ASTM D7187-05

(Test Method)Standard Test Method for Measuring Mechanistic Aspects of Scratch/Mar Behavior of Paint Coatings by Nanoscratching

Standard Test Method for Measuring Mechanistic Aspects of Scratch/Mar Behavior of Paint Coatings by Nanoscratching

SCOPE

1.1 This test method covers the nanoscratch method for determining the resistance of paint coatings on smooth flat surfaces to scratch/mar.

1.2 Previous methods used in scratch/mar evaluation first physically scratch or mar a samples surface with multiple contact cutting, and then use visual inspection to assign a ranking. It has been recognized that loss of appearance is mainly due to surface damages created. The philosophy of this method is to quantitatively and objectively measure scratch/mar behavior by making the evaluation process two steps with emphasis on surface damages. Step one is to find the relationship between damage shape and size and external input (such as forces, contact geometry, and deformation). Step two is to relate damage shape and size to visual loss of luster. The first step is covered by this method; in addition, a survey in the appendix provides an example of an experiment to relate the damage to the change in luster.

1.3 There are three elementary deformation mechanisms: elastic deformation, plastic deformation and fracture; only the latter two both contribute significantly to mar. This method evaluates scratch/mar based on the latter two damage mechanisms.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7187–05

Standard Test Method for

Measuring Mechanistic Aspects of Scratch/Mar Behavior of

Paint Coatings by Nanoscratching

This standard is issued under the fixed designation D7187; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D609 Practice for Preparation of Cold-Rolled Steel Panels

for Testing Paint, Varnish, Conversion Coatings, and

1.1 This test method covers the nanoscratch method for

Related Coating Products

determining the resistance of paint coatings on smooth flat

D823 Practices for Producing Films of Uniform Thickness

surfaces to scratch/mar.

of Paint, Varnish, and Related Products on Test Panels

1.2 Previous methods used in scratch/mar evaluation first

D1005 Test Method for Measurement of Dry-Film Thick-

physically scratch or mar a sample’s surface with multiple

ness of Organic Coatings Using Micrometers

contact cutting, and then use visual inspection to assign a

D1044 Test Method for Resistance of Transparent Plastics

ranking. It has been recognized that loss of appearance is

to Surface Abrasion

mainly due to surface damages created. The philosophy of this

D1186 Test Methods for Nondestructive Measurement of

method is to quantitatively and objectively measure scratch/

Dry Film Thickness of Nonmagnetic Coatings Applied to

mar behavior by making the evaluation process two steps with

a Ferrous Base

emphasis on surface damages. Step one is to find the relation-

D1400 Test Method for Nondestructive Measurement of

ship between damage shape and size and external input (such

DryFilmThicknessofNonconductiveCoatingsAppliedto

as forces, contact geometry, and deformation). Step two is to

a Nonferrous Metal Base

relate damage shape and size to visual loss of luster. The first

D3363 Test Method for Film Hardness by Pencil Test

step is covered by this method; in addition, a survey in the

D3924 Specification for Environment for Conditioning and

appendix provides an example of an experiment to relate the

Testing Paint, Varnish, Lacquer, and Related Materials

damage to the change in luster.

D5178 Test Method for Mar Resistance of Organic Coat-

1.3 There are three elementary deformation mechanisms:

ings

elastic deformation, plastic deformation and fracture; only the

D6037 Test Methods for Dry Abrasion Mar Resistance of

latter two both contribute significantly to mar. This method

High Gloss Coatings

evaluates scratch/mar based on the latter two damage mecha-

D6279 Test Method for Rub Abrasion Mar Resistance of

nisms.

High Gloss Coatings

1.4 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

3. Summary of Test Method

only.

3.1 This test method is based on representative samples of

1.5 This standard does not purport to address all of the

the paint film being scratched using a nanoscratch instrument.

safety problems, if any, associated with its use. It is the

From information received during a scratch test, values for

responsibility of the user of this standard to establish appro-

plastic resistance and fracture resistance can be determined.

priate safety and health practices and determine the applica-

3.2 From these values of plastic resistance and fracture

bility of regulatory limitations prior to use.

resistance, the mechanistic aspects of scratch/mar behavior of

2. Referenced Documents the coating can be subsequently compared.

2.1 ASTM Standards:

4. Significance and Use

4.1 This test attempts to address two major drawbacks in

This test method is under the jurisdiction of ASTM Committee D01 on Paint

existingmartestssuchasTestMethodsD1044,D3363,D5178,

and Related Coatings, Materials, andApplications and is the direct responsibility of

D6037, and D6279, namely:

Subcommittee D01.23 on Physical Properties of Applied Paint Films.

Current edition approved July 1, 2005. Published October 2005. DOI: 10.1520/

D7187-05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For ASTM Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Withdrawn. The last approved version of this historical standard is referenced

the ASTM website. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7187–05

4.1.1 Measured damage is caused by hundreds of contacts tial force response of the coating should be measured with a

with differing contact geometries making it difficult or impos- high data acquisition rate, such as a maximum of five µm

sible for mechanical quantities (force, displacement) at the between data points.

contact points to be reliably determined. 5.3 Suggested range for testing parameters:

5.3.1 Indenter size should range from 1 to 100 microns and

4.1.2 The damage is evaluated using subjective visual

assessments, which provide only a qualitative sense of wear should be spherical in geometry.

5.3.2 The scratch should be applied at a rate of 0.5 to 10

with little information about mar mechanisms.

millimetres per minute.

4.2 This test provides a quantitative assessment of a paint

5.3.3 The loading rate of the normal force should be applied

coating’s mechanistic aspects of scratch/mar behavior in vari-

at 5 to 200 mN per minute.

ous conditions. The ability to control testing variables such as

5.3.4 The scanning preload should be conducted with an

rate and temperature allow the study of the scratch/mar

applied force of 0.1 to 1 mN.

behavior in a variety of environments.

5.4 The following is an example of one particular applica-

4.3 This test method is particularly suitable for measure-

tion of the test ranges. This example is based on automotive

ment of paint coatings on laboratory test panels.

clear coats on a metal substrate.

4.4 The accuracy and precision of scratch/mar performance

5.4.1 Indenter size of 2 microns.

may be significantly influenced by surface nonuniformity and

5.4.2 Scratch rate of 3 millimetres per minute.

irregularities.

5.4.3 Loading rate of 40 mN per minute.

4.5 A correlation has been observed between good mar

5.4.4 Scanning preload of 0.2 mN.

resistance in field studies and a combination of high Plastic

5.4.5 Data acquisition rate of 3 µm between data points.

Resistance and high Fracture Resistance (terms are defined

below). When coatings have had either high Plastic Resistance

6. Test Specimen

and low Fracture Resistance, or low Plastic Resistance and

6.1 The substrate for the paint coating should be a smooth,

high Fracture Resistance, there have been contradictory results

plane, rigid surface, such as those specified in Practices D609

in field studies.

and D823.

4.6 Mar resistance characterizes the ability of the coating to

6.2 The thickness of the coating being tested, determined in

resist light damage. The difference between mar and scratch

accordancewitheitherTestMethodsD1005,D1186,orD1400,

resistance is that mar is related to only the relatively fine

should be uniform within 500 nm. In order to minimize the

surface scratches which spoil the appearance of the coating.

effect of the substrate for maximum accuracy, the penetration

The mechanistic aspects of mar resistance depend on a

depth should not exceed one-half the coating thickness.

complex interplay between visco-elastic and thermal recovery,

6.3 Atleastthreescratchesshouldbeperformedoneachtest

yield or plastic flow, and micro-fracture. Polymers are chal-

specimen.

lenging because they exhibit a range of mechanical properties

6.4 The surface of the specimens should be free of any dirt

from near liquid through rubber materials to brittle solids. The

and oils.

mechanical properties are rate and temperature dependent and

6.5 The specimen size should be sufficient to be adequately

visco-elastic recovery can cause scratches to change with time.

secured to the nanoscratch instrument, but not so small as to

4.7 Since this method measures mechanical qualities, such

interfere with the movement of the indenter tip or its support-

as forces and displacements (deformations) during the damage

ing cantilever.

making process, rate dependence, temperature dependence,

NOTE 1—Itisrecommendedthatsubstrateswithsimilarcompliancesbe

and visco-elastic-plastic recovery can be further investigated

used when comparing different coatings.

and visual impacts of damage can be related to deformation

mechanisms.

7. Conditioning

7.1 Cure the coated test specimens under conditions agreed

5. Apparatus

upon between the purchaser and seller that reflect the condi-

5.1 Paint Application Equipment, as described in Practices

tions of curing of the paint in actual service.

D609 and D823.

7.2 Condition and test the test specimens at 23 6 2ºC (73.5

5.2 Nanoscratch Instrument, consisting of an instrument

6 3.5ºF) and a relative humidity of 50 6 5 % for at least 24h,

with a well-defined indenter, which translates perpendicular to

unless the purchaser and seller agree on more suitable test

the coating surface and has the capacity to produce an

characteristics, as specified in the Standard Atmosphere of

instrumented scratch of controlled and variable normal force

Specification D3924.

and continuously measured displacement during testing. The

8. Procedure

normal force must be feedback controlled, in order to quickly

respond to variations in surface morphology. The force of the 8.1 Secure the specimen to the moveable stage on the

instrument should have a maximum normal force of at least 50 instrumentwiththesurfacetobemeasuredlocatedperpendicu-

mN (mN should be read as milli-Newtons) with a resolution of larly to the indenter tip. Ensure the panel is held rigidly to the

at least 0.1 mN. The maximum tangential force, if measured, stage and cannot be moved by the action of the subsequent

should be at least 50 mN with a resolution of at least 0.5 mN. scratch test.

The range of the displacement sensors should be at least 50 µm 8.2 Carefully move this area under the indenter and bring

with a resolution of at least 20 nm. Displacement and tangen- the indenter tip close to the sample surface.

D7187–05

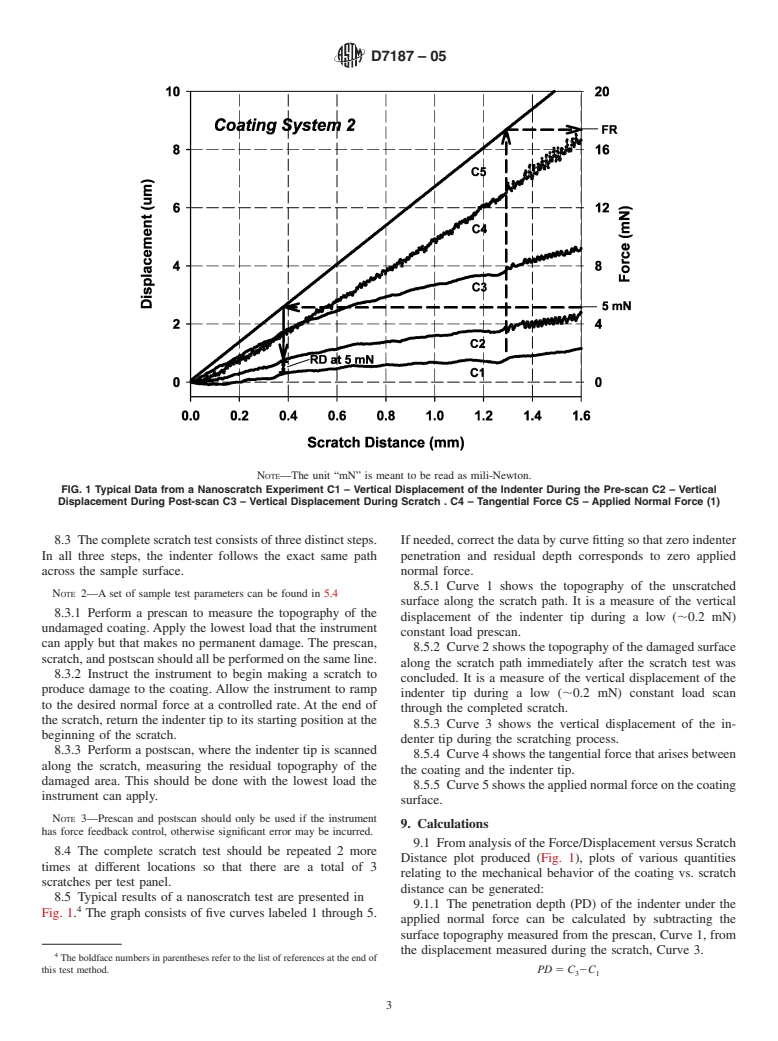

NOTE—The unit “mN” is meant to be read as mili-Newton.

FIG. 1 Typical Data from a Nanoscratch Experiment C1 – Vertical Displacement of the Indenter During the Pre-scan C2 – Vertical

Displacement During Post-scan C3 – Vertical Displacement During Scratch . C4 – Tangential Force C5 – Applied Normal Force (1)

8.3 Thecompletescratchtestconsistsofthreedistinctsteps. If needed, correct the data by curve fitting so that zero indenter

In all three steps, the indenter follows the exact same path penetration and residual depth corresponds to zero applied

across the sample surface. normal force.

8.5.1 Curve 1 shows the topography of the unscratched

NOTE 2—A set of sample test parameters can be found in 5.4

surface along the scratch path. It is a measure of the vertical

8.3.1 Perform a prescan to measure the topography of the

displacement of the indenter tip during a low (;0.2 mN)

undamaged coating. Apply the lowest load that the instrument

constant load prescan.

can apply but that makes no permanent damage. The prescan,

8.5.2 Curve 2 shows the topography of the damaged surface

scratch, and postscan should all be performed on the same line.

along the scratch path immediately after the scratch test was

8.3.2 Instruct the instrument to begin making a scratch to

concluded. It is a measure of the vertical displacement of the

produce damage to the coating. Allow the instrument to ramp

indenter tip during a low (;0.2 mN) constant load scan

to the desired normal force at a controlled rate. At the end of

through the completed scratch.

the scratch, return the indenter tip to its starting position at the

8.5.3 Curve 3 shows the vertical displacement of the in-

beginning of the scratch.

denter tip during the scratching process.

8.3.3 Perform a postscan, where the indenter tip is scanned

8.5.4 Curve 4 shows the tangential force that arises between

along the scratch, measuring the residual topography of the

the coating and the indenter tip.

damaged area. This should be done with the lowest load the

8.5.5 Curve5showstheappliednormalforceonthecoating

instrument can apply.

surface.

NOTE 3—Prescan and postscan should only be used if the instrument

9. Calculations

has force feedback control, otherwise significant error may be incurred.

9.1 From analysis of the Force/Displacement versus Scratch

8.4 The complete scratch test should be repeated 2 more

Distance plot produced (Fig. 1), plots of various quantities

times at different locations so that there are a total of 3

relating to the mechanical behavior of the coating vs. scratch

scratches per test panel.

distance can be generated:

8.5 Typical results of a nanoscratch test are presented in

9.1.1 The penetration depth (PD) of the indenter under the

Fig. 1. The graph consists of five curves labeled 1 through 5.

applied normal force can be calculated by subtracting the

surface topography measured from the prescan, Curve 1, from

the displacement measured during the scratch, Curve 3.

The boldface numbers in parentheses refer to the list of references at the end of

this test method. PD 5 C 2C

3 1

D7187–05

NOTE—The unit “mN” is meant to be read as mili-Newton.

FIG. 2 Variation of Plastic Resistance (PR) with Respect to Applied Normal Force. Note that the constant plastic resistance value at

higher (greater than 3 mN) applied loads. FR refers to the Fracture resistance, or critical load. (2)

where PD means Penetration Depth, and C and C correspond 9.2 Plastic resistance (PR) at a particular normal force can

3 1

to Curves 3 and 1 respectively. be calculated by dividing the normal force by the magnitude of

the permanent damage at that normal force before fracture

9.1.2 The magnitude of residual depth (RD), otherwise

occurs. Selecting the spot for measurement to be at a higher

known as permanent plastic deformation, to the coating can be

applied normal force results in values that reflect a more true

calculated by subtracting the surface topography before the

plastic resistance. This gives a value for plastic resistance that

scratch, Curve 1, from the topography after the scratch, Curve

isrelativelyconstantthatisinunitsofforceperunitofdamage

2.

depth, or mN/µm.

RD 5 C 2C

2 1

PR 5 F /RD

N

9.1.3 The difference between the displacement during the

scratch, Curve 3, and the surface topography after the scratch,

where:

Curve 2, is the elastic recovery (E

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.