ASTM D3035-08

(Specification)Standard Specification for Polyethylene (PE) Plastic Pipe (DR-PR) Based on Controlled Outside Diameter

Standard Specification for Polyethylene (PE) Plastic Pipe (DR-PR) Based on Controlled Outside Diameter

ABSTRACT

This specification covers polyethylene (PE) pipes made in thermoplastic pipe dimension ratios based on outside diameter, and pressure rated for water. All pipes produced under this specification may be used for the transport of water, industrial process liquids, effluents, slurries, municipal sewage, etc. Included are criteria for classifying PE plastic pipe materials and PE plastic pipe, and a system of nomenclature for PE plastic pipe. PE pipes shall be evaluated by the test procedures given herein, and shall conform to specified requirements for workmanship, dimensions, sustained pressure at ambient and elevated temperatures, hydrostatic burst pressure, tensile strength at yield, and environmental stress cracking.

SCOPE

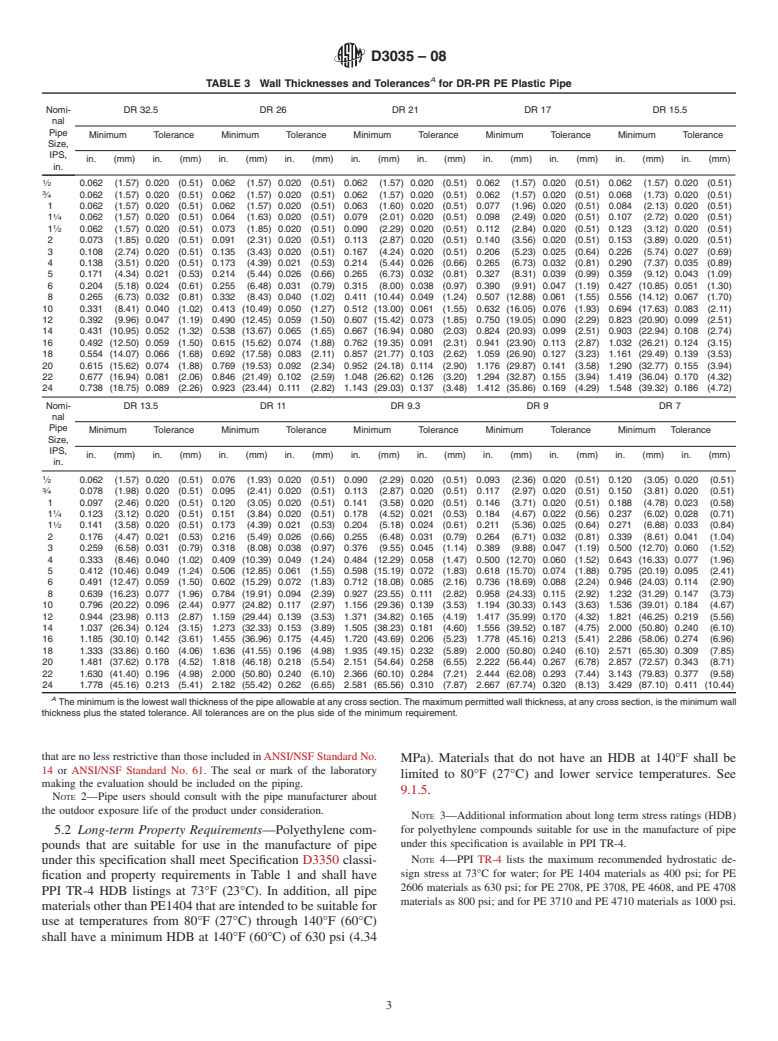

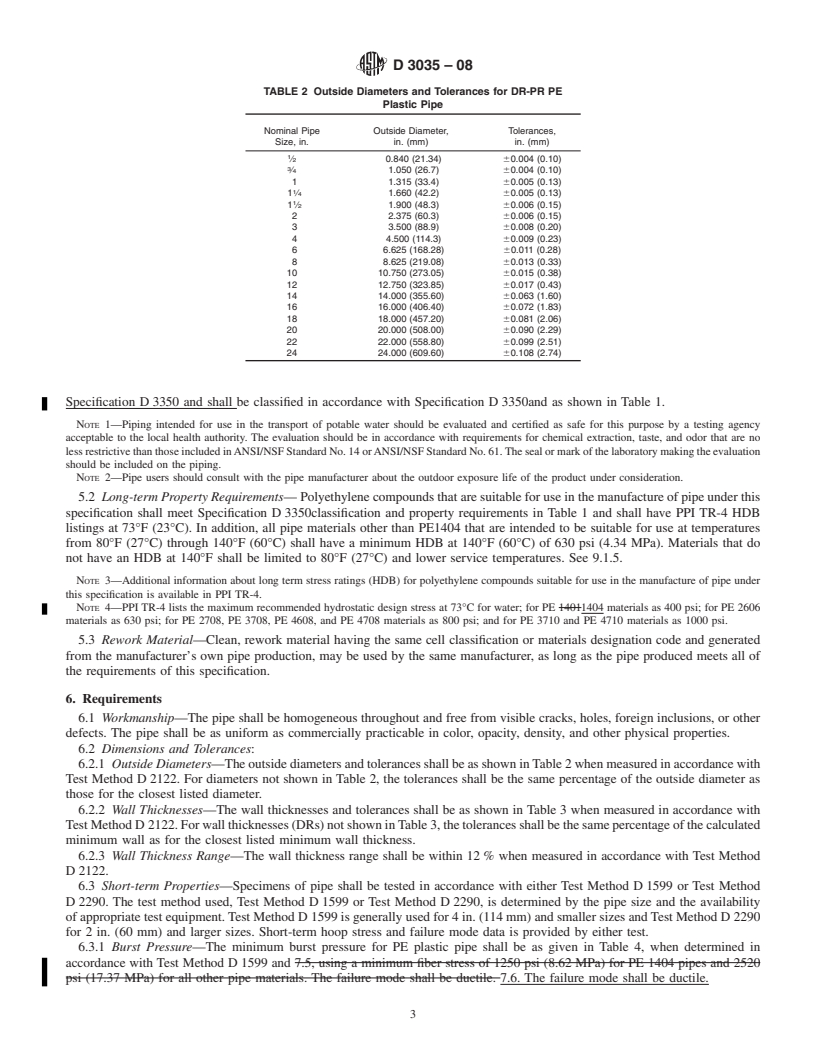

1.1 This specification covers polyethylene (PE) pipe made in thermoplastic pipe dimension ratios based on outside diameter and pressure rated for water (see Appendix X1). Included are criteria for classifying PE plastic pipe materials and PE plastic pipe, a system of nomenclature for PE plastic pipe, and requirements and test methods for materials, workmanship, dimensions, sustained pressure, burst pressure, and environmental stress cracking. Methods of marking are also given.

1.2 All pipes produced under this specification may be used for the transport of water, industrial process liquids, effluents, slurries, municipal sewage, etc. The user should consult the manufacturer to determine whether the material being transported is compatible with polyethylene pipe and will not affect the service life beyond limits acceptable to the user.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 7, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D3035 – 08

Standard Specification for

Polyethylene (PE) Plastic Pipe (DR-PR) Based on Controlled

1

Outside Diameter

This standard is issued under the fixed designation D3035; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D1599 Test Method for Resistance to Short-Time Hydraulic

Pressure of Plastic Pipe, Tubing, and Fittings

1.1 This specification covers polyethylene (PE) pipe made

D1600 Terminology for Abbreviated Terms Relating to

in thermoplastic pipe dimension ratios based on outside diam-

Plastics

eter and pressure rated for water (see Appendix X1). Included

D1603 Test Method for Carbon Black Content in Olefin

are criteria for classifying PE plastic pipe materials and PE

Plastics

plastic pipe, a system of nomenclature for PE plastic pipe, and

D2122 Test Method for Determining Dimensions of Ther-

requirements and test methods for materials, workmanship,

moplastic Pipe and Fittings

dimensions, sustained pressure, burst pressure, and environ-

D2290 Test Method for Apparent Hoop Tensile Strength of

mental stress cracking. Methods of marking are also given.

Plastic or Reinforced Plastic Pipe by Split Disk Method

1.2 All pipes produced under this specification may be used

D3350 Specification for Polyethylene Plastics Pipe and

for the transport of water, industrial process liquids, effluents,

Fittings Materials

slurries, municipal sewage, etc. The user should consult the

D4218 Test Method for Determination of Carbon Black

manufacturer to determine whether the material being trans-

Content in Polyethylene Compounds By the Muffle-

ported is compatible with polyethylene pipe and will not affect

Furnace Technique

the service life beyond limits acceptable to the user.

F412 Terminology Relating to Plastic Piping Systems

1.3 The values stated in inch-pound units are to be regarded

2.2 NSF International Standards:

as the standard. The values given in parentheses are for

ANSI/NSF Standard No. 14 for Plastic Piping Components

information only.

3

and Related Materials

1.4 The following safety hazards caveat pertains only to the

ANSI/NSF Standard No. 61 for Drinking Water System

test methods portion, Section 7, of this specification: This

3

Components—Health Effects

standard does not purport to address all of the safety concerns,

2.3 PPI Documents:

if any, associated with its use. It is the responsibility of the user

TR-4 Listing of Hydrostatic Design Bases (HDB), Strength

of this standard to establish appropriate safety and health

Design Bases (SDB), Pressure Design Bases (PDB) and

practices and determine the applicability of regulatory limita-

Minimum Required Strength (MRS) Ratings for Thermo-

tions prior to use.

4

plastic Piping Materials or Pipe

2. Referenced Documents TR-9 Recommended Design Factors for Thermoplastic

4

2

Pressure Pipe

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

3. Terminology

D1598 Test Method for Time-to-Failure of Plastic Pipe

3.1 Definitions—Definitions are in accordance with Termi-

Under Constant Internal Pressure

nology F412, and abbreviations are in accordance with Termi-

nology D1600, unless otherwise specified.

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

3.2 Definitions of Terms Specific to This Standard:

Piping Systems and is the direct responsibility of Subcommittee F17.26 on Olefin

3.2.1 hydrostatic design stress— the estimated maximum

Based Pipe.

tensile stress in the wall of the pipe in the circumferential

Current edition approved March 1, 2008. Published March 2008. Originally

approved in 1972. Last previous edition approved in 2006 as D3035 – 06. DOI:

10.1520/D3035-08.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from the National Sanitation Foundation, P.O. Box 1468,AnnArbor,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM MI 48106.

4

Standards volume information, refer to the standard’s Document Summary page on Available from the Plastics Pipe Institute, Inc., 1825 Connecticut Ave., NW,

the ASTM website. Suite 680 Washington, DC 20009.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3035 – 08

TABLE 1 Specification D3350 Cell Classifications for Polyethylene Pipe Materials

PE Material Designation Code PE 1404 PE 2606 PE 2708 PE 3608 PE 3708 PE 3710 PE 4608 PE 4708 PE 4710

Physical Property: Cell Class

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D3035–06 Designation: D 3035 – 08

Standard Specification for

Polyethylene (PE) Plastic Pipe (DR-PR) Based on Controlled

1

Outside Diameter

This standard is issued under the fixed designation D 3035; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 Thisspecificationcoverspolyethylene(PE)pipemadeinthermoplasticpipedimensionratiosbasedonoutsidediameterand

pressure rated for water (see Appendix X1). Included are criteria for classifying PE plastic pipe materials and PE plastic pipe, a

system of nomenclature for PE plastic pipe, and requirements and test methods for materials, workmanship, dimensions, sustained

pressure, burst pressure, and environmental stress cracking. Methods of marking are also given.

1.2 All pipes produced under this specification may be used for the transport of water, industrial process liquids, effluents,

slurries, municipal sewage, etc. The user should consult the manufacturer to determine whether the material being transported is

compatible with polyethylene pipe and will not affect the service life beyond limits acceptable to the user.

1.3 The values stated in inch-pound units are to be regarded as the standard.The values given in parentheses are for information

only.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 7, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 618 Practice for Conditioning Plastics for Testing

D 1598 Test Method for Time-to-Failure of Plastic Pipe Under Constant Internal Pressure

D 1599 Test Method for Resistance to Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and Fittings

D 1600 Terminology for Abbreviated Terms Relating to Plastics

D 1603 Test Method for Carbon Black Content in Olefin Plastics

D 2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

D 2290 Test Method for Apparent Hoop Tensile Strength of Plastic or Reinforced Plastic Pipe by Split Disk Method

D 3350 Specification for Polyethylene Plastics Pipe and Fittings Materials

D 4218 TestMethodforDeterminationofCarbonBlackContentinPolyethyleneCompoundsBytheMuffle-FurnaceTechnique

F 412 Terminology Relating to Plastic Piping Systems

2.2 NSF International Standards:

3

ANSI/NSF Standard No. 14 for Plastic Piping Components and Related Materials

3

ANSI/NSF Standard No. 61 for Drinking Water System Components—Health Effects

2.3 PPI Documents:

TR-4 Listing of Hydrostatic Design Bases (HDB), Strength Design Bases (SDB), Pressure Design Bases (PDB) and Minimum

4

Required Strength (MRS) Ratings for Thermoplastic Piping Materials or Pipe

4

TR-9 Recommended Design Factors for Thermoplastic Pressure Pipe

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.26 on Olefin Based

Pipe.

Current edition approved Dec. 15, 2006. Published January 2007. Originally approved in 1972. Last previous edition approved in 2003 as D3035–03a.

Current edition approved March 1, 2008. Published March 2008. Originally approved in 1972. Last previous edition approved in 2006 as D 3035 – 06.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from the National Sanitation Foundation, P.O. Box 1468, Ann Arbor, MI 48106.

4

Available from the Plastics Pipe Institute, Inc., 1825 Connecticut Ave., NW, Suite 680 Washington, DC 20009.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3035–08

3. Terminology

3.1 Definitions—Definitions are in accordance with Terminology F 412, and abbreviations are in accordance with Terminology

D 1600, unless otherwise

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.