ASTM E2910-12

(Guide)Standard Guide for Preferred Methods for Acceptance of Product

Standard Guide for Preferred Methods for Acceptance of Product

SIGNIFICANCE AND USE

5.1 Procurement practices encourage industry innovation and provide flexibility to achieve the benefits of continuous improvement.

5.2 There is an evolving industrial product quality philosophy that recognizes the need for quality policy changes that will provide producers with opportunities and incentives toward improvement of product quality and cooperative relationships between the producer and the consumer.

5.3 Process controls and statistical control methods are the preferable means of preventing nonconformances, controlling quality, and generating information for improvement. An effective process control system may also be used to provide information to assess the quality of deliverables submitted for acceptance. Producers are encouraged to use process control and statistical control procedures for their internal control and to submit effective process control procedures in lieu of prescribed sampling requirements to the consumer for approval.

5.4 Sampling inspection by itself is an inefficient industrial practice for demonstrating conformance to the requirements of a contract and its technical data package. The application of sampling plans for acceptance involves both consumer and producer risks; and increased sampling is one way of reducing these risks, but it also increases costs. Producers can reduce risks by employing efficient processes with appropriate process controls. To the extent that such practices are employed and are effective, risk is controlled and, consequently, inspection and testing can be reduced.

5.5 The following points provide the basis for this standard:

5.5.1 Producers are required to submit deliverables that conform to requirements and to generate and maintain sufficient evidence of conformance.

5.5.2 Producers are responsible for establishing their own manufacturing and process controls to produce results in accordance with requirements.

5.5.3 Producers are expected to use recognized prevention practices such as...

SCOPE

1.1 This guide establishes lot or batch and continuous sampling plans using MIL-STD-1916 as a basis. It represents an alternative sampling approach to attributes sampling (MIL-STD-105E, same as E2234), variables sampling (MIL-STD-414, E2762), and continuous sampling (MIL-STD-1235B, E2819).

1.2 This guide provides the sampling plans of MIL-STD-1916 in ASTM format for use by ASTM committees and others. It recognizes the continuing usage of MIL-STD-1916 in industries supported by ASTM. Most of the original text in MIL-STD-1916 is preserved in Sections 4-6 of this guide. The original wording of “Government” in MIL-STD-1916 has been changed to “consumer”, and “contractor” has been changed to “producer” to make this standard more generic.

1.3 Purpose—To encourage producers supplying goods and services to its consumers to submit efficient and effective process control (prevention) procedures in place of prescribed sampling requirements. The goal is to support the movement away from an AQL-based inspection (detection) strategy to implementation of an effective prevention-based strategy including a comprehensive quality system, continuous improvement and a partnership with the consumer. The underlying theme is a partnership between consumer and the producer, with the requisite competence of both parties, and a clear mutual benefit from processes capable of consistently high quality products and services. The objective is to create an atmosphere where every noncompliance is an opportunity for corrective action and improvement rather than one where acceptable quality levels are the contractually sufficient goals.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2910 − 12 An American National Standard

Standard Guide for

Preferred Methods for Acceptance of Product

This standard is issued under the fixed designation E2910; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This guide establishes lot or batch and continuous

E456 Terminology Relating to Quality and Statistics

sampling plans using MIL-STD-1916 as a basis. It represents

E2234 Practice for Sampling a Stream of Product by Attri-

an alternative sampling approach to attributes sampling (MIL-

butes Indexed by AQL

STD-105E, same as E2234), variables sampling (MIL-STD-

E2762 Practice for Sampling a Stream of Product by Vari-

414, E2762), and continuous sampling (MIL-STD-1235B,

ables Indexed by AQL

E2819).

E2819 Practice for Single- and Multi-Level Continuous

1.2 This guide provides the sampling plans of MIL-STD-

Sampling of a Stream of Product byAttributes Indexed by

1916 in ASTM format for use by ASTM committees and

AQL

others.ItrecognizesthecontinuingusageofMIL-STD-1916in 3

2.2 Other Standards:

industries supported by ASTM. Most of the original text in

MIL-STD-105E Sampling Procedures and Tables for In-

MIL-STD-1916 is preserved in Sections 4-6 of this guide. The

spection by Attributes

originalwordingof“Government”inMIL-STD-1916hasbeen

MIL-STD-1235B Single- and Multi-Level Continuous Sam-

changed to “consumer”, and “contractor” has been changed to

pling for Attributes

“producer” to make this standard more generic.

MIL-STD-1916 DoD Preferred Methods for Acceptance of

Product

1.3 Purpose—To encourage producers supplying goods and

MIL-STD-414 Sampling Procedures and Tables for Inspec-

services to its consumers to submit efficient and effective

tion by Variables for Percent Defective

process control (prevention) procedures in place of prescribed

sampling requirements. The goal is to support the movement

3. Terminology

away from an AQL-based inspection (detection) strategy to

3.1 Definitions—The terminology defined in Terminology

implementation of an effective prevention-based strategy in-

E456 applies to this guide except as modified below.

cluding a comprehensive quality system, continuous improve-

3.1.1 critical defect, n—a defect that judgment and experi-

ment and a partnership with the consumer. The underlying

ence indicate would result in hazardous or unsafe conditions

theme is a partnership between consumer and the producer,

for individuals using, maintaining, or depending upon the

with the requisite competence of both parties, and a clear

product, or a defect that judgment and experience indicate is

mutual benefit from processes capable of consistently high

likely to prevent performance of the function of a major end

quality products and services. The objective is to create an

item. E2234

atmosphere where every noncompliance is an opportunity for

3.1.2 inspection, n—the process of measuring, examining,

corrective action and improvement rather than one where

testing, or otherwise comparing the unit of product with the

acceptable quality levels are the contractually sufficient goals.

requirements. E2234

1.4 This standard does not purport to address all of the

3.1.3 major defect, n—a defect, other than critical, that is

safety concerns, if any, associated with its use. It is the

likely to result in failure, or to reduce materially the usability

responsibility of the user of this standard to establish appro-

of the unit of product for its intended purpose. E2234

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This guide is under the jurisdiction of ASTM Committee E11 on Quality and Standards volume information, refer to the standard’s Document Summary page on

Statistics and is the direct responsibility of Subcommittee E11.30 on Statistical the ASTM website.

Quality Control. Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Current edition approved Dec. 1, 2012. Published February 2013. DOI: 10.1520/ Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

E2910-12. dodssp.daps.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2910 − 12

3.1.4 minor defect, n—a defect that is not likely to reduce 3.2.13 quality assurance, n—a planned and systematic pat-

materially the usability of the unit of product for its intended tern of all actions necessary to provide adequate confidence

purpose, or is a departure from established standards having that adequate technical requirements are established; products

little bearing on the effective use or operation of the unit. and services conform to established technical requirements;

E2234 and satisfactory performance is achieved.

3.1.5 non-conforming item, n—an item containing at least

3.2.14 quality audit, n—asystematicexaminationoftheacts

one non-conformity. E2234

and decisions with respect to quality in order to independently

verify or evaluate the operational requirements of the quality

3.1.6 production interval, n—a finite period of production,

program or the specification or contract requirements of the

N items in length. E2819

product or service.

3.1.6.1 Discussion—In this guide, the production interval is

a period of production under continuous sampling assumed to

3.2.15 quality program, n—a program which is developed,

consist of essentially homogeneous quality. It is normally a

planned, and managed to carry out cost effectively all efforts to

shift;itcanbeadayifitisreasonablycertainthatshiftchanges

effect the quality of materials and services from concept

do not affect quality of product, but shall not be longer than a

through validation, full-scale development, production,

day.

deployment, and disposal.

3.1.7 screening, n—100 % inspection where all defective

3.2.16 screening inspection, n—see screening.

units are removed from the production flow. E2819

3.2.17 traceability, n—the ability to trace the history, appli-

3.1.7.1 Discussion—The two terms, screening and 100 %

cation or location of an item or activity, or similar items or

inspection, are used interchangeably in this practice.

activities, by means of recorded identification.

3.2 Definitions of Terms Specific to This Standard:

3.2.18 verification level (VL), n—prescribes the level of

3.2.1 acceptance, n—the act of an authorized representative

significance or utility of a characteristic to the user.

of the consumer by which the consumer, for itself or as a agent

3.2.18.1 Discussion—The amount of effort to assure confor-

of another, assumes ownership of existing identified supplied

mance can be allocated on the basis of importance to the user.

tendered or approves specific services rendered as partial or

(Major characteristics will require more verification effort than

complete performance of the contract.

minor characteristics.) VL-VII requires the highest level of

3.2.2 contract quality assurance, n—the various functions,

effort, and the effort decreases as the VL decreases to the

including inspection, performed by the consumer to determine

lowest level, VL-I.

whether a producer has fulfilled the contract obligations

pertaining to quality and quantity.

4. Summary of Practice

3.2.3 contract quality requirements, n—the technical re-

4.1 Acceptance by Producer-Proposed Provisions:

quirements in the contract relating to the quality of the product

4.1.1 General:

or service and those contract clauses prescribing inspection,

and other quality controls incumbent on the producer, to assure

4.1.1.1 This standard, when referenced in the contract or

that the product or service conforms to the contractual require-

product specifications, requires the producer to perform sam-

ments.

pling inspection in accordance with paragraph 4.2 and the

product specification. However, it is recognized that sampling

3.2.4 critical characteristic, n—see critical defect.

inspection alone does not control or improve quality. Product

3.2.5 critical nonconforming unit, n—a unit of product that

quality comes from proper product and process design and

fails to conform to specified requirements for one of more

process control activities. When such activities are effective,

critical characteristics.

sampling inspection is a redundant effort and an unnecessary

3.2.6 major characteristic, n—see major defect.

cost. Producers that have an acceptable quality system and

3.2.7 major nonconforming unit, n—a unit of product that

proven process controls on specific processes are encouraged

fails to conform to specified requirements for one or more

to consider submitting alternate acceptance methods for one or

major characteristics, but conforms to all critical characteris-

more contractually specified characteristics. In addition, pro-

tics.

ducers that have a successful quality system and a history of

successful process controls relevant to the products/services

3.2.8 minor characteristic, n—see minor defect.

being procured in this contract, are encouraged to consider

3.2.9 minor nonconforming unit, n—a unit of product that

submitting a systemic alternate acceptance method for all the

failstoconformtospecifiedrequirementsofoneormoreminor

contractual sampling inspection requirements associated with

characteristics, but conforms to all critical and major charac-

paragraph 4.2.

teristics.

4.1.1.2 Submissions shall describe the alternate acceptance

3.2.10 nonconformance, n—a departure from a specified

methods, the sampling inspection provision to be replaced, and

requirement for any characteristic.

an evaluation of the protection provided by the alternate

3.2.11 nonconforming unit, n—see non-conforming item.

methods as compared with the inspection requirement to be

3.2.12 quality, n—the composite of material attributes in- replaced. The alternate acceptance method shall include evi-

cluding performance features and characteristics of a product dence of process control and capability during production

or service to satisfy a given need. together with adequate criteria, measurement, and evaluation

E2910 − 12

procedures to maintain control of the process. The acceptabil- when the inability to maintain process stability and capability

ity of the alternate acceptance methods is dependent upon the over time becomes apparent.

existence of a quality system, the demonstration of its process

4.2 Acceptance by Tables:

focus, and the availability of objective evidence of effective-

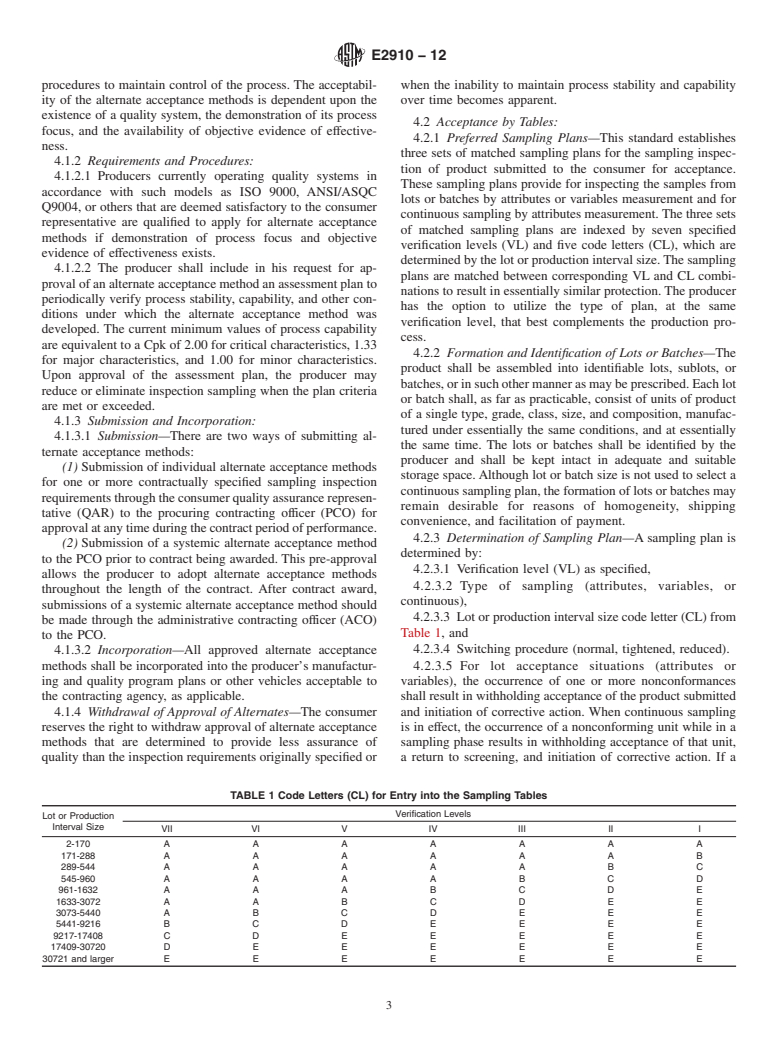

4.2.1 Preferred Sampling Plans—This standard establishes

ness.

three sets of matched sampling plans for the sampling inspec-

4.1.2 Requirements and Procedures:

tion of product submitted to the consumer for acceptance.

4.1.2.1 Producers currently operating quality systems in

These sampling plans provide for inspecting the samples from

accordance with such models as ISO 9000, ANSI/ASQC

lots or batches by attributes or variables measurement and for

Q9004, or others that are deemed satisfactory to the consumer

continuous sampling by attributes measurement. The three sets

representative are qualified to apply for alternate acceptance

of matched sampling plans are indexed by seven specified

methods if demonstration of process focus and objective

verification levels (VL) and five code letters (CL), which are

evidence of effectiveness exists.

determined by the lot or production interval size.The sampling

4.1.2.2 The producer shall include in his request for ap-

plans are matched between corresponding VL and CL combi-

proval of an alternate acceptance method an assessment plan to

nations to result in essentially similar protection. The producer

periodically verify process stability, capability, and other con-

has the option to utilize the type of plan, at the same

ditions under which the alternate acceptance method was

verification level, that best complements the production pro-

developed. The current minimum values of process capability

cess.

are equivalent to a Cpk of 2.00 for critical characteristics, 1.33

4.2.2 Formation and Identification of Lots or Batches—The

for major characteristics, and 1.00 for minor characteristics.

product shall be assembled into identifiable lots, sublots, or

Upon approval of the assessment plan, the producer may

batches,orinsuchothermannerasmaybeprescribed.Eachlot

reduce or eliminate inspection sampling when the plan criteria

or batch shall, as far as practicable, consist of units of product

are met or exceeded.

of a single type, grade, class, size, and composition, manufac-

4.1.3 Submission and Incorporation:

tured under essentially the same conditions, and at essentially

4.1.3.1 Submission—There are two ways of submitting al-

the same time. The lots or batches shall be identified by the

ternate acceptance methods:

producer and shall be kept intact in adequate and suitable

(1) Submission of individual alternate acceptance methods

storage space.Although lot or batch size is not used to select a

for one or more contractually specified sampling inspection

continuous sampling plan, the formation of lots or batches may

requirementsthroughtheconsumerqualityassurancerepresen-

remain desirable for reasons of homogeneity, shipping

tative (QAR) to the procuring contracting officer (PCO) for

convenience, and facilitation of payment.

approvalatanytimeduringthecontractperiodofperformance.

4.2.3 Determination of Sampling Plan—A sampling plan is

(2) Submission of a systemic alternate acceptance method

determined by:

to the PCO prior to contract being awarded. This pre-approval

4.2.3.1 Verification level (VL) as specified,

allows the producer to adopt alternate acceptance methods

4.2.3.2 Type of sampling (attributes, variables, or

throughout the length of the contract. After contract award,

continuous),

submissions of a systemic alternate acceptance method should

4.2.3.3 Lot or production interval size code letter (CL) from

be made through the administrative contracting officer (ACO)

Table 1, and

to the PCO.

4.2.3.4 Switching procedure (normal, tightened, reduced).

4.1.3.2 Incorporation—All approved alternate acceptance

methods shall be incorporated into the producer’s manufactur- 4.2.3.5 For lot acceptance situations (attributes or

ing and quality program plans or other vehicles acceptable to variables), the occurrence of one or more nonconformances

the contracting agency, as applicable. shall result in withholding

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.