ASTM D1561-92(2000)

(Practice)Standard Practice for Preparation of Bituminous Mixture Test Specimens by Means of California Kneading Compactor

Standard Practice for Preparation of Bituminous Mixture Test Specimens by Means of California Kneading Compactor

SCOPE

1.1 The practice covers the preparation of test specimens of bituminous paving mixtures by means of a mechanical compactor that imparts a kneading action to the test specimens by a series of individual impressions made with a ram.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.>

1.3 The values stated in acceptable metric units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1561–92 (Reapproved 2000)

Standard Practice for

Preparation of Bituminous Mixture Test Specimens by

Means of California Kneading Compactor

This standard is issued under the fixed designation D 1561; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 The practice covers the preparation of test specimens of

bituminous paving mixtures by means of a mechanical com-

pactor that imparts a kneading action to the test specimens by

a series of individual impressions made with a ram.

1.2 This standard does not purport to address all of the

safety problems, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.3 The values stated in acceptable metric units are to be

regarded as the standard.

2. Referenced Documents

2.1 ASTM Standards:

D 1560 Test Methods for Resistance to Deformation and

Cohesion of Bituminous Mixtures by Means of Hveem

Apparatus

D 4753 Specification for Evaluating, Selecting, and Speci-

fying Balances and Scales for Use in Soil, Rock and

Construction Materials Testing

3. Significance and Use

3.1 This practice can be used to prepare cylindrical speci-

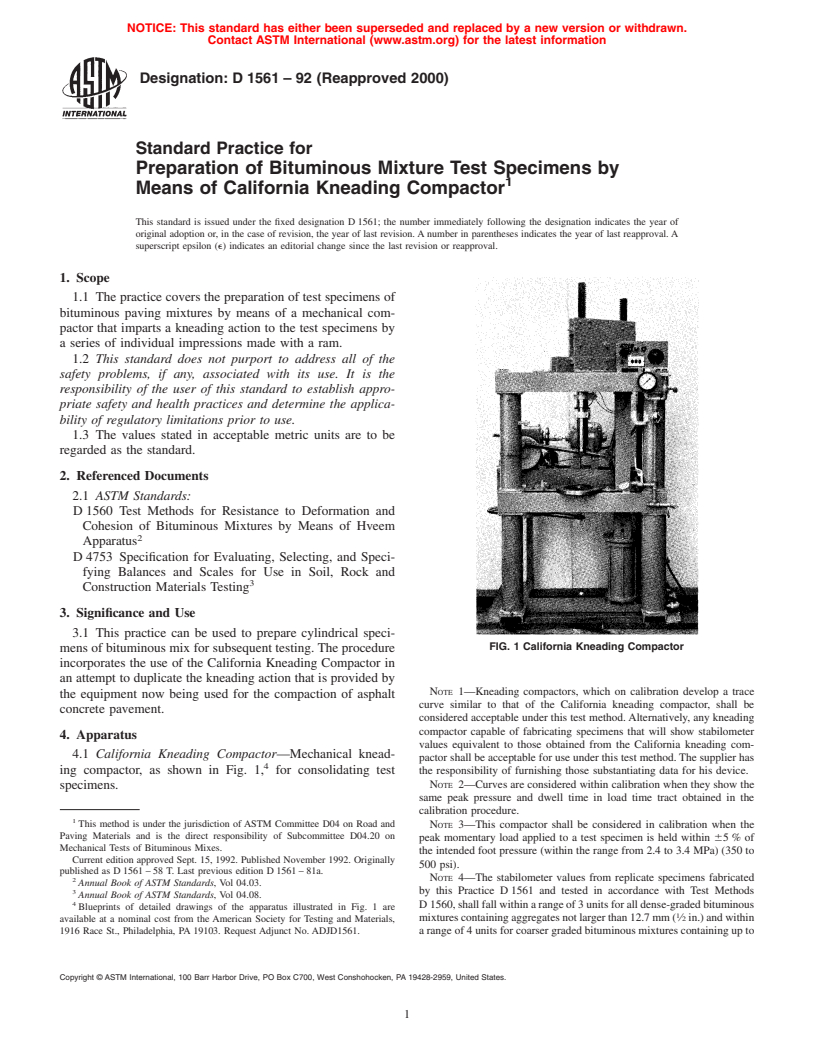

FIG. 1 California Kneading Compactor

mens of bituminous mix for subsequent testing. The procedure

incorporates the use of the California Kneading Compactor in

an attempt to duplicate the kneading action that is provided by

NOTE 1—Kneading compactors, which on calibration develop a trace

the equipment now being used for the compaction of asphalt

curve similar to that of the California kneading compactor, shall be

concrete pavement.

considered acceptable under this test method.Alternatively, any kneading

compactor capable of fabricating specimens that will show stabilometer

4. Apparatus

values equivalent to those obtained from the California kneading com-

4.1 California Kneading Compactor—Mechanical knead-

pactor shall be acceptable for use under this test method. The supplier has

ing compactor, as shown in Fig. 1, for consolidating test the responsibility of furnishing those substantiating data for his device.

NOTE 2—Curves are considered within calibration when they show the

specimens.

same peak pressure and dwell time in load time tract obtained in the

calibration procedure.

This method is under the jurisdiction of ASTM Committee D04 on Road and

NOTE 3—This compactor shall be considered in calibration when the

Paving Materials and is the direct responsibility of Subcommittee D04.20 on

peak momentary load applied to a test specimen is held within 65%of

Mechanical Tests of Bituminous Mixes.

the intended foot pressure (within the range from 2.4 to 3.4 MPa) (350 to

Current edition approved Sept. 15, 1992. Published November 1992. Originally

500 psi).

published as D 1561 – 58 T. Last previous edition D 1561 – 81a.

NOTE 4—The stabilometer values from replicate specimens fabricated

Annual Book of ASTM Standards, Vol 04.03.

3 by this Practice D 1561 and tested in accordance with Test Methods

Annual Book of ASTM Standards, Vol 04.08.

D 1560,shallfallwithinarangeof3unitsforalldense-gradedbituminous

Blueprints of detailed drawings of the apparatus illustrated in Fig. 1 are

mixturescontainingaggregatesnotlargerthan12.7mm( ⁄2in.)andwithin

available at a nominal cost from the American Society for Testing and Materials,

1916 Race St., Philadelphia, PA 19103. Request Adjunct No. ADJD1561. a range of 4 units for coarser graded bituminous mixtures containing up to

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1561

25.4-mm (1-in.) maximum size aggregates.

4.13 Sample Mixing Apparatus—Use suitable equipment.

Hand mixing is permissible, but mechanical mixing is recom-

4.2 CompactorFoot—Aramhavingafaceshapedasshown

mended.

in Fig. 2, and having an area of approximately 20.059 cm (3.1

4.14 Miscellaneous Apparatus—Thermometers, trowels,

in. ).

pans, spatulas, scoops, gloves, and metal pans.

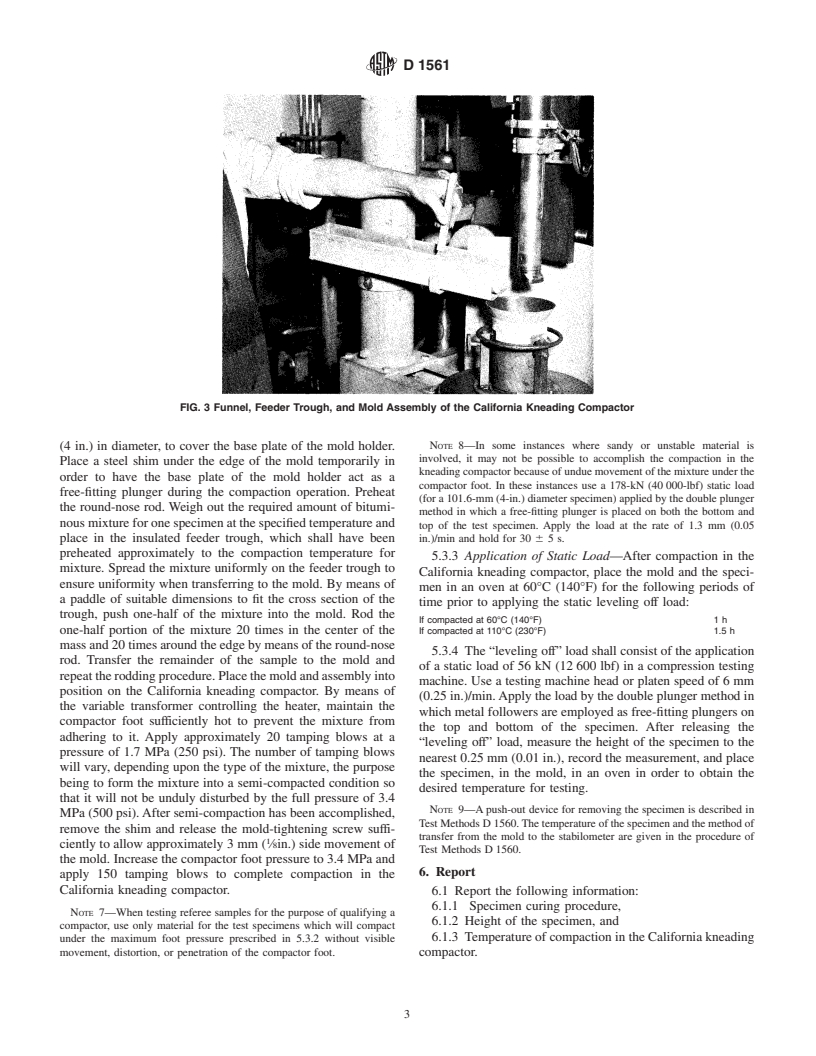

4.3 Mold Holder, Funnel, and Feeder Trough, as shown in

Fig. 3.

5. Test Specimens

4.4 Molds—Molding cylinders, 101.6 6 0.13 mm (4 6

5.1 Selection of Bitumen Content for Specimens—The op-

0.005 in.) in inside diameter by 127 mm (5 in.) in height. A

timumamountofbitumenfortheaggregatemaybedetermined

minimum of three such compaction molds is recommended.

by the method commonly employed by the laboratory.

4.5 Rod—Round-nose steel rod, 9.5 mm ( ⁄8 in.) in diameter

5.2 Preparation of Mixtures:

by 406.4 mm (16 in.) long.

5.2.1 Obtain a sieve analysis on the fine and coarse aggre-

4.6 Paper Disks—Heavy paper disks, 101.6 mm (4 in.) in

gate (aggregate shall be separated by means of a 4.75-mm (No.

diameter.

4) sieve). Separate the aggregate into the various size fractions

1 3

4.7 Shim—Steel shim, 6.4 mm ( ⁄4 in.) thick, 19.1 mm ( ⁄4

necessary for accurately recombining into test mixtures con-

in.) wide, and 63.5 mm (2 ⁄2 in.) long.

forming to specified grading requirements.

4.8 Metal Followers—Two metal followers, 101.2 mm

5.2.2 Combine the moisture-free aggregates into batches

(3.985 in.) in diameter; one 139.7 mm (5.5 in.) high, the other

weighing 1200 g. (Every effort should be made to fabricate test

38.1 mm (1.5 in.) high.

specimens 64 6 3 mm (2.5 6 0.1 in.) in height. Heat the

4.9 Testing Machine—A compression testing machine hav-

aggregate to the proper mixing temperature; then weigh the

ing a minimum capacity of 22 kN (50 000 lbf).

required amount of bitumen at the proper temperature into the

4.10 Ovens—Electric ovens capable of maintaining tem-

aggregate mixture. For mixes employing asphalt cement, the

peratures of up to 163°C (325°F).

temperature of the aggregate and asphalt at the time mixing

4.11 Balance—A balance having a minimum capacity of 5

begins shall be in accordance with the following:

kg and meeting the requirements of Specification D 4753 for a

Temperature Range, °C (°F)

balance with 0.01-g readability.

Grade min max

4.12 Sample Splitter, riffle-type, or equivalent.

AC-2.5, AR1000, or 200–300 Pen 99(210) 121(250)

AC-5, AR2000, or 120–150 Pen 110(230) 135(275)

AC-10, AR4000, or 85–100 Pen 121(250) 149(300)

AC-20, AR8000, or 60–70 Pen 132(270) 163(325)

AC-40, AR16000, or 40–50 Pen 132(270) 163(325)

Mixtures containing liquid asphalts do not require heat for

mixing. For tar mixtures, heat the aggregates and tar to the

desi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.