ASTM F791-96(2002)

(Test Method)Standard Test Method for Stress Crazing of Transparent Plastics

Standard Test Method for Stress Crazing of Transparent Plastics

SCOPE

1.1 This practice covers the determination of the critical crazing stress for a transparent-plastic material when exposed to a specific solvent, chemical, or compound at a specific temperature.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F791–96 (Reapproved 2002)

Standard Test Method for

Stress Crazing of Transparent Plastics

This standard is issued under the fixed designation F 791; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope oriented perpendicular to a tensile stress. Crazing may be

difficult to detect. It becomes more pronounced when viewed

1.1 This test method covers the determination of the critical

with a light source that is at an oblique angle.

crazing stress for a transparent plastic material when exposed

to a specific solvent, chemical, or compound at a specific

4. Significance and Use

temperature.

4.1 This test method provides a guide for evaluating a

1.2 This standard does not purport to address all of the

specific solvent, chemical, or compound that may be detrimen-

safety concerns, if any, associated with its use. It is the

tal to a transparent plastic as a result of a manufacturing

responsibility of the user of this standard to establish appro-

process, a fabrication operation, or the operational environ-

priate safety and health practices and determine the applica-

ment.All transparent plastics are susceptible to crazing, though

bility of regulatory limitations prior to use.

inwidelyvaryingdegreeandfromavarietyofcauses.Thistest

2. Referenced Documents method is intended to allow establishment of the crazing stress

when the simultaneous action of both load and a material that

2.1 ASTM Standards:

would cause crazing is applied producing non-reversible dam-

D 618 Methods of Conditioning Plastics for Testing

age that might limit the usage of that transparent plastic in a

E 691 Practice for Conducting an Interlaboratory Study to

specific application.

Determine the Precision of a Test Method

2.2 Other Method:

5. Apparatus

ARTC (Aircraft Research and Testing Committee of the

5.1 Test Fixture, with fluorescent light source illustrated and

Aircraft Industries Association of America, Inc.) Condi-

4 constructed as shown in Figs. 1 and 2.

tioning Method

5.2 Drill Fixture constructed as shown in Fig. 3.

3. Terminology 5.3 Marking Fixture, constructed as shown in Fig. 3.

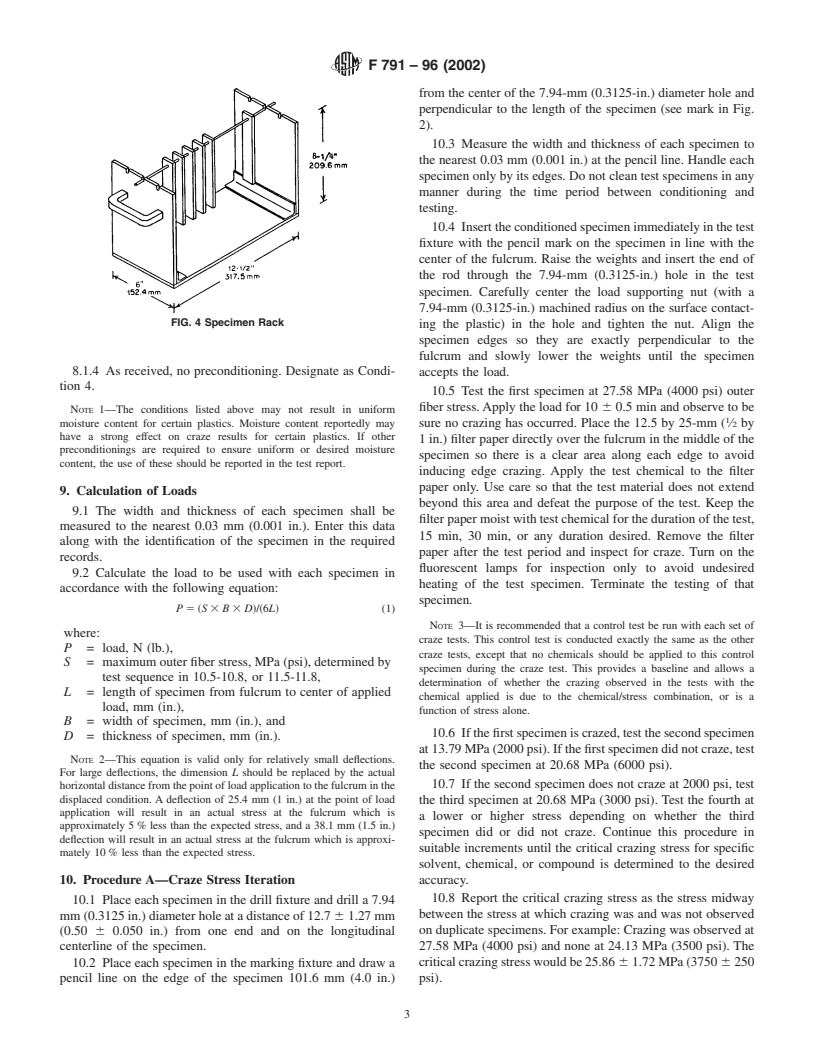

5.4 Portable Specimen Rack, constructed in the manner as

3.1 Definitions of Terms Specific to This Standard:

shown in Fig. 4 for handling and conditioning test specimens.

3.1.1 crazing—a group of surface fissures that appear to be

5.5 Weights—A container and shot for the application of

small cracks in the material, although they are not.

weight on the rack as shown in Fig. 1.

3.1.1.1 Discussion—Crazing is a form of yielding in poly-

5.6 Filter Paper, quantity of 0.50 by 1.0-in. (12.7 by

mers characterized by a spongy void filled fibrillar structure.

25.4-mm) pieces of filter, medium-retention filter paper.

The density in the craze changes resulting in a change in the

index of refraction, which causes light to be reflected off of the

6. Test Specimens

crazes. This light reflection causes the crazes to sparkle when

6.1 The test specimen shall be machined from the transpar-

viewed from certain angles. The crazes are sometimes random

ent plastic material to be evaluated. A minimum of six

and scattered with varied lengths and depths but usually are

specimens for each solvent, chemical, or compound is re-

quired. It is preferred that the transparent plastic sheet material

This test method is under the jurisdiction of ASTM Committee F07 on thickness be 6.35 6 0.64 mm (0.250 6 0.025 in.), but any

Aerospace and Aircraft and is the direct responsibility of Subcommittee F07.08 on

thickness material may be used. Orientation of each test

Transparent Enclosures and Materials.

specimen within the test sheet or part should be recorded.

Current edition approved Oct. 10, 1996. Published December 1996. Originally

6.2 Thetestspecimensshallbe25.4 60.8mm(1.00 60.03

published as F 791 – 82. Last previous edition F 791 – 82 (1988).

Annual Book of ASTM Standards, Vol 08.01.

in.) wide by 177.8 6 1.27 mm (7.00 6 0.05 in.) long by

Annual Book of ASTM Standards, Vol 14.02.

thickness.

Available from Aircraft Industries Association, 1725 DeSales St. NW, Wash-

ington, DC 20034.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F791–96 (2002)

FIG. 1 Accelerated Crazing Test Fixture

FIG. 3 Fixtures for Specimen Preparation

FIG. 2 Application of Test Liquid to Piece of Filter Paper on Top

Surface of Test Specimen

8. Conditioning

6.3 The edges shall be smooth machined surfaces without

8.1 Precondition the test specimens in accordance with one

cracks, and the test specimen surface shall be free of defects or

of the following procedures:

irregularities. If the test specimen has been machined to

8.1.1 Practice D 618 Procedure B—Forty-eight hours at

thickness, the nonmachined surface shall be the test surface.

50°C (122°F) followed by cooling to room temperature in

7. Preparation of Apparatus desiccator over anhydrous calcium chloride for at least 5 h.

Designate as Condition 1 and test within 15 min.

7.1 Once the load for a particular stress is calculated, that

8.1.2 Two hours at 90°C (194°F), ambient cooled, and

load will be the sum of the individual weights of the weight

followed by 7 days at 23 6 1.1°C (73.5 6 2°F) and 50 65%

rack, rod, lead weights, container, shot, and the radiused nut.

relative humidity. Designate as Condition 2 and test within 1 h.

For convenience of assembly, the weight rack pan may be

stamped with the total weight of the pan, rod, and nuts as a 8.1.3 ARTC Method—Sixteen hours at 14°C (25°F) below

unit. A container, such as a ⁄2-pt (0.24-L) paint can with a the average heat deflection temperature, cool at a rate not

6.4-mm ( ⁄4-in.) hole drilled in the center of the bottom and exceeding 28°C (50°F)/h and follow by 96 h at 23 6 1.1°C

installed so it slides up and down on the rod, can serve as a (73.5 6 2°F) and 50 6 5 % relative humidity. Designate as

receptacle for the lead shot to attain required weight. Condition 3 and test within 1 h.

F791–96 (2002)

from the center of the 7.94-mm (0.3125-in.) diameter hole and

perpendicular to the length of the specimen (see mark in Fig.

2).

10.3 Measure the width and thickness of each specimen to

the nearest 0.03 mm (0.001 in.) at the pencil line. Handle each

specimen only by its edges. Do not clean test specimens in any

manner during the time period between conditioning and

testing.

10.4 Inserttheconditionedspecimenimmediatelyinthetest

fixture with the pencil mark on the specimen in line with the

center of the fulcrum. Raise the weights and insert the end of

the rod through the 7.94-mm (0.3125-in.) hole in the test

specimen. Carefully center the load supporting nut (with a

7.94-mm (0.3125-in.) machined radius on the surface contact-

FIG. 4 Specimen Rack

ing the plastic) in the hole and tighten the nut. Align the

specimen edges so they are exactly perpendicular to the

fulcrum and slowly lower the weights until the specimen

8.1.4 As received, no preconditioning. Designate as Condi- accepts the load.

tion 4.

10.5 Test the first specimen at 27.58 MPa (4000 psi) outer

fiber stress.Apply the load for 10 6 0.5 min and observe to be

NOTE 1—The conditions listed above may not result in uniform

moisture content for certain plastics. Moisture content reportedly may sure no crazing has occurred. Place the 12.5 by 25-mm ( ⁄2 by

have a strong effect on craze results for certain plastics. If other

1 in.) filter paper directly over the fulcrum in the middle of the

preconditionings are required to ensure uniform or desired moisture

specimen so there is a clear area along each edge to avoid

content, the use of these should be reported in the test report.

inducing edge crazing. Apply the test chemical to the filter

paper only. Use care so that the test material does not extend

9. Calculation of Loads

beyond this area and defeat the purpose of the test. Keep the

9.1 The width and thickness of each specimen shall be

filter paper moist with test chemical for the duration of the test,

measured to the nearest 0.03 mm (0.001 in.). Enter this data

15 min, 30 min, or any duration desired. Remove the filter

along with the identification of the specimen in the required

paper after the test period and inspect for craze. Turn on the

records.

fluorescent lamps for inspection only to avoid undesired

9.2 Calculate the load to be used with each specimen in

heating of the test specimen. Terminate the testing of that

accordance with the following equation:

specimen.

P 5 ~S 3 B 3 D!/~6L! (1)

NOTE 3—It is recommended that a control test be run with each set of

where:

craze tests. This control test is conducted exactly the same as the other

P = load, N (lb.),

craze tests, except that no chemicals should be applied to this control

S = maximum outer fiber stress, MPa (psi), determined by

specimen during the craze test. This provides a baseline and allows a

test sequence in 10.5-10.8, or 11.5-11.8,

determination of whether the crazing observed in the tests with the

L = length of specimen from fulcrum to center of applied

chemical applied is due to the chemical/stress combination, or is a

load, mm (in.),

function of stress alone.

B = width of specimen, mm (in.), and

10.6 Ifthefirstspecimeniscrazed,testthesecondspecimen

D = thickness of specimen, mm (in.).

at13.79MPa(2000psi).Ifthefirstspecimendidnotcraze,test

NOTE 2—This equation is valid only for relatively small deflections.

the second specimen at 20.68 MPa (6000 psi).

For large deflections, the dimension L should be replaced by the actual

10.7 If the second specimen does not craze at 2000 psi, test

horizontal distance from the point of load application to the fulcrum in the

displaced condition. A deflection of 25.4 mm (1 in.) at the point of load the third specimen at 20.68 MPa (3000 psi). Test the fourth at

application will result in an actual stress at the fulcrum which is

a lower or higher stress depending on whether the third

approximately 5 % less than the expected stress, and a 38.1 mm (1.5 in.)

specimen did or did not craze. Continue this procedure in

deflection will result in an actual stress at the fulcrum which is approxi-

suitable increments until the critical crazing stress for specific

mately 10 % less than the expected stress.

solvent, chemical, or compound is determined to the desired

10. Procedure A—Craze Stress Iteration accuracy.

10.8 Report the critical crazing stress as the stress midway

10.1 Place each specimen in the drill fixture and drill a 7.94

between the stress at which crazing was and was not observed

mm (0.3125 in.) diameter hole at a distance of 12.7 6 1.27 mm

on duplicate specimens. For example: Crazing was observed at

(0.50 6 0.050 in.) from one end and on the longitudinal

centerline of the specimen. 27.58 MPa (4000 psi) and none at 24.13 MPa (3500 psi). The

criticalcrazingstresswouldbe25.86 61.72MPa(3750 6250

10.2 Place each specimen in the marking fixture and draw a

pencil line on the edge of the specimen 101.6 mm (4.0 in.) psi).

F791–96 (2002)

10.9 In the examination of the crazing, note all cracks at the point of load application. Place a pan under the point of load

edge of the specimen as “edge crazing.” Disregard this application to catch the chemical which drips off of the

condition when ascertaining the end point unless the edge of specimen. Continue the test for 15 minutes, 30 minutes, or any

crazing grows and extends across the entire width of the duration desired. During the test, monitor the specimen con-

specimen. tinuously for craze development. Record the time and location

10.10 Testing shall be at the specified temperature 63°C of the craze front as crazing progresses down the beam.

(65°F).

11.6 Calculate the craze stress for each recorded time with

the following equation:

11. Procedure B—Craze Stress Tracking

S 5 ~6 3 P 3 Z!/~B 3 D ! (2)

11.1 Place each specimen in the drill fixture and drill a

7.94-mm (0.3125-in.) diameter hole at a distance of 12.7 6

where:

1.27 mm (0.50 6 0.050 in.) from one end and on the

S = maximum outer fiber stress, MPa (psi),

longitudinal centerline of the specimen.

P = load, N (lb.),

11.2 Place each specimen in the marking fixture and draw a

Z = the distance from the point of load application to the

pencil line on the edge of the specimen 101.6 mm (4.0 in.)

craze front, mm (in.),

from the center of the 7.94-mm (0.3125-in.) diameter hole and B = width of specimen, mm (in.), and

D = thickness of specimen, mm (in.)

perpendicular to the length of the specimen (see the mark in

Fig. 2). On the side opposite the test surface, using an ink

11.7 If the first specimen does not craze, test the second

suitable for marking plastic, mark lines across the specimen

specimen at 41.37 MPa (6000 psi). If no crazing is observed at

surface perpendicular to the edge, from edge to edge, at 6.4

41.37 MPa (6000 psi), discontinue testing.

mm (0.25 in.) intervals, starting at the hole and progressing

11.8 If the first specimen breaks before the completion of

101.6 mm (4.0 in.) to the point at which the beam will rest on

thetest,testtheremainingspecimensatastresslevelbelowthe

the fulcrum.

stress at which the specimen fractured.

11.3 Measure the width and thickness of each specimen to

11.9 If the first specimen crazes below 6.895 MPa (1000

the nearest 0.03 mm (0.001 in.) at the pencil line. Handle each 3

psi) (more than ⁄4 of the way down the beam) conduct the

specimen only by its edges. Do not clean test specimens in any

remaining tests with 13.79 MPa (2000 psi) at the fulcrum.

manner during the time period between conditioning and

11.10 Calculate the minimum stress at which crazing oc-

testing.

curs. This stress may be calculated from the equation in 11.6.

11.4 Firmly press a 3.18 mm (0.125 in.) wide ribbon of

11.11 In the examination of the crazing, note all cracks at

non-compressible black butyl glazing tape sealant on the test

the edge of the specimen as edge crazing. Disregard this

surface of the specimen along each edge to create a dam which

condition when ascertaining the end point unless the edge

prevents the test chemical from coming in contact with the

crazing grows and extends across the entire width of the

specimen edges. Insert the conditioned specimen immediately

specimen.

in the test fixture with the pencil mark on the specimen in line

11.12 Testing shall be at the specified temperature 6 3°C

with the center of the fulcrum. Raise the weights and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.