ASTM D5514/D5514M-14

(Test Method)Standard Test Method for Large Scale Hydrostatic Puncture Testing of Geosynthetics

Standard Test Method for Large Scale Hydrostatic Puncture Testing of Geosynthetics

SIGNIFICANCE AND USE

4.1 Procedure A—This procedure is an index type test which can be used as a guide for acceptance of commercial shipments of geosynthetics. The standard cone and pyramid test fixtures can establish critical height (ch) consistency with similar material from previous lots or different suppliers, as well as testing from other laboratories. However, due to the time required to perform tests, it is generally not recommended for routine acceptance testing.

4.2 Procedures B and C—These procedures are performance tests intended as a design aid used to simulate the in-situ behavior of geosynthetics under hydrostatic compression. These test methods may assist a design engineer in comparing the ability of several candidate geosynthetic materials to conform to a site specific subgrade under specified use and conditions. In procedure B, the pressure is increased until a failure is observed. In procedure C, a given set of conditions (pressure, temperature and test duration) are maintained constant and the performance of the system is observed at the end of the test.

SCOPE

1.1 This test method evaluates the stress/time properties of geosynthetics by using hydrostatic pressure to compress the geosynthetic over synthetic or natural test bases consisting of manufactured test pyramids/cones, rocks, soil or voids.

1.2 This test method allows the user to determine the relative failure mode, points of failure for geosynthetics, or both.

1.3 This test method offers two distinct procedures.

1.3.1 Procedure A incorporates manufactured test pyramids or cones as the base of the testing apparatus. Procedure A is intended to create comparable data between laboratories, and can be used as a guide for routine acceptance test for various materials.

1.3.2 Procedures B and C incorporate site specific soil or other material selected by the user as the test base of the testing apparatus. Procedures B and C are methods for geosynthetic design for a specific site.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific warning statement, see Section 6.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5514/D5514M − 14

Standard Test Method for

1

Large Scale Hydrostatic Puncture Testing of Geosynthetics

This standard is issued under the fixed designation D5514/D5514M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

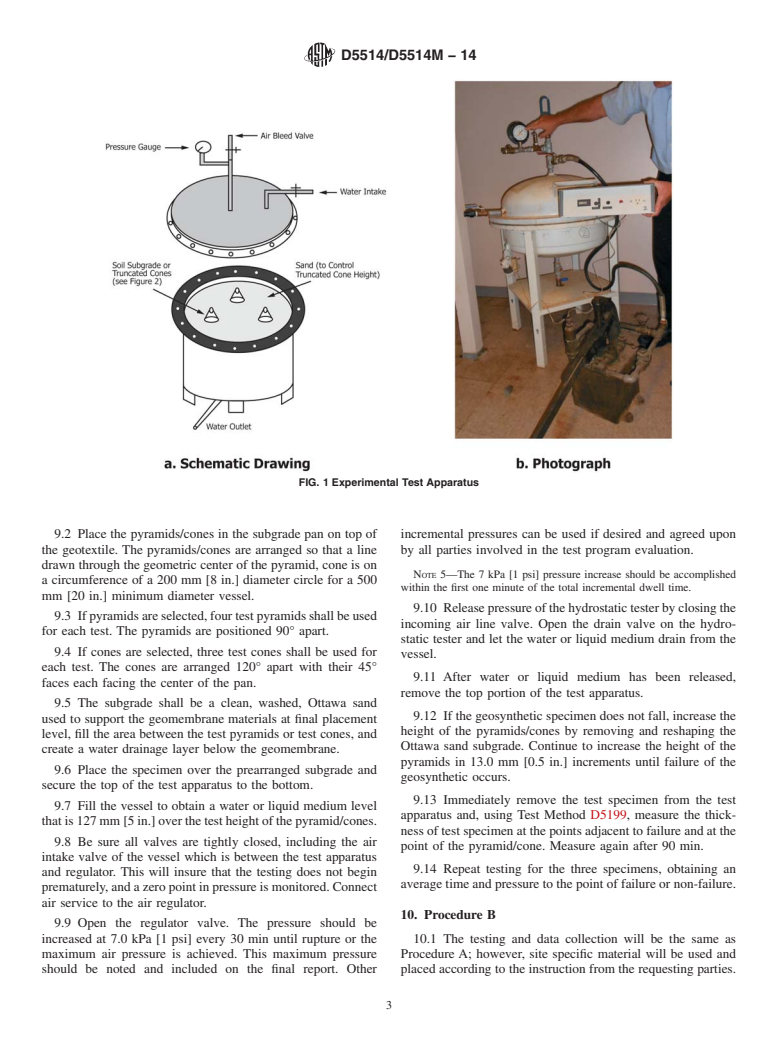

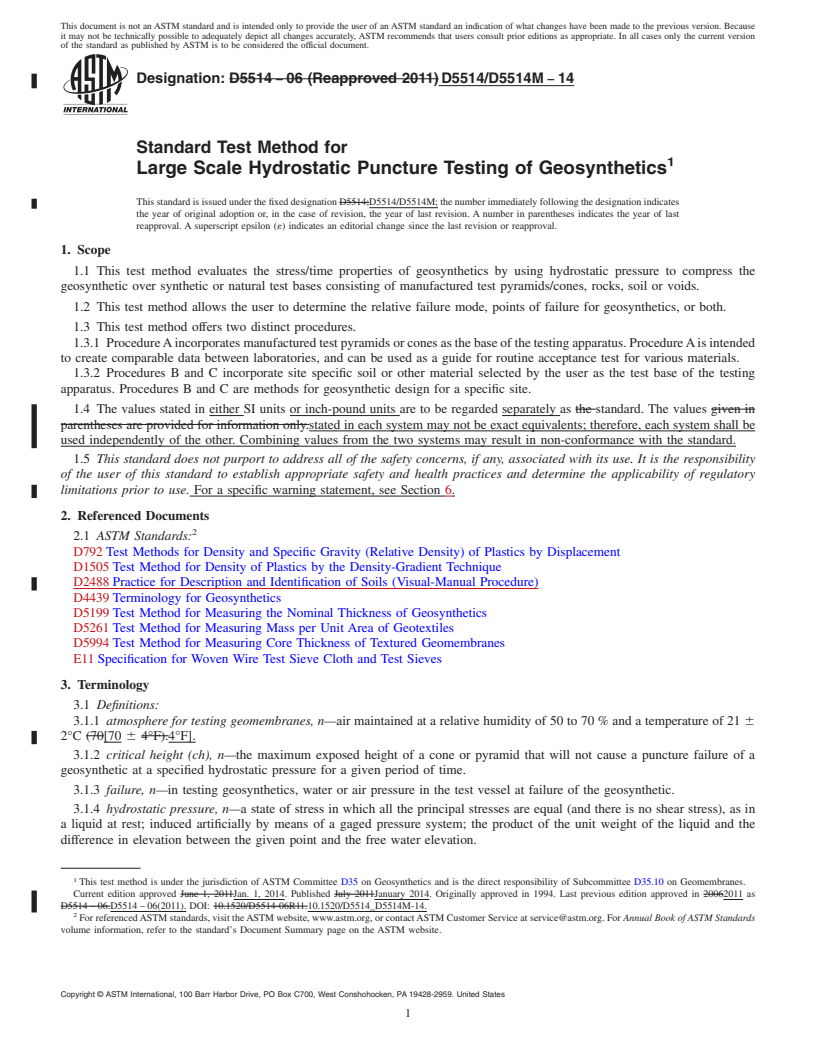

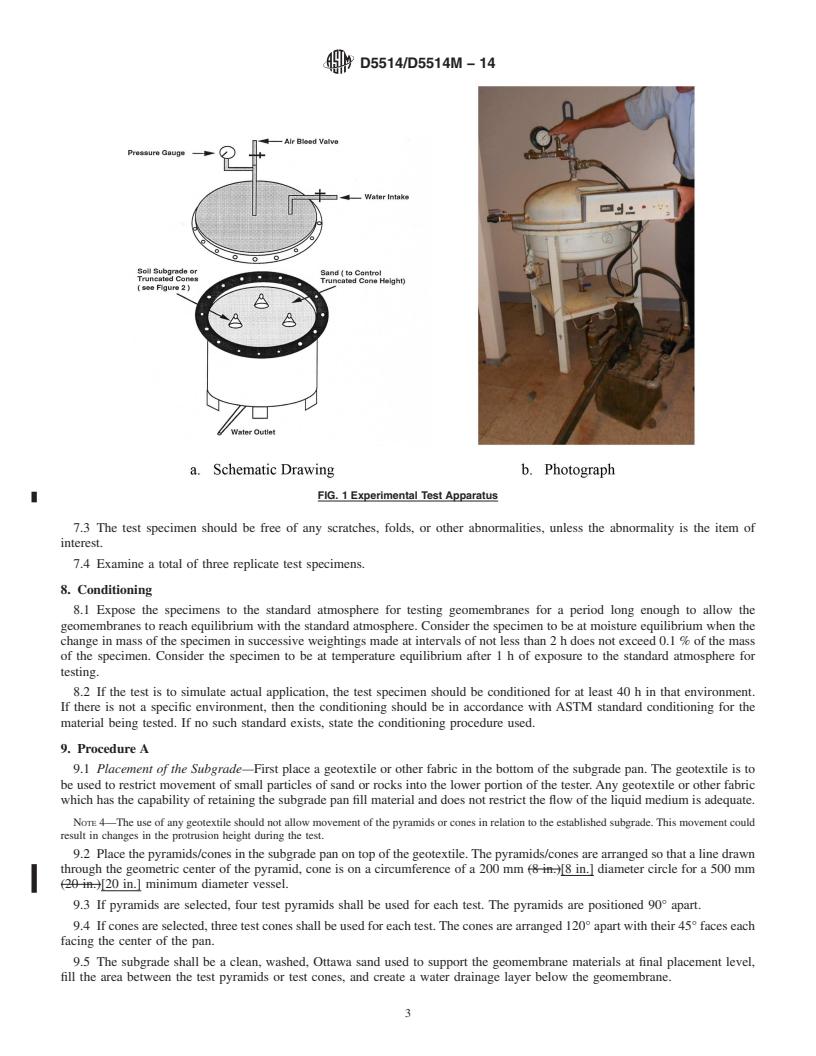

1. Scope D792Test Methods for Density and Specific Gravity (Rela-

tive Density) of Plastics by Displacement

1.1 This test method evaluates the stress/time properties of

D1505Test Method for Density of Plastics by the Density-

geosynthetics by using hydrostatic pressure to compress the

Gradient Technique

geosynthetic over synthetic or natural test bases consisting of

D2488Practice for Description and Identification of Soils

manufactured test pyramids/cones, rocks, soil or voids.

(Visual-Manual Procedure)

1.2 This test method allows the user to determine the

D4439Terminology for Geosynthetics

relative failure mode, points of failure for geosynthetics, or

D5199Test Method for Measuring the Nominal Thickness

both.

of Geosynthetics

D5261Test Method for Measuring Mass per Unit Area of

1.3 This test method offers two distinct procedures.

1.3.1 ProcedureAincorporates manufactured test pyramids Geotextiles

D5994Test Method for Measuring Core Thickness of Tex-

or cones as the base of the testing apparatus. Procedure A is

intended to create comparable data between laboratories, and tured Geomembranes

E11Specification forWovenWireTest Sieve Cloth andTest

can be used as a guide for routine acceptance test for various

materials. Sieves

1.3.2 Procedures B and C incorporate site specific soil or

3. Terminology

othermaterialselectedbytheuserasthetestbaseofthetesting

apparatus. Procedures B and C are methods for geosynthetic 3.1 Definitions:

design for a specific site.

3.1.1 atmosphere for testing geomembranes, n—air main-

tained at a relative humidity of 50 to 70% and a temperature

1.4 The values stated in either SI units or inch-pound units

of 21 6 2°C [70 6 4°F].

are to be regarded separately as standard. The values stated in

3.1.2 critical height (ch), n—the maximum exposed height

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining of a cone or pyramid that will not cause a puncture failure of

values from the two systems may result in non-conformance a geosynthetic at a specified hydrostatic pressure for a given

with the standard. period of time.

1.5 This standard does not purport to address all of the 3.1.3 failure, n—in testing geosynthetics, water or air pres-

sure in the test vessel at failure of the geosynthetic.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1.4 hydrostatic pressure, n—a state of stress in which all

priate safety and health practices and determine the applica-

the principal stresses are equal (and there is noshearstress),as

bility of regulatory limitations prior to use. For a specific

in a liquid at rest; induced artificially by means of a gaged

warning statement, see Section 6.

pressure system; the product of the unit weight of the liquid

and the difference in elevation between the given point and the

2. Referenced Documents

free water elevation.

2

2.1 ASTM Standards:

3.2 For definitions of other terms used in this test method,

refer to Terminology D4439.

1

This test method is under the jurisdiction of ASTM Committee D35 on

4. Significance and Use

GeosyntheticsandisthedirectresponsibilityofSubcommitteeD35.10onGeomem-

branes.

4.1 Procedure A—This procedure is an index type test

Current edition approved Jan. 1, 2014. Published January 2014. Originally

which can be used as a guide for acceptance of commercial

approved in 1994. Last previous edition approved in 2011 as D5514–06(2011).

DOI: 10.1520/D5514_D5514M-14.

shipments of geosynthetics. The standard cone and pyramid

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

test fixtures can establish critical height (ch) consistency with

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

similar material from previous lots or different suppliers, as

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. well as testing from other laboratories. However, due to the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5514/D5514M − 14

timerequiredtoperformtests,itisgenerallynotrecommended 6. Hazards

for routine acceptance testing.

6.1 Warning—In addition to other precautions, the tes

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5514 − 06 (Reapproved 2011) D5514/D5514M − 14

Standard Test Method for

1

Large Scale Hydrostatic Puncture Testing of Geosynthetics

This standard is issued under the fixed designation D5514;D5514/D5514M; the number immediately following the designation indicates

the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method evaluates the stress/time properties of geosynthetics by using hydrostatic pressure to compress the

geosynthetic over synthetic or natural test bases consisting of manufactured test pyramids/cones, rocks, soil or voids.

1.2 This test method allows the user to determine the relative failure mode, points of failure for geosynthetics, or both.

1.3 This test method offers two distinct procedures.

1.3.1 Procedure A incorporates manufactured test pyramids or cones as the base of the testing apparatus. Procedure A is intended

to create comparable data between laboratories, and can be used as a guide for routine acceptance test for various materials.

1.3.2 Procedures B and C incorporate site specific soil or other material selected by the user as the test base of the testing

apparatus. Procedures B and C are methods for geosynthetic design for a specific site.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as the standard. The values given in

parentheses are provided for information only.stated in each system may not be exact equivalents; therefore, each system shall be

used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For a specific warning statement, see Section 6.

2. Referenced Documents

2

2.1 ASTM Standards:

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

D1505 Test Method for Density of Plastics by the Density-Gradient Technique

D2488 Practice for Description and Identification of Soils (Visual-Manual Procedure)

D4439 Terminology for Geosynthetics

D5199 Test Method for Measuring the Nominal Thickness of Geosynthetics

D5261 Test Method for Measuring Mass per Unit Area of Geotextiles

D5994 Test Method for Measuring Core Thickness of Textured Geomembranes

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

3. Terminology

3.1 Definitions:

3.1.1 atmosphere for testing geomembranes, n—air maintained at a relative humidity of 50 to 70 % and a temperature of 21 6

2°C (70[70 6 4°F).4°F].

3.1.2 critical height (ch), n—the maximum exposed height of a cone or pyramid that will not cause a puncture failure of a

geosynthetic at a specified hydrostatic pressure for a given period of time.

3.1.3 failure, n—in testing geosynthetics, water or air pressure in the test vessel at failure of the geosynthetic.

3.1.4 hydrostatic pressure, n—a state of stress in which all the principal stresses are equal (and there is no shear stress), as in

a liquid at rest; induced artificially by means of a gaged pressure system; the product of the unit weight of the liquid and the

difference in elevation between the given point and the free water elevation.

1

This test method is under the jurisdiction of ASTM Committee D35 on Geosynthetics and is the direct responsibility of Subcommittee D35.10 on Geomembranes.

Current edition approved June 1, 2011Jan. 1, 2014. Published July 2011January 2014. Originally approved in 1994. Last previous edition approved in 20062011 as

D5514 – 06.D5514 – 06(2011). DOI: 10.1520/D5514-06R11.10.1520/D5514_D5514M-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5514/D5514M − 14

3.2 For definitions of other terms used in this test method, refer to Terminology D4439.

4. Significance and Use

4.1 Procedure A—This procedure is an index ty

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.