-1000 ug/

used in all tests. Unless otherwise indicated, it is intended that

mL—Prepare a stock standard solution by accurately weighing

allreagentsshallconformtothespecificationoftheCommittee

to within 10 % of the target weights for any or all of the target

on Analytical Reagents of the American Chemical Society,

standard compound(s) listed in 7.15.1, 7.15.2, and 7.15.3 into

where such specifications are available. Other grades may be

a 100 mL class A volumetric flask. Dilute to volume with the

used, provided that the reagent is of sufficiently high purity to

selected solvent described in 7.13. Calculate the actual con-

permit its use without lessening the accuracy of the determi-

centration of the stock standard solution(s) for each element by

nation.

usingtheequationbelowwiththeactualrecordedweightofthe

7.2 Purity of Water—Unless otherwise indicated, references target compound used for each element. This stock standard

to water shall be understood to mean Type 1 conforming to

solution can be further diluted to other desired concentrations.

Specification D1193. Other suitable materials, weights and volumes may be substi-

tuted in preparing stock calibration standards as long as the

7.3 Quartz Wool, (fine grade) or other suitable medium.

performance of the method is not degraded.

7.4 Argon, carrier gas minimum 99.9 % purity.

Target Standard Compound(s)

NOTE 2—Purification scrubbers to ensure the removal of containments

7.15.1 Flurobenzoic Acid, (Fluorine), 0.7375 g target

are recommended such as moisture (molecular sieve) and hydrocarbon

trap filters (activated charcoal or equivalent) are recommended. weight.

7.15.2 2,4,5 Trichlorophenol, (Chlorine), 0.1856 g target

7.5 Oxygen, combustion gas minimum 99.6 % purity.

weight.

7.6 Gas Regulators, two-stage, gas regulators capable of

7.15.3 Dibenzothiophene, (Sulfur), 0.5748 g target weight.

regulating the pressures to 40 to 60 psi must be used for the

carrier and combustion gases.

Calculation Formula

7.7 Calibration Standards, certified calibration standards

Stock Standard Solution ~µg/ml! 5 ~A!~B!~10 !/~C!~K! (1)

from commercial sources or calibration standards prepared in

where:

the laboratory containing the elements of interest at the

A = weight of the target compound actually weighed in

concentrations of interest.

grams, g,

NOTE 3—Other calibration standard sources and diluents may be used

B = % concentration of the elements in the respective target

if precision and accuracy are not degraded.

compounds listed in 7.8, 7.9, and 7.10,

NOTE 4—Calibration standards are typically re-mixed and re-certified

C = final diluted volume, mL, and

on a regular basis depending upon frequency of use and age. Calibration

K = 100 (factor correction for %).

standards can have a useful life of about 6 to 12 months if properly stored

in a cool, dark place.

7.16 Phosphate Stock Solution (1.00 mL = 1.00 mg

NOTE 5—A correction for chemical impurity can be used if deemed

Phosphate)—Weigh to within 10 % 1.433 g of potassium

necessary.

dihydrogen phosphate (KH PO ) in water and dilute to 1 L

2 4

7.8 Dibenzothiophene, FW 184.26, 17.399 % S.

with water in a class A volumetric flask and mix well.

7.9 Flurobenzoic Acid, FW 96.10, 13.56 % F.

7.17 Absorbing Solution—Dilute the Phosphate Stock Solu-

7.10 2,4,5 Trichlorophenol, FW 197.46, 53.87 % Cl.

tion with water in a class A volumetric flask to a final

7.11 Hy

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.