ASTM G19-88(1996)e1

(Test Method)Standard Test Method for Disbonding Characteristics of Pipeline Coatings by Direct Soil Burial

Standard Test Method for Disbonding Characteristics of Pipeline Coatings by Direct Soil Burial

SCOPE

1.1 This test method describes the determination of the relative disbonding characteristics of damaged coatings on steel pipe by cathodic protection potentials in direct soil burial. This test method is intended to apply to the testing of all types of nonmetallic pipeline coatings and tapes including thermoplastics, thermoset, and bituminous materials.

1.2 Results may vary widely when test sites are in different geographical areas of the country, and even in different localities.

1.3 This test method is limited to nonconducting, or nonmetallic pipe coatings and is not applicable to conducting materials such as zinc coatings on steel pipe.

1.4 This test method may involve hazardous operations and equipment. This test method does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this test method to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 The values stated in SI units to three significant decimals are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:G19–88(Reapproved 1996)

Standard Test Method for

Disbonding Characteristics of Pipeline Coatings by Direct

Soil Burial

ThisstandardisissuedunderthefixeddesignationG19;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Keywords were added editorially in June 1996.

1. Scope removed, the exposed area measured, and comparisons are

made to other specimens similarly exposed.

1.1 This test method describes the determination of the

relative disbonding characteristics of damaged coatings on

4. Significance and Use

steelpipebycathodicprotectionpotentialsindirectsoilburial.

4.1 Coated pipe is seldom, if ever, buried without some

This test method is intended to apply to the testing of all types

damage to the coating. Hence, an actual soil-burial test can

of nonmetallic pipeline coatings and tapes including thermo-

contribute significant data, provided the method of testing is

plastics, thermoset, and bituminous materials.

controlledandthetestspecimenmonitoredandtherelationship

1.2 Results may vary widely when test sites are in different

betweentheareadisbonded,thecurrentdemand,andthemode

geographical areas of the country, and even in different

of failure is fully understood.

localities.

4.2 Means are provided for measuring and following the

1.3 This test method is limited to nonconducting, or non-

electrical potential and current flow and relating these data to

metallic pipe coatings and is not applicable to conducting

the final measurement of disbonded area.

materials such as zinc coatings on steel pipe.

1.4 This standard does not purport to address all of the

5. Apparatus

safety concerns, if any, associated with its use. It is the

5.1 Anode—A standard packaged magnesium anode, mini-

responsibility of the user of this standard to establish appro-

mum 4.082 kg (9 lb), with a factory-sealed, 4107-cmil (14-

priate safety and health practices and determine the applica-

gage Awg) minimum, insulated copper wire shall be used. A

bility of regulatory limitations prior to use.

solution potential of not less than−1.45 V with respect to a

1.5 The values stated in SI units to three significant deci-

copper-copper sulfate reference electrode is required. Use

mals are to be regarded as the standard. The values given in

sufficient anodes to maintain required potential.

parentheses are for information only.

5.2 Connectors—The wiring circuit from anode to test

specimen and from specimen to reference electrode should be

2. Referenced Documents

4107-cmil (14-gage Awg) minimum insulated copper wire.

2.1 ASTM Standards:

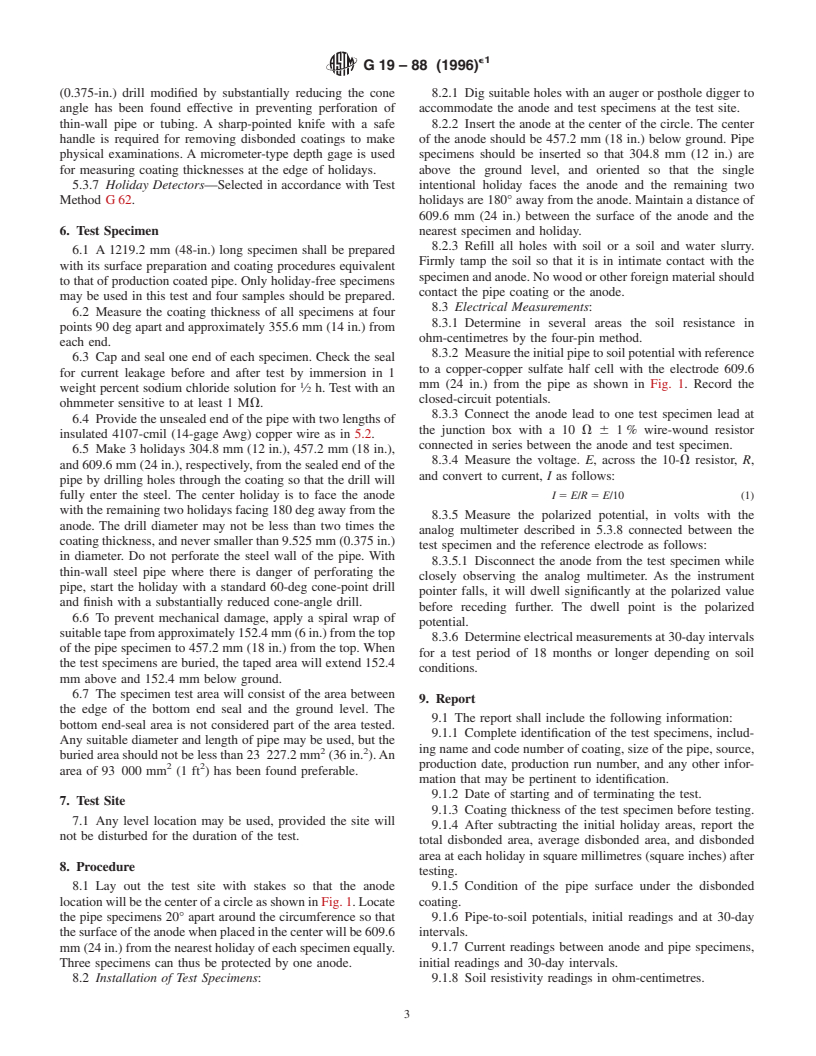

Attach the wires to the test specimen as shown in Fig. 1 by

G12 TestMethodforNondestructiveMeasurementofFilm

2 soldering or brazing at the air-exposed end, and coat the place

Thickness of Pipeline Coatings on Steel

of attachment with insulating material. A junction box is

G62 Test Methods for Holiday Detection in Pipeline Coat-

2 optionalforconnectingtheresistorinseriesbetweentheanode

ings

and the test specimen.

3. Summary of Test Method 5.3 The instruments used shall include the following:

5.3.1 Voltmeter, a suitable instrument such as a high imped-

3.1 Apparatus and materials are described whereby protec-

ance (>10mV) analog multimeter having a sensitivity of

tive coatings on steel pipe are subjected to disbonding by an

50 000V/ V minimum and a multiple range from 0.01 to 2 V

electrical stress. Specimens with intentionally damaged areas

for direct current is used for measuring the potential between

are buried in soil at an outdoor site and electrically connected

specimen and the reference electrode, current between speci-

to a magnesium anode. After test, the disbonded coating is

men and anode, and the resistance of the circuit. The same

instrument shall be used for measuring current between speci-

This test method is under the jurisdiction of ASTM Committee D-1 on Paint

men and anode. Alligator clips on the leads are permissible.

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.48 on Durability of Pipeline Coatings and Linings.

Current edition approved May 27, 1988. Published July 1988. Originally

published as G19–71T. Last previous edition G19–83. A pipe-to-soil Voltmeter-Ammeter, Agra Engineering Co., Tulsa, Okla., has

Annual Book of ASTM Standards, Vol 06.02. been found suitable for this test.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

G19–88 (1996)

FIG. 1 Three Specimens in a Circle with a Common Anode

5.3.2 Volt-Ohm-Meter for measuring resistance of the cir- 5.3.4 A suitable instrument is used to measure the soil

resistivity using the four-pin method. Pins should be spaced

cuit.

762 mm (30 in.) apart.

5.3.3 Reference Electrode, consisting of a copper-copper

5.3.5 Thickness Gages, to be used in accordance with Test

sulfate half cell in a conventional glass or plastic tube with

MethodG12.

porousplugconstruction,butpreferablynotover19.05mm( ⁄4

5.3.6 Holiday Tools—Holidays in the specimen are made

in.)indiameter,havingapotentialof−0.316Vwithrespectto

with conventional drills of the required diameter. A9.525-mm

a standard hydrogen electrode. A calomel electrode may be

used, but measurements made with it should be converted to

the copper-copper sulfate reference electrode for reporting, by

A Vibroground instrument, Associated Research Inc., 3758 Belmont Ave.,

adding−0.092 V to the observed reading. Chicago, Ill., has been found suitable for measuring soil resistivity.

e1

G19–88 (1996)

(0.375-in.) drill modified by substantially reducing the cone 8.2.1 Dig suitable holes with an auger or posthole digger to

angle has been found effective in preventing perforation of accommodate the anode and test specimens at the test site.

thin-wall pipe or tubing. A sharp-pointed knife with a safe 8.2.2 Insert the anode at the center of the circle. The center

handle is required for removing disbonded coatings to make of the anode should be 457.2 mm (18 in.) below ground. Pipe

physical examinations. A micrometer-type depth gage is used specimens should be inserted so that 304.8 mm (12 in.) are

for measuring coating thicknesses at the edge of holidays. above the ground level, and oriented so that the single

5.3.7 Holiday Detectors—Selected in accordance with Test intentional holiday faces the anode and the remaining two

MethodG

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.