ASTM D2880-03(2010)

(Specification)Standard Specification for Gas Turbine Fuel Oils

Standard Specification for Gas Turbine Fuel Oils

ABSTRACT

This specification covers the selection of fuels for gas turbines, excepting gas turbines used in aircraft, for the guidance of interested parties such as turbine manufacturers and the suppliers and purchasers of fuel oils. The specification sets forth the properties of fuels at the time and place of custody transfer to the user. The fuels shall be homogeneous mixtures of hydrocarbon oils free of inorganic acid, and free of excessive amounts of solid or fibrous foreign matter likely to make frequent cleaning of suitable strainers necessary. All grades containing residual components shall remain homogeneous in normal storage and not separated by gravity into light and heavy oil components outside the viscosity limits for the grade. The following test methods shall be performed to determine certain properties: flash point test, pour point test, water and sediment test, carbon residue test, ash test, distillation test, viscosity test, density test, and sulfur test.

SCOPE

1.1 This specification covers the selection of fuels for gas turbines, excepting gas turbines used in aircraft, for the guidance of interested parties such as turbine manufacturers and the suppliers and purchasers of fuel oils. The specification sets forth the properties of fuels at the time and place of custody transfer to the user.

1.2 Three appendixes are provided for informational purposes only and do not constitute a requirement of this specification unless mutually agreed upon between the interested parties.

1.2.1 Appendix X1 describes the five grades of gas turbine fuels covered by this specification. Further, it states the significance of various test methods used in inspecting the fuels.

1.2.2 Appendix X2 discusses the sources of fuel contaminants and notes the significance of such contaminants in the operation of gas turbines and gas turbine fuel systems. The particular significance of trace metals in gas turbine fuels is noted. Upper limits of trace metals are recommended for the various grades of gas turbine fuels, but these recommended limits do not constitute a requirement of the specification unless mutually agreed upon by the interested parties. Limitations due to the use of used or recycled oil are also noted.

Note 1—The gas turbine operator should consult Practice D4418 for methods of ensuring fuels of adequate cleanliness and for guidance on long-term storage of distillate fuels and on liquids from non-petroleum sources as gas turbine.

Note 2—Nothing in this specification shall preclude observance of federal, state, or local regulations which may be more restrictive.

Note 3—The generation and dissipation of static electricity can create problems in the handling of distillate gas turbine fuel oils. For more information on the subject, see Guide D4865.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2880 −03(Reapproved 2010)

Standard Specification for

Gas Turbine Fuel Oils

This standard is issued under the fixed designation D2880; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

1.1 This specification covers the selection of fuels for gas 2.1 ASTM Standards:

turbines, excepting gas turbines used in aircraft, for the D56 Test Method for Flash Point by Tag Closed Cup Tester

guidance of interested parties such as turbine manufacturers D86 Test Method for Distillation of Petroleum Products at

and the suppliers and purchasers of fuel oils. The specification Atmospheric Pressure

sets forth the properties of fuels at the time and place of D93 Test Methods for Flash Point by Pensky-Martens

custody transfer to the user. Closed Cup Tester

D97 Test Method for Pour Point of Petroleum Products

1.2 Three appendixes are provided for informational pur-

D129 Test Method for Sulfur in Petroleum Products (Gen-

poses only and do not constitute a requirement of this specifi-

eral High Pressure Decomposition Device Method)

cation unless mutually agreed upon between the interested

D396 Specification for Fuel Oils

parties.

D445 Test Method for Kinematic Viscosity of Transparent

1.2.1 Appendix X1 describes the five grades of gas turbine

and Opaque Liquids (and Calculation of Dynamic Viscos-

fuels covered by this specification. Further, it states the

ity)

significance of various test methods used in inspecting the

D482 Test Method for Ash from Petroleum Products

fuels.

D524 Test Method for Ramsbottom Carbon Residue of

1.2.2 Appendix X2 discusses the sources of fuel contami-

Petroleum Products

nants and notes the significance of such contaminants in the

D975 Specification for Diesel Fuel Oils

operation of gas turbines and gas turbine fuel systems. The

D1266 Test Method for Sulfur in Petroleum Products (Lamp

particular significance of trace metals in gas turbine fuels is

Method)

noted. Upper limits of trace metals are recommended for the

D1298 Test Method for Density, Relative Density (Specific

various grades of gas turbine fuels, but these recommended

Gravity), or API Gravity of Crude Petroleum and Liquid

limits do not constitute a requirement of the specification

Petroleum Products by Hydrometer Method

unless mutually agreed upon by the interested parties. Limita-

D1552 Test Method for Sulfur in Petroleum Products (High-

tions due to the use of used or recycled oil are also noted.

Temperature Method)

NOTE 1—The gas turbine operator should consult Practice D4418 for

D1796 Test Method for Water and Sediment in Fuel Oils by

methods of ensuring fuels of adequate cleanliness and for guidance on

the Centrifuge Method (Laboratory Procedure)

long-term storage of distillate fuels and on liquids from non-petroleum

D2622 Test Method for Sulfur in Petroleum Products by

sources as gas turbine.

Wavelength Dispersive X-ray Fluorescence Spectrometry

NOTE 2—Nothing in this specification shall preclude observance of

federal, state, or local regulations which may be more restrictive.

D2709 Test Method for Water and Sediment in Middle

NOTE 3—The generation and dissipation of static electricity can create

Distillate Fuels by Centrifuge

problems in the handling of distillate gas turbine fuel oils. For more

D3605 Test Method for Trace Metals in Gas Turbine Fuels

information on the subject, see Guide D4865.

by Atomic Absorption and Flame Emission Spectroscopy

D3828 Test Methods for Flash Point by Small Scale Closed

Cup Tester

This specification is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.E0 on Burner, Diesel, Non-Aviation Gas Turbine, and Marine Fuels. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2010. Published November 2010. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1970. Last previous edition approved in 2003 as D2880–03. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D2880-03R10. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2880−03 (2010)

D4052 Test Method for Density, Relative Density, and API 4.2 All grades containing residual components shall remain

Gravity of Liquids by Digital Density Meter homogeneous in normal storage and not separated by gravity

D4294 Test Method for Sulfur in Petroleum and Petroleum intolightandheavyoilcomponentsoutsidetheviscositylimits

Products by Energy Dispersive X-ray Fluorescence Spec- for the grade.

trometry

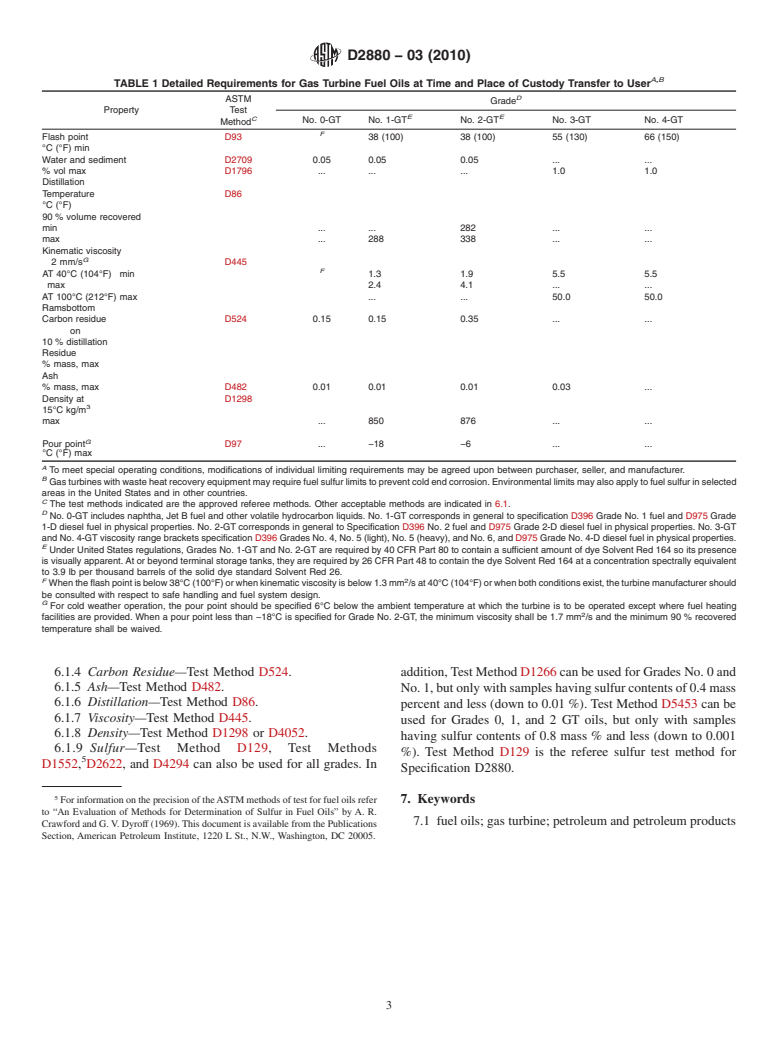

5. Detailed Requirements

D4418 Practice for Receipt, Storage, and Handling of Fuels

for Gas Turbines 5.1 The various grades of gas turbine fuel oil shall conform

to the limiting requirements shown in Table 1.As noted in the

D4865 Guide for Generation and Dissipation of Static Elec-

tricity in Petroleum Fuel Systems supplementaryfootnotestoTable1,therequirementsforGrade

Nos. 1-GT and 2-GT conform in most respects to correspond-

D5453 Test Method for Determination of Total Sulfur in

Light Hydrocarbons, Spark Ignition Engine Fuel, Diesel ing Grade Nos. 1 and 2 fuels in Specification D396, and to

Grade Nos. 1-D and 2-D in Specification D975. The viscosity

Engine Fuel, and Engine Oil by Ultraviolet Fluorescence

D5949 Test Method for Pour Point of Petroleum Products range of Grade Nos. 3-GT and 4-GT fuel brackets the Grade

Nos. 4, 5, and 6 of Specification D396 and Grade No. 4-D of

(Automatic Pressure Pulsing Method)

D5950 Test Method for Pour Point of Petroleum Products Specification D975. It is the intent that fuels meeting Specifi-

(Automatic Tilt Method) cation D396 and D975 requirements may also be supplied

D5985 Test Method for Pour Point of Petroleum Products under these specifications provided they meet the requirements

(Rotational Method) listed in Table 1.

D6469 GuideforMicrobialContaminationinFuelsandFuel

5.2 Modificationsoflimitingrequirementsandtheinclusion

Systems

of fuel additives to meet special operating conditions may be

D6728 Test Method for Determination of Contaminants in

agreed upon between the interested parties.

Gas Turbine and Diesel Engine Fuel by Rotating Disc

5.3 The properties listed in this specification are those of

Electrode Atomic Emission Spectrometry

greatest significance in obtaining acceptable performance of

2.2 Other Documents:

the turbine. However, trace metals, even in fractional parts per

26 CFR Part 48 Diesel Fuel Excise Tax; Dye Color and

million, are detrimental to gas turbine service life. Information

Concentration

on the maximum concentration of critical metallic elements in

40 CFR Part 80 Regulation of Fuels and Fuel Additives

the fuel as it enters the turbine combustor(s) is provided in

Appendix X2. Distillate fuels are usually of satisfactory purity

3. Terminology

as refined, but suppliers rarely have control over possible

contamination by trace metals in distribution and storage. The

3.1 Definitions of Terms Specific to This Standard:

limits in Appendix X2, although required as the fuel enters the

3.1.1 fuel contaminants—fuelcomponentsotherthanhydro-

combustor(s), do not apply to the fuel as delivered unless

carbon oils. In the present context the contaminants are foreign

mutually agreed upon by the interested parties. Fuels may,

materials that make the fuel less suitable or even unsuitable for

therefore, require on-site clean-up, quality control procedures,

the intended use.

special handling, or other arrangements.

3.1.1.1 Discussion—The contaminants of primary interest

are foreign materials introduced subsequent to the manufacture

6. Test Methods

of specification quality fuel. Hence they are materials intro-

6.1 The requirements enumerated in this specification shall

duced in the distribution system (that is, storage tanks, pipe-

be determined in accordance with the following ASTM meth-

lines, tank trucks, barges, etc.) or in the user’s storage and

ods except as noted:

handling system, or generated within these systems (rust

6.1.1 Flash Point—Test Methods D93, except where other

generated in steel pipes and tanks by moist fuel, and so forth).

methods are prescribed by law. For all grades, Test Method

Contaminants may be soluble or insoluble in the fuel.

D3828 may be used as an alternate with the same limits. For

3.1.2 fuel entering the combustor(s)—the fuel that is actu-

Grades No. 1-GT and No. 2-GT, Test Method D56 may be

ally burned in the gas turbine. Fuel may be sampled at a point

used as an alternative with the same limits provided the flash

upstream from the point of entry into the combustor(s),

point is below 93°C and the viscosity is below 5.5 mm /s at

provided the sample is representative of the fuel actually

40°C. This test method will give slightly lower values. In case

entering the combustor(s).

of dispute, Test Method D93 shall be used as the referee

method.

4. General Requirements

6.1.2 Pour Point—Test Method D97. For all grades, the

automatic Test Methods D5949, D5950,or D5985 can be used

4.1 The fuels herein specified shall be homogeneous mix-

tures of hydrocarbon oils free of inorganic acid, and free of as alternates with the same limits. In case of dispute, Test

Method D97 shall be used as the referee method.

excessive amounts of solid or fibrous foreign matter likely to

make frequent cleaning of suitable strainers necessary. 6.1.3 Water and Sediment—Test Method D2709 is used for

Grades 0-GT, 1-GT, and 2-GT. Test Method D1796 is used for

Grades 3-GT and 4-GT.

Available from Superintendent of Documents, U. S. Government Printing

Office, Washington, DC 20402. Other mutually acceptable methods may be used.

D2880−03 (2010)

A,B

TABLE 1 Detailed Requirements for Gas Turbine Fuel Oils at Time and Place of Custody Transfer to User

D

ASTM

Grade

Property Test

E E

C

No. 0-GT No. 1-GT No. 2-GT No. 3-GT No. 4-GT

Method

F

Flash point D93 38 (100) 38 (100) 55 (130) 66 (150)

°C (°F) min

Water and sediment D2709 0.05 0.05 0.05 . .

% vol max D1796 . . . 1.0 1.0

Distillation

Temperature D86

°C (°F)

90 % volume recovered

min . . 282 . .

max . 288 338 . .

Kinematic viscosity

G

2 mm/s D445

F

AT 40°C (104°F) min 1.3 1.9 5.5 5.5

max 2.4 4.1 . .

AT 100°C (212°F) max . . 50.0 50.0

Ramsbottom

Carbon residue D524 0.15 0.15 0.35 . .

on

10 % distillation

Residue

% mass, max

Ash

% mass, max D482 0.01 0.01 0.01 0.03 .

Density at D1298

15°C kg/m

max . 850 876 . .

G

Pour point D97 . −18 −6 . .

°C (°F) max

A

To meet special operating conditions, modifications of individual limiting requirements may be agreed upon between purchaser, seller, and manufacturer.

B

Gas turbines with waste heat recovery equipment may require fuel sulfur limits to prevent cold end corrosion. Environmental limits may also apply to fuel sulfur in selected

areas in the United States and in other countries.

C

The test methods indicated are the approved referee methods. Other acceptable methods are indicated in 6.1.

D

No. 0-GT includes naphtha, Jet B fuel and other volatile hydrocarbon liquids. No. 1-GT corresponds in general to specification D396 Grade No. 1 fuel and D975 Grade

1-D diesel fuel in physical properties. No. 2-GT corresponds in general to Specification D396 No. 2 fuel and D975 Grade 2-D diesel fuel in physical properties. No. 3-GT

and No. 4-GT viscosity range brackets specification D396 Grades No. 4, No. 5 (light), No. 5 (heavy), and No. 6, and D975 Grade No. 4-D diesel fuel in physical properties.

E

Under United States regulations, Grades No. 1-GT and No. 2-GT are required by 40 CFR Part 80 to contain a sufficient amount of dye Solvent Red 164 so its presence

is visually apparent. At or beyond terminal storage tanks, they are required by 26 CFR Part 48 to contain the dye Solvent Red 164 at a concentration spectrally equivalent

to 3.9 lb per thousand barrels of the solid dye standard Solvent Red 26.

F 2

When the flash point is below 38°C (100°F) or when kinematic viscosity is below 1.3 mm /s at 40°C (104°F) or when both conditions exist, the turbine manufacturer should

be consulted with respect to safe handling and fuel system design.

G

For cold weather operation, the pour point should be specified 6°C below the ambient temperature at which the turbine is to be operated except where fuel heating

facilities are provided. When a pour point less than −18°C is specified for Grade No. 2-GT, the minimum viscosity shall be 1.7 mm /s and the minimum 90 % recovered

temperature shall be waived.

6.1.4 Carbon Residue—Test Method D524. addition,TestMethodD1266canbeusedforGradesNo.0and

6.1.5 Ash—Test Method D482.

No.1,butonlywithsampleshavingsulfurcontentsof0.4mass

6.1.6 Distillation—Test Method D86.

percent and less (down to 0.01 %). Test Method D5453 can be

6.1.7 Viscosity—Test Method D445.

used for Grades 0, 1, and 2 GT oils, but only with samples

6.1.8 Density—Test Method D1298 or D4052.

having sulfur contents of 0.8 mass % and less (down to 0.001

6.1.9 Sulfur—Test Method D129, Test Methods

%). Test Method D129 is the referee sulfur test method for

D1552, D2622, and D4294 can also be used for all grades. In

Specification D2880.

ForinformationontheprecisionoftheASTMmethodsoftestforfueloilsrefer 7. Keywords

to “An Evaluation of Methods for Determination of Sulfur in Fuel Oils” by A. R.

7.1 fuel oils; gas turbine; petroleum and petroleum products

CrawfordandG.V.Dyroff(1969).ThisdocumentisavailablefromthePublications

Section, American Petroleum Institute, 1220 L St., N.W., Washington, DC 20005.

D2880−03 (2010)

APPENDIXES

(Nonmandatory Information)

X1. SIGNIFICANCE OF ASTM SPECIFICATIONS FOR GAS TURBINE FUEL OILS

X1.1 Scope X1.3 Selection of Particular Grade

X1.3.1 Theselectionofaparticulargasturbinefueloilfrom

X1.1.1 This specification divides the fuel oils encompassed

one of these five ASTM grades for use in a given gas turbine

by Specifications D396 and D975 into four grades, based upon

requires consideration of the following factors:

their applicability for use in gas turbines. Also there is a No.

X1.3.1.1 Availability of the fuel,

0-GTgradetocoverlow-flashnaphthas.Thespecificationdoes

X1.3.1.2 Design of the gas turbine and fuel handling sys-

not include fuels primarily intended for aircraft use. It places

tem,

limiting values on a nu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.