ASTM E712-80(1996)

(Practice)Standard Practice for Laboratory Screening of Metallic Containment Materials for Use With Liquids in Solar Heating and Cooling Systems

Standard Practice for Laboratory Screening of Metallic Containment Materials for Use With Liquids in Solar Heating and Cooling Systems

SCOPE

1.1 This practice describes several laboratory test procedures for evaluating corrosion performance of metallic containment materials under conditions similar to those that may occur in solar heating and cooling systems. All test results relate to the performance of the metallic containment material only as a part of a metal/fluid pair. Performance in these laboratory test procedures, taken by itself, does not necessarily constitute an adequate basis for acceptance or rejection of a particular metal/fluid pair in solar heating and cooling systems, either in general or in a particular design. This practice is not intended to preclude the use of other screening tests, particularly when those tests are designed to more closely simulate field service conditions.

1.2 This practice describes apparatus and procedures for several tests, any one or more of which may be used to evaluate the deterioration of the metallic containment material in a metal/fluid pair. The procedures are designed to permit simulation, heating, and cooling systems including ( ) operating full flow, ( ) stagnant full, ( ) stagnant partial fill, and ( ) stagnant empty. Particular attention should be directed to properly reflecting whether the system is open or closed to atmosphere.

1.3 This practice covers the following six tests: Practice A Basic Immersion Test at Atmospheric Pressure Practice B Heat-Rejecting Surface Test at Atmospheric Pressure Practice C High-Pressure Test Practice D Repeated Dip Dry Test at Atmospheric Pressure Practice E Crevice Test at Atmospheric Pressure Practice F Tube Loop Test at Atmospheric Pressure

1.4 Practice A is concerned with the interaction of metal and fluid when both are at the same temperature with no heat transfer from one to the other. It is regarded as useful for plumbing, pumps, tanking, etc., but of less significance, taken by itself, for collector panels. Practices B and F are concerned with the deterioration of the metal when there is transfer of heat from the metal into the heat transfer fluid. These practices are especially applicable to the collector panel. Practice C permits a variety of tests but is especially useful in relation to systems that experience high temperatures, or are closed to the atmosphere. Practices D and E evaluate specific corrosion problems that may be associated with particular metal/fluid pairs and particular designs of systems and components.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 712 – 80 (Reapproved 1996)

Standard Practice for

Laboratory Screening of Metallic Containment Materials for

Use With Liquids in Solar Heating and Cooling Systems

This standard is issued under the fixed designation E 712; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope that experience high temperatures, or are closed to the atmo-

sphere. Practices D and E evaluate specific corrosion problems

1.1 This practice covers several laboratory test procedures

that may be associated with particular metal/fluid pairs and

for evaluating corrosion performance of metallic containment

particular designs of systems and components.

materials under conditions similar to those that may occur in

1.5 This standard does not purport to address all of the

solar heating and cooling systems. All test results relate to the

safety concerns, if any, associated with its use. It is the

performance of the metallic containment material only as a part

responsibility of the user of this standard to establish appro-

of a metal/fluid pair. Performance in these laboratory test

priate safety and health practices and determine the applica-

procedures, taken by itself, does not necessarily constitute an

bility of regulatory limitations prior to use.

adequate basis for acceptance or rejection of a particular

metal/fluid pair in solar heating and cooling systems, either in

2. Referenced Documents

general or in a particular design. This practice is not intended

2.1 ASTM Standards:

to preclude the use of other screening tests, particularly when

D 1384 Test Method for Corrosion Test for Engine Coolants

those tests are designed to more closely simulate field service

in Glassware

conditions.

G 1 Practice for Preparing, Cleaning, and Evaluating Cor-

1.2 This practice describes apparatus and procedures for

rosion Test Specimens

several tests, any one or more of which may be used to evaluate

G 48 Test Methods for Pitting and Crevice Corrosion Re-

the deterioration of the metallic containment material in a

sistance of Stainless Steels and Related Alloys by the Use

metal/fluid pair. The procedures are designed to permit simu-

of Ferric Chloride Solution

lation, heating, and cooling systems including (1) operating full

flow, (2) stagnant full, (3) stagnant partial fill, and (4) stagnant

3. Significance and Use

empty. Particular attention should be directed to properly

3.1 At this time, none of these tests has been demonstrated

reflecting whether the system is open or closed to atmosphere.

to correlate with field service.

1.3 This practice covers the following six tests:

3.2 It is essential that consideration be given to the appro-

Practice A Basic Immersion Test at Atmospheric Pressure

priate pairing of metal and fluid since these procedures do not

Practice B Heat-Rejecting Surface Test at Atmospheric Pressure

Practice C High-Pressure Test

restrict the selection of either the containment material or the

Practice D Repeated Dip Dry Test at Atmospheric Pressure

fluid for testing. Likewise, knowledge of the corrosion protec-

Practice E Crevice Test at Atmospheric Pressure

tion mechanism and the probable mode of failure of a

Practice F Tube Loop Test at Atmospheric Pressure

particular metal is helpful in the selection of test conditions and

1.4 Practice A is concerned with the interaction of metal and

the observation, interpretation, and reporting of test results.

fluid when both are at the same temperature with no heat

3.3 The design of solar heating and cooling systems

transfer from one to the other. It is regarded as useful for

strongly affects the applicability of the results of the laboratory

plumbing, pumps, tanking, etc., but of less significance, taken

screening tests. Therefore, the results of these laboratory

by itself, for collector panels. Practices B and F are concerned

procedures should be confirmed by component and systems

with the deterioration of the metal when there is transfer of heat

testing under actual or simulated service conditions.

from the metal into the heat transfer fluid. These practices are

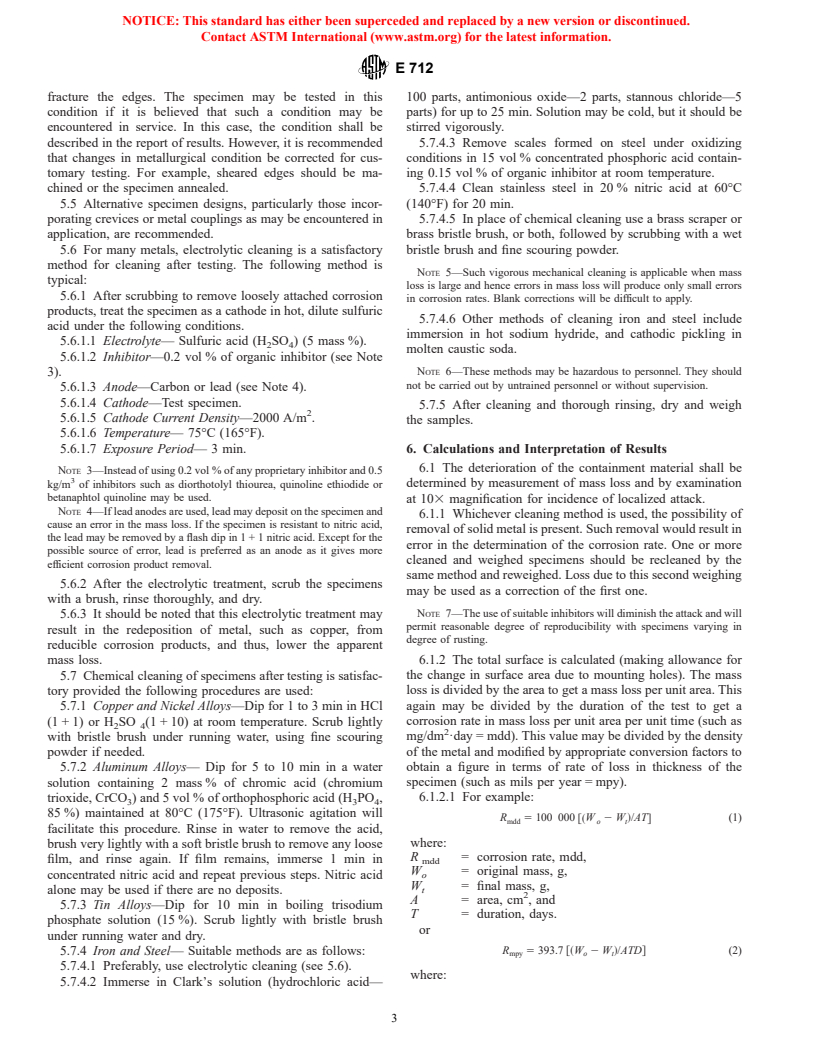

3.4 Table 1 is provided to assist in an orderly consideration

especially applicable to the collector panel. Practice C permits

of the important factors in testing. It is expected that the user

a variety of tests but is especially useful in relation to systems

of the test procedure will investigate a range of test times and

temperatures for the containment material in a metal/fluid pair,

and adjust the time and temperature of testing as necessary.

These test methods are under the jurisdiction of ASTM Committee E44 on

Solar, Geothermal, and Other Alternative Energy Sources and is the direct

responsibility of Subcommittee E44.05 on Solar Heating and Cooling Subsystems

and Systems. Annual Book of ASTM Standards, Vol 15.05.

Current edition approved Feb. 5, 1980. Published April 1980. Annual Book of ASTM Standards, Vol 03.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 712

A

TABLE 1 Significant Variables in Evaluation of Containment Material/Heat Transfer Fluid Pairs

Variable

Test Aspect

Temperature Flow Rate

I. Operating Conditions of System:

A. Operating, full flow normal operating normal operating

B. Stagnant, full fluid boiling point without pressurization or no-flow temperature with pressurization convection

C. Stagnant, partial fill same as stagnant, full convection

D. Stagnant, empty no-flow temperature not applicable

II. Test Specimen Design A. flat metal couple

B. metal couple with crevice

C. dissimilar metal couple

D. dissimilar metal couple with crevice

III. Fluid Type A. fluid intended for use in system

B. fluid pretreated by thermal exposure or chemical contamination

IV. Test Cycle A. long time, constant temperature

B. cycles of heating, holding, and cooling

C. cycles of operating full flow, and stagnation

D. cycles of wetting and drying

A

In this table, the subdivisions are not necessarily related in correspondence to their lettering.

NOTE 1—Corrosion, whether general or localized, is a time-dependent

4.3 Particular attention shall be directed to avoidance of

phenomenon. This time dependence can show substantial nonlinearity. For

materials, fluids, or metal/fluid pairs that can be hazardous to

example, formation of a protective oxide will diminish corrosion with

the operator. The flammability, vapor pressure, and toxicity of

time, while certain forms of localized attack accelerate with time. The

the heat-transfer fluid shall be known prior to initiation of

minimum time required for a test to provide a corrosion rate that can be

testing and appropriate precautionary measures shall be taken

extrapolated for the prediction of long-term performance varies widely,

to ensure the safety of all test personnel.

depending on the selection of metal and fluid, and on the form of corrosion

attack. Therefore, it is not possible to establish a single minimum length

5. Sampling and Test Specimens

of test applicable to all materials and conditions. However, it is recom-

mended that for the tests described in this practice, a test period of no less

5.1 The test specimens shall be selected from material that

than 30 days be used. Furthermore, it is recommended that the effect of

may reasonably represent that material as it would be applied

time of testing be evaluated to detect any significant time dependence of

in a solar heating and cooling system.

corrosion attack.

5.2 For laboratory corrosion tests that simulate exposure to

3.5 It is essential for the meaningful application of these

service environments, a commercial surface, such as a mill

procedures that the length of the test be adequate to detect

finish, closely resembling the one that would be used in

changes in the nature of the fluid that might significantly alter

service, will yield the most significant results. For more

the corrosivity of the fluid. For example, exhaustion of

searching tests of either the metal or the environment, standard

chemical inhibitor or chemical breakdown of the fluid may

surface finishes may be preferred. Ideally, the surface finish

occur after periods of months in selected cycles of operation.

should be recorded in surface roughness terms, such as rms

inches.

NOTE 2—Many fluids that may be considered for solar applications

contain additives to minimize the corrosivity of the fluid. Many such

5.3 General Cleaning:

additives are useful only within a specific concentration range, and some

5.3.1 General cleaning may be accomplished with a wide

additives may actually accelerate corrosion if the concentration falls

variety of cleaning media. Water-based cleaners should be

below a critical level. Depletion kinetics can be a strong function of the

followed by an alcohol dip after thorough rinsing. Solvent

exposed metal surface area. Therefore, for tests involving fluids with such

cleaners such as petroleum fractions, aromatic hydrocarbons,

additives, consideration must be given to the ratio of metal surface area to

and chlorinated hydrocarbons are generally acceptable. Chlo-

fluid volume as it may relate to an operating system.

rinated solvents, however, should not be used on titanium,

4. Selection of Materials and Reagents

stainless steel, or aluminum. Mechanical cleaning of very

4.1 Any metallic material may be selected for evaluation. smooth surfaces may be accomplished by the use of a paste of

The material shall be capable of being described with sufficient magnesium oxide or alumina.

accuracy to permit reproduction of the test. 5.3.2 Any of the methods suitable for cleaning a given

4.2 Any heat-transfer fluid may be selected for evaluation. corroded specimen may be used to complete the cleaning of

However, it is expected that the fluid will be selected with specimens prior to test, provided that they do not cause

consideration given to possible interactions of material and localized attack. The cleaned specimens should be measured

fluid under the conditions of testing. The fluid should be and weighed. Dimensions determined to the third significant

capable of being described chemically, as to its basic compo- figure and mass determined in the fifth significant figure are

nents and the presence or absence of minor components that usually satisfactory.

affect the interaction with the metal. It is permitted to precon- 5.4 Metallurgical Condition—Specimen preparation may

dition the fluid before testing. Any such preconditioning change the metallurgical condition of the metal. For example,

treatment shall be described in the report. shearing a specimen to size will cold-work and possibly

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 712

fracture the edges. The specimen may be tested in this 100 parts, antimonious oxide—2 parts, stannous chloride—5

condition if it is believed that such a condition may be parts) for up to 25 min. Solution may be cold, but it should be

encountered in service. In this case, the condition shall be stirred vigorously.

described in the report of results. However, it is recommended 5.7.4.3 Remove scales formed on steel under oxidizing

that changes in metallurgical condition be corrected for cus- conditions in 15 vol % concentrated phosphoric acid contain-

tomary testing. For example, sheared edges should be ma- ing 0.15 vol % of organic inhibitor at room temperature.

chined or the specimen annealed. 5.7.4.4 Clean stainless steel in 20 % nitric acid at 60°C

5.5 Alternative specimen designs, particularly those incor- (140°F) for 20 min.

porating crevices or metal couplings as may be encountered in 5.7.4.5 In place of chemical cleaning use a brass scraper or

application, are recommended. brass bristle brush, or both, followed by scrubbing with a wet

5.6 For many metals, electrolytic cleaning is a satisfactory bristle brush and fine scouring powder.

method for cleaning after testing. The following method is

NOTE 5—Such vigorous mechanical cleaning is applicable when mass

typical:

loss is large and hence errors in mass loss will produce only small errors

5.6.1 After scrubbing to remove loosely attached corrosion

in corrosion rates. Blank corrections will be difficult to apply.

products, treat the specimen as a cathode in hot, dilute sulfuric

5.7.4.6 Other methods of cleaning iron and steel include

acid under the following conditions.

immersion in hot sodium hydride, and cathodic pickling in

5.6.1.1 Electrolyte— Sulfuric acid (H SO ) (5 mass %).

2 4

molten caustic soda.

5.6.1.2 Inhibitor—0.2 vol % of organic inhibitor (see Note

NOTE 6—These methods may be hazardous to personnel. They should

3).

not be carried out by untrained personnel or without supervision.

5.6.1.3 Anode—Carbon or lead (see Note 4).

5.6.1.4 Cathode—Test specimen.

5.7.5 After cleaning and thorough rinsing, dry and weigh

5.6.1.5 Cathode Current Density—2000 A/m .

the samples.

5.6.1.6 Temperature— 75°C (165°F).

5.6.1.7 Exposure Period— 3 min. 6. Calculations and Interpretation of Results

6.1 The deterioration of the containment material shall be

NOTE 3—Instead of using 0.2 vol % of any proprietary inhibitor and 0.5

kg/m of inhibitors such as diorthotolyl thiourea, quinoline ethiodide or determined by measurement of mass loss and by examination

betanaphtol quinoline may be used.

at 103 magnification for incidence of localized attack.

NOTE 4—If lead anodes are used, lead may deposit on the specimen and

6.1.1 Whichever cleaning method is used, the possibility of

cause an error in the mass loss. If the specimen is resistant to nitric acid,

removal of solid metal is present. Such removal would result in

the lead may be removed by a flash dip in 1 + 1 nitric acid. Except for the

error in the determination of the corrosion rate. One or more

possible source of error, lead is preferred as an anode as it gives more

cleaned and weighed specimens should be recleaned by the

efficient corrosion product removal.

same method and reweighed. Loss due to this second weighing

5.6.2 After the electrolytic treatment, scrub the specimens

may be used as a correction of the first one.

with a brush, rinse thoroughly, and dry.

NOTE 7—The use of suitable inhibitors will diminish the attack and will

5.6.3 It should be noted that this electrolytic treatm

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.