ASTM F1130-99(2005)

(Practice)Standard Practice for Inspecting the Coating System of a Ship

Standard Practice for Inspecting the Coating System of a Ship

SIGNIFICANCE AND USE

This practice establishes the procedure for the inspection of coating systems on board ships. It contains a series of diagrams to be used to report the extent of damage to coatings.

SCOPE

1.1 This practice covers a standard procedure for inspecting the coating system of a ship's topside and superstructure, tanks and voids, decks and deck machinery, and underwater hull and boottop during drydocking. Included are a standard inspection form to be used for reporting the inspection data, a diagram that divides topside and superstructure individual inspection areas, and a series of diagrams that are used to report the extent of damage to the coating system.

1.2 This practice is intended for use only by an experienced marine coating inspector.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:F 1130–99 (Reapproved 2005)

Standard Practice for

1

Inspecting the Coating System of a Ship

This standard is issued under the fixed designation F 1130; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

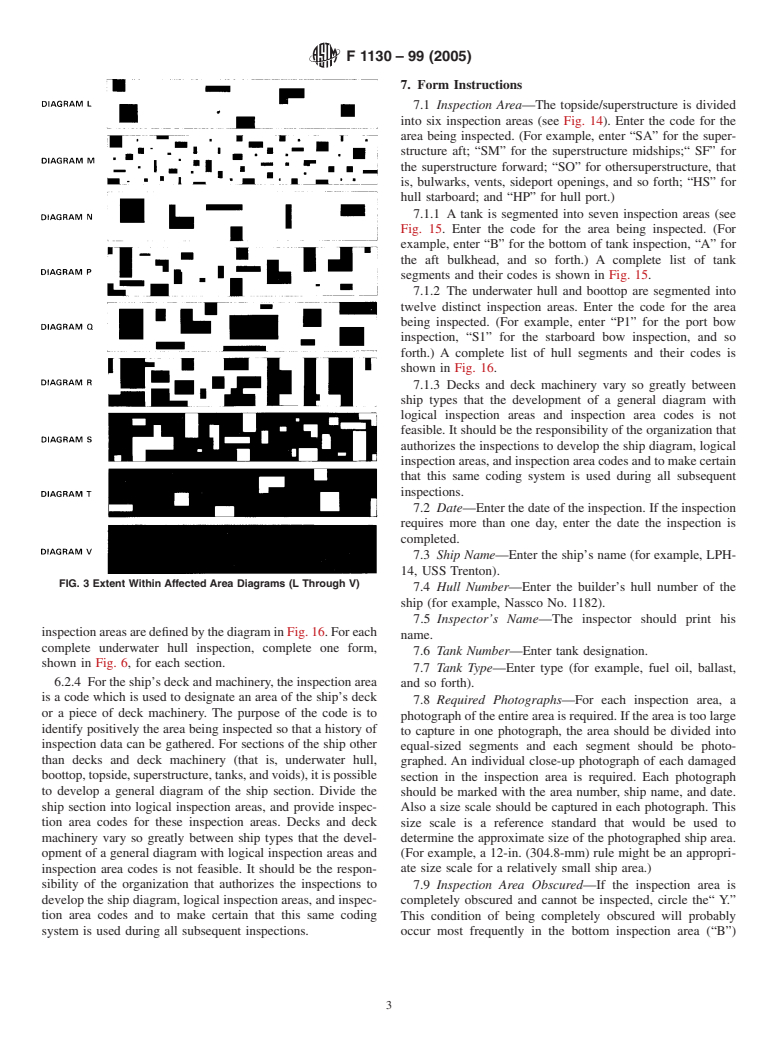

1. Scope 3. Significance and Use

1.1 This practice covers a standard procedure for inspecting 3.1 This practice establishes the procedure for the inspec-

the coating system of a ship’s topside and superstructure, tanks tion of coating systems on board ships. It contains a series of

and voids, decks and deck machinery, and underwater hull and diagrams to be used to report the extent of damage to coatings.

boottop during drydocking. Included are a standard inspection

4. Reference Standards

form to be used for reporting the inspection data, a diagram

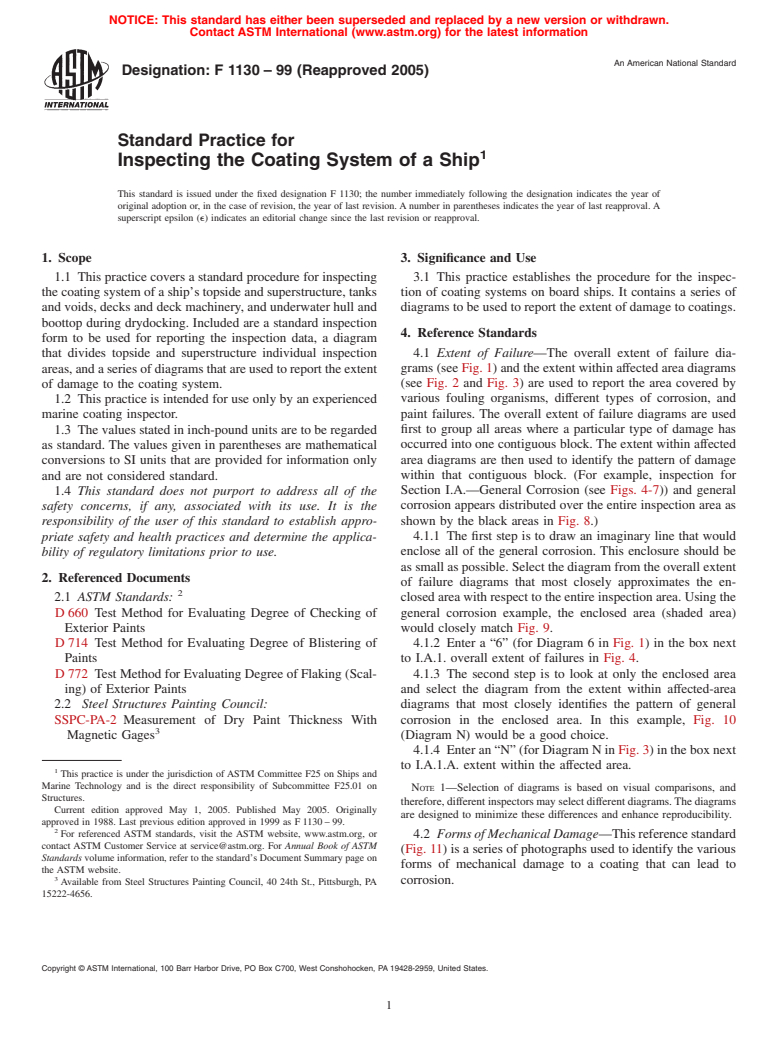

4.1 Extent of Failure—The overall extent of failure dia-

that divides topside and superstructure individual inspection

areas,andaseriesofdiagramsthatareusedtoreporttheextent grams (see Fig. 1) and the extent within affected area diagrams

(see Fig. 2 and Fig. 3) are used to report the area covered by

of damage to the coating system.

1.2 This practice is intended for use only by an experienced various fouling organisms, different types of corrosion, and

paint failures. The overall extent of failure diagrams are used

marine coating inspector.

1.3 The values stated in inch-pound units are to be regarded first to group all areas where a particular type of damage has

occurred into one contiguous block. The extent within affected

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only area diagrams are then used to identify the pattern of damage

within that contiguous block. (For example, inspection for

and are not considered standard.

1.4 This standard does not purport to address all of the Section I.A.—General Corrosion (see Figs. 4-7)) and general

corrosion appears distributed over the entire inspection area as

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- shown by the black areas in Fig. 8.)

4.1.1 The first step is to draw an imaginary line that would

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. enclose all of the general corrosion. This enclosure should be

as small as possible. Select the diagram from the overall extent

2. Referenced Documents

of failure diagrams that most closely approximates the en-

2

2.1 ASTM Standards: closed area with respect to the entire inspection area. Using the

D 660 Test Method for Evaluating Degree of Checking of general corrosion example, the enclosed area (shaded area)

Exterior Paints would closely match Fig. 9.

D 714 Test Method for Evaluating Degree of Blistering of 4.1.2 Enter a “6” (for Diagram 6 in Fig. 1) in the box next

Paints to I.A.1. overall extent of failures in Fig. 4.

D 772 Test Method for Evaluating Degree of Flaking (Scal- 4.1.3 The second step is to look at only the enclosed area

ing) of Exterior Paints and select the diagram from the extent within affected-area

2.2 Steel Structures Painting Council: diagrams that most closely identifies the pattern of general

SSPC-PA-2 Measurement of Dry Paint Thickness With corrosion in the enclosed area. In this example, Fig. 10

3

Magnetic Gages (Diagram N) would be a good choice.

4.1.4 Enter an “N” (for Diagram N inFig. 3) in the box next

to I.A.1.A. extent within the affected area.

1

This practice is under the jurisdiction of ASTM Committee F25 on Ships and

Marine Technology and is the direct responsibility of Subcommittee F25.01 on

NOTE 1—Selection of diagrams is based on visual comparisons, and

Structures.

therefore,differentinspectorsmayselectdifferentdiagrams.Thediagrams

Current edition approved May 1, 2005. Published May 2005. Originally

are designed to minimize these differences and enhance reproducibility.

approved in 1988. Last previous edition approved in 1999 as F 1130 – 99.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.2 FormsofMechanicalDamage—Thisreferencestandard

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

(Fig. 11) is a series of photographs used to identify the various

Standards volume information, refer to the standard’s Document Summary page on

forms of mechanical damage to a coating that can lead to

the ASTM website.

3

corrosion.

Available from Steel Structures Painting Council, 40 24th St., Pittsburgh, PA

15222-4656.

Copyright © ASTM International, 100

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.