ASTM D3464-96(2007)

(Test Method)Standard Test Method for Average Velocity in a Duct Using a Thermal Anemometer

Standard Test Method for Average Velocity in a Duct Using a Thermal Anemometer

SIGNIFICANCE AND USE

The method presented is a “short method” that may be used where contamination levels are less than 5000 ppm by weight or volume, temperatures are between 0°C (32°F) and 65°C (150°F), and the humidity is not considered. The gas is considered as standard air and the velocity is read directly from the instrument.

This test method is useful for determining air velocities in HVAC ducts, fume hoods, vent stacks of nuclear power stations, and in performing model studies of pollution control devices.

SCOPE

1.1 This test method describes the measurement of the average velocity with a thermal anemometer for the purpose of determining gas flow in a stack, duct, or flue (1-5). It is limited to those applications where the gas is essentially air at ambient conditions and the temperature, moisture, and contaminant loading are insignificant as sources of error compared to the basic accuracy of the typical field situation.

1.2 The range of the test method is from 1 to 30 m/s (3 to 100 ft/s).

1.3 The values stated in SI units are to be regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3464 − 96(Reapproved 2007)

Standard Test Method for

Average Velocity in a Duct Using a Thermal Anemometer

This standard is issued under the fixed designation D3464; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Terminology

1.1 This test method describes the measurement of the 3.1 For definitions of terms used in this test method, refer to

average velocity with a thermal anemometer for the purpose of Terminology D1356.

determininggasflowinastack,duct,orflue (1-5). Itislimited

4. Summary of Test Method

to those applications where the gas is essentially air at ambient

conditions and the temperature, moisture, and contaminant

4.1 This test method describes the operational and calibra-

loading are insignificant as sources of error compared to the

tion procedures necessary for the measurement of point veloc-

basic accuracy of the typical field situation.

ity and calculation of the average velocity of air or gas flows in

flues, ducts, or stacks utilizing a thermal anemometer.

1.2 The range of the test method is from 1 to 30 m/s (3 to

100 ft/s).

5. Significance and Use

1.3 The values stated in SI units are to be regarded as the

5.1 The method presented is a “short method” that may be

standard.

used where contamination levels are less than 5000 ppm by

1.4 This standard does not purport to address all of the

weight or volume, temperatures are between 0°C (32°F) and

safety concerns, if any, associated with its use. It is the

65°C (150°F), and the humidity is not considered. The gas is

responsibility of the user of this standard to establish appro-

consideredasstandardairandthevelocityisreaddirectlyfrom

priate safety and health practices and determine the applica-

the instrument.

bility of regulatory limitations prior to use.

5.2 This test method is useful for determining air velocities

in HVAC ducts, fume hoods, vent stacks of nuclear power

2. Referenced Documents

stations, and in performing model studies of pollution control

2.1 ASTM Standards:

devices.

D1356 Terminology Relating to Sampling and Analysis of

Atmospheres

6. Apparatus

D3796 Practice for Calibration of Type S Pitot Tubes

6.1 Thermal Anemometer—A commercially available elec-

2.2 Other Standards:

trically operated hot sensor anemometer with direct readout.A

ASME PTC 19.5-72Application of Fluid Meters, Sixth Ed.

thermal anemometer senses the cooling effect of a moving gas

1971 (Interim Supplement 19.5 on Instruments & Appa-

stream passing over an electrically heated sensor. This cooling

ratus)

effectorheattransferrateiscorrelatedtothevelocityofthegas

stream. The instrument is calibrated to display a direct readout

in terms of velocity.

This test method is under the jurisdiction of ASTM Committee D22 on Air

6.2 Sensors and Probes—There are a number of different

Quality and is the direct responsibility of Subcommittee D22.03 on Ambient

Atmospheres and Source Emissions.

types of sensors available for thermal anemometry including

Current edition approved April 1, 2007. Published June 2007. Originally

the hot-wire sensor, the hot-film sensor, and the quartz-coated

approved in 1975. Last previous edition approved in 2001 as D3464 - 96(2001).

sensor. Probes are available in many different shapes depend-

DOI: 10.1520/D3464-96R07.

ing upon application.

The boldface numbers in parentheses refer to the references listed at the end of

this method.

6.3 Temperature Compensation—If the temperature of the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

gas stream changes during velocity measurements, the an-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

emometer reading will change accordingly unless a constant-

the ASTM website.

temperature or “temperature-compensated” anemometer is uti-

Available from American Society of Mechanical Engineers (ASME), ASME

lized. This type of instrument shall be specified for most

International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

www.asme.org. applications of this measurement standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

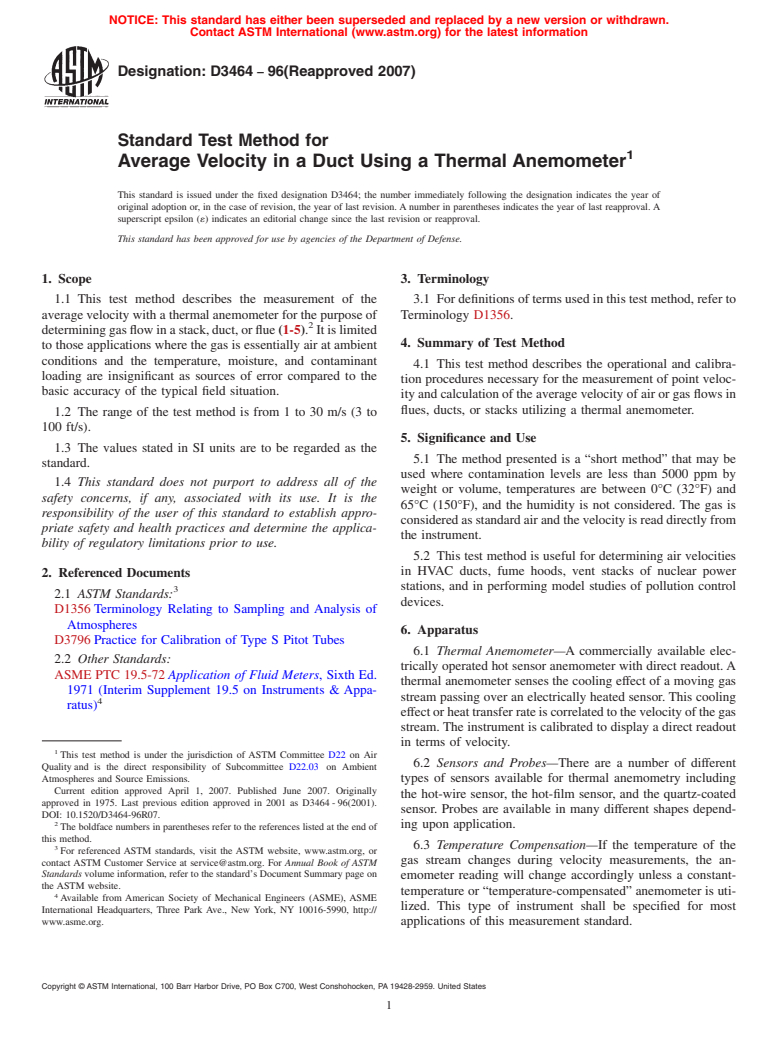

D3464 − 96 (2007)

6.3.1 Temperature-Compensated Anemometer—A patterns are essentially uniform, that is, 80 to 90 % of the

temperature-compensated anemometer has a temperature- measurements are greater than 10 % of the maximum flow. In

sensing probe within the instrument sensor that automatically all cases, divide the effective inside area of the flue into a

corrects errors caused by changes in temperature in the gas number of equal areas, and record the gas velocity at the

stream. For temperature-compensated anemometers, a change centroid of each of these areas.

in temperature (∆T) of 28°C (50°F) typically produces an error 9.2.1 In rectangular flues, divide the cross-sectional area

of 2 %. intoequalrectangularsubareasasshowninFig.1.Thenumber

6.3.2 Temperature-Uncompensated Anemometer—For a of areas to be used depends on the flow pattern and flue size.

“constant-current” or uncompensated anemometer a change in Use Table 1 to find the minimum number of areas when

temperature (∆T) of 28°C (50°F) typically produces a 25 % sampling at least eight equivalent diameters downstream and

error. For laboratory work where this type of anemometer two equivalent diameters upstream from the nearest flow

might be preferred, the output data shall be corrected for disturbance, such as a bend, expansion or contraction. The

temperature changes in the gas stream. equivalent diameter can be determined as follows:

D 5 2LW/ L1W (1)

6.4 Calibration Apparatus: ~ !

e

6.4.1 Flows above 3 m/s (10 ft/s)—See Section 6, Practice

where:

D3796.

D = equivalent diameter, m (ft),

e

6.4.2 Flows below 3 m/s (10 ft/s)—See PTC 19.5-72.

L = duct length, m (ft), and

W = duct width, m (ft).

7. Calibration

If a site less than eight diameters downstream and two

7.1 For velocities in excess of 3 m/s (10 ft/s) calibrate the

diameters upstream from a flow disturbance, such as a bend,

thermal anemometer with a standard pitot tube, in accordance

expansion or contraction is used increase the number of

with Practice D3796. It is preferable to make these calibrations

sampling points in accordance with 9.2.4.

under laboratory conditions; however, where expediency

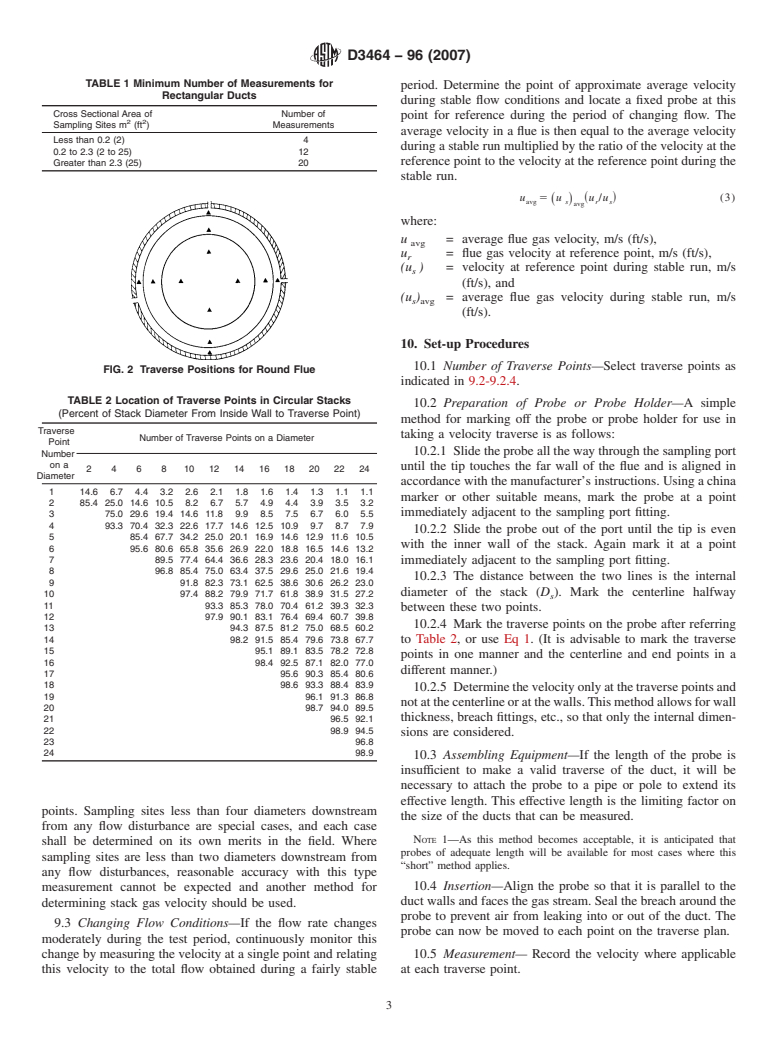

9.2.2 In circular flues divide the area concentrically as

dictates, field calibration at the sampling site is permissible.

showninFig.2.Theminimumnumberareastobeusedandthe

7.2 For velocities below 3 m/s (10 ft/s) calibrate in the

distance to the test point are shown in Table 2 or calculate as

laboratory using a calibrated orifice or nozzle in accordance

follows:

with PTC 19.5-72.

=

r 5 D ~2n 2 1!/4N (2)

n s

7.3 Calibrate the thermal anemometer for a minimum of

three velocities covering the range of velocities which are

where:

anticipated for a particular test. Calibrate an increased number

D = internal diameter of flue, cm (in.),

s

of points, typically five to seven, for the complete range of the

r = radial distance from center of flue to nth sampling

n

instrument if the anticipated test velocity range is not known.

point, cm (in.),

(Warning— If this test method is used for gases other than air,

n = nth sampling point from center of flue, and

calibrate using the test gas.)

N = number of sampling points across a diameter.

Conduct traverses across two diameter axes right angles to

8. Single-Point Velocity Measurement

each other. Again, if a site less than eight diameters down-

8.1 Velocity—The hot-wire anemometer is effective for

stream and two diameters upstream from a flow disturbance is

measuring velocities over a range from 1 m/s (3 ft/s) to 30 m/s

used, increase the number of sampling points as indicated in

(100 ft/s). Record measurements at specific points within the

9.2.4.

flue in accordance with a plan determined by the flue size.

9.2.3 When readings must be taken in an irregular-shaped

Place marks on the instrument probe or probe extension to aid

flue, divide the flue into equal areas of any shape, and measure

in locating the sampling points at w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.