ASTM D5041-98(2012)

(Test Method)Standard Test Method for Fracture Strength in Cleavage of Adhesives in Bonded Joints

Standard Test Method for Fracture Strength in Cleavage of Adhesives in Bonded Joints

SIGNIFICANCE AND USE

This test method provides a means of measuring the cleavage forces and energies required to fail adhesively bonded reinforced flat bonded specimens. It also offers a semi-quantitative observation of failure mode.

This test method has found application in screening structural adhesives for bonding reinforced plastics where simple lap shear testing has proven to be inadequate in distinguishing differences between adhesives.

It is important to note that the test method measures performance properties of the total bonded system (for example, reinforced plastic and adhesive) but will not yield fundamental properties of the adhesive alone.

SCOPE

1.1 This test method covers the determination of fracture strength in cleavage of adhesive bonds when tested on standard reinforced plastic specimens and under specified conditions of preparation and testing (Note 1).

Note 1—While this test method is intended for use in reinforced plastic applications, it may be used for measuring fracture properties of adhesives using other plastic adherends, provided consideration is given to the thickness and should be of equal rigidity to the plastic adherends.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5041 −98 (Reapproved 2012)

Standard Test Method for

Fracture Strength in Cleavage of Adhesives in Bonded

Joints

This standard is issued under the fixed designation D5041; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 failure initiation energy, E—the area under the load

i

deflection curve where the first significant load drop occurs

1.1 This test method covers the determination of fracture

after the start of the test, showing the onset of permanent

strengthincleavageofadhesivebondswhentestedonstandard

damage to the bonded assembly (see Fig. 1).

reinforced plastic specimens and under specified conditions of

3.2.2 failure propagation energy, E —the area under the

preparation and testing (Note 1).

p

load-deflection curve beginning at the failure initiation energy

NOTE 1—While this test method is intended for use in reinforced plastic

and ending at the catastrophic failure of the bonded assembly.

applications, it may be used for measuring fracture properties of adhesives

(See Fig. 1).

using other plastic adherends, provided consideration is given to the

thickness and should be of equal rigidity to the plastic adherends.

3.2.3 semirigid—indicates that the adherends shall have

1.2 The values stated in SI units are to be regarded as the such dimensions and physical properties as to permit bending

standard. The values given in parentheses are for information them through any angle of up to 30° without breaking or

only. cracking.

1.3 This standard does not purport to address all of the 3.2.4 semirigid adherend, n—an adherend that has dimen-

safety concerns, if any, associated with its use. It is the sions and physical properties that permit bending at designated

responsibility of the user of this standard to establish appro- test temperature through any angle up to 30° without breaking

priate safety and health practices and determine the applica- or cracking.

bility of regulatory limitations prior to use.

3.2.5 total energy—failure initiation energy plus failure

propagation energy.

2. Referenced Documents

4. Significance and Use

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

4.1 This test method provides a means of measuring the

D907 Terminology of Adhesives

cleavageforcesandenergiesrequiredtofailadhesivelybonded

D2093 Practice for Preparation of Surfaces of Plastics Prior

reinforced flat bonded specimens. It also offers a semi-

to Adhesive Bonding

quantitative observation of failure mode.

D5573 Practice for Classifying Failure Modes in Fiber-

4.2 This test method has found application in screening

Reinforced-Plastic (FRP) Joints

structural adhesives for bonding reinforced plastics where

E4 Practices for Force Verification of Testing Machines

simple lap shear testing has proven to be inadequate in

distinguishing differences between adhesives.

3. Terminology

4.3 It is important to note that the test method measures

3.1 Definitions—Many of the terms used in this test method

performance properties of the total bonded system (for

are defined in Terminology D907.

example, reinforced plastic and adhesive) but will not yield

3.2 Definitions of Terms Specific to This Standard:

fundamental properties of the adhesive alone.

5. Apparatus

This test method is under the jurisdiction of ASTM Committee D14 on

AdhesivesandisthedirectresponsibilityofSubcommitteeD14.40onAdhesivesfor

5.1 Testing Machine, any suitable testing machine capable

Plastics.

of control of constant-rate-of-crosshead movement and com-

Current edition approved May 1, 2012. Published May 2012. Originally

prising essentially the following:

approved in 1990. Last previous edition approved in 2004 as D5041 – 98 (2004).

DOI: 10.1520/D5041-98R12.

5.1.1 Drive Mechanism, a mechanism for imparting to the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

cross-head movable member, a uniform, controlled velocity

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

with respect to the base (fixed member); this velocity is to be

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. regulated as specified in Section 10.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5041−98 (2012)

FIG. 2Wedge with Removable Tip

FIG. 1A Typical Load versus Deflection Curve for Wedge Test

5.1.2 Load Indicator, a mechanism capable of showing the

total compressive load carried by the test specimen. The

mechanism is to be essentially free from inertia-lag at the

specified rate of testing and indicate the load with an accuracy

of 61 % of the maximum indicated value of the test (load).

Verify the accuracy of the testing machine at least once a year

in accordance with Practices E4.

5.2 Wedge, made of either aluminum or steel with an

included angle of 45°. The sides of the wedge are machined FIG. 3Test Setup

smooth with the edge having a radius not to exceed 0.02 mm

(0.01 in).

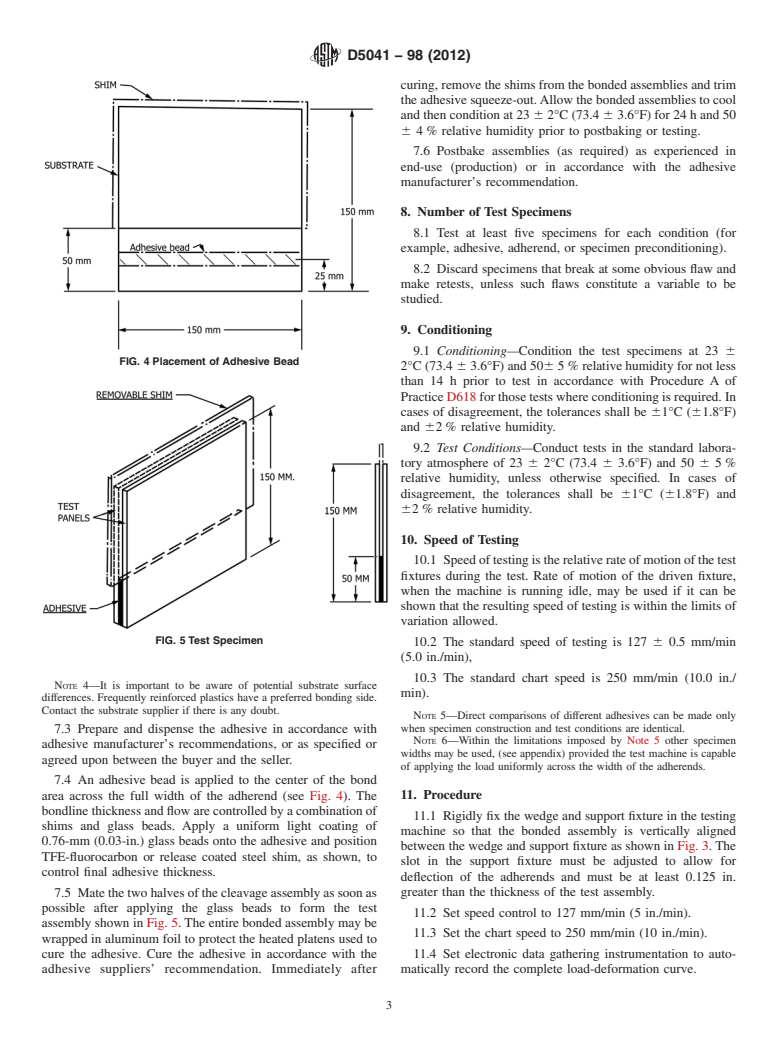

6. Test Assemblies

NOTE 2—A stainless steel wedge is recommended, has been found to

6.1 Flat Adherend, unless otherwise specified in material

work well, and is very durable. Due to the weight of a steel wedge, the

specifications, make the test adherends in conformance to the

removal of excess metal, which does not adversely affect the stiffness of

the wedge, is recommended. form and dimensions shown in Fig. 4. Cut them from flat

semirigid plastic panels having a nominal thickness of 2.54

5.3 Removable Tip (Optional)—In some cases, the tip of the

mm (0.1 in.) 60.5 %. Cut adherends into sections, 150 by 150

traveling wedge will strike the adhesive before catastrophic

mm (6 by 6 in.), 60.5 %. (See appendix for optional specimen

failure. This phenomenon will lead to grossly distorted test

sizes.)

data. Should this be a problem in some adhesively bonded

assemblies, a removable tip wedge of the design shown in Fig.

7. Preparation

2 is suggested.

7.1 Laminated test assemblies (Fig. 5) consist of two

5.4 Support Fixture, an adjustable fixture used to support

adherends of similar stiffness properly prepared and bonded

andcenterthebondedassemblyunderthetipofthewedge.See

together.

Fig. 3.

NOTE 3—If the bonded test assembly is constructed with adherends of

5.5 Integrator, a mechanical or electronic device or com-

different stiffness, the result is a peel rather than a cleavage test. (For

puter for the determination of failure energies.

example, higher stiffness promotes cleavage; lower stiffness, peel.)

5.6 Bond Fixture, any suitable fixture with temperature- and 7.2 Prepare the surface of the substrate prior to bonding in

pressure-controlled platens, capable of bonding test assemblies accordance with the adhesive suppliers’ recommendations.

in accordance with the adhesive manufacturer’s recommenda- Typical surface preparations include solvent scrubbing, appli-

tions. cation of primers and, in some cases, only a dry rag wipe.

D5041−98 (2012)

curing, remove the shims from the bonded assemblies and trim

the adhesive squeeze-out.Allow the bonded assemblies to cool

and then condition at 23 6 2°C (73.4 6 3.6°F) for 24 h and 50

6 4 % relative humidity prior to postbaking or testing.

7.6 Postbake assemblies (as required) as experienced in

end-use (production) or in accordance with the adhesive

manufacturer’s recommendation.

8. Number of Test Specimens

8.1 Test at least five specimens for each condition (for

example, adhesive, adherend, or specimen preconditioning).

8.2 Discard specimens that break at some obvious flaw and

make retests, unless such flaws constitute a variable to be

studied.

9. Conditioning

9.1 Conditioning—Condition the test specimens at 23 6

FIG. 4Placement of Adhesive Bead

2°C (73.4 6 3.6°F) and 506 5 % relative humidity for not less

than 14 h prior to test in accordance with Procedure A of

Practice D618 for those tests where conditioning is required. In

cases of disagreement, the tolerances shall be 61°C (61.8°F)

and 62 % relative humidity.

9.2 Test Conditions—Conduct tests in the standard labora-

tory atmosphere of 23 6 2°C (73.4 6 3.6°F) and 50 6 5%

relative humidity, unl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.