ASTM D5596-03(2009)

(Test Method)Standard Test Method for Microscopic Evaluation of the Dispersion of Carbon Black in Polyolefin Geosynthetics

Standard Test Method for Microscopic Evaluation of the Dispersion of Carbon Black in Polyolefin Geosynthetics

SIGNIFICANCE AND USE

Carbon black is added to many polymers to provide long-term resistance to ultraviolet-induced degradation. To achieve this, carbon black should be dispersed uniformly throughout the as-manufactured geosynthetic material. This test method is used to evaluate the uniformity of carbon black dispersion.

This test method is suitable only for those geosynthetics that can be sampled using a rotary or sledge microtome. The geometry, stiffness (hardness), or elasticity of some geosynthetic products precludes their being sampled with a micro-tome. The cross-sectional area of the geosynthetic must be composed of a continuous solid polyolefin material to be sampled using a microtome.

Extruded and oriented geogrids will require that microtome specimens be cut from the nonoriented bars of uniaxial products and the non-oriented nodes of biaxial products.

SCOPE

1.1 This test method covers equipment, specimen preparation techniques, and procedures for evaluating the dispersion of carbon black in polyolefin geosynthetics containing less than 5 % carbon black by weight.

1.2 This test method allows for a qualitative evaluation of carbon black agglomerates and other inclusions in polyolefin geosynthetics. This evaluation is based on carbon black dispersion size calculated area within microscopic fields of view.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—This test method is for the evaluation of carbon black dispersion. This test method does not support or evaluate the distribution of carbon black.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5596 −03(Reapproved 2009)

Standard Test Method For

Microscopic Evaluation of the Dispersion of Carbon Black

in Polyolefin Geosynthetics

This standard is issued under the fixed designation D5596; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope particles and coalesced particle aggregates of colloidal size,

obtained by partial combustion or thermal decomposition of

1.1 This test method covers equipment, specimen prepara-

hydrocarbons. (D3053)

tiontechniques,andproceduresforevaluatingthedispersionof

3.1.2 carbon black agglomerate, n—a cluster of physically

carbon black in polyolefin geosynthetics containing less than

bound and entangled aggregates. (D3053)

5% carbon black by weight.

3.1.3 geosynthetic, n—a planar product manufactured from

1.2 This test method allows for a qualitative evaluation of

polymeric material used with soil, rock, earth, or other geo-

carbon black agglomerates and other inclusions in polyolefin

technical engineering-related material as an integral part of a

geosynthetics. This evaluation is based on carbon black dis-

man-made project, structure, or system. (D4439)

persion size calculated area within microscopic fields of view.

3.1.4 micrograph, n—a graphic reproduction of an object as

1.3 The values stated in SI units are to be regarded as the

seen through the microscope or equivalent optical instrument,

standard. The values given in parentheses are for information

atmagnificationsgreaterthantendiameters(micrograph). (E7)

only.

3.1.5 microtome, n (that is, sliding microtome)—an appara-

1.4 This standard does not purport to address all of the

tus capable of cutting thin slices (less than 20 µm in thickness)

safety concerns, if any, associated with its use. It is the

of various geosynthetic samples.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 3.1.6 polyolefin, n—a polymer prepared by the polymeriza-

bility of regulatory limitations prior to use. tion of an olefin(s) as the sole monomer(s). (D883)

3.1.7 dispersion, n—a polyolefin product formulated with

NOTE 1—This test method is for the evaluation of carbon black

dispersion. This test method does not support or evaluate the distribution carbon black.

of carbon black.

3.1.8 distribution, n—a property of a carbon black formu-

lated polyolefin product that refers to the existence of streaks,

2. Referenced Documents

light or dark, within a microsectioned sample.

2.1 ASTM Standards:

D883Terminology Relating to Plastics

4. Summary of Test Method

D3053Terminology Relating to Carbon Black

4.1 This test method consists of two parts: (1) microtome

D4439Terminology for Geosynthetics

specimen preparation and (2) microscopic evaluation.

E7Terminology Relating to Metallography

4.1.1 Microtome Specimen Preparation—A sample is

clamped in the sample holder, which can be raised or lowered

3. Terminology

precisely in increments of approximately 1 µm.Arigid knife is

3.1 Definitions:

slid manually across the sample so that the specimens range in

3.1.1 carbon black, n—a material consisting essentially of

thickness from 8 to 20 µm.

elemental carbon black in the form of near spherical colloidal

4.1.2 Microtomespecimenexamination:Thesethinsections

are evaluated microscopically calculating the largest agglom-

This test method is under the jurisdiction of ASTM Committee D35 on erate or inclusion in each random field of view (Rf). The

Geosynthetics and is the direct responsibility of Subcommittee D35.02 on Endur-

associated carbon dispersion chart can be used to assist to

ance Properties.

determining shape and area

CurrenteditionapprovedJune1,2009.PublishedJuly2009.Originallyapproved

in 1994. Last previous edition approved in 2003 as D5596 – 03. DOI: 10.1520/

5. Significance and Use

D5596-03R09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1 Carbon black is added to many polymers to provide

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

long-term resistance to ultraviolet-induced degradation. To

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. achieve this, carbon black should be dispersed uniformly

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5596−03 (2009)

throughout the as-manufactured geosynthetic material. This 6.7 Balsam cement or suitable, clear substitute (for

test method is used to evaluate the uniformity of carbon black example, clear nail polish), required (Note 2).

dispersion.

NOTE 2—This clear, adhesive medium should not dissolve or

chemically interact otherwise with the thin section.

5.2 This test method is suitable only for those geosynthetics

that can be sampled using a rotary or sledge microtome. The

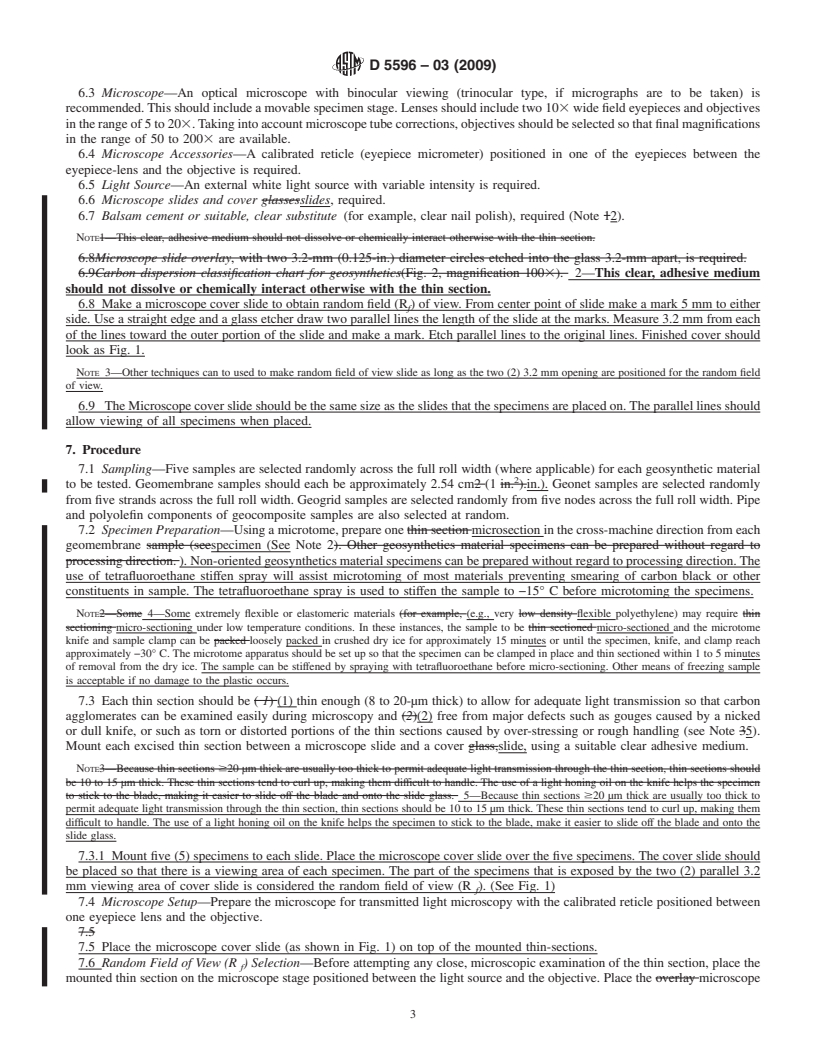

6.8 Make a microscope cover slide to obtain random field

geometry, stiffness (hardness), or elasticity of some geosyn-

(R) of view. From center point of slide make a mark 5 mm to

f

thetic products precludes their being sampled with a micro-

either side. Use a straight edge and a glass etcher draw two

tome. The cross-sectional area of the geosynthetic must be

parallel lines the length of the slide at the marks. Measure 3.2

composed of a continuous solid polyolefin material to be

mmfromeachofthelinestowardtheouterportionoftheslide

sampled using a microtome.

and make a mark. Etch parallel lines to the original lines.

Finished cover should look as Fig. 1.

5.3 Extruded and oriented geogrids will require that micro-

tome specimens be cut from the nonoriented bars of uniaxial

NOTE 3—Other techniques can to used to make random field of view

products and the non-oriented nodes of biaxial products.

slide as long as the two (2) 3.2 mm opening are positioned for the random

field of view.

6. Equipment

6.9 The Microscope cover slide should be the same size as

the slides that the specimens are placed on. The parallel lines

6.1 Microtome—A rotary or sledge-type microtome

equipped with a sample clamp and knife holder is required. should allow viewing of all specimens when placed.

Steel knives are recommended; however, glass knives may be

suitable. 7. Procedure

6.2 Microtome Accessories—Lubricant, dust cover, and 7.1 Sampling—Five samples are selected randomly across

tweezers are recommended. the full roll width (where applicable) for each geosynthetic

material to be tested. Geomembrane samples should each be

6.3 Microscope—An optical microscope with binocular

approximately 2.54 cm (1 in.). Geonet samples are selected

viewing (trinocular type, if micrographs a

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5596–94

Standard Test Method for Designation: D 5596 – 03

(Reapproved 2009)

Standard Test Method For

Microscopic Evaluation of the Dispersion of Carbon Black

in Polyolefin Geosynthetics

This standard is issued under the fixed designation D5596; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thistestmethodcoversequipment,specimenpreparationtechniques,andproceduresforevaluatingthedispersionofcarbon

black in polyolefin geosynthetics containing less than 5% carbon black by weight.

1.2This test method allows for a qualitative evaluation of carbon black agglomerates and other inclusions in polyolefin

geosynthetics.This evaluation is based on visual comparisons between microscopic fields of view and micrographs on the carbon

dispersion reference chart.

1.2 This test method allows for a qualitative evaluation of carbon black agglomerates and other inclusions in polyolefin

geosynthetics. This evaluation is based on carbon black dispersion size calculated area within microscopic fields of view.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is

the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability

of regulatory limitations prior to use.

NOTE 1—This test method is for the evaluation of carbon black dispersion. This test method does not support or evaluate the distribution of carbon

black.

2. Referenced Documents

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

D3053 Terminology Relating to Carbon Black

D4439 Terminology for Geotextiles Terminology for Geosynthetics

E7 Terminology Relating to Metallography

2.2ASTM Adjuncts: ASTM

D35—Carbon Dispersion Reference Chart Terminology Relating to Metallography

3. Terminology

3.1 Definitions:

3.1.1 carbon black, n—a material consisting essentially of elemental carbon black in the form of near spherical colloidal

particles and coalesced particle aggregates of colloidal size, obtained by partial combustion or thermal decomposition of

hydrocarbons. (D 3053)

3.1.2 carbon black agglomerate, n—a cluster of physically bound and entangled aggregates. (D 3053)

3.1.3 geosynthetic, n—aplanarproductmanufacturedfrompolymericmaterialusedwithsoil,rock,earth,orothergeo-technical

This test method is under the jurisdiction of ASTM Committee D-35 D35 on Geosynthetics and is the direct responsibility of Subcommittee D35.02 on Endurance

Properties.

Current edition approved August 15, 1994. Published January 1995.

Current edition approved June 1, 2009. Published July 2009. Originally approved in 1994. Last previous edition approved in 2003 as D5596 – 03.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vols 08.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5596 – 03 (2009)

engineering-related material as an integral part of a man-made project, structure, or system. (D 4439)

3.1.4 micrograph, n—a graphic reproduction of an object as seen through the microscope or equivalent optical instrument, at

magnifications greater than ten diameters (micrograph). (E 7)

3.1.5 microtome, n (that is, sliding microtome)— an apparatus capable of cutting thin slices (less than 20 µm in thickness) of

various geosynthetic samples.

3.1.6 polyolefin, n—a polymer prepared by the polymerization of an olefin(s) as the sole monomer(s). (D 883)

3.1.7 dispersion, n—a polyolefin product formulated with carbon black.

3.1.8 distribution, n—a property of a carbon black formulated polyolefin product that refers to the existence of streaks, light

or dark, within a microsectioned sample.

4. Summary of Test Method

4.1This test method consists of two parts: (1) microtome specimen preparation and ( 2) microscopic evaluation.

4.1 This test method consists of two parts: (1) microtome specimen preparation and (2) microscopic evaluation.

4.1.1 Microtome Specimen Preparation—Asample is clamped in the sample holder, which can be raised or lowered precisely

in increments of approximately 1 µm. A rigid knife is slid manually across the sample so that the specimens range in thickness

from 8 to 20 µm. These thin sections are then evaluated microscopically using a visual comparison between each random field of

view (R ) and the carbon dispersion reference chart. Each R is classified or rated according to the arrangement of categories on

f f

the reference chart. — A sample is clamped in the sample holder, which can be raised or lowered precisely in increments of

approximately 1 µm. A rigid knife is slid manually across the sample so that the specimens range in thickness from 8 to 20 µm.

4.1.2 Microtome specimen examination: These thin sections are evaluated microscopically calculating the largest agglomerate

or inclusion in each random field of view (Rf). The associated carbon dispersion chart can be used to assist to determining shape

and area

5. Significance and Use

5.1 Carbonblackisaddedtomanypolymerstoprovidelong-termresistancetoultraviolet-induceddegradation.Toachievethis,

carbon black should be dispersed and distributed uniformly throughout the as-manufactured geosynthetic material. This test

method is used to evaluate the uniformity of carbon black dispersion.

5.2 This test method is suitable only for those geosynthetics that can be sampled using a rotary or sledge microtome. The

geometry, stiffness (hardness), or elasticity of some geosynthetic products precludes their being sampled with a micro-tome. The

cross-sectional area of the geosynthetic must be composed of a continuous solid polyolefin material to be sampled using a

microtome.

5.3 Extruded and oriented geogrids will require that microtome specimens be cut from the non-oriented bars of uniaxial

products and the non-oriented nodes of biaxial products.

6. Equipment

6.1 Microtome—A rotary or sledge-type microtome equipped with a sample clamp and knife holder is required. Steel knives

are recommended; however, glass knives may be suitable (Fig. 1). suitable.

6.2 Microtome Accessories—Lubricant, dust cover, and tweezers are recommended.

FIG. 1 Microscope Cover Slide Overlay Configuration

D 5596 – 03 (2009)

6.3 Microscope—An optical microscope with binocular viewing (trinocular type, if micrographs are to be taken) is

recommended.Thisshouldincludeamovablespecimenstage.Lensesshouldincludetwo103widefieldeyepiecesandobjectives

intherangeof5to203.Takingintoaccountmicroscopetubecorrections,objectivesshouldbeselectedsothatfinalmagnifications

in the range of 50 to 2003 are available.

6.4 Microscope Accessories—A calibrated reticle (eyepiece micrometer) positioned in one of the eyepieces between the

eyepiece-lens and the objective is required.

6.5 Light Source—An external white light source with variable intensity is required.

6.6 Microscope slides and cover glassesslides, required.

6.7 Balsam cement or suitable, clear substitute (for example, clear nail polish), required (Note 12).

NOTE1—This clear, adhesive medium should not dissolve or chemically interact otherwise with the thin section.

6.8Microscope slide overlay, with two 3.2-mm (0.125-in.) diameter circles etched into the glass 3.2-mm apart, is required.

6.9Carbon dispersion classification chart for geosynthetics(Fig. 2, m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.