ASTM D3705-14(2019)

(Test Method)Standard Test Method for Misting Properties of Lubricating Fluids

Standard Test Method for Misting Properties of Lubricating Fluids

SIGNIFICANCE AND USE

5.1 This test provides a guide for evaluating the misting characteristics of oils for use in industrial mist lubrication systems. The degree of correlation between this test and service performance has not been fully determined.

SCOPE

1.1 This test method covers the determination of the misting characteristics of lubricating fluids.

Note 1: This test method should not be used to evaluate fluids containing solid additives such as graphite.

1.2 The values stated in SI units are to be regarded as standard.

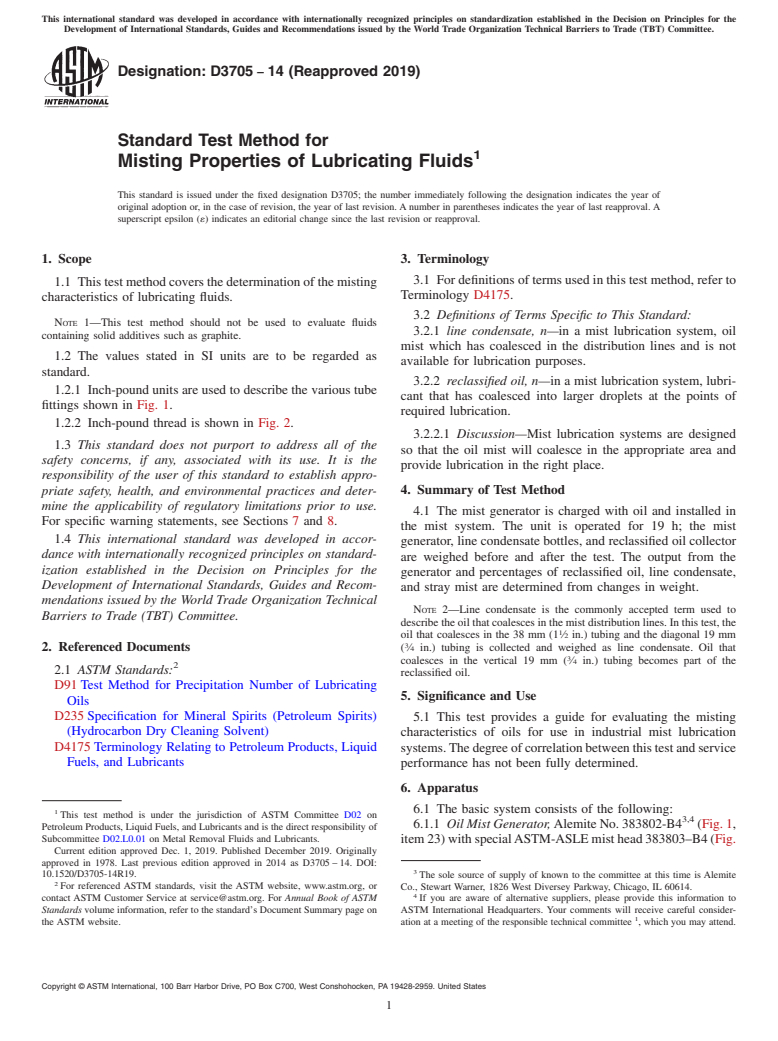

1.2.1 Inch-pound units are used to describe the various tube fittings shown in Fig. 1.

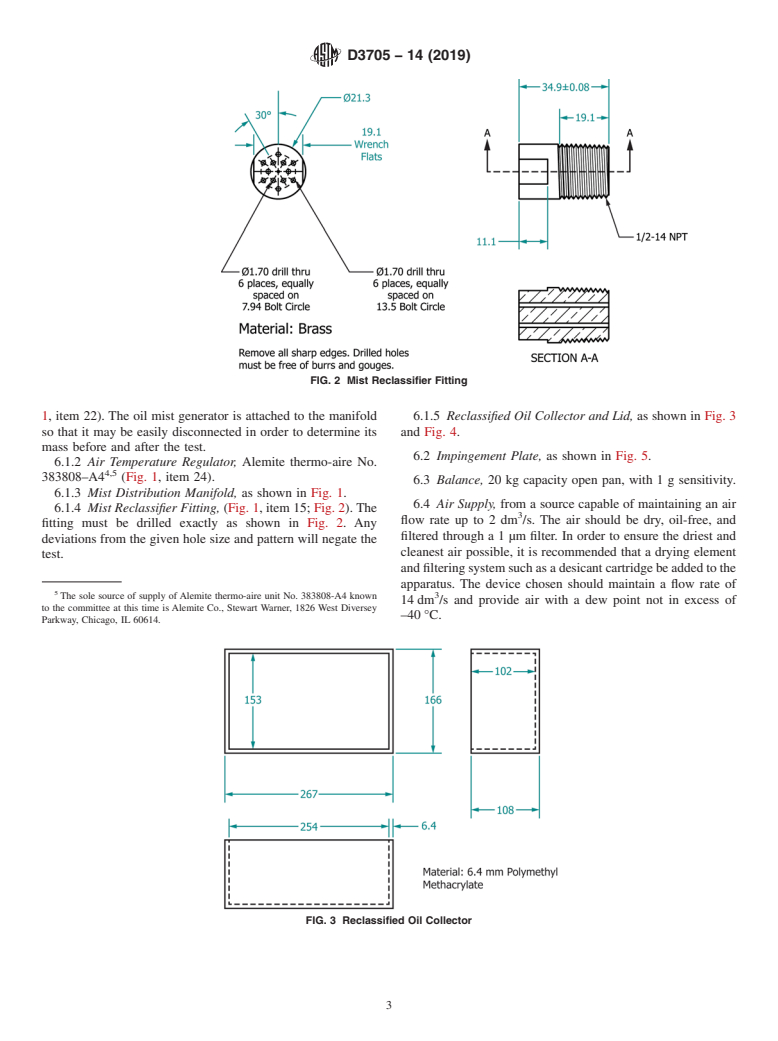

1.2.2 Inch-pound thread is shown in Fig. 2.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see Sections 7 and 8.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3705 − 14 (Reapproved 2019)

Standard Test Method for

Misting Properties of Lubricating Fluids

This standard is issued under the fixed designation D3705; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

3.1 For definitions of terms used in this test method, refer to

1.1 Thistestmethodcoversthedeterminationofthemisting

Terminology D4175.

characteristics of lubricating fluids.

3.2 Definitions of Terms Specific to This Standard:

NOTE 1—This test method should not be used to evaluate fluids

3.2.1 line condensate, n—in a mist lubrication system, oil

containing solid additives such as graphite.

mist which has coalesced in the distribution lines and is not

1.2 The values stated in SI units are to be regarded as

available for lubrication purposes.

standard.

3.2.2 reclassified oil, n—in a mist lubrication system, lubri-

1.2.1 Inch-pound units are used to describe the various tube

cant that has coalesced into larger droplets at the points of

fittings shown in Fig. 1.

required lubrication.

1.2.2 Inch-pound thread is shown in Fig. 2.

3.2.2.1 Discussion—Mist lubrication systems are designed

1.3 This standard does not purport to address all of the

so that the oil mist will coalesce in the appropriate area and

safety concerns, if any, associated with its use. It is the

provide lubrication in the right place.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter- 4. Summary of Test Method

mine the applicability of regulatory limitations prior to use.

4.1 The mist generator is charged with oil and installed in

For specific warning statements, see Sections 7 and 8.

the mist system. The unit is operated for 19 h; the mist

1.4 This international standard was developed in accor-

generator, line condensate bottles, and reclassified oil collector

dance with internationally recognized principles on standard-

are weighed before and after the test. The output from the

ization established in the Decision on Principles for the

generator and percentages of reclassified oil, line condensate,

Development of International Standards, Guides and Recom-

and stray mist are determined from changes in weight.

mendations issued by the World Trade Organization Technical

NOTE 2—Line condensate is the commonly accepted term used to

Barriers to Trade (TBT) Committee.

describe the oil that coalesces in the mist distribution lines. In this test, the

oil that coalesces in the 38 mm (1 ⁄2 in.) tubing and the diagonal 19 mm

2. Referenced Documents ( ⁄4 in.) tubing is collected and weighed as line condensate. Oil that

coalesces in the vertical 19 mm ( ⁄4 in.) tubing becomes part of the

2.1 ASTM Standards:

reclassified oil.

D91 Test Method for Precipitation Number of Lubricating

5. Significance and Use

Oils

D235 Specification for Mineral Spirits (Petroleum Spirits)

5.1 This test provides a guide for evaluating the misting

(Hydrocarbon Dry Cleaning Solvent) characteristics of oils for use in industrial mist lubrication

D4175 Terminology Relating to Petroleum Products, Liquid

systems.Thedegreeofcorrelationbetweenthistestandservice

Fuels, and Lubricants performance has not been fully determined.

6. Apparatus

6.1 The basic system consists of the following:

This test method is under the jurisdiction of ASTM Committee D02 on

3,4

6.1.1 Oil Mist Generator,AlemiteNo.383802-B4 (Fig.1,

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.L0.01 on Metal Removal Fluids and Lubricants.

item23)withspecialASTM-ASLEmisthead383803–B4(Fig.

Current edition approved Dec. 1, 2019. Published December 2019. Originally

approved in 1978. Last previous edition approved in 2014 as D3705 – 14. DOI:

10.1520/D3705-14R19. The sole source of supply of known to the committee at this time is Alemite

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Co., Stewart Warner, 1826 West Diversey Parkway, Chicago, IL 60614.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM If you are aware of alternative suppliers, please provide this information to

Standards volume information, refer to the standard’s Document Summary page on ASTM International Headquarters. Your comments will receive careful consider-

the ASTM website. ation at a meeting of the responsible technical committee , which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3705 − 14 (2019)

1 1

(1) 1 ⁄2C×1 ⁄2 in. MPT union (19) Air flow meter (L/s)

(2) 1 ⁄2 in. copper tubing, 3 in. long (20) Pressure gage, 7 kPa

(3) 1 ⁄2 in. C × C Return bend (21) Air filter

(4) 1 ⁄2 in. C Union (22) Oil mist head assembly with adjusting screw

1 3 1

(5) 1 ⁄2 × ⁄4×1 ⁄2in.C×C×Ctee (23) Oilmist generator

(6) 1 ⁄2 in. C 45 deg ftg Ell (straight ell) (24) Thermo-aire unit

(7) ⁄4 in. ftg × MPT adapter (25) Pressure gage, 4 kPa

1 1 3

(8) 1 ⁄2×1 ⁄2 × ⁄4in.C×C×Ctee (26) Thermocouple

(9) ⁄4 in. C 45 deg ftg ell (27) Impingement plate

1 3

(10) 1 ⁄2 ftg × ⁄4 in. C extended bushing (28) Collection box

(11) ⁄4 in. C Union (29) Lid for collection box

3 1

(12) ⁄4 in. ftg × C 45 deg ftg ell (30) 1 ⁄2 in. type “M” hard copper tubing, 41.3 mm

O.D. × 38.3 mm I.D.

3 3

(13) ⁄4 in. ftg × C 90 deg ftg ell (31) ⁄4 in. type “K” hard copper tubing, 22.2 mm

O.D. × 18.9 mm. I.D.

3 1

(14) ⁄4C× ⁄2 in. FPT adapter (32) Flexible hose

(15) ⁄2 in. reclassifier fitting

(16) Collector bottle, 1 L plastic with ⁄4 female NPT top

(17) Thermometer

(18) Pressure regulator with gage (2 mPa)

FIG. 1 Mist Distribution Manifold

D3705 − 14 (2019)

FIG. 2 Mist Reclassifier Fitting

1, item 22). The oil mist generator is attached to the manifold 6.1.5 Reclassified Oil Collector and Lid, as shown in Fig. 3

so that it may be easily disconnected in order to determine its and Fig. 4.

mass before and after the test.

6.2 Impingement Plate, as shown in Fig. 5.

6.1.2 Air Temperature Regulator, Alemite thermo-aire No.

4,5

383808–A4 (Fig. 1, item 24).

6.3 Balance, 20 kg capacity open pan, with 1 g sensitivity.

6.1.3 Mist Distribution Manifold, as shown in Fig. 1.

6.4 Air Supply, from a source capable of maintaining an air

6.1.4 Mist Reclassifier Fitting, (Fig. 1, item 15; Fig. 2). The

flow rate up to 2 dm /s. The air should be dry, oil-free, and

fitting must be drilled exactly as shown in Fig. 2. Any

filtered througha1µm filter. In order to ensure the driest and

deviations from the given hole size and pattern will negate the

cleanest air possible, it is recommended that a drying element

test.

andfilteringsystemsuchasadesicantcartridgebeaddedtothe

apparatus. The device chosen should maintain a flow rate of

The sole source of supply of Alemite thermo-aire unit No. 383808-A4 known

14 dm /s and provide air with a dew point not in excess of

to the committee at this time is Alemite Co., Stewart Warner, 1826 West Diversey

–40 °C.

Parkway, Chicago, IL 60614.

FIG. 3 Reclassified Oil Collector

D3705 − 14 (2019)

FIG. 4 Reclassified Oil Collector Lid

NOTE 3—The oil mist generator head and mist reclassifier fitting are

8.5 Disconnect the mist head and remove the oil adjustment

available from the Alemite Co. Orders should specify Special ASTM-

screw; rinse the head and screw with naphtha and blow dry.

ASLE mist head and reclassifier fitting.

NOTE 4—While not required, the addition of an oil bath temperature 8.6 Remove the reclassifier fitting and rinse it with naphtha;

regulator (Alemite 383807–A4) is recommended. Results will be more

examine the orifices for deposits or buildup. If necessary, the

consistent if the oil is kept at a constant temperature.

orifices may be cleaned with a fine pipe cleaner.

7. Reagents

9. Procedure

7.1 Stoddard Solvent, as specified in Specification D235

9.1 Break-In Period:

(Type 1). (Warning

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.