ASTM D8000-15(2020)

(Practice)Standard Practice for Flow Conditioning of Natural Gas and Liquids

Standard Practice for Flow Conditioning of Natural Gas and Liquids

SIGNIFICANCE AND USE

4.1 Flow conditioners are used for the conditioning of the turbulent flow profile of gases or liquids to reduce the ADD (velocity profile distortion) DEL (turbulence), swirl, or irregularities caused by the installation effects of piping elbows, length of pipe, valves, tees, and other such equipment or piping configurations that will affect the reading of flow measurement meters thus inducing measurement errors as a result of the flow profile of the gas or liquid not having a fully developed flow profile at the measurement point.4

SCOPE

1.1 This practice covers flow conditioners that produce a fully developed flow profile for liquid and gas phase fluid flow for circular duct sizes 1- to 60-in. (25.4- to 1525-mm) diameter and Reynolds Number (Re) ranges from transition (100) to 100 000 000. These flow conditioners can be used for any type of flow meter or development of a fully developed flow profile for other uses.

1.2 The central single-hole configuration that is derived using fundamental screen theory is referenced as the flow conditioner described herein.

1.3 Piping lengths upstream and downstream of a flow conditioner are considered a critical component of a flow conditioner and constitute the complete flow conditioner system.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D8000 −15 (Reapproved 2020)

Standard Practice for

Flow Conditioning of Natural Gas and Liquids

This standard is issued under the fixed designation D8000; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 AGA Standard:

AGA Report No. 8 Compressibility Factor of Natural Gas

1.1 This practice covers flow conditioners that produce a

and Related Hydrocarbon Gases

fully developed flow profile for liquid and gas phase fluid flow

for circular duct sizes 1- to 60-in. (25.4- to 1525-mm) diameter

3. Terminology

and Reynolds Number (Re) ranges from transition (100) to

100 000 000. These flow conditioners can be used for any type 3.1 Refer to Terminology D4150 for general definitions

of flow meter or development of a fully developed flow profile related to gaseous fuels. Definitions specific to this standard

for other uses. follow.

1.2 The central single-hole configuration that is derived 3.2 Definitions of Terms Specific to This Standard:

using fundamental screen theory is referenced as the flow

3.2.1 annuli, n—ring-shaped object, structure, or region.

conditioner described herein.

3.2.2 axial symmetry, n—symmetry around an axis; an

1.3 Piping lengths upstream and downstream of a flow object is axially symmetric if its appearance is unchanged if

conditioner are considered a critical component of a flow rotated around an axis.

conditioner and constitute the complete flow conditioner sys-

3.2.3 Reynolds number, n—dimensionless number used in

tem.

fluid mechanics to indicate whether fluid flow past a body or in

1.4 The values stated in inch-pound units are to be regarded a duct is steady or turbulent.

as standard. The values given in parentheses are mathematical

3.2.4 velocity profile, n—variation in velocity along a line at

conversions to SI units that are provided for information only

right angles to the general direction of flow.

and are not considered standard.

4. Significance and Use

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4.1 Flow conditioners are used for the conditioning of the

responsibility of the user of this standard to establish appro-

turbulent flow profile of gases or liquids to reduce the ADD

priate safety, health, and environmental practices and deter-

(velocity profile distortion) DEL (turbulence), swirl, or irregu-

mine the applicability of regulatory limitations prior to use.

larities caused by the installation effects of piping elbows,

1.6 This international standard was developed in accor-

lengthofpipe,valves,tees,andothersuchequipmentorpiping

dance with internationally recognized principles on standard-

configurations that will affect the reading of flow measurement

ization established in the Decision on Principles for the

meters thus inducing measurement errors as a result of the flow

Development of International Standards, Guides and Recom-

profile of the gas or liquid not having a fully developed flow

mendations issued by the World Trade Organization Technical

profile at the measurement point.

Barriers to Trade (TBT) Committee.

5. Flow Conditioner Design Methodology

2. Referenced Documents

5.1 Pipe Flow Profiles—Almost any description can be

2.1 ASTM Standards:

prescribed by using the perforated plate utilizing screen theory.

D4150 Terminology Relating to Gaseous Fuels

That is, any upstream velocity profile, U , can be changed to a

1 downstream velocity profile, U , with the use of a screen

This practice is under the jurisdiction of ASTM Committee D03 on Gaseous 2

Fuels and is the direct responsibility of Subcommittee D03.12 on On-Line/At-Line (herein referred to as a flow conditioner) (see Fig. 1).

Analysis of Gaseous Fuels.

Current edition approved Nov. 1, 2020. Published December 2020. Originally

approved in 1986. Last previous edition approved in 2015 as D8000 – 15. DOI:

10.1520/D8000-15R20. Available from the American Gas Association, 400 N. Capital St., NW,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Washington, DC 20001, www.techstreet.com/aga.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Per various Coriolis Flow Meter manufacturer statements: A Coriolis Flow

Standards volume information, refer to the standard’s Document Summary page on Meter reportedly does not require flow conditioning, therefore this ASTM standard

the ASTM website. does not apply.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D8000−15 (2020)

FIG. 1Pipe Flow Profile

NOTE 1—The upstream flow profile need not be mathematically defined

where:

or even known.

U = velocity at location, r;

r

5.1.1 The intent of the screen theory methodology is to U = maximum velocity at pipe center line;

max

r = r location;

suppress or allow flow such that the axi-symmetric distribution

R = r at pipe wall; and

of the fluid flow eventually manifests itself into a fully

n = 1/friction factor.

developed state—g(r). Separating the pipe flow into annuli and

correlating the openness of each annulus in terms of an

5.1.3.2 In terms of U and U (at pipe center line), we

ave max

effective beta ratio of that annulus with respect to a discretized

obtain:

reference fully developed velocity flow profile is then done to

2n

have the resultant velocity flow profile fully developed [or

U 5 U (2)

F G

ave max

~n 1 1!~2 n 1 1!

some chosen function, g(r)] . The annuli and accompanying

where:

nomenclature are defined in Fig. 2.

values for U and U are in Table 1.

ave max

5.1.2 For a screen, the relationship between the downstream

5.1.4 Step 2—Choose an overall flow conditioner pressure

U and upstream U velocities can be shown to follow the

2 1

loss coefficient that is suitable for the intended flow require-

relationship between sudden enlargements and contractions

ments. Note that the overall effectiveness or isolating capabil-

(the flow conditioner holes) as a fully developed state by using

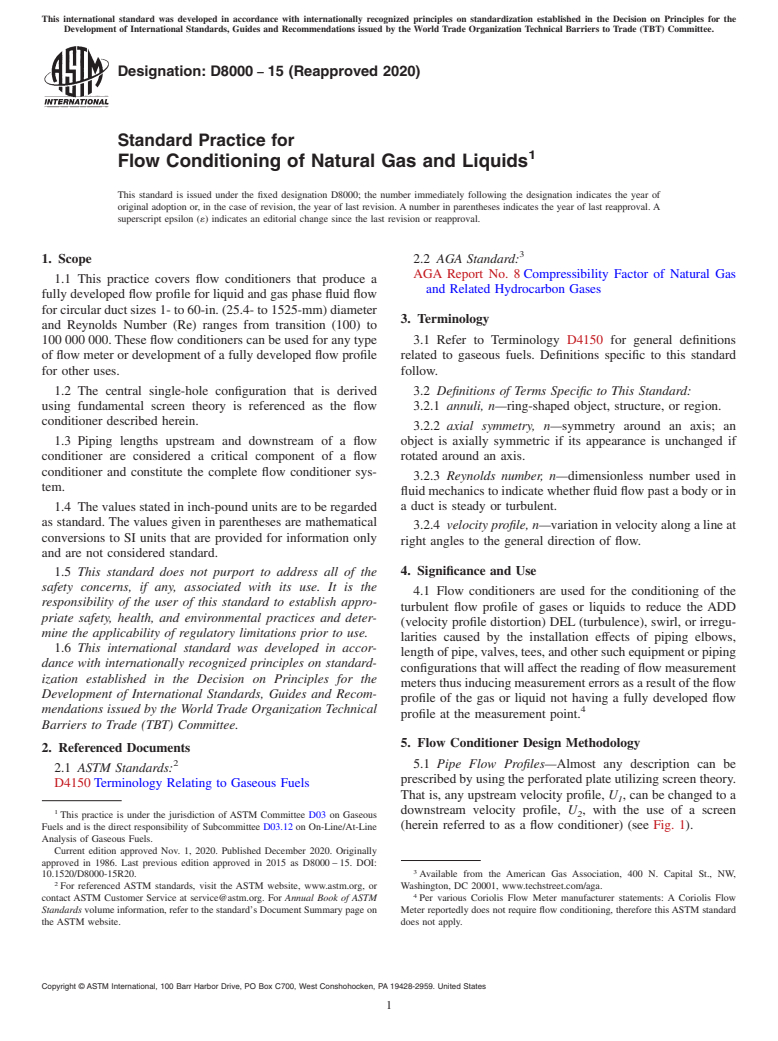

ityoftheflowisaverystrongfunctionofthepressureloss.The

Equation X (Karnik and Erdal). This equation relates the

relationship between effectiveness and pressure drop is indi-

pressure drop of the holes considered as sudden enlargements

cated in Fig. 2. Eq 4 can be used to accomplish this.

and the designer can use as many annuli (n) as they wish. The

user of this practice is cautioned that manufacturing difficulty

∆P

K 5 (3)

increases with the number of annuli chosen. It is also recom- 0

ρU

ave

mended that the downstream velocity relationship (function,

equation) be that which is of a fully developed state.

5.1.5 Step 3—Pressure drop of each ring (i).

5.1.3 Step 1—Choose a downstream velocity function. For

pipeline flow measurement, all flow meters are on a baseline

U U Y n

i max i

5 (4)

against a fully developed flow profile. It is recommended that S D

U U R

ave ave

a function replicating the fully developed state be used at the

chosen Reynolds number. 5.1.6 Step 4—Plug all terms into flow conditioner pressure

drop coefficient Eq 5.

5.1.3.1 In this case, a power law flow profile is chosen such

2 2

as Eq 1:

0.7 1 2 λ 1 2λ U

~ !

i i i

K 5 1 (5)

F G F G

0 2

1 1

λ λ U

i i ave

U r n U y n

r y

5 1 2 or 5 (1)

S D S D

U R U R

max max 5.1.7 Step 5—Equate Eq 6 for each hole size and number of

holes for each ring.

π

n a

S D

λ 5 (6)

i 2 2

π~R 2 R !

i11 i

TABLE 1 U and U

ave max

n U /U U /U

ave max max ave

1 0.333 3

2 0.533 1.875

3 0.643 1.56

4 0.711 1.41

5 0.758 1.32

6 0.791 1.26

7 0.816 1.22

8 0.836 1.19

9 0.851 1.173

10 0.865 1.155

FIG. 2Annuli and Nomenclature

D8000−15 (2020)

where: 5.3.1 The nomenclature used to specify a flow-conditioning

device is the following (9 in. (23 cm) not included in the

λ = porosity of ring, i;

i

description):

n = number of holes in ring, i;

a = area of each hole; and [NPS] [AA] [BB] [CC ANSI Rating] [Material Type]

R = r at x.

5.3.2 The terms for a complete description are:

x

5.3.2.1 AA = Nominal Pipe Size (NPS)

5.2 Flow Conditioner Qualification Pipe Flow Profiles—To

(1) NPS does not refer to the pipe outside diameter up to

comply with the requirements of this practice, the flow

NPS 12-in. (30.5-cm) pipe. For NPS 14-in. (35.5-cm) and

conditioner shall be shown to provide a state of flow within the

larger pipe sizes, NPS corresponds to pipe outside diameter.

pipe that resembles the fluid flow characteristics of a straight

(2) In 90 % of applications, NPS will correspond with a

piece of pipe not shorter than 200 inside pipe diameters. This

publishedpipeschedule.InapplicationsthatexceedNPS30in.

shall be shown when installed downstream of any piping

(76 cm), actual pipe inside diameters are used more than

installation effect in any pipe length chosen.

schedules. This may be due to difficulty meeting pressure

5.2.1 This requirement ensures that specific flow meter type

containment requirements with published pipe schedules in

and flow conditioner peculiarities are avoided.

larger pipe sizes. In some instances [even if smaller pipe sizes;

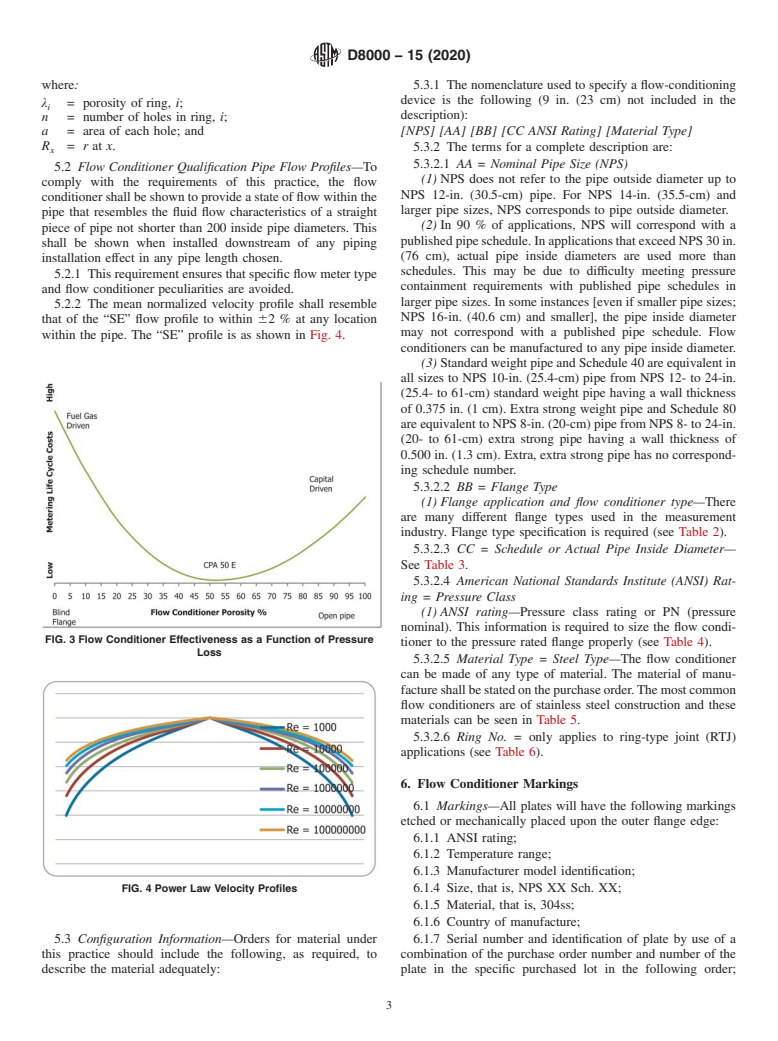

5.2.2 The mean normalized velocity profile shall resemble

NPS 16-in. (40.6 cm) and smaller], the pipe inside diameter

that of the “SE” flow profile to within 62 % at any location

may not correspond with a published pipe schedule. Flow

within the pipe. The “SE” profile is as shown in Fig. 4.

conditioners can be manufactured to any pipe inside diameter.

(3) Standard weight pipe and Schedule 40 are equivalent in

all sizes to NPS 10-in. (25.4-cm) pipe from NPS 12- to 24-in.

(25.4- to 61-cm) standard weight pipe having a wall thickness

of 0.375 in. (1 cm). Extra strong weight pipe and Schedule 80

are equivalent to NPS 8-in. (20-cm) pipe from NPS 8- to 24-in.

(20- to 61-cm) extra strong pipe having a wall thickness of

0.500 in. (1.3 cm). Extra, extra strong pipe has no correspond-

ing schedule number.

5.3.2.2 BB = Flange Type

(1) Flange application and flow conditioner type—There

are many different flange types used in the measurement

industry. Flange type specification is required (see Table 2).

5.3.2.3 CC = Schedule or Actual Pipe Inside Diameter—

See Table 3.

5.3.2.4 American National Standards Institute (ANSI) Rat-

ing = Pressure Class

(1) ANSI rating—Pressure class rating or PN (pressure

nominal). This information is required to size the flow condi-

FIG. 3Flow Conditioner Effectiveness as a Function of Pressure

tioner to the pressure rated flange properly (see Table 4).

Loss

5.3.2.5 Material Type = Steel Type—The flow conditioner

can be made of any type of material. The material of manu-

factureshallbestatedonthepurchaseorder.Themostcommon

flow conditioners are of stainless steel construction and these

materials can be seen in Table 5.

5.3.2.6 Ring No. = only applies to ring-type joint (RTJ)

applications (see Table 6).

6. Flow Conditioner Markings

6.1 Markings—All plates will have the following markings

etched or mechanically placed upon the outer flange edge:

6.1.1 ANSI rating;

6.1.2 Temperature range;

6.1.3 Manufacturer model identification;

FIG. 4Power Law Velocity Profiles 6.1.4 Size, that is, NPS XX Sch. XX;

6.1.5 Material, that is, 304ss;

6.1.6 Country of manufacture;

5.3 Configuration Information—Orders for material under 6.1.7 Serial number and identification of plate by use of a

this practice should include the following, as required, to combination of the purchase order number and number of the

describe the material adequately: plate in the specific purchased lot in the following order;

D8000−15 (2020)

TABLE 2 Flange Type

Flange Type Flow Conditioner Description Nomenclature

Raised Face Type A Raised Face (RF) Compressed between two raised face FOE (flange on end)

flanges in meter tube with thin

flange—most popular—requires meter

tube to be rolled to remove flow

conditioner.

Raised Face Wafer Compressed between two raised face FWO (full width option)

flanges in meter tube with full width

flange—least popular—does not

require meter tube to be rolled to

remove flow conditioner.

Pinned in Pipe Pinned Flanges are replaced by a TBR (tube bundle replacement)

threadolette and set screw. Used

where conventional tube bundles are

to be retrofitted.

Ring-Type Joint (RTJ) RTJ Compressed between two RTJ RTJ (ring-type joint)

flanges in meter tube.

Ring-Type Joint (RTJ) RTJ Insert The flow conditioner is inserted into a RIS (ring-type joint insert style)

counter bore machined into the meter

tube RTJ flange.

purchase order number XXXX, followed by plate number XX, there shall be a ⁄8-in. (3.155-mm) notch that will be top dead

out of total number of the lot XX as shown in Example 1. center (tdc). Place new top indication as such “Top↑notch↑”as

6.1.7.1 Example 1—Purchase order 1234 that has ordered

shown in Fig. 6.

three plates on this order will have the following number for

6.2 Bore Scope Marking

the first plate in the lot: 123431; but, if there is only one plate

6.2.1 To provide a second level of identification, the flow

in this example order, then the number would be 123411, thus,

conditioner type can be machined into the downstream face of

the format: [order number] + [plate number out of the lot] +

the flow conditioner as indicated in Fig. 7.

[total number of plates in the lot];

6.2.2 The order of indication shall be: NPSXX_Sch XX.

6.1.8 Flow (see Fig. 5);

6.1.8.1 Top indication (see Fig. 6); and

6.1.9 Heat number [using Material Test Report (MTR)]. 7. Installation Distances

6.1.10 The customers paint over the flow conditioners and

7.1 Markings—Toprovidethebestflowconditionspossible,

cannot see the labeling on the flow conditioner—top indication

the flow conditioner shall be installed carefully. The flow

recovery is paramount.

conditioner shall not be installed in distances less than shown

6.1.11 While the holes are being machined, a top indication

in Fig. 8.

will be machined as follows:

6.1.11.1 A ⁄8-in. (3.155-mm) diameter cutting tool will side 7.2 Minimum Meter Run Distances—Any distance longer

cut into the flange of the flow conditioner to a depth of ⁄8-in. than indicated will result in higher quality flow profiles (see

(3.155-mm)asshowninFig.6.Toavoidorientationconfusion, Table 7).

D8000−15 (2020)

TABLE3 Continued

TABLE 3 Schedule or Actual Pipe Inside Diameter

Nominal Pipe Size Schedule Inside Flange

Nominal Pipe Size Schedule Inside Flange

Diameter Thickness

Diameter Thickness

Outsi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.