ASTM D4700-91(2006)

(Guide)Standard Guide for Soil Sampling from the Vadose Zone

Standard Guide for Soil Sampling from the Vadose Zone

SIGNIFICANCE AND USE

Chemical analyses of liquids, solids, and gases from the vadose zone can provide information on the presence, possible source, migration route, and physical-chemical behavior of contaminants. Remedial or mitigating measures can be formulated based on this information. This guide describes devices and procedures that can be used to obtain vadose zone soil samples.

Soil sampling is useful for the reasons presented in Section 1. However, it should be recognized that the general method is destructive, and that resampling at an exact location is not possible. Therefore, if a long term monitoring program is being designed, other methods for obtaining samples should be considered.

SCOPE

1.1 This guide covers procedures that may be used for obtaining soil samples from the vadose zone (unsaturated zone). Samples can be collected for a variety of reasons including the following:

1.1.1 Stratigraphic description,

1.1.2 Hydraulic conductivity testing,

1.1.3 Moisture content measurement,

1.1.4 Moisture release curve construction,

1.1.5 Geotechnical testing,

1.1.6 Soil gas analyses,

1.1.7 Microorganism extraction, or

1.1.8 Pore liquid and soils chemical analyses.

1.2 This guide focuses on methods that provide soil samples for chemical analyses of the soil or contained liquids or contaminants. However, comments on how methods may be modified for other objectives are included.

1.3 This guide does not describe sampling methods for lithified deposits and rocks (for example, sandstone, shale, tuff, granite).

1.4 In general, it is prudent to perform all field work with at least two people present. This increases safety and facilitates efficient data collection.

1.5 &inch-pound-units;

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 This guide offers an organized collection of information or a series of options and does not recommend a specific course of action. This document cannot replace education or experience and should be used in conjunction with professional judgment. Not all aspects of this guide may be applicable in all circumstances. This ASTM standard is not intended to represent or replace the standard of care by which the adequacy of a given professional service must be judged, nor should this document be applied without consideration of a project's many unique aspects. The word "Standard" in the title of this document means only that the document has been approved through the ASTM consensus process.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4700 − 91(Reapproved 2006)

Standard Guide for

Soil Sampling from the Vadose Zone

This standard is issued under the fixed designation D4700; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope judgment. Not all aspects of this guide may be applicable in all

circumstances. This ASTM standard is not intended to repre-

1.1 This guide covers procedures that may be used for

sent or replace the standard of care by which the adequacy of

obtaining soil samples from the vadose zone (unsaturated

a given professional service must be judged, nor should this

zone). Samples can be collected for a variety of reasons

document be applied without consideration of a project’s many

including the following:

unique aspects. The word “Standard” in the title of this

1.1.1 Stratigraphic description,

document means only that the document has been approved

1.1.2 Hydraulic conductivity testing,

through the ASTM consensus process.

1.1.3 Moisture content measurement,

1.1.4 Moisture release curve construction,

2. Referenced Documents

1.1.5 Geotechnical testing,

2.1 ASTM Standards:

1.1.6 Soil gas analyses,

D653 Terminology Relating to Soil, Rock, and Contained

1.1.7 Microorganism extraction, or

Fluids

1.1.8 Pore liquid and soils chemical analyses.

D1452 Practice for Soil Exploration and Sampling byAuger

1.2 This guide focuses on methods that provide soil samples

Borings

for chemical analyses of the soil or contained liquids or

D1586 Test Method for Penetration Test (SPT) and Split-

contaminants. However, comments on how methods may be

Barrel Sampling of Soils

modified for other objectives are included.

D1587 Practice for Thin-Walled Tube Sampling of Soils for

1.3 This guide does not describe sampling methods for Geotechnical Purposes

lithified deposits and rocks (for example, sandstone, shale, tuff, D2488 Practice for Description and Identification of Soils

granite). (Visual-Manual Procedure)

D3550 Practice for Thick Wall, Ring-Lined, Split Barrel,

1.4 In general, it is prudent to perform all field work with at

Drive Sampling of Soils

least two people present. This increases safety and facilitates

D4220 Practices for Preserving and Transporting Soil

efficient data collection.

Samples

1.5 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

3. Terminology

conversions to SI units that are provided for information only

3.1 Definitions:

and are not considered standard.

3.1.1 Except where noted, all terms and symbols in this

1.6 This standard does not purport to address all of the

guide are in accordance with the following publications. In

safety concerns, if any, associated with its use. It is the

order of consideration they are:

responsibility of the user of this standard to establish appro-

3.1.1.1 Terminology D653.

priate safety and health practices and determine the applica-

3.1.1.2 Compilation of ASTM Standard Terminology, and

bility of regulatory limitations prior to use.

3.1.1.3 Webster’s New Collegiate Dictionary.

1.7 This guide offers an organized collection of information

3.1.2 For definitions and classifications of soil related terms

or a series of options and does not recommend a specific

used, refer to Practice D2488 and Terminology D653. Addi-

course of action. This document cannot replace education or

tional terms that require clarification are defined in 3.2.

experienceandshouldbeusedinconjunctionwithprofessional

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This guide is under the jurisdiction ofASTM Committee D18 on Soil and Rock contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and is the direct responsibility of Subcommittee D18.21 on Groundwater and Standards volume information, refer to the standard’s Document Summary page on

Vadose Zone Investigations. the ASTM website.

Current edition approved July 1, 2006. Published August 2006. Originally Compilation of ASTM Standard Terminology, Sixth edition, ASTM

ε1

approved in 1991. Last previous edition approved in 1998 as D4700 – 91 (1998) . International, 100 Barr Harbor Drive, West Conshohocken, PA, 1986.

DOI: 10.1520/D4700-91R06. Webster’s New Collegiate Dictionary, Fifth edition, 1977.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4700 − 91 (2006)

5.2 Soil sampling is useful for the reasons presented in

Section 1. However, it should be recognized that the general

method is destructive, and that resampling at an exact location

is not possible.Therefore, if a long term monitoring program is

being designed, other methods for obtaining samples should be

considered.

6. Criteria for Selecting Soil Samplers

6.1 Important criteria to consider when selecting devices for

vadose zone soil sampling include the following:

6.1.1 Type of sample: An encased core sample, an uncased

core sample, a depth-specific representative sample, or a

sample according to requirements of the analyses,

6.1.2 Sample size requirements,

FIG. 1 Criteria for Selecting Soil Sampling Equipment

6.1.3 Suitability for sampling various soil types,

6.1.4 Maximum sampling depth,

6.1.5 Suitability for sampling soils under various moisture

conditions,

3.2 Definitions of Terms Specific to This Standard:

6.1.6 Ability to minimize cross contamination,

3.2.1 cascading water—perched ground water that enters a

6.1.7 Accessibility to the sampling site, and

well casing via cracks or uncovered perforations, trickling, or

6.1.8 Personnel requirements.

pouring down the inside of the casing.

6.2 The sampling devices described in this guide have been

3.2.2 sludge—a water charged sedimentary deposit.

evaluated for these criteria. The results are summarized in Fig.

3.2.2.1 Discussion—The water-formed sedimentary deposit

1.

may include all suspended solids carried by the water and trace

elementsthatwereinsolutioninthewater.Sludgeusuallydoes

7. Sampling with Hand Operated Devices

not cohere sufficiently to retain its physical shape when

7.1 These devices, that have mostly been developed for

mechanical means are used to remove it from the surface on

agricultural purposes, include:

whichitdeposits,butitmaybebakedinplaceandbeadherent.

7.1.1 Screw-type augers,

7.1.2 Barrel augers,

4. Summary of Guide

7.1.3 Tube-type samplers,

4.1 Sampling vadose zone soil involves inserting into the

7.1.4 Hand held power augers, and

ground a device that retains and recovers a sample. Devices

7.1.5 Trench sampling with shovels in conjunction with

and systems for vadose zone sampling are divided into two

machine excavations.

general groups, namely the following: samplers used in con-

7.2 The advantages of using hand operated devices over

junction with hand operated devices; and samplers used in

drill rigs are the ease of equipment transport to locations with

conjunction with multipurpose or auger drill rigs. This guide

poor vehicle access, and the lower costs of setup and decon-

discusses these groups and their associated practices.

tamination. However, a major disadvantage is that these

4.2 The discussion of each device is organized into three

devices are limited to shallower depths than drill rigs.

sections, describing the device, describing sampling methods,

7.3 Screw-Type Augers:

and limitations and advantages of its use.

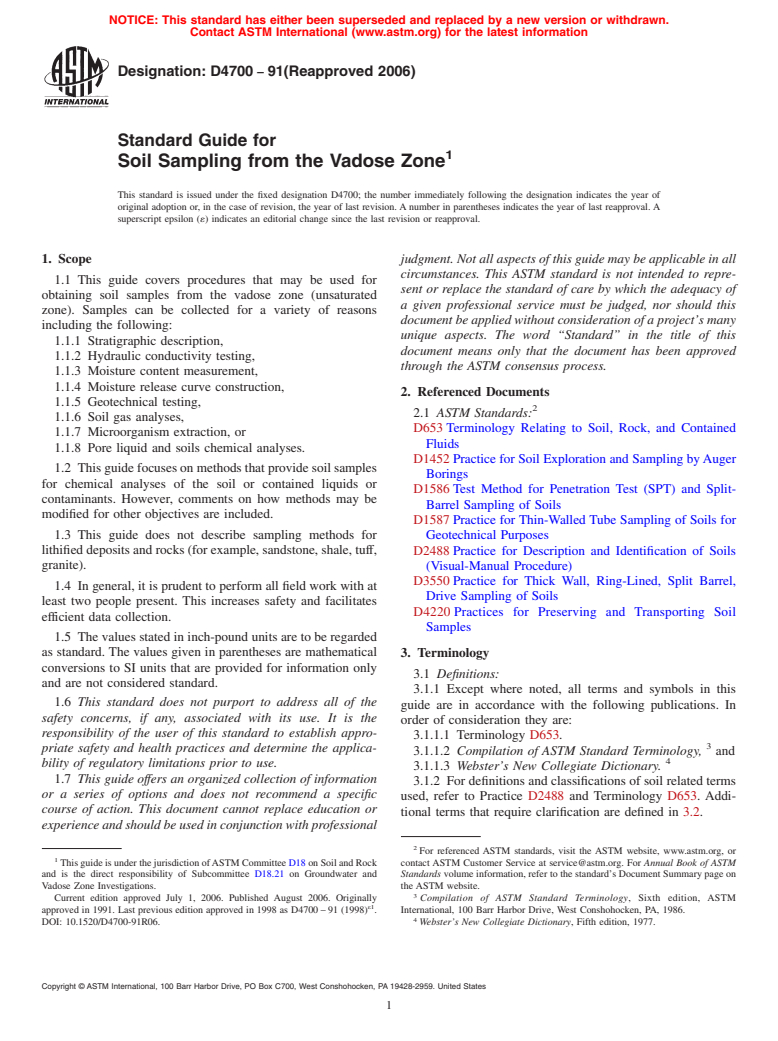

7.3.1 Description—The screw or ship auger is essentially a

4.3 This guide identifies and describes a number of sam-

small diameter (for example, 1.5 in. (3.81 cm)) wood auger

pling methods and samplers. It is advisable to consult available

from which the cutting side flanges and tip have been removed

site-specific geological and hydrological data to assist in

(1) (see Fig. 2(a)).According to the Soil Survey Staff (1) , the

determining the sampling method and sampler best suited for a

spiral part of the auger should be about 7 in. (18 cm) long, with

specific project. It is also advisable to contact a local firm

the distances between flights about the same as the diameter

providing the services required as not all sampling and drilling

(for example, 1.5 in.) of the auger. This facilitates measuring

methods described in this guide are available nationwide.

the depth of penetration of the tool. Variations on this design

include the closed spiral auger and the Jamaica open spiral

5. Significance and Use

auger (2) (see Fig. 2(b) and (c)). The auger is welded onto a

length of solid or tubular rod. The upper end of this rod is

5.1 Chemical analyses of liquids, solids, and gases from the

threaded, to accept a handle or extension rods. As many

vadose zone can provide information on the presence, possible

extensions are used as are required to reach the target sampling

source, migration route, and physical-chemical behavior of

contaminants. Remedial or mitigating measures can be formu-

lated based on this information. This guide describes devices

and procedures that can be used to obtain vadose zone soil

The boldface numbers in parentheses refer to the list of references at the end of

samples. the text.

D4700 − 91 (2006)

7.4 Barrel Augers:

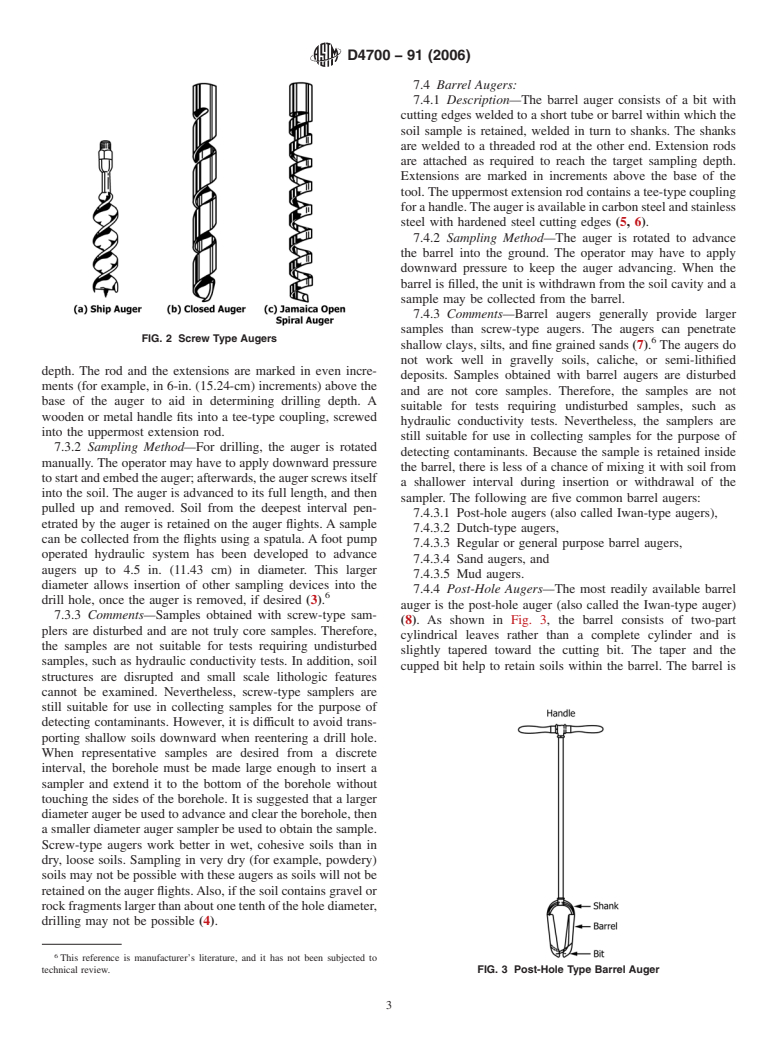

7.4.1 Description—The barrel auger consists of a bit with

cutting edges welded to a short tube or barrel within which the

soil sample is retained, welded in turn to shanks. The shanks

are welded to a threaded rod at the other end. Extension rods

are attached as required to reach the target sampling depth.

Extensions are marked in increments above the base of the

tool.The uppermost extension rod contains a tee-type coupling

forahandle.Theaugerisavailableincarbonsteelandstainless

steel with hardened steel cutting edges (5, 6).

7.4.2 Sampling Method—The auger is rotated to advance

the barrel into the ground. The operator may have to apply

downward pressure to keep the auger advancing. When the

barrel is filled, the unit is withdrawn from the soil cavity and a

sample may be collected from the barrel.

7.4.3 Comments—Barrel augers generally provide larger

samples than screw-type augers. The augers can penetrate

FIG. 2 Screw Type Augers

shallow clays, silts, and fine grained sands (7). The augers do

not work well in gravelly soils, caliche, or semi-lithified

depth. The rod and the extensions are marked in even incre-

deposits. Samples obtained with barrel augers are disturbed

ments (for example, in 6-in. (15.24-cm) increments) above the

and are not core samples. Therefore, the samples are not

base of the auger to aid in determining drilling depth. A

suitable for tests requiring undisturbed samples, such as

wooden or metal handle fits into a tee-type coupling, screwed

hydraulic conductivity tests. Nevertheless, the samplers are

into the uppermost extension rod.

still suitable for use in collecting samples for the purpose of

7.3.2 Sampling Method—For drilling, the auger is rotated

detecting contaminants. Because the sample is retained inside

manually. The operator may have to apply downward pressure

the barrel, there is less of a chance of mixing it with soil from

tostartandembedtheauger;afterwards,theaugerscrewsitself

a shallower interval during insertion or withdrawal of the

into the soil. The auger is advanced to its full length, and then

sampler. The following are five common barrel augers:

pulled up and removed. Soil from the deepest interval pen-

7.4.3.1 Post-hole augers (also called Iwan-type augers),

etrated by the auger is retained on the auger flights. A sample

7.4.3.2 Dutch-type augers,

can be collected from the flights using a spatula. A foot pump

7.4.3.3 Regular or general purpose barrel augers,

operated hydraulic system has been developed to advance

7.4.3.4 Sand augers, and

augers up to 4.5 in. (11.43 cm) in diameter. This larger

7.4.3.5 Mud augers.

diameter allows insertion of other sampling devices into the

7.4.4 Post-Hole Augers—The most readily available barrel

drill hole, once the auger is removed, if desired (3).

auger is the post-hole auger (also called the Iwan-type auger)

7.3.3 Comments—Samples obtained with screw-type sam-

(8). As shown in Fig. 3, the barrel consists of two-part

plers are disturbed and are not truly core samples. Therefore,

cylindrical leaves rather than a complete cylinder and is

the samples are not suitable for tests requiring undisturbed

slightly tapered toward the cutting bit. The taper and the

samples, such as hydraulic conductivity tests. In addition, soil

cupped bit help to retain soils within the barrel. The barrel is

structures are disrupted and small scale lithologic features

cannot be examined. Nevertheless, screw-type samplers are

still suitable for use in collecting samples for the purpose of

detecting contaminants. However, it is difficult to avoid trans-

porting shallow soils downward when reentering a drill hole.

When representative samples are desired from a discrete

interval, the borehole must be made large enough to insert a

sampler and extend it to the bottom of the borehole without

touching the sides of the borehole. It is suggested that a larger

diameter auger be used to advance and clear the borehole, then

a smaller diameter auger sampler be used to obtain the sample.

Screw-type augers work better in wet, cohesive soils than in

dry, loose soils. Sampling in very dry (for example, powdery)

soils may not be possible with these augers as soils will not be

retained on the auger flights.Also, if the soil contains gravel or

rockfragmentslargerthanaboutonetenthoftheholediameter,

drilling may not be possible (4).

This reference is manufacturer’s literature, and it has not been subjected to

technical review. FIG. 3 Post-Hole Type Barrel Auger

D4700 − 91 (2006)

available witha3to 12-in. (7.62 to 30.48-cm) diameter. There

are two types of drilling systems, one has a single rod and

handle, and the other has two handles. In stable, cohesive soils,

the auger can be advanced up to 25 ft (7.62 m) (8).

7.4.5 Dutch-Type Augers—The Dutch-type auger (commer-

cially developed by Eijkelkamp) is a smaller variation of the

post-hole auger design. As shown in Fig. 4, the pointed bit is

continuous with two, narrow part-cylindrical barrel segments,

welded onto the shanks. The barrel generally hasa3in.

(7.62 cm) outside diameter. This tool is best suited for sam-

pling wet, clayey soils.

7.4.6 Regular or General Purpose Barrel Augers—A ver-

sion of the barrel auger commonly used by soil scientists and

county agricultural agents is depicted in Fig. 5(a) and (b). As

shown, the barrel is a complete cylinder.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.