ASTM D1518-85(1998)e1

(Test Method)Standard Test Method for Thermal Transmittance of Textile Materials

Standard Test Method for Thermal Transmittance of Textile Materials

SCOPE

1.1 This test method covers the determination of the overall thermal transmission coefficients due to the combined action of conduction, convection, and radiation for dry specimens of textile fabrics, battings, and other materials within the limits specified in 1.2. It measures the time rate of heat transfer from a warm, dry, constant-temperature, horizontal flat-plate up through a layer of the test material to a relatively calm, cool atmosphere.

1.2 For practical purposes, this test method is limited to determinations on specimens of fabrics, layered fabric assemblages, and battings having thermal transmittances (U2>>, as defined in 3.1.2) within a range of 0.7 to 14 W/m [dot]K and thicknesses not in excess of 50 mm.

1.3 The coefficients obtained apply strictly only to the particular specimens tested and for the specified thermal and environmental conditions of each test. This test method gives values that are valid for comparison under the same conditions of test, that is, with the specified air velocity, temperature difference between the warm plate and the cool air, and air gap for measuring cool air temperature.

1.4 This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.>

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn

Contact ASTM International (www.astm.org) for the lastest information

e1

Designation:D1518–85(Reapproved 1998)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Thermal Transmittance of Textile Materials

This standard is issued under the fixed designation D1518; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial changes were made throughout June 1998.

1. Scope 3. Terminology

1.1 This test method covers the determination of the overall 3.1 Definitions:

thermaltransmissioncoefficientsduetothecombinedactionof 3.1.1 bulk density, n—apparent mass per unit volume.

conduction, convection, and radiation for dry specimens of 3.1.1.1 Discussion—In testing the thermal transmittance of

textile fabrics, battings, and other materials within the limits fabrics, bulk density is calculated from the fabric weight per

specified in 1.2. It measures the time rate of heat transfer from unit area and the thickness value used to calculate thermal

a warm, dry, constant-temperature, horizontal flat-plate up conductivity.

through a layer of the test material to a relatively calm, cool 3.1.2 clo, n—unit of thermal resistance defined as the

atmosphere. insulationrequiredtokeeparestingman(producingheatatthe

1.2 For practical purposes, this test method is limited to rate of 58 W/m ) comfortable in an environment at 21°C, air

determinations on specimens of fabrics, layered fabric assem- movement 0.1 m/s, or roughly the insulation value of typical

,

blies, and battings having thermal transmittances (U , as indoor clothing. (Syn. intrinsic clo).

defined in 3.1.2.1) within a range of 0.7 to 14 W/m ·K and 3.1.2.1 Discussion—Numerically the clo is equal to 0.155

thicknesses not in excess of 50 mm. K·m /W.

1.3 The coefficients obtained apply strictly only to the 3.1.3 heat transfer coeffıcient, n—see thermal transmit-

particular specimens tested and for the specified thermal and tance.

environmental conditions of each test. This test method gives 3.1.4 intrinsic clo, n—see clo.

values that are valid for comparison under the same conditions 3.1.5 specific clo, n—the specific thermal resistance in clo

of test, that is, with the specified air velocity, temperature units per unit thickness.

difference between the warm plate and the cool air, and air gap 3.1.6 thermal conductance, n—see thermal transmittance.

for measuring cool air temperature. 3.1.7 thermal conductivity, n—time rate of unidirectional

1.4 The values stated in metric units are to be regarded as heat transfer per unit area, in the steady-state, between parallel

the standard. Conversion factors, for thermal conductance and planes separated by unit distance, per unit difference of

conductivity and thermal resistance and resistivity, to other temperature of the planes.

units in common use are given in Tables 1-5 3.1.7.1 Discussion—Numerically, thermal conductivity

1.5 This standard does not purport to address the safety equals the product of the heat transfer coefficient and the

concerns associated with its use. It is the responsibility of distance separating the planes. Thus, k, the thermal conductiv-

whoever uses this standard to consult and establish appropri- ity of the fabric only, is the product of U and the fabric

ate safety and health practices and determine the applicability thickness. Units of thermal conductivity are W/m·K.

of regulatory limitations prior to use. 3.1.8 thermal resistance, n—reciprocal of thermal transmit-

tance.

2. Referenced Documents

3.1.9 thermal resistivity, n—reciprocal of thermal conduc-

2.1 ASTM Standards: tivity.

D123 Terminology Relating to Textiles

3.1.10 thermaltransmittance,n—timerateofunidirectional

D1777 Method for Measuring Thickness of Textile Mate- heat transfer per unit area, in the steady-state, between parallel

rials

planes, per unit difference of temperature of the planes (Syn.

thermal conductance, heat transfer coefficient).

3.1.10.1 Discussion—Thermaltransmittanceisexpressedas

watts per square metre of test specimen per kelvin difference

ThistestmethodisunderthejurisdictionofASTMCommitteeD-13onTextiles

between the hot plate and the cool atmosphere (W/m ·K).

and is the direct responsibility of Subcommittee D13.51 on Chemical Conditioning

and Performance.

Current edition approved July 26, 1985. Published September 1985. Originally

American Society of Heating, Refrigerating, and Air-Conditioning Engineers.

published as D1518–57T. Last previous edition D1518–77.

Gagge, A. P., Burton, A. C., Bazett, H. C., Science, Vol 94, Nov. 7, 1941, pp.

Annual Book of ASTM Standards, Vol 07.01.

428–430.

D1518

A

TABLE 1 Conversion Factors for Thermal Conductivity

To Convert

Thermal Con- Multiply by

ductivity

From kg-cal·cm/ Btu·in/

B 2

W/m·K W·cm/m ·K W/cm·K cal/s·cm·K kg-cal/h·m·K Btu/h·ft·°F in/clo mm/clo

2 2

to h·m ·K h·ft ·°F

+2 −2 −3 −1 +1 −1 +2

1.3 10 2.3883 10 8.5983 10 8.5983 10 5.7783 10 6.934 6.093 1.5483 10

W/m·K 1. 1.3 10

−2 −4 −5 −3 −1 −3 −2 −2

W·cm/ 1.3 10 1. 1.3 10 2.3883 10 8.5983 10 8.5983 10 5.7783 10 6.9343 10 6.0933 10 1.548

m ·K

+2 +4 −1 +1 +3 +1 +2 +2 +4

W/cm·K 1.3 10 1.3 10 1. 2.3883 10 8.5983 10 8.5983 10 5.7783 10 6.9343 10 6.0933 10 1.5483 10

+2 +4 +2 +4 +2 +3 +3 +4

cal/s·cm·K 4.1873 10 4.1873 10 4.187 1. 3.63 10 3.63 10 2.4193 10 2.9033 10 2.5513 10 6.4803 10

kg-cal/

+2 −2 −3 +2 −1 +2

h·m·K 1.163 1.1633 10 1.1633 10 2.7783 10 1. 1.3 10 6.7203 10 8.064 7.087 1.83 10

kg-cal·cm/

2 −2 −4 −5 −2 −3 −2 −2

h·m ·K 1.1633 10 1.163 1.1633 10 2.7783 10 1.3 10 1. 6.7203 10 8.0643 10 7.0873 10 1.8

+2 −2 −3 +2 +1 +1 +2

Btu/h·ft·°F 1.731 1.7313 10 1.7313 10 4.1343 10 1.488 1.4883 10 1. 1.23 10 1.0553 10 2.6793 10

Btu·in/

2 −1 +1 −3 −4 −1 +1 −2 −1 +1

h·ft ·°F 1.4423 10 1.4423 10 1.4423 10 3.4453 10 1.2403 10 1.2403 10 8.3333 10 1. 8.7883 10 2.2323 10

−1 +1 −3 −4 −1 −1 −2 +1

in/clo 1.6413 10 1.6413 10 1.6413 10 3.9203 10 1.4113 10 1.4113 10 9.4823 10 1.138 1. 2.5403 10

−3 −1 −5 −5 −3 −1 −3 −3 −2

mm/clo 6.4613 10 6.4613 10 6.4613 10 1.5433 10 5.5563 10 5.5563 10 3.7333 10 4.4803 10 3.9373 10 1.

A

Units are given in terms of: (1) the absolute joule per second, or watt; (2) the calorie (International Table)5 4.1868 J; (3) the British thermal unit (International

Table)5 1055.06 J; and (4) the clo (unit of clothing resistance)5 0.155 K·m /W.

B

Recommended (SI) units.

A

TABLE 2 Conversion Factors for Thermal Transmittance

To Convert

Thermal Multiply by

Transmittance

From

2 B 2 2 2 2 −1

W/m ·K W/cm ·K cal/s·cm ·K kg-cal/h·m ·K Btu/h·ft ·°F clo

to

2 −4 −5 −1 −1 −1

W/m ·K 1. 1.3 10 2.3883 10 8.5983 10 1.7613 10 1.5483 10

2 +4 −1 +3 +3 +3

W/cm ·K 1.3 10 1. 2.3883 10 8.5983 10 1.7613 10 1.5483 10

2 +4 +4 +3 +3

cal/s·cm ·K 4.1873 10 4.187 1. 3.63 10 7.3733 10 6.4803 10

2 −4 −5 −1 −1

kg-cal/h·m ·K 1.163 1.1633 10 2.7783 10 1. 2.0483 10 1.83 10

2 −4 −4 −1

Btu/h·ft ·°F 5.678 5.6783 10 1.3563 10 4.882 1. 8.7883 10

−1 −4 −4

clo 6.461 6.4613 10 1.5433 10 5.556 1.138 1.

A

Units are given in terms of: (1) the absolute joule per second, or watt; (2) the calorie (International Table)5 4.1868 J; (3) the British thermal unit (International

Table)5 1055.06 J; and (4) the clo (unit of clothing resistance)5 0.155 K·m /W.

B

Recommended (SI) units.

A

TABLE 3 Conversion Factors for Thermal Resistivity

To Convert

Thermal Multiply by

B

Resistivity

2 2

From m ·K·h/kg- ft ·°F·h/

B 2

m·K/W m ·K/W·cm cm·K/W cm·K·s/cal m·K·h/kg-cal ft·°F·h/Btu clo/in clo/mm

to cal·cm Btu·in

−2 +2 +2 −2 −1 −1 −3

m·K/W 1. 1.3 10 1.3 10 4.1873 10 1.163 1.1633 10 1.731 1.4423 10 1.6413 10 6.4613 10

2 +2 +4 +4 +2 +2 +1 −1 −1

m ·K/W· 1.3 10 1. 1.3 10 4.1873 10 1.1633 10 1.163 1.7313 10 1.4423 10 1.6413 10 6.4613 10

cm

−2 −4 −2 −4 −2 −3 −3 −5

cm·K/W 1.3 10 1.3 10 1. 4.187 1.1633 10 1.1633 10 1.7313 10 1.4423 10 1.6413 10 6.4613 10

−3 −5 −1 −3 −5 −3 −4 −4 −5

cm·K·s/cal 2.3883 10 2.3883 10 2.3883 10 1. 2.7783 10 2.7783 10 4.1343 10 3.4453 10 3.9203 10 1.5433 10

−1 −3 +1 +2 −2 −1 −1 −3

m·K·h/kg- 8.5983 10 8.5983 10 8.5983 10 3.63 10 1. 1.3 10 1.488 1.2403 10 1.4113 10 5.5563 10

cal

2 +1 −1 +3 +4 +2 +2 +1 +1 −1

m ·K·h/kg- 8.5983 10 8.5983 10 8.5983 10 3.63 10 1.3 10 1. 1.4883 10 1.2403 10 1.4113 10 5.5563 10

cal·cm

−1 −3 +1 +2 −1 −3 −2 −2 −3

ft·°F·h/Btu 5.7783 10 5.7783 10 5.7783 10 2.4193 10 6.7203 10 6.7203 10 1. 8.3333 10 9.4823 10 3.7333 10

2 −2 +2 +3 −2 +1 −3

ft ·°F·h/ 6.934 6.9343 10 6.9343 10 2.9033 10 8.064 8.0643 10 1.23 10 1. 1.138 4.4803 10

Btu·in

−2 +2 +3 −2 +1 −1 −2

clo/in 6.093 6.0933 10 6.0933 10 2.5513 10 7.087 7.0873 10 1.0553 10 8.7883 10 1. 3.9373 10

+2 +4 +4 +2 +2 +1 +1

clo/mm 1.5483 10 1.548 1.5483 10 6.4803 10 1.83 10 1.8 2.6793 10 2.2323 10 2.5403 10 1.

A

Units are given in terms of: (1) the absolute joule per second, or watt; (2) the calorie (International Table)5 4.1868 J; (3) the British thermal unit (International

Table)5 1055.06 J; and (4) the clo (unit of clothing resistance)5 0.155 K·m /W.

B

Recommended (SI) units.

D1518

A

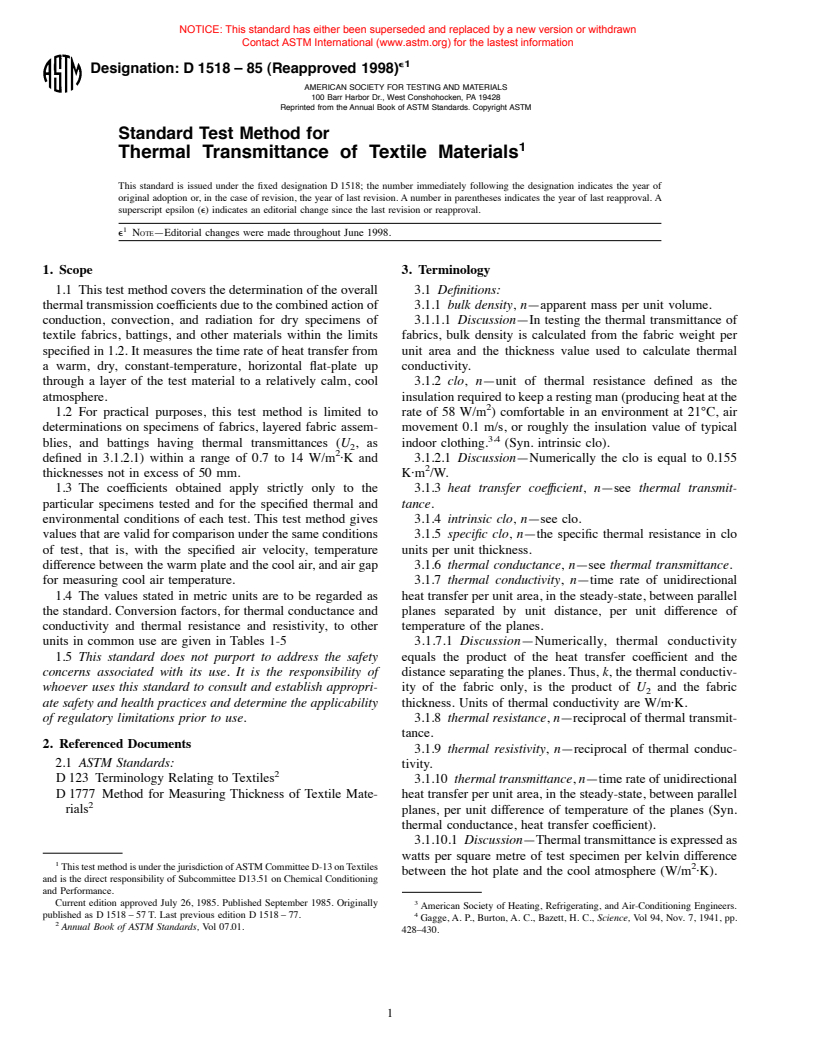

TABLE 4 Conversion Factors for Thermal Resistance

To Convert

Thermal Multiply by

Resistance

From

2 B 2 2 2 2

m ·K/W cm ·K/W cm ·K·s/cal m ·K·h/kg-cal ft ·°F·h/Btu clo

to

2 +4 +4

·K/W 1. 1.3 10 4.1873 10 1.163 5.678 6.461

m

2 −4 −4 −4 −4

cm ·K/W 1.3 10 1. 4.187 1.1633 10 5.6783 10 6.4613 10

2 −5 −1 −5 −4 −4

cm ·K·s/cal 2.3883 10 2.3883 10 1. 2.7783 10 1.3563 10 1.5433 10

2 −1 +3 +4

m ·K·h/kg-cal 8.5983 10 8.5983 10 3.63 10 1. 4.882 5.556

2 −1 +3 +3 −1

ft ·°F·h/Btu 1.7613 10 1.7613 10 7.3733 10 2.0483 10 1. 1.138

−1 +3 +3 −1 −1

clo 1.5483 10 1.5483 10 6.4803 10 1.83 10 8.7883 10 1.

A

Units are given in terms of: (1) the absolute joule per second, or watt; (2) the calorie (International Table)5 4.1868 J; (3) the British thermal unit (International

Table)5 1055.06 J; and (4) the clo (unit of clothing resistance)5 0.155 K·m /W.

B

Recommended (SI) units.

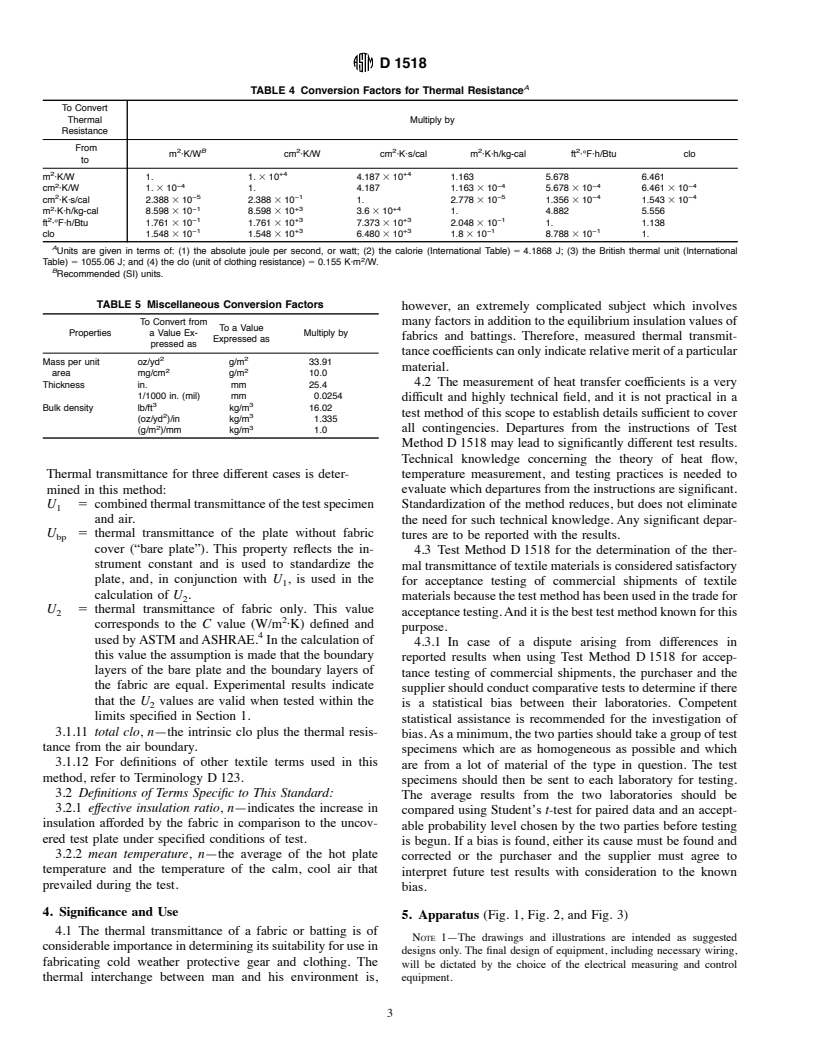

TABLE 5 Miscellaneous Conversion Factors

however, an extremely complicated subject which involves

To Convert from manyfactorsinadditiontotheequilibriuminsulationvaluesof

To a Value

Properties a Value Ex- Multiply by

fabrics and battings. Therefore, measured thermal transmit-

Expressed as

pressed as

tancecoefficientscanonlyindicaterelativemeritofaparticular

2 2

Mass per unit oz/yd g/m 33.91

material.

2 2

area mg/cm g/m 10.0

4.2 The measurement of heat transfer coefficients is a very

Thickness in. mm 25.4

1/1000 in. (mil) mm 0.0254

difficult and highly technical field, and it is not practical in a

3 3

Bulk density lb/ft kg/m 16.02

test method of this scope to establish details sufficient to cover

2 3

(oz/yd )/in kg/m 1.335

2 3

all contingencies. Departures from the instructions of Test

(g/m )/mm kg/m 1.0

Method D1518 may lead to significantly different test results.

Technical knowledge concerning the theory of heat flow,

Thermal transmittance for three different cases is deter- temperature measurement, and testing practices is needed to

evaluatewhichdeparturesfromtheinstructionsaresignificant.

mined in this method:

U 5 combinedthermaltransmittanceofthetestspecimen

Standardization of the method reduces, but does not eliminate

and air. the need for such technical knowledge.Any significant depar-

U 5 thermal transmittance of the plate without fabric

tures are to be reported with the results.

bp

cover (“bare plate”). This property reflects the in-

4.3 Test Method D1518 for the determination of the ther-

strument constant and is used to standardize the

maltransmittanceoftextilematerialsisconsideredsatisfactory

plate, and, in conjunction with U , is used in the

for acceptance testing of commercial shipments of textile

calculation of U .

materialsbecausethetestmethodhasbeenusedinthetradefor

U 5 thermal transmittance of fabric only. This value

2 acceptancetesting.Anditisthebesttestmethodknownforthis

corresponds to the C value (W/m ·K) defined and

purpose.

used byASTM andASHRAE. In the calculation of

4.3.1 In case of a dispute arising from differences in

this value the assumption is made that the boundary

reported results when using Test Method D1518 for accep-

layers of the bare plate and the boundary layers of

tance testing of commercial shipments, the purchaser and the

the fabric are equal. Experimental results indicate

suppliershouldconductcomparativeteststodetermineifthere

that the U values are valid when tested within the

2 is a statistical bias between their laboratories. Competent

limits specified in Section 1.

statistical assistance is recommended for the investigation of

3.1.11 total clo, n—the intrinsic clo plus the thermal resis-

bias.Asaminimum,thetwopartiesshouldtakeagroupoftest

tance from the air boundary.

specimens which are as homogeneous as possible and which

3.1.12 For definitions of other textile terms used in this

are from a lot of material of the type in question. The test

method, refer to Terminology D123.

specimens should then be sent to each laboratory for testing.

3.2 Definitions of Terms Specific to This Standard:

The average results from the two laboratories should be

3.2.1 effective insulation ratio, n—indicates the increase in

compared using Student’s t-test for paired data and an accept-

insulation afforded by the fabric in comparison to the uncov-

able probability level chosen by the two parties before testing

ered test plate under specified conditions of test.

is begun. If a bias is found, either its cause must be found and

3.2.2 mean temperature, n—the average of the hot plate

corrected or the purchaser and the supplier must agree to

temperature and the temperature of the calm, cool air that

interpret future test results with consideration to the known

prevailed during the test.

bias.

4. Significance and Use

5. Apparatus (Fig. 1, Fig. 2, and Fig. 3)

4.1 The thermal transmittance of a fabric or batting is of

NOTE 1—The drawings and illustrations are intended as suggested

considerableimportanceindeterminingitssuitabilityforusein

designs only. The final design of equipment, including necessary wiring,

fabricating cold weather protective gear and clothing. The

will be dictated by the choice of the electrical measuring and control

thermal interchange between man and his environment is, equipment.

D1518

centeroftheuppersurfaceofthehot-plateassembly.Itshallbe

made of aluminum or copper and painted a dull black to

approximate the emissivity of the human skin. The heating

elementshallconsistofparallelwires,preferablyofconstantan

metal,insulatedfrom,butmountedwithin3mm(0.1in.)ofthe

upper plate.

5.1.2 Guard Ring—The guard rin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.