ASTM F1811-97

(Practice)Standard Practice for Estimating the Power Spectral Density Function and Related Finish Parameters from Surface Profile Data

Standard Practice for Estimating the Power Spectral Density Function and Related Finish Parameters from Surface Profile Data

SCOPE

1.1 This practice defines the methodology for calculating a set of commonly used statistical parameters and functions of surface roughness from a set of measured surface profile data. Its purposes are to provide fundamental procedures and notation for processing and presenting data, to alert the reader to related issues that may arise in user-specific applications, and to provide literature references where further details can be found.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1811 – 97

Standard Practice for

Estimating the Power Spectral Density Function and Related

Finish Parameters from Surface Profile Data

This standard is issued under the fixed designation F 1811; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope profile across the surface, or the “ensemble” average of an

infinite number of finite-length profiles. In contrast, real profile

1.1 This practice defines the methodology for calculating a

data are available in the form of one or more sets of digitized

set of commonly used statistical parameters and functions of

height data measured at a finite number of discrete positions on

surface roughness from a set of measured surface profile data.

the surface under test. This practice gives both the abstract

Its purposes are to provide fundamental procedures and nota-

definitions of the statistical quantities of interest, and numerical

tion for processing and presenting data, to alert the reader to

procedures for determining values of these abstract quantities

related issues that may arise in user-specific applications, and

from sets of measured data. In the notation of this practice

to provide literature references where further details can be

these numerical procedures are called “estimators” and the

found.

results that they produce are called “estimates”.

1.2 The present practice is limited to the analysis of one-

1.6 This practice gives “periodogram” estimators for deter-

dimensional or profile data taken at uniform intervals along

mining the root-mean-square (rms) roughness, rms slope, and

straight lines across the surface under test, although reference

power spectral density (PSD) of the surface directly from

is made to the more general case of two-dimensional measure-

profile height or slope measurements. The statistical literature

ments made over a rectangular array of data points.

uses a circumflex to distinguish an estimator or estimate from

1.3 The data analysis procedures described in this practice

its abstract or ensemble-average value. For example, Â denotes

are generic and are not limited to specific surfaces, surface-

an estimate of the quality A. However, some word-processors

generation techniques, degrees of roughness, or measuring

cannot place a circumflex over consonants in text. Any

techniques. Examples of measuring techniques that can be used

symbolic or verbal device may be used instead.

to generate profile data for analysis are mechanical profiling

1.7 The quality of estimators of surface statistics are, in

instruments using a rigid contacting probe, optical profiling

turn, characterized by higher-order statistical properties that

instruments that sample over a line or an array over an area of

describe their “bias” and “fluctuation” properties with respect

the surface, optical interferometry, and scanning-microscopy

to their abstract or ensemble-average versions. This practice

techniques such as atomic-force microscopy. The distinctions

does not discuss the higher-order statistical properties of the

between different measuring techniques enter the present

estimators given here since their practical significance and use

practice through various parameters and functions that are

are application-specific and beyond the scope of this document.

defined in Sections 3 and 5, such as their sampling intervals,

Details of these and related subjects can be found in References

bandwidths, and measurement transfer functions.

(1–10) at the end of this practice.

1.4 The primary interest here is the characterization of

1.8 Raw measured profile data generally contain trending

random or periodic aspects of surface finish rather than isolated

components that are independent of the microtopography of the

surface defects such as pits, protrusions, scratches or ridges.

surface being measured. These components must be subtracted

Although the methods of data analysis described here can be

before the difference or residual errors are subjected to the

equally well applied to profile data of isolated surface features,

statistical-estimation routines given here. These trending com-

the parameters and functions that are derived using the

ponents originate from both extrinsic and intrinsic sources.

procedures described in this practice may have a different

Extrinsic trends arise from the rigid-body positioning of the

physical significance than those derived from random or

part under test in the measuring apparatus. In optics these

periodic surfaces.

displacement and rotation contributions are called “piston” and

1.5 The statistical parameters and functions that are dis-

“tilt” errors. In contrast, intrinsic trends arise from deliberate or

cussed in this practice are, in fact, mathematical abstractions

accidental shape errors inherent in the surface under test, such

that are generally defined in terms of an infinitely-long linear

as a circular or parabolic curvature. In the absence of a-priori

information about the true surface shape, the intrinsic shape

This practice is under the jurisdiction of ASTM Committee F-1 on Electron-

icsand is the direct responsibility of Subcommittee F01.06 on Silicon Materials and

Process Control. The boldface numbers in parentheses refer to the list of references at the end of

Current edition approved June 10, 1997. Published August 1997. this practice.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1811

error is frequently limited to a quadratic (parabolic) curvature parameters or functions generated by the procedures described

of the surface. Detrending of intrinsic and extrinsic trends is

herein be accompanied by an identifying description of mea-

generally accomplished simultaneously by subtracting a de- suring instrument used, estimates of its low- and high-

trending polynomial from the raw measured data, where the

frequency limits, LFL and HFL, and a statement of whether or

polynomial coefficients are determined by least-squares fitting not restoration techniques were used.

to the measured data.

1.13 In order to make a quantitative comparison between

1.9 Although surfaces and surface measuring instruments

profile data obtained from different measurement techniques,

exist in real or configuration space, they are most easily

the statistical parameters and functions of interest must be

understood in frequency space, also known as Fourier trans-

compared over the same or comparable spatial-frequency

form, reciprocal or spatial-frequency space. This is because

regions. The most common quantities used to compare surfaces

any practical measurement process can be considered to be a

are their root-mean-square (rms) roughness values, which are

“linear system”, meaning that the measured profile is the

the square roots of the areas under the PSD between specified

convolution of the true surface profile and the impulse response

surface-frequency limits. Surface statistics derived from mea-

of the measuring system; and equivalently, the Fourier-

surements involving different spatial-frequency ranges cannot

amplitude spectrum of the measured profile is the product of

be compared quantitatively except in an approximate way. In

that of the true profile and the frequency-dependent “transfer

some cases measurements with partially or even nonoverlap-

function” of the measurement system. This is expressed

ping bandwidths can be compared by using analytic models of

symbolically by the following equation:

the PSDs to extrapolate the PSDs outside their measurement

A ~ f ! 5 A ~ f ! · T ~f ! bandwidth.

meas x true x x

1.14 Examples of specific band-width limits can be drawn

where:

from the optical and semiconductor industries. In optics the

A = the Fourier amplitudes,

so-called total integrated scatter or TIS measurement technique

T( f ) = instrument response function or the measurement

x

leads to rms roughness values involving an annulus in two-

transfer function, and

–1

dimensional spatial frequencies space from 0.069 to 1.48 μm ;

f = surface spatial frequency.

x

that is, a dynamic range of 1.48/0.069 = 21/1. In contrast, the

This factorization permits the surface and the measuring

range of spatial frequencies involved in optical and mechanical

system to be discussed independently of each other in fre-

scanning techniques are generally much larger than this,

quency space, and is an essential feature of any discussion of

frequently having a dynamic ranges of 512/1 or more. In the

measurement systems.

–1

latter case the subrange of 0.0125 to 1 μm has been used to

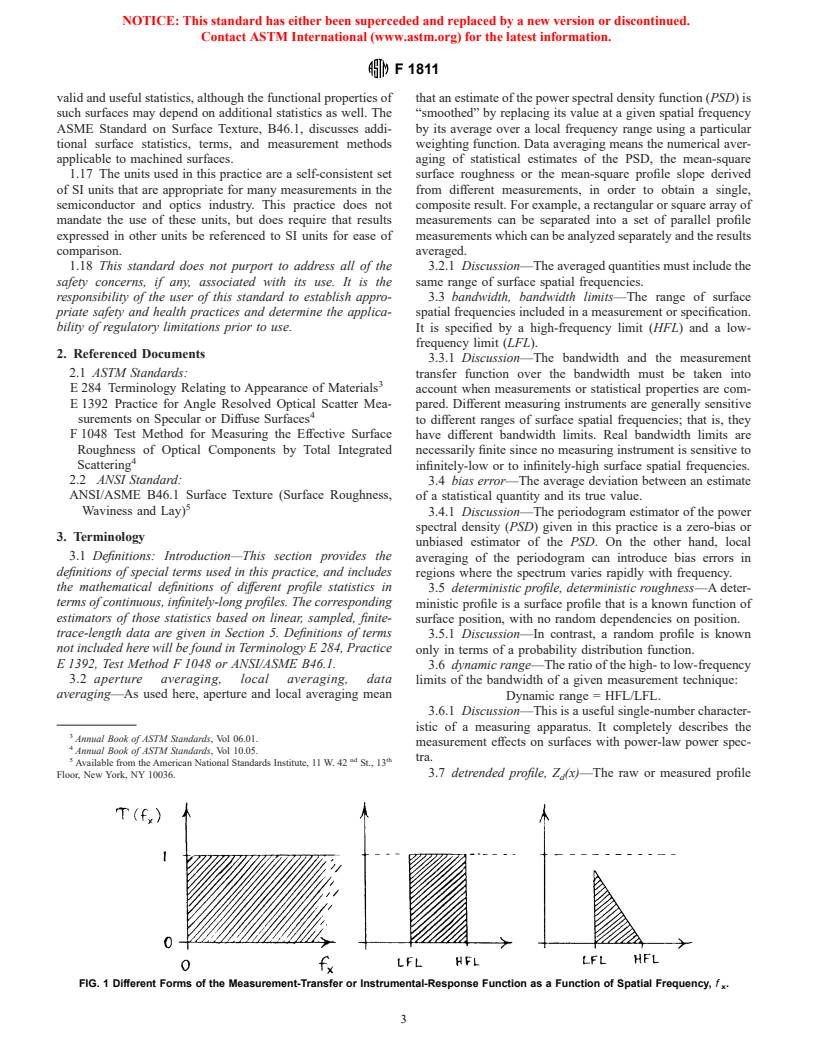

1.10 Figure 1 sketches different forms of the measurement

discuss the rms surface roughness in the semiconductor indus-

transfer function, T( f ):

x

try. These numbers are provided to illustrate the magnitudes

1.10.1 Case (a) is a perfect measuring system, which has

and ranges of HFL and LFL encountered in practice but do not

T ( f ) = 1 for all spatial frequencies, 0 # f # ‘ . This is

x x

constitute a recommendation of particular limits for the speci-

unrealistic since no real measuring instrument is equally

fication of surface finish parameters. Such selections are

sensitive to all spatial frequencies. Case (b) is an ideal mea-

application dependent, and are to be made at the users’

suring system, which has T (f )=1for LFL # f # HFL and

x x

discretion.

T (f ) = 0 otherwise, where LFL and HFL denote the

x

1.15 The limits of integration involved in the determination

low-frequency and high-frequency limits of the measurement.

of rms roughness and slope values from measured profile data

The range LFL # f # HFL is called the bandpass or

x

are introduced by multiplying the measured PSD by a factor

bandwidth of the measurement, and ratio HFL/LFL is called

equal to zero for spatial frequencies outside the desired

the dynamic range of the measurement. Case (c) represents a

bandpass and unity within the desired bandpass, as shown in

realistic measuring system, since it includes the fact that T (f )

x

Case (b) in Fig. 1. This is called a top-hat or binary filter

need not be unity within the measurement bandpass or strictly

function. Before the ready availability of digital frequency-

zero outside the bandpass.

domain processing as employed in this practice, bandwidth

1.11 If the measurement transfer function is known to

limits were imposed by passing the profile data through analog

deviate significantly from unity within the measurement band-

or digital filters without explicitly transforming them into the

pass, the measured power spectral density (PSD) can be

frequency domain and multiplying by a top-hat function. The

transformed into the form that would have been measured by

two processes are mathematically equivalent, providing the

an instrument with the ideal rectangular form through the

data filter has the desired frequency response. Real data filters,

process of digital “restoration.” In its simplest form restoration

however, frequently have Gaussian or RC forms that only

involves dividing the measured PSD by the known form of

approximate the desired top-hat form that introduces some

?T ~ f ! ? over the measurement bandpass. Restoration is par-

x

ambiguity in their interpretation. This practice recommends the

ticularly relevant to measuring instruments that involve optical

determination of rms roughness and slope values using top-hat

microscopes since the transfer functions of microscope systems

windowing of the measured PSD in the frequency domain.

are not unity over their bandpass but tend to fall linearly

between unity at T (0) = 1 and T(HFL) = 0. The need for, and 1.16 The PSD and rms roughness are surface statistics of

methodology of digital restoration is instrument specific and particular interest to the optics and semiconductor industries

this practice places no requirements on its use. because of their direct relationship to the functional properties

1.12 This practice requires that any data on surface finish of such surfaces. In the case of rougher surfaces these are still

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1811

valid and useful statistics, although the functional properties of that an estimate of the power spectral density function (PSD)is

such surfaces may depend on additional statistics as well. The “smoothed” by replacing its value at a given spatial frequency

ASME Standard on Surface Texture, B46.1, discusses addi- by its average over a local frequency range using a particular

tional surface statistics, terms, and measurement methods weighting function. Data averaging means the numerical aver-

applicable to machined surfaces. aging of statistical estimates of the PSD, the mean-square

1.17 The units used in this practice are a self-consistent set surface roughness or the mean-square profile slope derived

of SI units that are appropriate for many measurements in the from different measurements, in order to obtain a single,

semiconductor and optics industry. This practice does not composite result. For example, a rectangular or square array of

mandate the use of these units, but does require that results measurements can be separated into a set of parallel profile

expressed in other units be referenced to SI units for ease of measurements which can be analyzed separately and the results

comparison. averaged.

1.18 This standard does not purport to address all of the 3.2.1 Discussion—The averaged quantities must include the

safety concerns, if any, associated with its use. It is the same range of surface spatial frequencies.

responsibility of the user of this standard to establish appro- 3.3 bandwidth, bandwidth limits—The range of surface

priate safety and health practices and determine the applica- spatial frequencies included in a measurement or specification.

bility of regulatory limitations prior to use. It is specified by a high-frequency limit (HFL) and a low-

frequency limit (LFL).

2. Referenced Documents

3.3.1 Discussion—The bandwidth and the measurement

2.1 ASTM Standards:

transfer function over the bandwidth must be taken into

E 284 Terminology Relating to Appearance of Materials account when measurements or statistical properties are com-

E 1392 Practice for Angle Resolved Optical Scatter Mea-

pared. Different measuring instruments are general

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.