ASTM B227-03

(Specification)Standard Specification for Hard-Drawn Copper-Clad Steel Wire

Standard Specification for Hard-Drawn Copper-Clad Steel Wire

SCOPE

1.1 This specification covers bare hard-drawn round copper-clad steel wire for electrical purposes (Note 1).

Note 1—Wire ordered to this specification is not intended for redrawing. If wire is desired for this purpose, consult the manufacturer.

1.2 Four grades of wire are specified, designated as follows (Note 2): Grade 40 HS, Grade 40 EHS, Grade 30 HS, and Grade 30 EHS.

Note 2—The grades covered by this specification correspond to the following commercial designations:

Grade 40 HS,High Strength, 40 % Conductivity.

Grade 40 EHS, Extra High Strength, 40 % Conductivity

Grade 30 HS, High Strength, 30 % Conductivity.

Grade 30 EHS, Extra High Strength, 30 % Conductivity.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are in SI units.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 227 – 03

Standard Specification for

1

Hard-Drawn Copper-Clad Steel Wire

This standard is issued under the fixed designation B 227; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.1 Quantity of each size and grade,

3.1.2 Wire size: diameter in inches (see 5.1 and Table 1),

1.1 This specification covers bare hard-drawn round copper-

3.1.3 Grade (see 1.2 and Table 1),

clad steel wire for electrical purposes (Note 1).

3.1.4 Method of measuring elongation (see 7.3 and 7.4),

NOTE 1—Wire ordered to this specification is not intended for redraw-

3.1.5 Package size (see 14.1),

ing. If wire is desired for this purpose, consult the manufacturer.

3.1.6 Special package marking, if required (Section 13), and

1.2 Four grades of wire are specified, designated as follows

3.1.7 Place of inspection (Section 15).

(Note 2): Grade 40 HS, Grade 40 EHS, Grade 30 HS, and

4. Material

Grade 30 EHS.

4.1 The wire shall be composed of a steel core with a

NOTE 2—The grades covered by this specification correspond to the

substantially uniform and continuous copper cladding thor-

following commercial designations:

oughly bonded to it throughout.

Grade 40 HS, High Strength, 40 % Conductivity.

Grade 40 EHS, Extra High Strength, 40 % Conductivity 4.2 The finished copper-clad steel wire shall conform to the

Grade 30 HS, High Strength, 30 % Conductivity.

requirements prescribed in this specification.

Grade 30 EHS, Extra High Strength, 30 % Conductivity.

5. Dimensions and Permissible Variations

1.3 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are in SI units. 5.1 The size shall be expressed as the diameter of the wire

in decimal fractions of an inch using four places of decimals,

2. Referenced Documents

that is, in tenths of mils (Note 3).

2.1 The following documents of the issue in effect on date

NOTE 3—The values of wire diameters in Table 1 are given to the

of material purchase form a part of this specification to the

nearest 0.0001 in. and correspond to the standard sizes given in Specifi-

extent referenced herein.

cation B 258. In specifying diameters of wire or in inspecting wire,

2.2 ASTM Standards:

express the diameter to the fourth decimal place. The diameters preceded

by asterisks are not in the American Wire Gage series and are also given

B 193 Test Method for Resistivity of Electrical Conductor

2

to four places of decimals. They correspond to certain numbers of the

Materials

Birmingham Wire Gage of the British Standard Wire Gage and are used

B 258 Specification for Standard Nominal Diameters and

for communication lines. The use of gage numbers in specifying wire sizes

Cross-Sectional Areas of AWG Sizes of Solid Round Wires

is not recognized in these specifications because of the possibility of

2

Used as Electrical Conductors

confusion. An excellent discussion of wire gages and related subjects is

2.3 National Institute of Standards and Technology:

contained in NBS Handbook 100 of the National Institute of Standards and

3

3

NBS Handbook 100—Copper Wire Tables Technology.

5.2 Within the range of diameters included in Table 1, the

3. Ordering Information

wire shall not vary from the specified diameter by more than

3.1 Orders for material under this specification shall include

the following amounts rounded off to the nearest 0.1 mil

the following information:

(0.0001 in.):

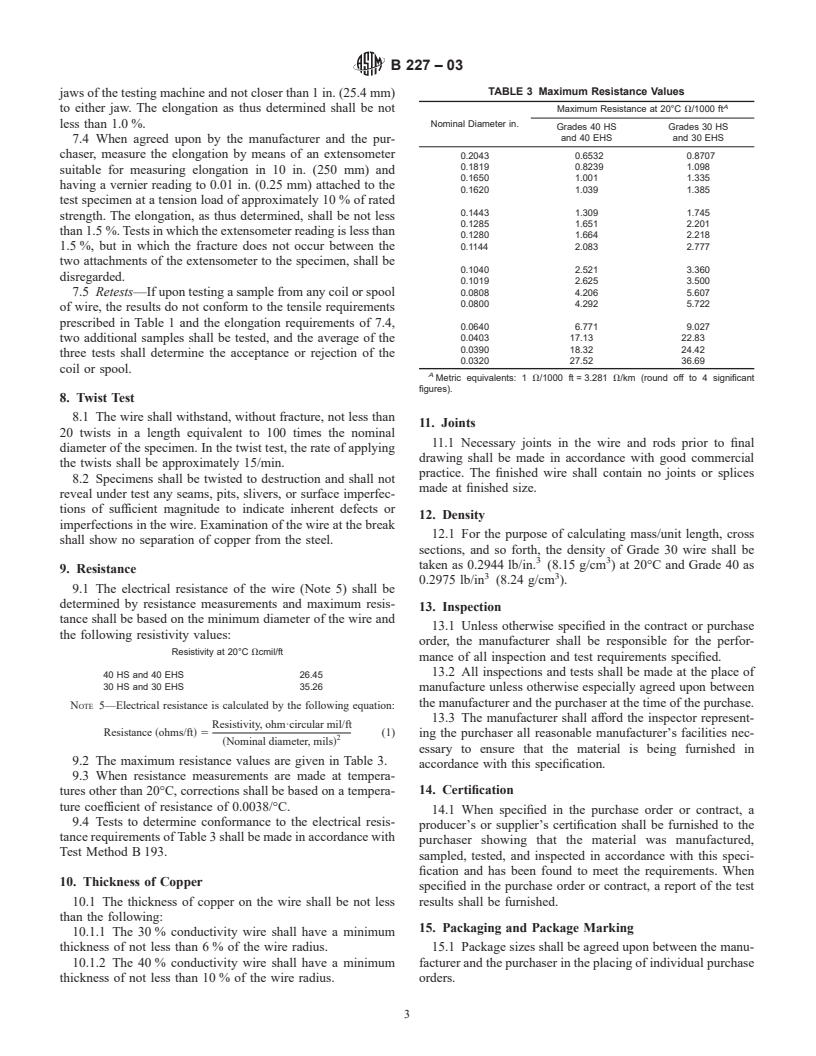

Specified Diameter, Permissible Variations in Specified

in. (mm) Diameter

1

This specification is under the jurisdiction of the ASTM Committee B01 on

Electrical Conductors and is the direct responsibility of Subcommittee B01.06 on

0.2043 (5.189) to 0.1000 (2.540), incl 61.5 %

Composite Conductors.

0.0999 (2.537) to 0.0800 (2.032), incl 60.0015 in. (1.5 mils) (0.038 mm)

Current edition approved October 1, 2003. Published October 2003. Originally

0.799 (2.029) to 0.0600 (1.524), incl +0.0010 in. (1.0 mils) (0.025 mm)

approved in 1948. Last previous edition approved in 2002 as B 227 – 02.

–0.0015 in. (1.5 mils) (0.038 mm)

2

Annual Book of ASTM Standards, Vol 02.03. 0.0599 (1.521) and under 60.0010 in. (1.0 mils) (0.025 mm)

3

Available from National Institute of Standards and Technology, (NIST),

Gaithersburg, MD 20899.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 227–03

TABLE 1 Tensile Requirements

A

Area at 20°C Tensile Strength, min, psi

Nominal Diameter,

2,A

cmil in. Grade 40 G

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.