ASTM D5887-99

(Test Method)Standard Test Method for Measurement of Index Flux Through Saturated Geosynthetic Clay Liner Specimens Using a Flexible Wall Permeameter

Standard Test Method for Measurement of Index Flux Through Saturated Geosynthetic Clay Liner Specimens Using a Flexible Wall Permeameter

SCOPE

1.1 This test method is an index test that covers laboratory measurement of flux through saturated geosynthetic clay liner (GCL) specimens using a flexible wall permeameter.

1.2 This test method is applicable to GCL products having geotextile backing(s). It may not be applicable to GCL products with geomembrane backing(s).

1.3 This test method provides a measurement of flux under a prescribed set of conditions that can be used for manufacturing quality control. The test method can also be used to check conformance. The flux value determined using this test method is not considered to be representative of the in-service flux of GCLs.

1.4 The values stated in SI units are to be regarded as the standard, unless other units are specifically given.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5887 – 99

Standard Test Method for

Measurement of Index Flux Through Saturated Geosynthetic

Clay Liner Specimens Using a Flexible Wall Permeameter

This standard is issued under the fixed designation D 5887; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 145 Specification for Gravity—Convection and Forced-

Ventilation Ovens

1.1 This test method is an index test that covers laboratory

E 691 Practice for Conducting an Interlaboratory Study to

measurement of flux through saturated geosynthetic clay liner

Determine the Precision of a Test Method

(GCL) specimens using a flexible wall permeameter.

1.2 This test method is applicable to GCL products having

3. Terminology

geotextile backing(s). It may not be applicable to GCL prod-

3.1 Definitions:

ucts with geomembrane backing(s).

3.1.1 flux, n—the rate of discharge of water under laminar

1.3 This test method provides a measurement of flux under

flow conditions through a unit cross-sectional area of a GCL

a prescribed set of conditions that can be used for manufactur-

specimen.

ing quality control. The test method can also be used to check

3.1.2 geosynthetic clay liner (GCL), n—a factory-

conformance. The flux value determined using this test method

manufactured geosynthetic hydraulic barrier consisting of clay

is not considered to be representative of the in-service flux of

supported by geotextiles, or geomembranes, or both, that are

GCLs.

held together by needling, stitching, or chemical adhesives.

1.4 The values stated in SI units are to be regarded as the

3.1.3 index test, n—a test procedure that may contain a bias,

standard, unless other units are specifically given.

but that may be used to establish an order for a set of specimens

1.5 This standard does not purport to address all of the

with respect to the property of interest.

safety concerns, if any, associated with its use. It is the

3.1.4 For definitions of other terms used in this test method,

responsibility of the user of this standard to establish appro-

see Terminology D 653 and Terminology D 4439.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Summary of Test Method

2. Referenced Documents 4.1 This test method involves permeation of a 100-mm

(4-in.) diameter GCL test specimen. The specimen is set up in

2.1 ASTM Standards:

a flexible-wall permeameter, subjected to a total stress of 550

D 653 Terminology Relating to Soil, Rock, and Contained

2 kPa (80 psi) and a backpressure of 515 kPa (75 psi) for a period

Fluids

of 48 h. Flow is initiated using deionized water by raising the

D 2216 Test Method for Laboratory Determination of Water

2 pressure on the influent side of the test specimen to 530 kPa (77

(Moisture) Content of Soil and Rock

3 psi). The flux is determined when inflow and outflow are

D 4439 Terminology for Geosynthetics

approximately equal (within 625 %).

D 4753 Specification for Evaluating, Selecting, and Speci-

fying Balances and Scales for Use in Testing Soil, Rock,

5. Significance and Use

and Related Construction Materials

5.1 This test method yields the flux of water through a

D 5084 Test Method for Measurement of Hydraulic Con-

saturated GCL specimen that is consolidated, hydrated, and

ductivity of Saturated Porous Materials Using a Flexible

2 permeated under a prescribed set of conditions.

Wall Permeameter

5.2 This test method can be performed to determine if the

flux of a GCL specimen exceeds the maximum value stated by

This test method is under the jurisdiction of ASTM Committee D-35 on the manufacturer.

Geosynthetics and is the direct responsibility of Subcommittee D35.04 on Geosyn-

thetic Clay Liners.

Current edition approved Jan. 10, 1999. Published April 1999. Originally

published as D5887–95. Last previous edition D5887–96.

2 4

Annual Book of ASTM Standards, Vol 04.08. Annual Book of ASTM Standards, Vol 14.04.

3 5

Annual Book of ASTM Standards, Vol 04.13. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5887–99

5.3 This test method can be used to determine the variation other device of suitable accuracy. More information on testing

in flux within a sample of GCL by testing a number of different with a constant rate of flow is given in the literature.

6.1.4 System De-Airing—The hydraulic system shall be

specimens.

designed to facilitate rapid and complete removal of free air

5.4 This test method does not provide a flux value to be used

bubbles from flow lines.

directly in design calculations.

6.1.5 Back Pressure System—The hydraulic system shall

NOTE 1—Flux for in-service conditions depends on a number of factors,

have the capability to apply back pressure to the specimen to

including confining pressure, type of hydration fluid, degree of hydration,

facilitate saturation. The system shall be capable of maintain-

degree of saturation, type of permeating fluid, and hydraulic gradient.

ing the applied back pressure throughout the duration of

Correlation between flux values obtained with this test method and flux

hydraulic conductivity measurements. The back pressure sys-

through GCLs subjected to in-service conditions has not been fully

tem shall be capable of applying, controlling, and measuring

investigated.

the back pressure within 65 % of the applied pressure. The

5.5 This test method does not provide a value of hydraulic

back pressure may be provided by a compressed gas supply, a

conductivity. Although hydraulic conductivity can be deter-

deadweight acting on a piston, or any other method capable of

mined in a manner similar to the method described herein, the

applying and controlling the back pressure to the tolerance

thickness of the specimen is needed to calculate hydraulic

prescribed in this paragraph.

conductivity. This test method does not include procedures for

NOTE 2—Application of gas pressure directly to a fluid will dissolve

measuring the thickness of the GCL nor of the clay component

gas in the fluid. A variety of techniques are available to minimize

within the GCL.

dissolution of gas in the back pressure fluid, including separation of gas

5.6 The apparatus used in this test method is commonly

and liquid phases with a bladder and frequent replacement of the liquid

with de-aired water.

used to determine the hydraulic conductivity of soil specimens.

However, flux values measured in this test are typically much

6.2 Flow Measurement System—Both inflow and outflow

lower than those commonly measured for most natural soils. It

volumes shall be measured unless the lack of leakage, conti-

is essential that the leakage rate of the apparatus used in this

nuity of flow, and cessation of consolidation or swelling can be

test be less than 10 % of the flux.

verified by other means. Flow volumes shall be measured by a

graduated accumulator, graduated pipette, vertical standpipe in

6. Apparatus

conjunction with an electronic pressure transducer, or other

volume-measuring device of suitable accuracy.

6.1 Hydraulic System, constant head (Test Method A),

6.2.1 Flow Accuracy—Required accuracy for the quantity

falling head (Test Methods B and C), or constant rate of flow

of flow measured over an interval of time is 65%.

(Test Method D) systems may be utilized provided they meet

6.2.2 De-Airing and Compliance of the System—The flow-

the criteria outlined as follows:

measurement system shall contain a minimum of dead space

6.1.1 Constant Head—The system shall be capable of

and be capable of complete and rapid de-airing. Compliance of

maintaining constant hydraulic pressures to within 65 % and

the system in response to changes in pressure shall be

shall include means to measure the hydraulic pressures to

minimized by using a stiff flow measurement system. Rigid

within the prescribed tolerance. In addition, the head loss

tubing, such as metallic or rigid thermoplastic tubing, shall be

across the test specimen must be held constant to within 65%

used.

and shall be measured with the same accuracy or better.

6.2.3 Head Losses—Head losses in the tubes, valves, po-

Pressures shall be measured by a pressure gage, electronic

rous end pieces, and filter paper may lead to error. To guard

pressure transducer, or any other device of suitable accuracy.

against such errors, the permeameter shall be assembled with

6.1.2 Falling Head—The system shall allow for measure-

no specimen inside and then the hydraulic system filled. If a

ment of the applied head loss to within 65 % at any time. In

constant or falling head test is to be used, the hydraulic

addition, the ratio of initial head loss divided by final head loss

pressures or heads that will be used in testing a specimen shall

over an interval of time shall be measured such that this

be applied, and the rate of flow measured with an accuracy of

computed ratio is accurate to within 65 %. The head loss shall

65 %. This rate of flow shall be at least ten times greater than

be measured with a pressure gage, electronic pressure trans-

the rate of flow that is measured when a specimen is placed

ducer, engineer’s scale, graduated pipette, or any other device

inside the permeameter and the same hydraulic pressures or

of suitable accuracy. Falling head tests may be performed with

heads are applied. If a constant rate of flow test is to be used,

either a constant tailwater elevation (Test Method B) or a rising

the rate of flow to be used in testing a specimen shall be

tailwater elevation (Test Method C).

supplied to the permeameter and the head loss measured. The

6.1.3 Constant Rate of Flow—The system shall be capable head loss without a specimen shall be less than 0.1 times the

of maintaining a constant rate of flow through the specimen to head loss when a specimen is present.

within 65 %. Flow measurement shall be by calibrated sy-

ringe, graduated pipette, or other device of suitable accuracy.

Olson, H. W., Morin, R. H., and Nichols, R. W., “Flow Pump Applications in

The head loss across the specimens shall be measured to an

Triaxial Testing,” Symposium on Advanced Triaxial Testing of Soil and Rock, ASTM

accuracy of 65 % using an electronic pressure transducer or STP 977, ASTM, 1988, pp. 68–81.

D5887–99

6.3 Permeameter Cell Pressure System—The system for or by monitoring of either a loading piston or an extensometer

pressurizing the permeameter cell shall be capable of applying extending through the top plate of the cell bearing on the top

and controlling the cell pressure to within 65 % of the applied cap and attached to a dial indicator or other measuring device.

pressure. However, the effective stress on the test specimen The piston or extensometer should pass through a bushing and

shall be maintained to the desired value with an accuracy of seal incorporated into the top plate and shall be loaded with

65 %. The device for pressurizing the cell may consist of a sufficient force to compensate for the cell pressure acting over

reservoir connected to the permeameter cell and partially filled the cross-sectional area of the piston where it passes through

with de-aired water, with the upper part of the reservoir the seal. If deformations are measured, the deformation indi-

connected to a compressed gas supply or other source of cator shall be a dial indicator or cathetometer graduated to 0.3

pressure (see Note 3). The gas pressure shall be controlled by mm (0.01 in.) or better and having an adequate travel range.

a pressure regulator and measured by a pressure gage, elec- Any other measuring device meeting these requirements is

tronic pressure transducer, or any other device capable of acceptable.

measuring to the prescribed tolerance. A hydraulic system

6.4.2 To facilitate gas removal, and thus saturation of the

pressurized by deadweight acting on a piston or any other hydraulic system, four drainage lines leading to the specimen,

pressure device capable of applying and controlling the per-

two each to the base and top cap, are recommended. The

meameter cell pressure to the tolerance prescribed in this

drainage lines shall be controlled by no-volume-change valves,

paragraph may be used.

such as ball valves, and shall be designed to minimize dead

space in the lines.

NOTE 3—De-aired water is commonly used for the cell fluid to

6.5 Top Cap and Base—An impermeable, rigid top cap and

minimize potential for diffusion of air through the membrane into the

specimen. Other fluids, such as oils, which have low gas solubilities, are base shall be used to support the specimen and provide for

also acceptable, provided they do not react with components of the

transmission of permanent liquid to and from the specimen.

permeameter and the flexible membrane. Also, use of a long (approxi-

The diameter or width of the top cap and base shall be equal to

mately 5 to 7 m) tube connecting the pressurized cell liquid to cell helps

the diameter or width of the specimen 65 %. The base shall

to delay the appearance of air in the cell fluid and to reduce the flux of

prevent leakage, lateral motion, or tilting, and the top cap shall

dissolved air into the cell.

be deigned to receive the piston or extensometer, if used, such

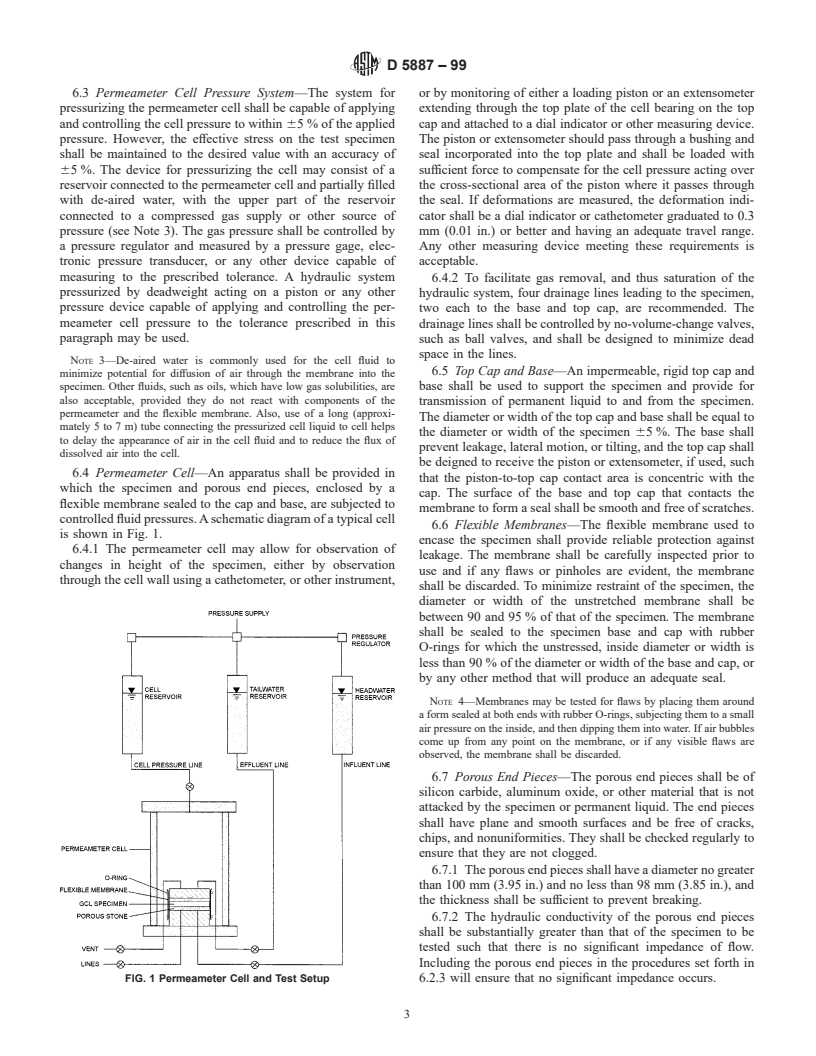

6.4 Permeameter Cell—An apparatus shall be provided in

that the piston-to-top cap contact area is concentric with the

which the specimen and porous end pieces, enclosed by a

cap. The surface of the base and top cap that contacts the

flexible membrane sealed to the cap and base, are subjected to

membrane to form a seal shall be smooth and free of scratches.

controlled fluid pressures. A schematic diagram of a typical cell

6.6 Flexible Membranes—The flexible membrane used to

is shown in Fig. 1.

encase the specimen shall provide reliable protection against

6.4.1 The permeameter cell may allow for observation of

leakage. The membrane shall be carefully inspected prior to

changes in height of the specimen, either by observation

use and if any flaws or pinholes are evident, the membrane

through the cell wall using a cathetometer, or other instrument,

shall be discarded. To minimize restraint of the specimen, the

diameter or width of the unstretched membrane shall be

between 90 and 95 % of that of the specimen. The membrane

shall be sealed to the specimen base and cap with rubber

O-rings for which the unstressed, inside diameter or width is

less than 90 % of the diameter or width of the base and cap, or

by any other method that will produce an adequate seal.

NOTE 4—Membranes may be tested for flaws by placi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.