ASTM F2454-05

(Practice)Standard Practice for Sealing Lateral Connections and lines from the mainline Sewer Systems by the Lateral Packer Method, Using Chemical Grouting

Standard Practice for Sealing Lateral Connections and lines from the mainline Sewer Systems by the Lateral Packer Method, Using Chemical Grouting

SIGNIFICANCE AND USE

The inspection, testing, and repair of lateral connections for sanitary sewers are regular practice necessary for the maintenance and optimal performance of the system. It is important to identify methods that use the most current compounds and technology to ensure the reduction of infiltration and exfiltration. It is important to minimize disruption to traffic and lessen the environmental impacts for both the municipal and private owners.

This practice serves as a means to inspect, test, and seal sewer lateral connections and a predetermined portion of the lateral lines from the mainline sewer, having selected the appropriate chemical grouts using the lateral packer method. Television (or optical) inspection and sewer lateral connection testing are used to assess the condition and document any repairs.

This practice should not be used where mainline and lateral connections are found with longitudinally cracked pipe, structurally unsound pipe, or flattened or out of round pipe.

SCOPE

1.1 This practice covers the procedures for testing and sealing sewer lateral connections and lateral lines from the mainline sewer with appropriate chemical grouts using the lateral packer method. Chemical grouting is used to stop infiltration of ground water and exfiltration of sewage in gravity flow sewer systems that are structurally sound.

1.2 This practice applies to mainline sewer diameters of 6 to 24 in. with 4, 5, or 6 in. diameter laterals. Larger diameter pipes with lateral connections and lines can be grouted with special packers or man-entry methods. The mainline and lateral pipes must be structurally adequate to create an effective seal.

1.3 Worker safety training should include reviewing the biohazards and gases from sewage, confined spaces, pumping equipment, and related apparatus. Additional safety considerations including proper handling, mixing, and transporting of chemical grouts should be provided by the chemical grout manufacturer or supplier, or both. Their safe operating practices and procedures should describe in detail appropriate personal protective equipment (PPE) for the various grouting operations. Operations covered should include the proper storage, transportation, mixing, and disposal of chemical grouts, additives, and their associated containers.

1.4 The values stated in inch/pound units are to be regarded as the standard. The values in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:F2454–05

Standard Practice for

Sealing Lateral Connections and lines from the mainline

Sewer Systems by the Lateral Packer Method, Using

Chemical Grouting

This standard is issued under the fixed designation F2454; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Theinfiltrationofwaterinsanitarysewersystemsthroughthelateralserviceconnectionandthefirst

few joints of the lateral below the groundwater table is a major problem for collection system owners.

The combined length of the lateral services often exceeds the length of the mainline sewers. Often, the

lateral services have been built with little or no supervision and little or no above-ground access for

monitoring and inspection.

1. Scope responsibility of the user of this standard to establish appro-

priate safety and health practices and to determine the

1.1 This practice covers the procedures for testing and

applicability of regulatory limitations prior to use.

sealing sewer lateral connections and lateral lines from the

mainline sewer with appropriate chemical grouts using the

2. Referenced Documents

lateral packer method. Chemical grouting is used to stop

2.1 ASTM Standards:

infiltration of ground water and exfiltration of sewage in

F2304 Practice for Rehabilitation of Sewers Using Chemi-

gravity flow sewer systems that are structurally sound.

cal Grouting

1.2 Thispracticeappliestomainlinesewerdiametersof6to

2.2 Other Documents:

24in.with4,5,or6in.diameterlaterals.Largerdiameterpipes

NASSCO Specification Guidelines, 2003, Wastewater Col-

with lateral connections and lines can be grouted with special

lection System Maintenance and Rehabilitation

packers or man-entry methods. The mainline and lateral pipes

must be structurally adequate to create an effective seal.

3. Significance and Use

1.3 Worker safety training should include reviewing the

3.1 The inspection, testing, and repair of lateral connections

biohazards and gases from sewage, confined spaces, pumping

for sanitary sewers are regular practice necessary for the

equipment, and related apparatus. Additional safety consider-

maintenance and optimal performance of the system. It is

ations including proper handling, mixing, and transporting of

important to identify methods that use the most current

chemical grouts should be provided by the chemical grout

compounds and technology to ensure the reduction of infiltra-

manufacturer or supplier, or both. Their safe operating prac-

tion and exfiltration. It is important to minimize disruption to

tices and procedures should describe in detail appropriate

traffic and lessen the environmental impacts for both the

personal protective equipment (PPE) for the various grouting

municipal and private owners.

operations. Operations covered should include the proper

3.2 This practice serves as a means to inspect, test, and seal

storage, transportation, mixing, and disposal of chemical

sewer lateral connections and a predetermined portion of the

grouts, additives, and their associated containers.

lateral lines from the mainline sewer, having selected the

1.4 The values stated in inch/pound units are to be regarded

appropriate chemical grouts using the lateral packer method.

as the standard. The values in parentheses are for information

Television (or optical) inspection and sewer lateral connection

only.

testing are used to assess the condition and document any

1.5 This standard does not purport to address all of the

repairs.

safety concerns, if any, associated with its use. It is the

1 2

This practice is under the jurisdiction ofASTM Committee F36 on Technology For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and Underground Utilities and is the direct responsibility of Subcommittee F36.20 contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

on Inspection and Renewal of Water and Wastewater Infrastructure. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Feb. 1, 2005. Published February 2005. DOI: 10.1520/ the ASTM website.

F2454-05. AvailablefromNASSCO,1314BedfordAve.,Suite201Baltimore,MD21208.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2454–05

3.3 This practice should not be used where mainline and other data relative to the project, such as, maps, drawings,

lateral connections are found with longitudinally cracked pipe, construction specifications sewer system records, and so forth.

structurally unsound pipe, or flattened or out of round pipe.

4.1.13 Authorization, to perform work that must be per-

formed during nighttime hours, on weekends, or on holidays.

4. Contract Responsibilities 4.1.14 Traffıc Control, by uniformed officers when the

safety of workers or the public requires such protection, or as

4.1 The lateral connection sealing contracts should define or

may be specified.

affix responsibility for, or make provisions for, the following

4.1.15 The contractor shall certify that backup equipment is

items:

available and can be delivered to the site within 48 hours.

4.1.1 Notice Of Client/Owner Requirements, which are

4.1.16 Submitequipmentutilizationscheduletotheowner’s

relevant to, and within the scope of, work to be performed

representative for review and approval prior to commencement

under the contract.

of the project.

4.1.2 Municipal And Other Licenses And Permits, (see

4.1.17 Submitequipmentoperatingproceduresandsystems

F2304) and assistance in obtaining approvals or consent from

to the owner’s representative for review and approval prior to

utilities or carriers or other persons or organizations upon

commencement of the project.

whose property or authority might be impinged by the perfor-

mance of work under the contract; or a written release from

5. Chemical Grouts (Chemical Sealing Materials)

responsibilityfortheperformanceofworkunderthecontractif

and to the extent that such work is precluded by the inability to

5.1 Intent—The intent of this section is to define the

obtain approvals or consent. If working on private property properties that a chemical sealing material must have to

permission from the owner’s representative, the sewer line

perform effectively in the intended application and under

owner and the building department. expected field conditions. The intended application is remotely

4.1.3 Access To Site Of Work, to be provided to the extent sealing sewer lateral connections and a predetermined portion

that the owner is legally able to do so, if unable to, a written of the lateral from the connection to the mainline sewer with a

release from responsibility for the performance of work at sites lateral packer as specified in Section 12.

where access cannot be made available. 5.1.1 Generic chemical sealing materials currently in use

4.1.4 Clearances of Blockages or Obstructions, in the sewer are listed in 5.3 with the basic properties, performance stan-

system, if any, if such clearance is required for performance of dards, and mix ratios, which are known to give acceptable

work under the contract and if such clearance is not otherwise performance.

provided for within the contract.

5.1.2 It is recognized that new and improved chemical

4.1.5 Location and Exposure of All Manholes, unless other- sealing materials will become available from time to time.

wiseprovidedforinthetechnicalspecificationsofthecontract. Sources, manufacturers, and product names of chemical seal-

ing materials will thus change, and therefore; specific sources,

4.1.6 A Manhole Numbering System , for all areas of the

project, and accurate manhole invert elevations when required manufacturers, and product names are not given.

for performance of the work. 5.1.3 In every case, mixing and handling of chemical

sealing materials shall be in accordance with the manufactur-

4.1.7 The Shutdown or Manual Operation of Certain Pump

er’s or supplier’s, or both, recommendations.

Stations, if such becomes necessary for performance of the

5.2 General—All chemical-sealing materials used in the

work.

performance of the work specified must have the following

4.1.8 Water, necessary for performance of work under the

characteristics:

contract, with permission to use water from fire hydrants at the

5.2.1 While being injected, the chemical sealant must be

site of work, or other suitable designated sources within a

reasonable distance from work areas. able to react/perform in the presence of water (groundwater).

4.1.9 Disposal Area , for all materials removed from the 5.2.2 The cured material must withstand submergence in

water without degradation.

sewers during the performance of the work and the unencum-

bered right of the contractor to transport and expeditiously 5.2.3 The resultant chemical grout formation must prevent

disposeofsuchmaterialsatalocationdesignatedbytheowner. the passage of groundwater (infiltration) through the surround-

4.1.10 A Secure Storage Area, of a size adequate to accom- ing soil ring, the sewer lateral connection, and the joints within

the predetermined portion of the lateral from the lateral

modate the required vehicles, equipment, and materials for the

period of the contract. connection to the mainline sewer.

4.1.11 Notice To Third Parties, (such as utilities) of the 5.2.4 The sealant material, after curing, must be flexible as

opposed to brittle.

contractor’s intent to perform work in an area where such

parties may have rights to underground property or facilities. 5.2.5 The cured sealant must not be biodegradable.

Request for maps or other descriptive information as to the 5.2.6 The cured sealant should be chemically stable and

nature and location of such underground facilities or property resistant to the mild concentrations of acids, alkalis, and

and assurance of the contractor’s ability to enter any public or organics found in normal sewage.

privatelandstowhichaccessisrequiredforperformanceofthe

5.2.7 Packaging of component materials must be compat-

work under the contract. ible with field storage and handling requirements. Packaging

4.1.12 Information Pertinent To The Site, including reports must provide for worker safety and proper clean up procedures

preparedunderpreviouslyaccomplishedstudiesorsurveysand should spillage occur.

F2454–05

5.2.8 Measurement of the component materials being mixed 5.3.3.6 A relatively rapid viscosity increase of the

must be compatible with field operations not requiring precise prepolymer/water mix. Viscosity should increase rapidly in the

measurements of the ingredients by field personnel. first minute for 1 to 8 prepolymer/water ratio at 50°F.

5.2.9 Cleanup must be done without inordinate use of 5.3.3.7 Areaction(curing)thatproducesachemicallystable

and non-biodegradable, tough, flexible gel.

flammable or hazardous chemicals.

5.2.10 Residual sealing materials must be easily removable 5.3.3.8 The ability to increase mix viscosity, density, gel

strength, and resistance and shrinkage by the use of additives.

from the sewer line to correct conditions that affect the sewage

flow.

6. Optional Additives

5.3 Chemical Sealing Materials—The following is a ge-

6.1 Additives enhance the performance of the chemical

neric listing of chemical sealing materials currently in use and

sealing materials and can be used for specific applications.

the basic requirements, properties, and characteristics of each:

Owner’s Representative should consult with grout manufactur-

5.3.1 Acrylamide base gel:

ers to determine appropriate additives.

5.3.1.1 A minimum of 10 % acrylamide base material by

weight in total sealant mix. A higher concentration of acryla-

7. Sewer Line Cleaning Procedures

mide base material may be used to increase strength or offset

7.1 The intent of sewer line cleaning is to remove foreign

dilution during injection.

materials from the lines to obtain proper seating of the packer.

5.3.1.2 The ability to tolerate some dilution and react in

Refer to Nassco Specification Guidelines.

moving water during injection.

5.3.1.3 A viscosity of approximately 2 centipoise, which

8. Sewer Flow Control

can be increased with additives.

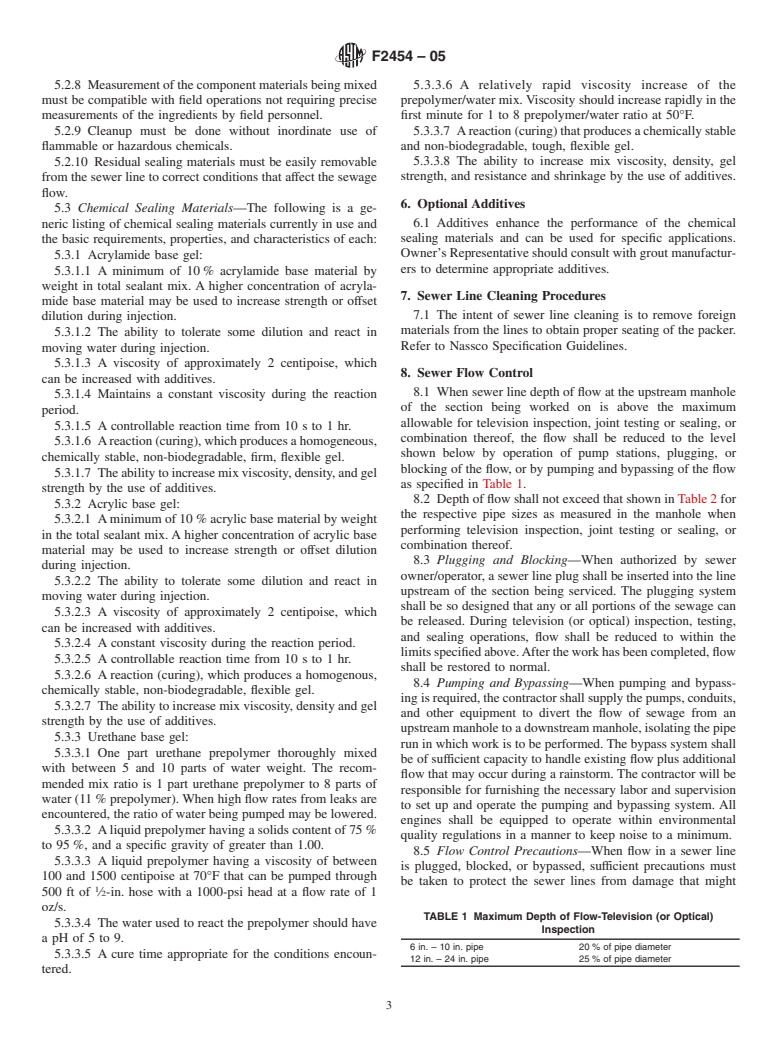

8.1 When sewer line depth of flow at the upstream manhole

5.3.1.4 Maintains a constant viscosity during the reaction

of the section being worked on is above the maximum

period.

allowable for television inspection, joint testing or sealing, or

5.3.1.5 A controllable reaction time from 10 s to 1 hr.

combination thereof, the flow shall be reduced to the level

5.3.1.6 Areaction(curing),whichproducesahomogeneous,

shown below by operation of pump stations, plugging, or

chemically stable, non-biodegradable, firm, flexible gel.

blocking of the flow, or by pumping and bypassing of the flow

5.3.1.7 Theabilitytoincreasemixviscosity,density,andgel

as specified in Table 1.

strength by the use of additives.

8.2 Depth of flow shall not exceed that shown inTable 2 for

5.3.2 Acrylic base gel:

the respective pipe sizes as measured in the manhole when

5.3.2.1 Aminimum of 10 % acrylic base material by weight

performing television inspection, joint testing or sealing, or

in the total sealant mix.Ahigher concentration of acrylic base

combination thereof.

material may be used to increase strength or offset dilution

8.3 Plugging and Blocking—When authorized by sewer

during injection.

owner/operator, a sewer line plug shall be inserted into the line

5.3.2.2 The ability to tolerate some dilution and react in

upstream of the section being serviced. The plugging system

moving water during injection.

shall be so designed that any or all portions of the sewage can

5.3.2.3 A viscosity of approximately 2 centipoise, which

be released. During television (or optical) inspection, testing,

can be increased with additives.

and sealing operations, flow shall be reduced to within the

5.3.2.4 A constant viscosity during the reaction period.

limitsspecifiedabove.Aftertheworkhasbeencompleted,flow

5.3.2.5 A controllable reaction time from 10 s to 1 hr.

shall be restored to normal.

5.3.2.6 A reaction (curing), which produces a homogenous,

8.4 Pumping and Bypassing—When pumping and bypass-

chemically stable, non-biodegradable, flexible gel.

ingisrequired,thecontractorshallsupplythepumps,conduits,

5.3.2.7 The ability to increase mix viscosity, density and gel

and other equipment to divert the flow of sewage from an

strength by the use of additives.

upstream manhole to a downstream manhole, isolating the pipe

5.3.3 Urethane base gel:

run in which work is to be performed. The bypass system s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.