ASTM D5540-13(2021)

(Practice)Standard Practice for Flow Control and Temperature Control for On-Line Water Sampling and Analysis

Standard Practice for Flow Control and Temperature Control for On-Line Water Sampling and Analysis

SIGNIFICANCE AND USE

5.1 Sample conditioning systems must be designed to accommodate a wide range of sample source temperatures and pressures. Additionally, efforts must be made to ensure that the resultant sample has not been altered during transport and conditioning and has not suffered excessive transport delay. Studies have shown that sample streams will exhibit minimal deposition of ionic and particulate matter on wetted surfaces at specific flow rates (1-5). 3

5.1.1 To ensure that the physical and chemical properties of the sample are preserved, this flow rate must be controlled throughout the sampling process, regardless of expected changes of source temperature and pressure, for example, during startup, or changing process operating conditions.

5.2 The need to use analyzer temperature compensation methods is dependent on the required accuracy of the measurement. Facilities dealing with ultra-pure water will require both closely controlled sample temperature and temperature compensation to ensure accurate measurements. The temperature can be controlled by adding a second or trim cooling stage. The temperature compensation must be based on the specific contaminants in the sample being analyzed. In other facilities in which some variation in water chemistry can be tolerated, the use of either trim cooling or accurate temperature compensation may provide sufficient accuracy of process measurements. This does not negate the highly recommended practice of constant temperature sampling, especially at 25°C, as the most proven method of ensuring repeatable and comparable analytical results.

5.3 A separate class of analysis exists that does not require or, in fact, cannot use the fully conditioned sample for accurate results. For example, the collection of corrosion product samples requires that the sample remain at near full system pressure, but cooled below the flash temperature, in order to ensure a representative collection of particulates. Only some of the primary conditioni...

SCOPE

1.1 This practice covers the conditioning of a flowing water sample for the precise measurement of various chemical and physical parameters of the water, whether continuous or grab. This practice addresses the conditioning of both high- and low-temperature and pressure sample streams, whether from steam or water.

1.2 This practice provides procedures for the precise control of sample flow rate to minimize changes of the measured variable(s) due to flow changes.

1.3 This practice provides procedures for the precise control of sample temperature to minimize changes of the measured variable(s) due to temperature changes.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5540 − 13 (Reapproved 2021)

Standard Practice for

Flow Control and Temperature Control for On-Line Water

Sampling and Analysis

This standard is issued under the fixed designation D5540; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1129 Terminology Relating to Water

D3370 Practices for Sampling Water from Flowing Process

1.1 This practice covers the conditioning of a flowing water

Streams

sample for the precise measurement of various chemical and

D3864 Guide for On-Line Monitoring Systems for Water

physical parameters of the water, whether continuous or grab.

Analysis

This practice addresses the conditioning of both high- and

low-temperature and pressure sample streams, whether from

3. Terminology

steam or water.

3.1 Definitions:

1.2 This practice provides procedures for the precise control

3.1.1 For definitions of terms used in this standard, refer to

of sample flow rate to minimize changes of the measured

Terminology D1129.

variable(s) due to flow changes.

3.2 Definitions of Terms Specific to This Standard:

1.3 This practice provides procedures for the precise control

3.2.1 approach temperature, n—the difference in tempera-

of sample temperature to minimize changes of the measured

ture between cooling water temperature in and sample tem-

variable(s) due to temperature changes.

perature out.

1.4 The values stated in SI units are to be regarded as

3.2.1.1 Discussion—This term is used in heat exchanger

standard. The values given in parentheses after SI units are

applications and applies to all types of heat exchangers. The

provided for information only and are not considered standard.

term is defined as: the difference between the outlet tempera-

tureinonestreamandtheinlettemperatureintheotherstream.

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.2.2 crud deposition, n—on interior surfaces of sample

responsibility of the user of this standard to establish appro-

tubing or other hardware, the disposition of fine insoluble

priate safety, health, and environmental practices and deter-

particles (of iron oxides and other byproducts of metallic

mine the applicability of regulatory limitations prior to use.

corrosion) that are present throughout the system.

1.6 This international standard was developed in accor-

3.2.2.1 Discussion—The term “crud” is generally used for

dance with internationally recognized principles on standard-

all types of fouling.

ization established in the Decision on Principles for the

3.2.3 sample conditioning, n—reduction of the temperature

Development of International Standards, Guides and Recom-

and pressure of a flowing sample from process conditions to a

mendations issued by the World Trade Organization Technical

controlled temperature and pressure, and maintenance of a

Barriers to Trade (TBT) Committee.

constant flow rate both in incoming sample lines and through

on-line analyzers.

2. Referenced Documents

3.2.4 sample cooler, n—a small heat exchanger designed to

2.1 ASTM Standards:

cool small streams of water or steam.

D1066 Practice for Sampling Steam

3.2.5 temperature compensation, n—by the use of electronic

adjustment or data manipulation, the adjustment of the ana-

This practice is under the jurisdiction of ASTM Committee D19 on Water and

lyzer’s measured temperature for variation in sample tempera-

is the direct responsibility of Subcommittee D19.03 on Sampling Water and

Water-Formed Deposits, Analysis of Water for Power Generation and Process Use, ture from a preestablished value.

On-Line Water Analysis, and Surveillance of Water.

Current edition approved July 1, 2021. Published July 2021. Originally approved

4. Summary of Practice

in 1994. Last previous edition approved in 2013 as D5540 – 13. DOI: 10.1520/

D5540-13R21.

4.1 This practice covers the system design, operating

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

procedures, and selection of equipment to help ensure the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

appropriate flow and temperature control for analysis of water

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. and steam samples. This control is essential to ensure the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5540 − 13 (2021)

accuracy and repeatability of on-line analyzers. Variations in 6.2 Studies (3-5) have shown that the loss of ionic and

types of analysis, sample characteristics, and their effect on particulate components is minimized by maintaining the water

sample conditioning are included. samplevelocityat1.8m/sinthesampletubingtransportingthe

sample. The turbulent flow at 1.8 m/s (6 ft/s) presents a stable

4.2 The equipment and procedures described in this practice

condition of deposition and removal. Changes in sample flow

are intended to represent current state-of-the art technology

rate or flow rates beyond a median range of approximately 1.8

available from major manufacturers of sample conditioning

m/s can upset this equilibrium condition.

equipment. Refer to Practices D1066 and D3370 and Guide

D3864 for additional information on sampling.

6.3 Saturated steam and superheated steam samples present

difficulttransportproblemsbetweenthesourceandtheprimary

5. Significance and Use

sample cooling equipment (4). Saturated steam samples with

5.1 Sample conditioning systems must be designed to ac-

transport velocities typically above 11 m/s (36 ft/s) provide

commodate a wide range of sample source temperatures and

adequate turbulent flow to ensure the transport of most

pressures.Additionally, efforts must be made to ensure that the

particulates and ionic components. Excessively large or small

resultant sample has not been altered during transport and

steam sample lines can affect the sample quality and quantity

conditioning and has not suffered excessive transport delay.

significantly. If the sample tubing has too large an inside

Studies have shown that sample streams will exhibit minimal

diameter, the steam velocity may be too low to transport the

deposition of ionic and particulate matter on wetted surfaces at

condensed portion of the steam along with the vapor. If the

specific flow rates (1-5).

sample tubing has too small an inside diameter, the pressure

5.1.1 To ensure that the physical and chemical properties of

drop may be excessive, reducing the quantity of sample

the sample are preserved, this flow rate must be controlled

available at the sample panel. In the case of super-heated

throughout the sampling process, regardless of expected

steam, significant ionic deposition can occur in the sample

changes of source temperature and pressure, for example,

tubing transport as the steam desuperheats. This can affect

during startup, or changing process operating conditions.

sample analysis accuracy significantly. Superheated samples

should use a process to inject cooled sample into the sample

5.2 The need to use analyzer temperature compensation

line at or near the nozzle outlet to desuperheat the sample so as

methods is dependent on the required accuracy of the measure-

to minimize deposition in the initial portion of the tubing run.

ment. Facilities dealing with ultra-pure water will require both

closely controlled sample temperature and temperature com-

6.4 Samples may become contaminated by products intro-

pensation to ensure accurate measurements. The temperature

duced into the stream by the tubing, valves, or other associated

canbecontrolledbyaddingasecondortrimcoolingstage.The

conditioning hardware. To minimize contamination of the

temperature compensation must be based on the specific

sample, high-grade tubing, such asType 316 SS, must be used.

contaminants in the sample being analyzed. In other facilities

Cobalt contamination from valve hardening material can intro-

in which some variation in water chemistry can be tolerated,

duce significant error in transition metal analysis by ion

the use of either trim cooling or accurate temperature compen-

chromatography.

sation may provide sufficient accuracy of process measure-

6.5 AirleakageintosamplelinescanaffectpH,conductivity

ments. This does not negate the highly recommended practice

(specific, cation, and degassed), and especially dissolved oxy-

of constant temperature sampling, especially at 25°C, as the

gen measurements.

most proven method of ensuring repeatable and comparable

analytical results.

6.6 The operation of a sample system includes periodically

taking grab samples and adding and removing on-line analyz-

5.3 A separate class of analysis exists that does not require

ers.Theaccuracyoftheanalysescanbeaffectediftheflowrate

or, in fact, cannot use the fully conditioned sample for accurate

through any on-line analyzer changes because of these proce-

results. For example, the collection of corrosion product

dures. The same is true if these actions change the flow rate in

samples requires that the sample remain at near full system

the incoming sample line to the system.

pressure, but cooled below the flash temperature, in order to

ensure a representative collection of particulates. Only some of

6.7 Changingthetemperatureofthesampleflowingthrough

theprimaryconditioningcriteriaapplyinthiscase,asinothers.

an on-line analyzer can alter the accuracy of the analysis.

Temperature compensation is not applicable since the material

Sample temperature can change because of a change in flow

being analyzed is not in a liquid state.

rate through the heat exchangers, because of a change of flow

rate of the cooling water in the heat exchangers, or from a

6. Interferences

change in temperature of the heat exchanger cooling water

6.1 Samples can be degraded by the loss of ionic or

supply. Every effort should be made to ensure constant sample

particulate components, introduction of contaminants by com-

temperature. The ideal sample temperature is 25 6 0.5°C

ponents or leaks, changes of sample flow rate through an

(77 6 1°F) because this is the standard for comparing readings

analyzer, excessively long sample lines, sample temperature

of temperature-sensitive analyses.

changes, and inaccurate temperature compensation of on-line

6.8 Electronic compensation is able to compensate for the

analysis equipment.

deviations in sample temperature for a known chemical matrix

(contamination). If an unknown source of contamination is

The boldface numbers in parentheses refer to a list of references at the end of

this standard. introduced, the analyzer may not be programmed, or

D5540 − 13 (2021)

programmable, to respond to the new solution. An error is and6.3.Keepthesamplelinesasshortaspossible(particularly

introduced as a result. The further the sample temperature steam)toeliminatealterationofthesamplepriortotheprimary

deviates from 25°C (77°F), the greater the error. cooling point.

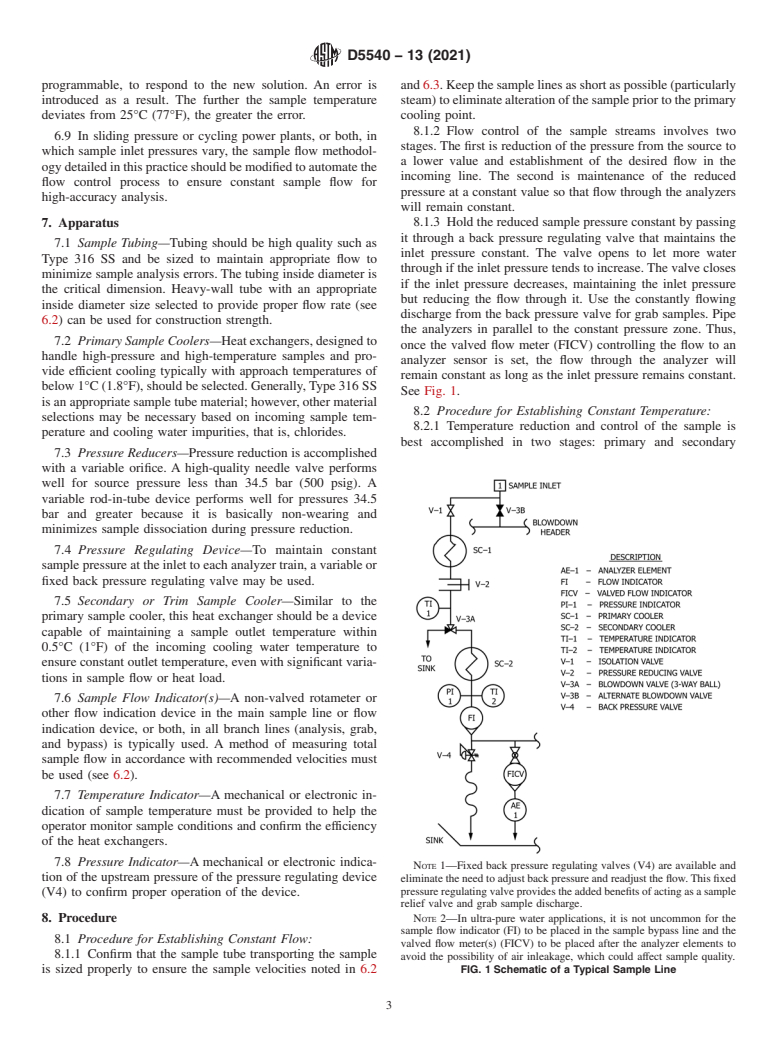

8.1.2 Flow control of the sample streams involves two

6.9 In sliding pressure or cycling power plants, or both, in

stages. The first is reduction of the pressure from the source to

which sample inlet pressures vary, the sample flow methodol-

a lower value and establishment of the desired flow in the

ogydetailedinthispracticeshouldbemodifiedtoautomatethe

incoming line. The second is maintenance of the reduced

flow control process to ensure constant sample flow for

pressure at a constant value so that flow through the analyzers

high-accuracy analysis.

will remain constant.

7. Apparatus 8.1.3 Hold the reduced sample pressure constant by passing

it through a back pressure regulating valve that maintains the

7.1 Sample Tubing—Tubing should be high quality such as

inlet pressure constant. The valve opens to let more water

Type 316 SS and be sized to maintain appropriate flow to

through if the inlet pressure tends to increase. The valve closes

minimize sample analysis errors. The tubing inside diameter is

if the inlet pressure decreases, maintaining the inlet pressure

the critical dimension. Heavy-wall tube with an appropriate

but reducing the flow through it. Use the constantly flowing

inside diameter size selected to provide proper flow rate (see

discharge from the back pressure valve for grab samples. Pipe

6.2) can be used for construction strength.

the analyzers in parallel to the constant pressure zone. Thus,

7.2 Primary Sample Coolers—Heat exchangers, designed to

once the valved flow meter (FICV) controlling the flow to an

handle high-pressure and high-temperature samples and pro-

analyzer sensor is set, the flow through the analyzer will

vide efficient cooling typically with approach temperatures of

remain constant as long as the inlet pressure remains constant.

below 1°C (1.8°F), should be selected. Generally,Type 316 SS

See Fig. 1.

is an appropriate sample tube material; however, other material

8.2 Procedure for Establishing Constant Temperature:

selections may be necessary based on incoming sample tem-

8.2.1 Temperature reduction and control of the sample is

perature and cooling water impurities, that is, chlorides.

best accomplished in two stages: primary and secondary

7.3 Pressure Reducers—Pressure reduction is accomplished

with a variable orifice. A high-quality needle valve performs

well for source pressure less than 34.5 bar (500 psig). A

variable rod-in-tube device performs well for pressures 34.5

bar and greater because it is basically non-wearing and

minimizes sample dissociation during pressure reduction.

7.4 Pressure Regulating Device—To maintain constant

sample pressure at the inlet to each analyzer train, a variable or

fixed back pressure regulating valve may be used.

7.5 Secondary or Trim Sample Cooler—Similar to the

primary sample cooler, this heat exchanger should be a device

capable of maintaining a sample outlet temperature within

0.5°C (1°F) of the incoming cooling water temperature to

ensure constant outlet temperature, even with significant varia-

tions in sample flow or heat load.

7.6 Sample Flow Indicator(s)—A non-valved rotameter or

other flow indication device in the main sample line or flow

indication device, or both, in all branch lines (analysis, grab,

and bypass) is typically used. A method of measuring total

sample flow in accordance with recommended velocities must

be used (see 6.2).

7.7 Temperature Indicator—A me

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.