ASTM F1759-97(2018)

(Practice)Standard Practice for Design of High-Density Polyethylene (HDPE) Manholes for Subsurface Applications

Standard Practice for Design of High-Density Polyethylene (HDPE) Manholes for Subsurface Applications

SIGNIFICANCE AND USE

4.1 Uses—The requirements of this practice are intended to provide manholes suitable for installation in pipeline or conduit trenches, landfill perimeters, and landfills with limited settlement characteristics. Direct installation in sanitary landfills or other fills subject to large (in excess of 10 %) soil settlements may require special designs outside the scope of this practice.

4.1.1 Manholes are assumed to be subject to gravity flow only.

4.2 Design Assumption—The design methodology in this practice applies only to manholes that are installed in backfill consisting of Class I, Class II, or Class III material as defined in Practice D2321, which has been compacted to a minimum of 90 % standard proctor density. The designs are based on the backfill extending at least 3.5 ft (1 m) from the perimeter of the manhole for the full height of the manhole and extending laterally to undisturbed in situ soil. Manholes are assumed placed on a stable base consisting of at least 12 in. (30.5 cm) of Class I material compacted to at least 95 % standard proctor density or a concrete slab. The foundation soils under the base must provide adequate bearing strength to carry downdrag loads.

4.2.1 Manholes installed in sanitary landfills or other fills experiencing large settlements may require special designs beyond the scope of this practice. The designer should evaluate each specific site to determine the suitability for use of HDPE manholes and the designer should prepare a written specification for installation, which is beyond the scope of this practice.

SCOPE

1.1 This practice covers general and basic procedures related to the design of manholes and components manufactured from high-density polyethylene (HDPE) for use in subsurface applications and applies to personnel access structures. The practice covers the material, the structural design requirements of the manhole barrel (also called vertical riser or shaft), floor (bottom), and top, and joints between shaft sections.

1.2 This practice offers the minimum requirements for the proper design of an HDPE manhole. Due to the variability in manhole height, diameter, and the soil, each manhole must be designed and detailed individually. When properly used and implemented, this practice can help ensure a safe and reliable structure for the industry.

1.3 Disclaimer—The reader is cautioned that independent professional judgment must be exercised when data or recommendations set forth in this practice are applied. The publication of the material contained herein is not intended as a representation or warranty on the part of ASTM that this information is suitable for general or particular use, or freedom from infringement of any patent or patents. Anyone making use of this information assumes all liability arising from such use. The design of structures is within the scope of expertise of a licensed architect, structural engineer, or other licensed professional for the application of principles to a particular structure.

1.4 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are provided for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1759 − 97 (Reapproved 2018) An American National Standard

Standard Practice for

Design of High-Density Polyethylene (HDPE) Manholes for

Subsurface Applications

This standard is issued under the fixed designation F1759; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.1 This practice covers general and basic procedures re-

mendations issued by the World Trade Organization Technical

lated to the design of manholes and components manufactured

Barriers to Trade (TBT) Committee.

from high-density polyethylene (HDPE) for use in subsurface

applications and applies to personnel access structures. The

2. Referenced Documents

practice covers the material, the structural design requirements

2.1 ASTM Standards:

of the manhole barrel (also called vertical riser or shaft), floor

D653 Terminology Relating to Soil, Rock, and Contained

(bottom), and top, and joints between shaft sections.

Fluids

1.2 This practice offers the minimum requirements for the

D1600 Terminology forAbbreviatedTerms Relating to Plas-

proper design of an HDPE manhole. Due to the variability in

tics

manhole height, diameter, and the soil, each manhole must be

D2321 PracticeforUndergroundInstallationofThermoplas-

designed and detailed individually. When properly used and

tic Pipe for Sewers and Other Gravity-Flow Applications

implemented, this practice can help ensure a safe and reliable

D2657 Practice for Heat Fusion Joining of Polyolefin Pipe

structure for the industry.

and Fittings

1.3 Disclaimer—The reader is cautioned that independent D2837 Test Method for Obtaining Hydrostatic Design Basis

professional judgment must be exercised when data or recom-

forThermoplasticPipeMaterialsorPressureDesignBasis

mendations set forth in this practice are applied. The publica- for Thermoplastic Pipe Products

tion of the material contained herein is not intended as a

D3035 SpecificationforPolyethylene(PE)PlasticPipe(DR-

representation or warranty on the part of ASTM that this PR) Based on Controlled Outside Diameter

information is suitable for general or particular use, or freedom

D3212 Specification for Joints for Drain and Sewer Plastic

frominfringementofanypatentorpatents.Anyonemakinguse

Pipes Using Flexible Elastomeric Seals

of this information assumes all liability arising from such use. D3350 Specification for Polyethylene Plastics Pipe and Fit-

The design of structures is within the scope of expertise of a

tings Materials

licensed architect, structural engineer, or other licensed profes- F412 Terminology Relating to Plastic Piping Systems

sional for the application of principles to a particular structure.

F477 Specification for Elastomeric Seals (Gaskets) for Join-

ing Plastic Pipe

1.4 The values stated in inch-pound units are to be regarded

F714 Specification for Polyethylene (PE) Plastic Pipe (DR-

as the standard. The SI units given in parentheses are provided

PR) Based on Outside Diameter

for information only.

F894 Specification for Polyethylene (PE) Large Diameter

1.5 This standard does not purport to address all of the

Profile Wall Sewer and Drain Pipe

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety, health, and environmental practices and deter-

3.1 Definitions:

mine the applicability of regulatory limitations prior to use.

3.1.1 Definitionsusedinthispracticeareinaccordancewith

1.6 This international standard was developed in accor-

Terminology F412 and Terminology D1600 unless otherwise

dance with internationally recognized principles on standard-

indicated.

3.2 Definitions of Terms Specific to This Standard:

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.26 on Olefin

Based Pipe. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 1, 2018. Published March 2018. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1997. Last previous edition approved in 2010 as F1759 – 97 (2010). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/F1759-97R18. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1759 − 97 (2018)

3.2.1 anchor connection ring—an HDPE ring attached to

the manhole riser on which to place an antiflotation device,

such as a concrete anchor ring.

3.2.2 arching—mobilization of internal shear resistance

within a soil mass that results in a change in soil pressure

acting on an underground structure.

3.2.3 benching—the internal floor of a manhole when it is

elevated above the manhole invert, usually provided as a place

for personnel to stand.

3.2.4 closed profile—a manhole barrel construction that

presents an essentially smooth internal surface braced with

projections or ribs, which are joined by an essentially smooth

outer wall. Solid wall construction is considered a special case

of the closed profile.

3.2.5 downdrag—downward shear force acting on the

shaft’s external surface and resulting from settlement of the

manhole backfill.

3.2.6 extrusion welding—a joining technique that is accom-

plished by extruding a molten polyethylene bead between two

prepared surface ends.

3.2.7 floor—the lowest internal surface of the manhole. The

floor and bottom are often the same.

3.2.8 inlet/outlet—pipe (conduit) passing through the wall

of the manhole.

FIG. 1 Manhole Terminology

3.2.9 invert—the flow channel in the floor of a manhole.

This may consist of the lower half of a pipe, thus the name

“invert”.

4.2 Design Assumption—The design methodology in this

3.2.10 manhole—an underground service access structure,

practice applies only to manholes that are installed in backfill

which can access pipelines, conduits, or subsurface equipment.

consisting of Class I, Class II, or Class III material as defined

3.2.11 manhole bottom—the lowest external surface of the inPracticeD2321,whichhasbeencompactedtoaminimumof

manhole. 90 % standard proctor density. The designs are based on the

backfillextendingatleast3.5ft(1m)fromtheperimeterofthe

3.2.12 manhole cone—the top portion of the manhole

manhole for the full height of the manhole and extending

through which entrance to the manhole is made and where the

laterally to undisturbed in situ soil. Manholes are assumed

diameter may increase from the entrance way to the larger

placed on a stable base consisting of at least 12 in. (30.5 cm)

manhole barrel. Sometimes referred to as the manway reducer.

of Class I material compacted to at least 95 % standard proctor

3.2.13 open profile—a manhole barrel construction that

density or a concrete slab. The foundation soils under the base

presents an essentially smooth internal surface with a ribbed or

must provide adequate bearing strength to carry downdrag

corrugated external surface. Open profile barrel constructions

loads.

are normally not used for manholes.

4.2.1 Manholes installed in sanitary landfills or other fills

3.2.14 performance limits—mechanisms by which the func-

experiencing large settlements may require special designs

tion of a structure may become impaired.

beyondthescopeofthispractice.Thedesignershouldevaluate

each specific site to determine the suitability for use of HDPE

3.2.15 riser—the vertical barrel or “shaft” section of a

manholes and the designer should prepare a written specifica-

manhole.

tion for installation, which is beyond the scope of this practice.

3.3 See Fig. 1 for illustration of manhole terminology.

5. Materials

4. Significance and Use

5.1 HDPE Material—Manhole components, such as the

4.1 Uses—The requirements of this practice are intended to

riser,base,andanchorconnectionring,shallbemadeofHDPE

providemanholessuitableforinstallationinpipelineorconduit

plastic compound having a cell classification of 334433C or

trenches, landfill perimeters, and landfills with limited settle-

higher, in accordance with Specification D3350.

ment characteristics. Direct installation in sanitary landfills or

NOTE 1—Materials for use in manholes may be subjected to significant

other fills subject to large (in excess of 10 %) soil settlements

tensile and compressive stresses. The material must have a proven

may require special designs outside the scope of this practice.

capacity for sustaining long-term stresses. There are no existing ASTM

4.1.1 Manholes are assumed to be subject to gravity flow

standardsthatestablishsuchastressratingexceptforTestMethodD2837.

only. Work is currently in progress to develop an alternate method for stress

F1759 − 97 (2018)

rating materials and when completed, this standard will be altered

accordingly.

5.2 Other Material—Manholecomponents,suchastopsand

lids,maybefabricatedfrommaterialsotherthanHDPEaslong

as agreed to by the user and manufacturer.

6. Subsurface Loading on Manhole Riser

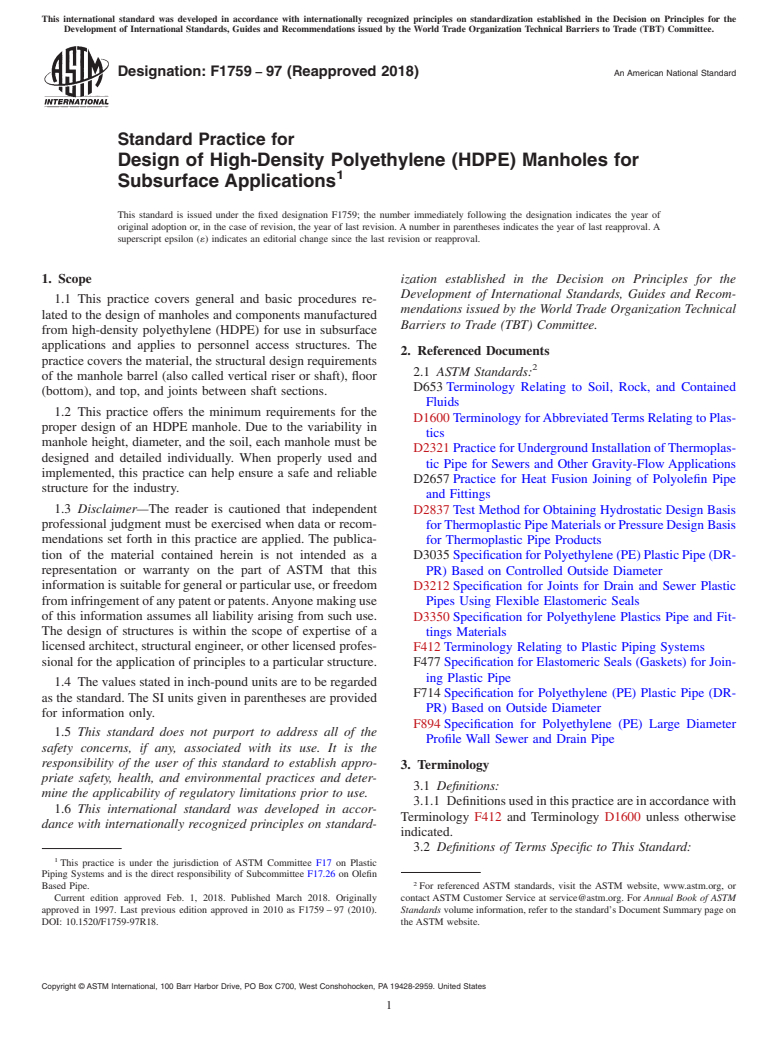

6.1 Performance Limits—The manhole riser’s performance

limits include ring deflection, ring (hoop) and axial stress (or

strain), and ring and axial buckling. Radially directed loads

acting on a manhole cause ring deformation and ring bending

stresses.Theradialloadvariesalongthelengthofthemanhole.

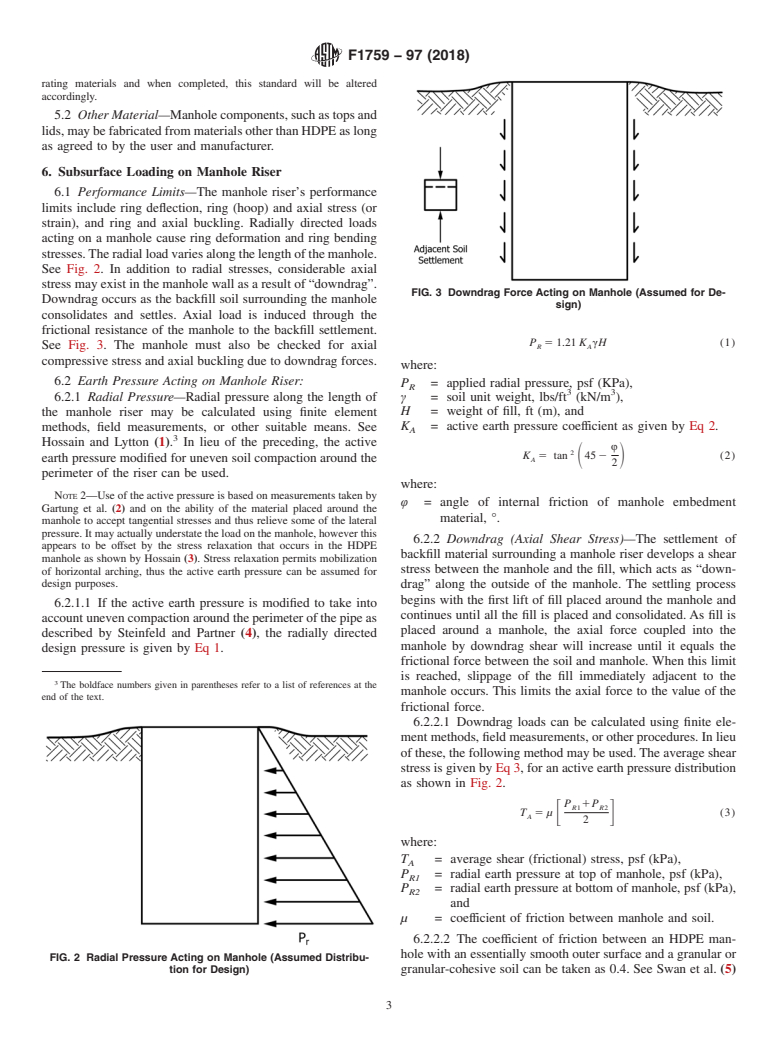

See Fig. 2. In addition to radial stresses, considerable axial

stress may exist in the manhole wall as a result of “downdrag”.

FIG. 3 Downdrag Force Acting on Manhole (Assumed for De-

Downdrag occurs as the backfill soil surrounding the manhole

sign)

consolidates and settles. Axial load is induced through the

frictional resistance of the manhole to the backfill settlement.

P 5 1.21 K γH (1)

See Fig. 3. The manhole must also be checked for axial R A

compressive stress and axial buckling due to downdrag forces.

where:

6.2 Earth Pressure Acting on Manhole Riser:

P = applied radial pressure, psf (KPa),

R

3 3

6.2.1 Radial Pressure—Radial pressure along the length of

γ = soil unit weight, lbs/ft (kN/m ),

H = weight of fill, ft (m), and

the manhole riser may be calculated using finite element

K = active earth pressure coefficient as given by Eq 2.

methods, field measurements, or other suitable means. See

A

Hossain and Lytton (1). In lieu of the preceding, the active

φ

K 5 tan 45 2 (2)

S D

earth pressure modified for uneven soil compaction around the A

perimeter of the riser can be used.

where:

NOTE 2—Use of the active pressure is based on measurements taken by

φ = angle of internal friction of manhole embedment

Gartung et al. (2) and on the ability of the material placed around the

material, °.

manhole to accept tangential stresses and thus relieve some of the lateral

pressure. It may actually understate the load on the manhole, however this

6.2.2 Downdrag (Axial Shear Stress)—The settlement of

appears to be offset by the stress relaxation that occurs in the HDPE

backfill material surrounding a manhole riser develops a shear

manhole as shown by Hossain (3). Stress relaxation permits mobilization

stress between the manhole and the fill, which acts as “down-

of horizontal arching, thus the active earth pressure can be assumed for

design purposes. drag” along the outside of the manhole. The settling process

begins with the first lift of fill placed around the manhole and

6.2.1.1 If the active earth pressure is modified to take into

continues until all the fill is placed and consolidated. As fill is

accountunevencompactionaroundtheperimeterofthepipeas

placed around a manhole, the axial force coupled into the

described by Steinfeld and Partner (4), the radially directed

manhole by downdrag shear will increase until it equals the

design pressure is given by Eq 1.

frictional force between the soil and manhole. When this limit

is reached, slippage of the fill immediately adjacent to the

The boldface numbers given in parentheses refer to a list of references at the

manhole occurs. This limits the axial force to the value of the

end of the text.

frictional force.

6.2.2.1 Downdrag loads can be calculated using finite ele-

ment methods, field measurements, or other procedures. In lieu

of these, the following method may be used.The average shear

stress is given by Eq 3, for an active earth pressure distribution

as shown in Fig. 2.

P 1P

R1 R2

T 5 µ (3)

F G

A

where:

T = average shear (frictional) stress, psf (kPa),

A

P = radial earth pressure at top of manhole, psf (kPa),

R1

P = radial earth pressure at bottom of manhole, psf (kPa),

R2

and

µ = coefficient of friction between manhole and soil.

6.2.2.2 The coefficient of friction between an HDPE man-

hole with an essentially smooth outer surface and a granular or

FIG. 2 Radial Pressure Acting on Manhole (Assumed Distribu-

tion for Design) granular-cohesive soil can be taken as 0.4. See Swan et al. (5)

F1759 − 97 (2018)

and Martin et al. (6). In some applications the coefficient of where:

friction may be reduced by coating the exterior of the manhole

P ' = applied radial pressure, psf (kPa),

R

with bentonite or some other lubricant.

K = active earth pressure coefficient,

A

H = height of fill, ft (m),

NOTE 3—The use of external stiffeners or open profiles to stiffen the

γ = unit weight of water, pcf (kN/m ), and

W

riser greatly increases the downdrag load due to their impeding the

γ = unit weight of saturated soil, pcf (kN/m ).

S

settlement of soil beside the manhole. This has the effect of increasing the

6.3.3 Where partial saturation of the soil exists, that is

average shear stress in Eq 3. Where open profiles are used, the coefficient

of friction may equal or exceed 1.0.

where the groundwater level is below the ground surface but

above the manhole invert, the radial pressure can be found by

6.2.2.3 The downdrag creates an axial-directed load (down-

combining the pressure due to the soil above the groundwater

drag load) in the manhole wall that increases with depth. The

levelandthepressuregiveninEq5duetothegroundwaterand

axial force developed on the manhole can be found by

the submerged soil. In this case, H' as given in Eq 6 should be

integrating the shear stress (or frictional stress) between the

substituted for H in Eq 5. See Appendix X2.

manhole and soil over the height of the fill. This integrati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.