ASTM E1182-93(1998)

(Test Method)Standard Test Method for Measurement of Surface Layer Thickness by Radial Sectioning

Standard Test Method for Measurement of Surface Layer Thickness by Radial Sectioning

SCOPE

1.1 This test method covers the radial sectioning technique 2,3,4 for measurement of the thickness of thin surface layers, made by a wide variety of processes, on metals, alloys, carbides, and oxides.

1.2 This test method is applicable to measurement of a wide variety of surface layer types where the interface between the layer and substrate is discernible by natural color or reflectivity differences or by means of color or reflectivity differences due to etching or staining.

1.3 This test method does not pertain to layer thickness measurements made by analysis of compositional variations.

1.4 This test method deals only with the recommended test method and nothing in it should be construed as defining or establishing limits of acceptability for any coating method.

1.5 The measurement values stated are in the metric system, as defined in Standard E380.

1.6 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1182 – 93 (Reapproved 1998)

Standard Test Method for

Measurement of Surface Layer Thickness by Radial

Sectioning

This standard is issued under the fixed designation E 1182; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E 7 Terminology Relating to Metallography

E 380 Practice for Use of the International System of Units

1.1 This test method covers the radial sectioning tech-

2,3,4

(SI) (the Modernized Metric System)

nique for measurement of the thickness of thin surface

E 407 Practice for Microetching Metals and Alloys

layers, made by a wide variety of processes, on metals, alloys,

E 691 Practice for Conducting an Interlaboratory Study to

carbides, and oxides.

Determine the Precision of a Test Method

1.2 This test method is applicable to measurement of a wide

F 110 Test Method for Thickness of Epitaxial or Diffused

variety of surface layer types where the interface between the

Layers in Silicon by the Angle Lapping and Staining

layer and substrate is discernible by natural color or reflectivity

Technique

differences or by means of color or reflectivity differences due

to etching or staining.

3. Terminology

1.3 This test method does not pertain to layer thickness

3.1 Definitions:

measurements made by analysis of compositional variations.

3.1.1 For definitions of terms used in this test method, see

1.4 This test method deals only with the recommended test

Terminology E 7.

method and nothing in it should be construed as defining or

3.2 Definitions of Terms Specific to This Standard:

establishing limits of acceptability for any coating method.

3.2.1 arcuic trigonometric measurement—method for mea-

1.5 The measurement values stated are in the metric system,

suring the thickness of a surface layer using a radial cut of

as defined in Practice E 380.

radius R through the layer into the substrate and measurement

1.6 This standard does not purport to address all of the

of the widths of the cut at the top of the layer and at the

safety concerns associated with its use. It is the responsibility

layer-substrate interface.

of the user of this standard to establish appropriate safety and

3.2.2 radial sectioning—a machining procedure for produc-

health practices and determine the applicability of regulatory

ing a precise groove on the surface of a sample to a depth

limitations prior to use. For specific precautionary statements,

below the layer interface, that is, through a surface layer into

see Section 7.

the substrate, using a line or spot spindle of known radius.

2. Referenced Documents 3.3 Symbols:Symbols:

3.3.1 R—radius of the machined groove.

2.1 ASTM Standards:

3.3.2 W — width of the groove at the top surface.

B 487 Test Method for Measurement of Metal and Oxide

3.3.3 W — width of the groove at the layer-substrate

Coating Thickness by Microscopical Examination of a 2

interface.

Cross Section

3.3.4 x —thickness of the surface layer.

t

3.3.5 C—correlation factor to correct for the deflection of

the spindle when the spindle contacts the specimen.

This test method is under the jurisdiction of ASTM Committee E-4 on

4. Summary of Test Method

Metallography and is the direct responsibility of Subcommittee E04.14 on Quanti-

tative Metallography.

4.1 Radial sectioning, using either a line or spot sectioning

Current edition approved Aug. 15, 1993. Published October 1993. Originally

spindle with a known, constant diameter, is used to cut

published as E 1182 – 87. Last previous edition E 1182 – 87.

Happ, W. W., and Shockley, W., “Diffusion Depths in Silicon Measured by tangentially into the surface of a coated specimen to a depth

Using Cylindrical Grooves,” Bulletin of the American Physical Society, Series II,

below the interface between the surface layer and the substrate.

Vol 1, 1956, p. 382.

4.2 The interface between the layer and substrate is revealed

McDonald, B., and Goetzuberger, A., “Measurement of the Depth of Diffused

Layers in Silicon by the Grooving Method,” Journal of the Electrochemical Society,

Vol 109, February 1962, pp. 141–144.

Whitelam, F. E., “Using Radial Sectioning to Measure Thin Layers,” Metal

Annual Book of ASTM Standards, Vol 03.01.

Progress, Vol 127, March 1985, pp. 45, 46, 49, and 50.

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 02.05.

Annual Book of ASTM Standards, Vol 10.05.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 1182

by appropriate etching or staining techniques. For certain

materials, such as oxide, carbide, or nitride layers, the interface

will be clearly visible after radial sectioning.

4.3 The groove is examined using a metallurgical micro-

scope and the widths, W and W , are measured using a reticle

1 2

scale or filar micrometer eyepiece.

4.4 The layer thickness, x , is calculated using the following

t

equation:

2 1 2 2 1 2

W / W /

2 1

2 2

x 5 R 2 2 C 2 R 2 2 C (1)

F S D G F S D G

t

2 2

The terms are defined in 3.3.

5. Significance and Use

5.1 Many processes are used to produce a specific type of

surface layer on a substrate to produce desired surface prop-

erties, such as corrosion resistance, wear resistance, and so

forth. Measurement of the thickness of these layers is an

important quality control procedure.

5.2 The radial sectioning method is suitable for process

control, research, development, and materials acceptance pur-

poses.

5.3 The radial sectioning method and arcuic trigonometric

measurement procedure are suited for measurement of surface

layers with thicknesses in the range of 0.05 to 200 μm. Thicker

layers should be measured by other procedures, such as

standard cross sections, as described in Test Method B 487.

5.4 This test method shall not be used as a referee method

for layers thinner than 0.5 μm if a more suitable method is

available.

5.5 Measurement of the thickness of surface layers is

influenced by the smoothness of the substrate and by the

uniformity of the layer thickness.

6. Apparatus

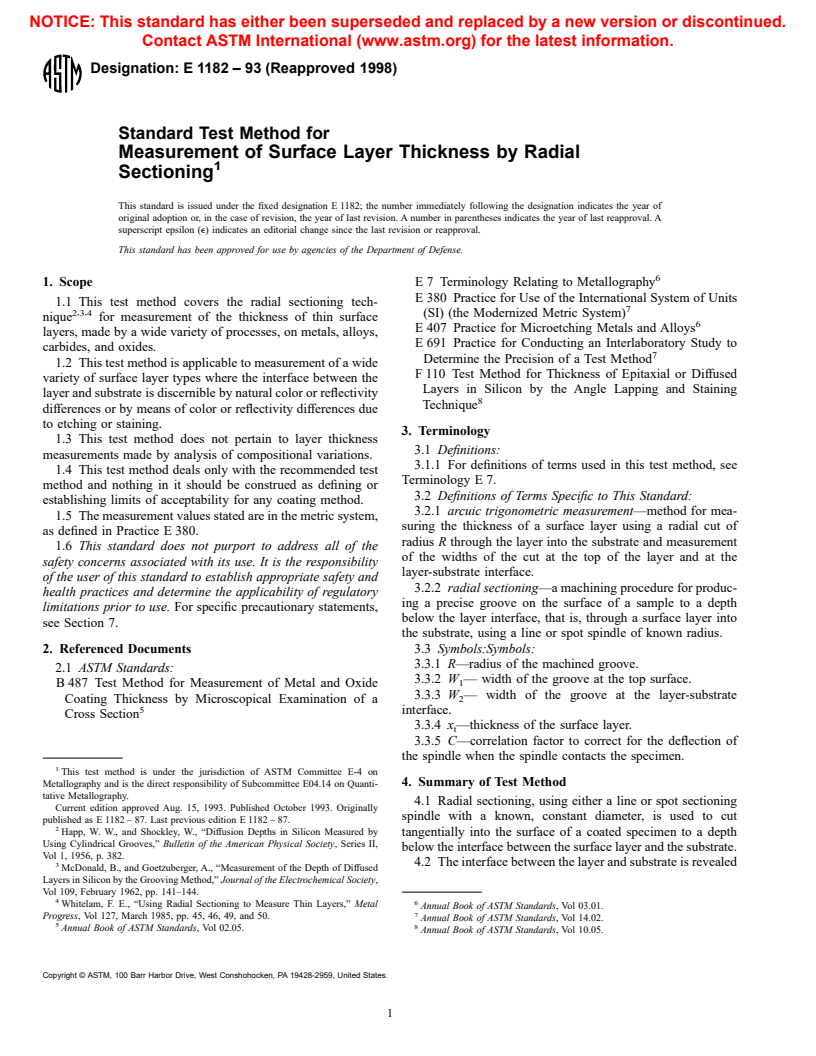

FIG. 1 Schematic Showing the Rotating Spindle ( C), Drive Motor

(M), Specimen Holder (A) and Specimen (B) for Producing Radial

6.1 Line or Spot Spindle, uniformly coated with a thin layer

Sections in Coated Specimens

of abrasive, motor driven to rotate concentrically about its axis

within 60.0127 mm (60.0005 in.). The abrasive particle size,

spindle–binder type, lubricant–coolant type, spindle rpm, and

8. Sampling, Test Specimens, and Test Units

section force are selected to provide the maximum cutting rate

and optimum surface finish consistent with the characteristics 8.1 The thickness of surface layers and coatings will vary

of the coating and substrate. Typical abrasive particle sizes across the specimen. The thickness variability will depend on

range from 0.25 to 15.0 μm with a size uniformity of 633 % the coating process and parameters, size and shape of the

for abrasives with a nominal size greater than 1 μm and coated specimen, etc.

6100 % for abrasives smaller than 1 μm. Fig. 1 shows a

8.2 Specimens shall be taken from one or more locations to

schematic of the device and the relationship of the specimen to

assess the thickness and its variability. If cutting or shearing is

the device.

required to obtain the required test specimens, such processes

6.2 Specimen Holder, to firmly hold the specimen against should not alter the surface layer of interest.

the rotating spindle. Holder may be a frame device designed to

8.3 Specimens should be selected from areas that are

accommodate a variety of sample shapes and sizes while

representative of the bulk sample, are in critical areas, or are at

holding the specimen rigidly.

locations where coating uniformity is difficult to obtain,

6.3 Metallurgical Microscope, equipped with a measuring

depending on the purpose of the examination.

reticle or filar micrometer eyepiece, or a toolmaker’s micro-

8.4 The extent of sampling must be guided by good engi-

scope.

neering practice so that enough locations are tested to define

the thickness without incurring excessive testing costs.

7. Safety Precautions

8.5 Specimen surfaces to be tested by radial sectioning shall

7.1 Safety precautions for handling etchants are provided in be cleaned before testing. The cleaning solvents shall not alter

Test Methods B 487, F 110, and Practice E 407. the coated surface.

E 1182

9. Calibration and Standardization the layer interface or interfaces.

10.11 When the interface or interfaces are clearly defined,

9.1 The micrometer eyepiece or recticle scale shall be

remove the specimen and halt the etching or staining action by

calibrated with a certified stage micrometer at the same

rinsing the specimen with flowing water. Rinse the specimen

magnification, by the same operator, using the same optics and

with alcohol and dry it with a blast of hot air or compressed air.

lighting as used for the measurements. Filtered or monochro-

Reinspect the specimen to ensure that the interface or inter-

matic light shall be used for best precision. The calibration

faces are clearly and distinctly revealed. Repeat the etching or

interval on the stage micrometer shall be centered in the field

staining operation if necessary.

of view and shall be restricted to the center portion of the

10.12 Place the specimen on the stage of a high quality

image.

reflected-light microscope or metallograph, or toolmaker’s

9.2 The distance between the two lines of the stage mi-

microscope, fitted with a calibrated measuring eyepiece reticle

crometer used for the calibration shall be known within 0.2 μm

or filar micrometer eyepiece and adjust the magnification,

or 0.1 %, whichever is greater.

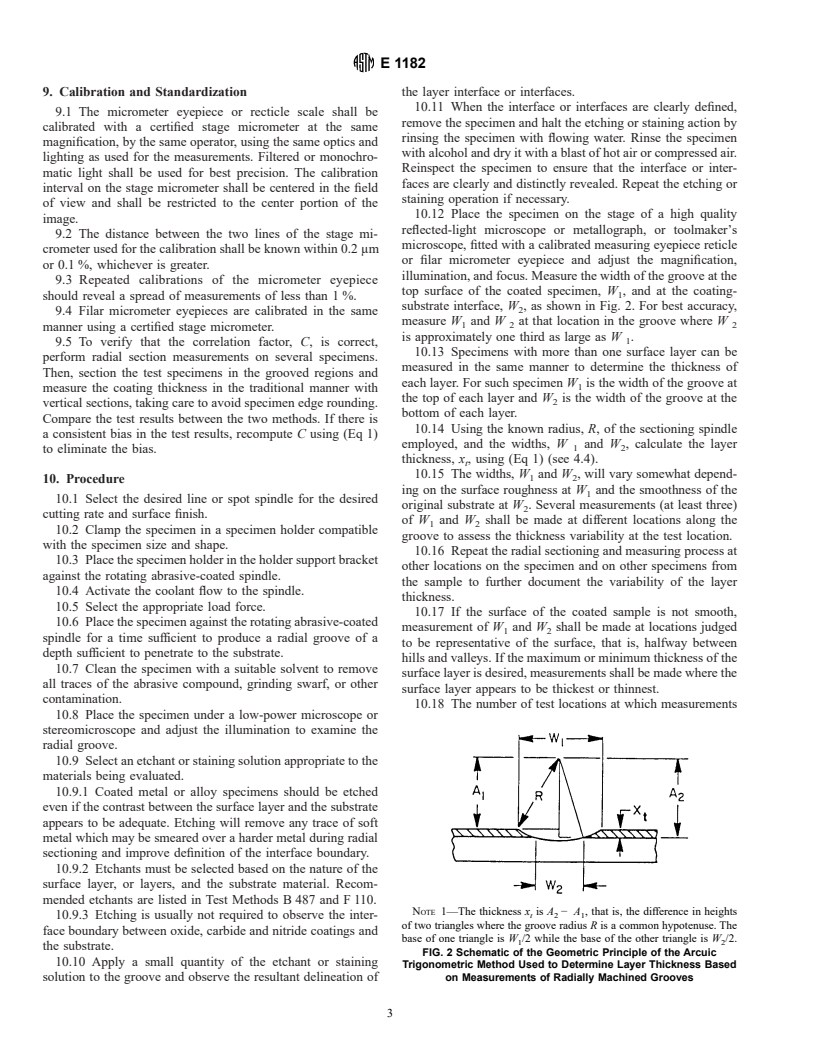

illumination, and focus. Measure the width of the groove at the

9.3 Repeated calibrations of the micrometer eyepiece

top surface of the coated specimen, W , and at the coating-

should reveal a spread of measurements of less than 1 %.

substrate interface, W , as shown in Fig. 2. For best accuracy,

9.4 Filar micrometer eyepieces are calibrated in the same

measure W and W at that location in the groove where W

1 2 2

manner using a certified stage micrometer.

is approximately one third as large as W .

9.5 To verify that the correlation factor, C, is correct,

10.13 Specimens with more than one surface layer can be

perform radial section measurements on several specimens.

measured in the same manner to determine the thickness of

Then, section the test specimens in the grooved regions and

each layer. For such specimen W is the width of the groove at

measure the coating thickness in the traditional manner with

the top of each layer and W is the width of the groove at the

vertical sections, taking care to avoid specimen edge rounding.

bottom of each layer.

Compare the test results between the two methods. If there is

10.14 Using the known radius, R, of the sectioning spindle

a consistent bias in the test results, recompute C using (Eq 1)

employed, and the widths, W and W , calculate the layer

1 2

to eliminate the bias.

thickness, x , using (Eq 1) (see 4.4).

t

10.15 The widths, W and W , will vary somewhat depend-

1 2

10. Procedure

ing on the surface roughness at W and the smoothness of the

10.1 Select the desired line or spot spindle for the desired

original substrate at W . Several measurements (at least three)

cutting rate and surface finish.

of W and W shall be made at different locations along the

1 2

10.2 Clamp the specimen in a specimen holder compatible

groove to assess the thickness variability at the test location.

with the specimen size and shape.

10.16 Repeat the radial sectioning and measuring process at

10.3 Place the specimen holder in the holder support bracket

other locations on the specimen and on other specimens from

against the rotating abrasive-coated spindle.

the sample to further document the variability of the layer

10.4 Activate the coolant flow to the spindle.

thickness.

10.5 Select the appropriate load force.

10.17 If the surface of the coated sample is not smooth,

10.6 Place the specimen against the rotating abrasive-coated

measurement of W and W shall be made at locations judged

1 2

spindle for a time sufficient to produce a radial groove of a

to be representative of the surface, that is, halfway between

depth sufficient to penetrate to the substrate.

hills and valleys. If the maximum or minimum thickness of the

10.7 Clean the specimen with a suitable solvent to remove

surface layer is desired, measurements shall be made where the

all traces of the abrasive compound, grinding swarf, or other

surface layer appears to be thickest or thinnest.

contamination.

10.18 The number of test locations at which measurements

10.8 Place the specimen under a low-power microscope or

stereomicroscope and adjust the illumination to examine the

radial groove.

10.9 Select an etchant or staining solution appropriate to the

materials being evaluated.

10.9.1 Coated metal or alloy specimens should be etched

even if the contrast between the surface layer and the substrate

appears to be adequate. Etching will remove any trace of soft

metal which may be smeared over a harder metal during radial

sectioning and improve definition of the interface boundary.

10.9.2 Etchants must be selected based on the nature of the

surface layer, or layers, and the substrate material. Recom-

mended etchants are listed in Test Methods B 487 and F 110.

NOTE 1—The thickness x is A − A , that is, the difference in heights

t 2 1

10.9.3 Etching is usually not required to observe the inter-

of two triangles where the groove radius R is a common hypotenuse. The

face boundary between oxide, carbide and nitride coatings and

base of one triangle is W /2 while the base of the other triangle is W /2.

1 2

the substrate.

FIG. 2 Schematic of the Geometric Principle of the Arcuic

10.10 Apply a small quantity of the etchant or staining

Trigonometric Method Used to Determine Layer Thickness Based

solution to the groove and observe the resultant delineation of on Measurements of Radially Machined Grooves

E 1182

are made, and the number of radial sections measured at each 12. Precision and Bias

test location, shall be sufficient to ensure statistical confidence

12.1 The radial sectioning procedure for measuring the

that the thickness measurement definition meets the required

thickness of surface layers is best suited for measurement of

needs.

thin layers, that is, thicknesses from 0.0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.