ASTM D4398-02

(Test Method)Standard Test Method for Determining the Chemical Resistance of Fiberglass-Reinforced Thermosetting Resins by One-Side Panel Exposure

Standard Test Method for Determining the Chemical Resistance of Fiberglass-Reinforced Thermosetting Resins by One-Side Panel Exposure

SCOPE

1.1 This test method is intended for use in the evaluation of the chemical resistance of fiberglass-reinforced thermosetting resins that are subjected to one-side panel exposure to specific environments. It takes into consideration the coldwall effects and radiation losses of heat transfer through the laminate wall.

1.2 This test method is supplemental to Practice C 581 and does not supersede it.

Note 1—There is no similar or equivalent ISO standard.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D 4398–02

Standard Test Method for

Determining the Chemical Resistance of Fiberglass-

Reinforced Thermosetting Resins by One-Side Panel

1

Exposure

This standard is issued under the fixed designation D 4398; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* strength-to-weight ratio. Glass fibers are used commercially in

the reinforcement of rigid engineering plastic structures.

1.1 This test method is intended for use in the evaluation of

3.1.2 thermosetting resins—linear, relatively low molecular

the chemical resistance of fiberglass-reinforced thermosetting

weight thermoplastic polymer chains with 88crosslinks’’ which

resins that are subjected to one-side panel exposure to specific

bond the chains together with primary valence bonds. Once

environments. It takes into consideration the coldwall effects

cross-linked, such three-dimensional polymers will not soften

and radiation losses of heat transfer through the laminate wall.

up appreciably to their decomposition temperature. Typical of

1.2 This test method is supplemental to Practice C 581 and

such resin systems are the polymers, vinyl esters, and epoxies.

does not supersede it.

NOTE 1—There is no similar or equivalent ISO standard. 4. Significance and Use

4.1 The results obtained by this test method may serve as a

1.3 This standard does not purport to address all of the

safety problems, if any, associated with its use. It is the guide in, but not as the sole basis for, predicting the possible

performance of the particular glass-fiber-reinforced thermoset-

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- ting resin laminate in the one-side exposure to the specific

environment under evaluation. No attempt has been made to

bility of regulatory limitations prior to use.

incorporateintothetestmethodallofthefactorsthatmayenter

2. Referenced Documents

into the serviceability of a glass-fiber-reinforced resin structure

2.1 ASTM Standards: when subjected to chemical environments.

C 581 Practice for Determining Chemical Resistance of 4.2 This test method provides for the determination of

Thermosetting Resins Used in Glass Fiber Reinforced changes in the physical properties of the test panel and test

2

Structures Intended for Liquid Service media during and after the one-side exposure in the test media.

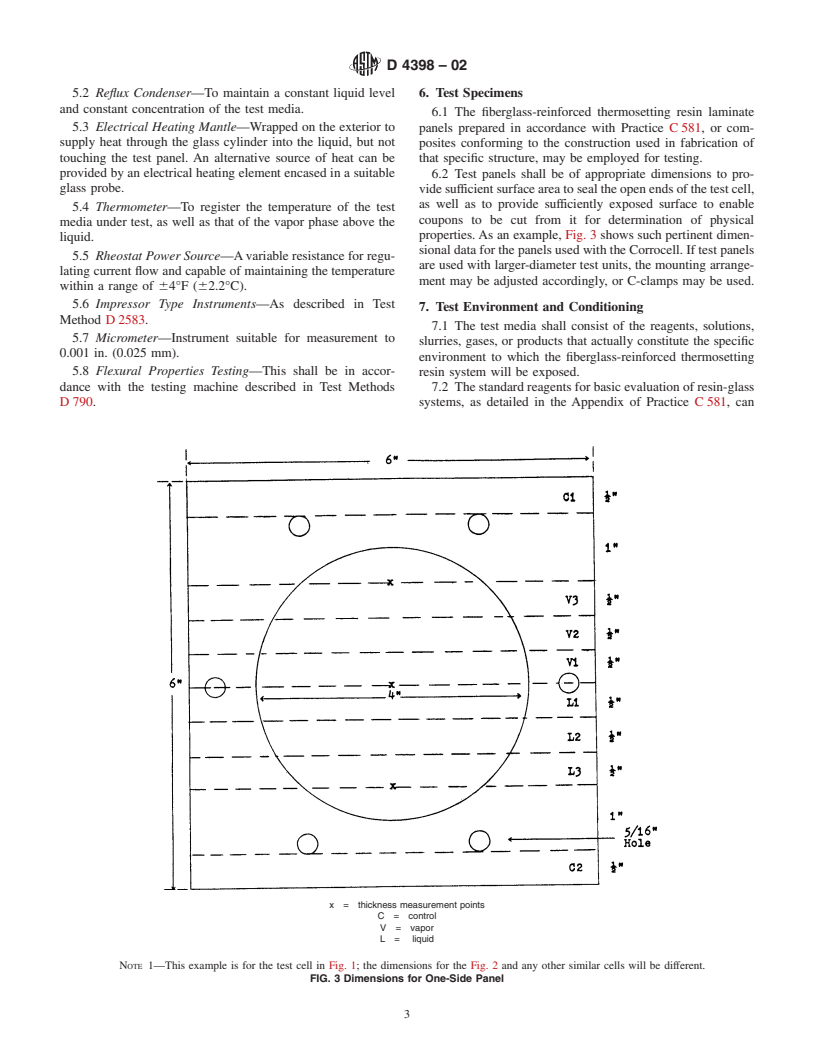

D 790 TestMethodsforFlexuralPropertiesofUnreinforced Determination of changes include: Barcol hardness, appear-

and Reinforced Plastics and Electrical Insulating Materi- ance of panel, appearance of test media, flexural properties,

3

als and thickness.

D 2583 Test Method for Indentation Hardness of Rigid

4 5. Apparatus

Plastics by Means of a Barcol Impressor

5.1 Test Cell—This is a laboratory unit in which only the

3. Terminology

surface of one side of a test panel is subjected to the corrosive

3.1 Definitions of Terms Specific to This Standard: or aggressive environment, which is the normal experience of

3.1.1 glass fiber—glass filaments for engineering applica- chemical processing equipment in actual plant operations. It

tions, chiefly of a so-called 88E’’ type made from a lime- consists of an open-ended glass cylinder, with several ground-

alumina borosilicate glass that is relatively soda free, of high glass joint nozzles for insertion of appropriate auxiliaries. The

ends of the open glass cylinder are closed off with the

fiberglass-reinforced resin panel to be tested, and are tightly

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

sealedwithchemical-resistantgaskets,allowingonesideofthe

and is the direct responsibility of Subcommittee D20.23 on Reinforced Plastic

panel to come in contact with the test media.

Piping Systems and Chemical Equipment.

5.1.1 Typical test cells are shown in Fig. 1 and Fig. 2. Other

Current edition approved March 10, 2002. Published May 2002. Originally

published as D 4398 – 84. Last previous edition D 4398 – 95.

laboratoryunitsforone-sidecorrosiontestingofequalorlarger

2

Annual Book of ASTM Standards, Vol 08.04.

diameter may be used also with correspondingly appropriate

3

Annual Book of ASTM Standards, Vol 08.01.

4 panel sizes.

Annual Book of ASTM Standards, Vol 08.02.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 4398–02

FIG. 1 Test Cells

FIG. 2 Test Cells

2

---------------------- Page:

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.