ASTM D5031-01(2006)

(Practice)Standard Practice for Enclosed Carbon-Arc Exposure Tests of Paint and Related Coatings

Standard Practice for Enclosed Carbon-Arc Exposure Tests of Paint and Related Coatings

SCOPE

1.1 This practice covers the selection of test conditions for accelerated exposure testing of coatings and related products in enclosed carbon arc devices operated according to Practices G 151 and G 153. This practice also covers the preparation of test specimens, the test conditions suited for coatings, and the evaluation of test results. describes commonly used test conditions.Note 1

Previous versions of this practice referenced carbon arc devices described by Practice G 23, which described very specific equipment designs. Practice G 23 has been withdrawn and replaced by Practice G 151, which describes performance criteria for all exposure devices that use laboratory light sources, and by Practice G 153, which gives requirements for exposing nonmetallic materials in enclosed carbon-arc devices.

1.2 This practice does not cover filtered open-flame carbon-arc exposures of paints and related coatings, which is described in Practice D 822. Another procedure for exposing these products is covered by Practice D 3361, in which the specimens are subjected to radiation from an unfiltered open-flame carbon arc that produces shorter wavelengths and higher levels of short wavelength radiation than filtered open flame or enclosed carbon arcs.Note 2

Practice D 3361 requires use of open-flame carbon-arc apparatus with automatic humidity control.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5031 − 01 (Reapproved2006)

Standard Practice for

Enclosed Carbon-Arc Exposure Tests of Paint and Related

Coatings

This standard is issued under the fixed designation D5031; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This practice covers the selection of test conditions for 2.1 ASTM Standards:

acceleratedexposuretestingofcoatingsandrelatedproductsin D358 Specification for Wood to Be Used as Panels in

enclosed carbon arc devices operated according to Practices Weathering Tests of Coatings

G151 and G153. This practice also covers the preparation of D523 Test Method for Specular Gloss

test specimens, the test conditions suited for coatings, and the D609 Practice for Preparation of Cold-Rolled Steel Panels

evaluationoftestresults.Table1describescommonlyusedtest for Testing Paint, Varnish, Conversion Coatings, and

conditions. Related Coating Products

D610 Practice for Evaluating Degree of Rusting on Painted

NOTE 1—Previous versions of this practice referenced carbon arc

Steel Surfaces

devices described by Practice G23, which described very specific equip-

D659 Method for Evaluating Degree of Chalking of Exterior

ment designs. Practice G23 has been withdrawn and replaced by Practice

G151, which describes performance criteria for all exposure devices that

Paints (Withdrawn 1990)

use laboratory light sources, and by Practice G153, which gives require-

D660 Test Method for Evaluating Degree of Checking of

ments for exposing nonmetallic materials in enclosed carbon-arc devices.

Exterior Paints

1.2 This practice does not cover filtered open-flame carbon-

D662 Test Method for Evaluating Degree of Erosion of

arcexposuresofpaintsandrelatedcoatings,whichisdescribed

Exterior Paints

in Practice D822. Another procedure for exposing these prod-

D714 Test Method for Evaluating Degree of Blistering of

ucts is covered by Practice D3361, in which the specimens are

Paints

subjected to radiation from an unfiltered open-flame carbon arc

D772 Test Method for Evaluating Degree of Flaking (Scal-

that produces shorter wavelengths and higher levels of short

ing) of Exterior Paints

wavelength radiation than filtered open flame or enclosed

D822 Practice for Filtered Open-Flame Carbon-Arc Expo-

carbon arcs.

sures of Paint and Related Coatings

D823 Practices for Producing Films of Uniform Thickness

NOTE 2—Practice D3361 requires use of open-flame carbon-arc appa-

of Paint, Varnish, and Related Products on Test Panels

ratus with automatic humidity control.

D1005 Test Method for Measurement of Dry-Film Thick-

1.3 The values stated in SI units are to be regarded as the

ness of Organic Coatings Using Micrometers

standard. The values given in parentheses are for information

D1186 Test Methods for Nondestructive Measurement of

only.

Dry Film Thickness of Nonmagnetic Coatings Applied to

1.4 This standard does not purport to address all of the 3

a Ferrous Base (Withdrawn 2006)

safety concerns, if any, associated with its use. It is the

D1400 TestMethodforNondestructiveMeasurementofDry

responsibility of the user of this standard to establish appro-

Film Thickness of Nonconductive Coatings Applied to a

priate safety and health practices and determine the applica- 3

Nonferrous Metal Base (Withdrawn 2006)

bility of regulatory limitations prior to use.

1 2

This practice is under the jurisdiction of ASTM Committee D01 on Paint and For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Related Coatings, Materials, and Applications and is the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D01.27 on Accelerated Testing. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Nov. 1, 2006. Published November 2006. Originally the ASTM website.

approved in 1989. Last previous edition approved in 2001 as D5031 – 01. DOI: The last approved version of this historical standard is referenced on

10.1520/D5031-01R06. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5031 − 01 (2006)

A

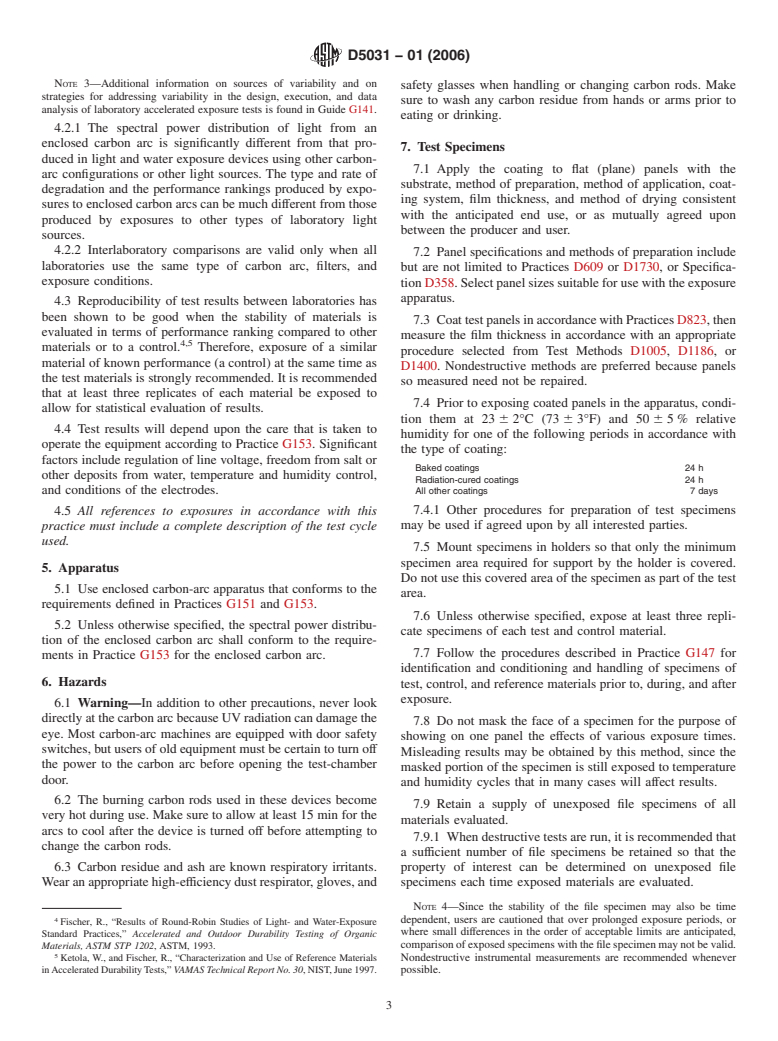

TABLE 1 Test Cycles Commonly Used for Enclosed Carbon-Arc Exposure Testing of Paints and Related Coatings

Uninsulated Black

B

Panel Temperature

C

Cycle Number Cycle Description (°C) (°F) Typical Uses

E

1 Continuous light 63 ± 2.5 145 ± 5 General coatings and historical convention

102 min light only at 50 ± 5 % RH

D

18 min light and water spray

Repeated continuously

2 18 h continuous light using: 63±2.5 145±5 General coatings

102 min light only at 50 ± 5 % RH 24±1.5 75±3

18 min light and water spray

6 h dark using:

95 % relative humidity (no water spray)

Repeated continuously

3 48min light at 50±5%RH 63 ± 2.5 145 ± 5 Coatings used in original equipment manufacturing

12 min light and water spray

Repeated continuously

4 4hlight at 50±5%RH 63 ± 2.5 145 ± 5 Exterior pigmented stains

4 h dark with water spray

Repeated continuously

5 12hlight at 50±5%RH 63 ± 2.5 145 ± 5 Exterior wood stains and clears

12 h dark water spray

Repeated continuously

6 8hlight at 50±5%RH 63 ± 2.5 145 ± 5 Marine enamels

10 h light and water spray

6 h dark with water spray

Repeated continuously

A

The cycles described are not listed in any order indicating importance, and are not necessarily recommended for the applications listed.

B

Unless otherwise indicated, black panel temperatures apply during the light-only portion of the cycle. The equilibrium black panel temperature is obtained without a spray

period. For light intervals less than 30 min, the black panel temperature might not reach equilibrium.

C

Typical uses do not imply that results from exposures of these materials according to the cycle described will correlate to those from actual use conditions.

D

Unless otherwise specified, water spray refers to water sprayed on the exposed surfaces of the test specimens.

E

Historical convention has established this as a very commonly used test cycle. This cycle may not adequately simulate the effects of outdoor exposure.

D1729 Practice for Visual Appraisal of Colors and Color G151 Practice for Exposing Nonmetallic Materials inAccel-

Differences of Diffusely-Illuminated Opaque Materials erated Test Devices that Use Laboratory Light Sources

D1730 Practices for Preparation of Aluminum and G152 Practice for Operating Open Flame Carbon Arc Light

Aluminum-Alloy Surfaces for Painting Apparatus for Exposure of Nonmetallic Materials

D2244 Practice for Calculation of Color Tolerances and G153 Practice for Operating Enclosed Carbon Arc Light

Color Differences from Instrumentally Measured Color Apparatus for Exposure of Nonmetallic Materials

Coordinates G169 Guide for Application of Basic Statistical Methods to

D2616 Test Method for Evaluation of Visual Color Differ- Weathering Tests

ence With a Gray Scale

3. Terminology

D3361 Practice for Unfiltered Open-Flame Carbon-Arc Ex-

3.1 The definitions given in Terminology G113 are appli-

posures of Paint and Related Coatings

cable to this practice.

D3980 Practice for Interlaboratory Testing of Paint and

Related Materials (Withdrawn 1998)

4. Significance and Use

D4214 Test Methods for Evaluating the Degree of Chalking

4.1 The ability of a paint or coating to resist deterioration of

of Exterior Paint Films

its physical and optical properties caused by exposure to light,

D5870 Practice for Calculating Property Retention Index of

heat, and water can be very significant for many applications.

Plastics

This practice is intended to induce property changes associated

E691 Practice for Conducting an Interlaboratory Study to

with end-use conditions, including the effects of sunlight,

Determine the Precision of a Test Method

moisture, and heat. The exposure used in this practice is not

E1347 Test Method for Color and Color-Difference Mea-

intended to simulate the deterioration caused by localized

surement by Tristimulus Colorimetry

weather phenomena such as atmospheric pollution, biological

G23 Practice for Operating Light-Exposure Apparatus

attack, and saltwater exposure.

(Carbon-Arc Type) With and Without Water for Exposure

of Nonmetallic Materials (Withdrawn 2000) 4.2 Cautions—Variation in results may be expected when

G113 Terminology Relating to Natural andArtificial Weath- different operating conditions are used.Therefore, no reference

ering Tests of Nonmetallic Materials to the use of this practice shall be made unless accompanied by

G141 Guide for Addressing Variability in Exposure Testing a report prepared according to Section 10 that describes the

of Nonmetallic Materials specific operating conditions used. Refer to Practice G151 for

G147 Practice for Conditioning and Handling of Nonmetal- detailed information on the caveats applicable to use of results

lic Materials for Natural and Artificial Weathering Tests obtained according to this practice.

D5031 − 01 (2006)

NOTE 3—Additional information on sources of variability and on

safety glasses when handling or changing carbon rods. Make

strategies for addressing variability in the design, execution, and data

sure to wash any carbon residue from hands or arms prior to

analysis of laboratory accelerated exposure tests is found in Guide G141.

eating or drinking.

4.2.1 The spectral power distribution of light from an

enclosed carbon arc is significantly different from that pro-

7. Test Specimens

duced in light and water exposure devices using other carbon-

7.1 Apply the coating to flat (plane) panels with the

arc configurations or other light sources. The type and rate of

substrate, method of preparation, method of application, coat-

degradation and the performance rankings produced by expo-

ing system, film thickness, and method of drying consistent

sures to enclosed carbon arcs can be much different from those

with the anticipated end use, or as mutually agreed upon

produced by exposures to other types of laboratory light

between the producer and user.

sources.

4.2.2 Interlaboratory comparisons are valid only when all

7.2 Panel specifications and methods of preparation include

laboratories use the same type of carbon arc, filters, and

but are not limited to Practices D609 or D1730, or Specifica-

exposure conditions.

tion D358. Select panel sizes suitable for use with the exposure

apparatus.

4.3 Reproducibility of test results between laboratories has

been shown to be good when the stability of materials is

7.3 CoattestpanelsinaccordancewithPracticesD823,then

evaluated in terms of performance ranking compared to other

measure the film thickness in accordance with an appropriate

4,5

materials or to a control. Therefore, exposure of a similar

procedure selected from Test Methods D1005, D1186,or

material of known performance (a control) at the same time as

D1400. Nondestructive methods are preferred because panels

the test materials is strongly recommended. It is recommended

so measured need not be repaired.

that at least three replicates of each material be exposed to

7.4 Prior to exposing coated panels in the apparatus, condi-

allow for statistical evaluation of results.

tion them at 23 6 2°C (73 6 3°F) and 50 6 5 % relative

4.4 Test results will depend upon the care that is taken to

humidity for one of the following periods in accordance with

operate the equipment according to Practice G153. Significant

the type of coating:

factors include regulation of line voltage, freedom from salt or

Baked coatings 24 h

other deposits from water, temperature and humidity control,

Radiation-cured coatings 24 h

and conditions of the electrodes. All other coatings 7 days

7.4.1 Other procedures for preparation of test specimens

4.5 All references to exposures in accordance with this

may be used if agreed upon by all interested parties.

practice must include a complete description of the test cycle

used.

7.5 Mount specimens in holders so that only the minimum

specimen area required for support by the holder is covered.

5. Apparatus

Do not use this covered area of the specimen as part of the test

5.1 Use enclosed carbon-arc apparatus that conforms to the

area.

requirements defined in Practices G151 and G153.

7.6 Unless otherwise specified, expose at least three repli-

5.2 Unless otherwise specified, the spectral power distribu-

cate specimens of each test and control material.

tion of the enclosed carbon arc shall conform to the require-

7.7 Follow the procedures described in Practice G147 for

ments in Practice G153 for the enclosed carbon arc.

identification and conditioning and handling of specimens of

6. Hazards

test, control, and reference materials prior to, during, and after

exposure.

6.1 Warning—In addition to other precautions, never look

directly at the carbon arc because UVradiation can damage the

7.8 Do not mask the face of a specimen for the purpose of

eye. Most carbon-arc machines are equipped with door safety

showing on one panel the effects of various exposure times.

switches, but users of old equipment must be certain to turn off

Misleading results may be obtained by this method, since the

the power to the carbon arc before opening the test-chamber

masked portion of the specimen is still exposed to temperature

door.

and humidity cycles that in many cases will affect results.

6.2 The burning carbon rods used in these devices become

7.9 Retain a supply of unexposed file specimens of all

very hot during use. Make sure to allow at least 15 min for the

materials evaluated.

arcs to cool after the device is turned off before attempting to

7.9.1 When destructive tests are run, it is recommended that

change the carbon rods.

a sufficient number of file specimens be retained so that the

6.3 Carbon residue and ash are known respiratory irritants.

property of interest can be determined on unexposed file

Wearanappropriatehigh-efficiencydustrespirator,gloves,and specimens each time exposed materials are evaluated.

NOTE 4—Since the stability of the file specimen may also be time

dependent, users are cautioned that over prolonged exposure periods, or

Fischer, R., “Results of Round-Robin Studies of Light- and Water-Exposure

where small differences in the order of acceptable limits are anticipated,

Standard Practices,” Accelerated and Outdoor Durability Testing of Organic

comparisonofexposedspecimenswiththefilespecimenmaynotbevalid.

Materials, ASTM STP 1202, ASTM, 1993.

Ketola, W., and Fischer, R., “Characterization and Use of Reference Materials Nondestructive instrumental measurements are recommended

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.