ASTM F1466-99

(Specification)Standard Specification for Iron-Nickel-Cobalt Alloys for Metal-to-Ceramic Sealing Applications

Standard Specification for Iron-Nickel-Cobalt Alloys for Metal-to-Ceramic Sealing Applications

SCOPE

1.1 This specification covers two iron-nickel-cobalt alloys, the former, (UNS No. K94630), containing nominally 29% nickel, 17% cobalt, and 53% iron, the latter, (UNS No. K94620), nominally 27% nickel, 25% cobalt and 48% iron, in the forms of wire, rod, bar, strip, sheet, and tubing, intended primarily for brazed metal-to-ceramic seals with alumina ceramics, for vacuum electronic applications. Unless otherwise indicated, all articles apply to both alloys.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following hazard caveat pertains only to the test method portion, Sections 14 and 16 of this specification. This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 1466 – 99

Standard Specification for

Iron-Nickel-Cobalt Alloys for Metal-to-Ceramic Sealing

Applications

This standard is issued under the fixed designation F 1466; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E112 Test Methods for Determining Average Grain Size

E140 Standard Hardness Conversion Tables for Metals

1.1 This specification covers two iron-nickel-cobalt alloys,

E228 Test Method for Linear Thermal Expansion of Solid

the former, (UNS No. K94630), containing nominally 29%

Materials with a Vitreous Silica Dilatometer

nickel, 17% cobalt, and 53% iron, the latter, (UNS No.

E 354 Test Methods for Chemical Analysis of High-

K94620), nominally 27% nickel, 25% cobalt and 48% iron,

Temperature, Electrical, Magnetic and Other Similar Iron,

in the forms of wire, rod, bar, strip, sheet, and tubing, intended

Nickel and Cobalt Alloys

primarily for brazed metal-to-ceramic seals with alumina

E1019 Test Methods for Determination of Carbon, Sulfur,

ceramics,forvacuumelectronicapplications.Unlessotherwise

Nitrogen, Oxygen and Hydrogen in Steel and in Iron,

indicated, all articles apply to both alloys.

Nickel and Cobalt Alloys

1.2 The values stated in inch-pound units are to be regarded

E1060 Practice for Interlaboratory Testing of Spectro-

as the standard. The values given in parentheses are for

chemical Methods of Analysis

information only.

F15 Specification for Iron-Nickel-Colbalt Sealing Alloy

1.3 The following hazard caveat pertains only to the test

method portion, Sections 14 and 16 of this specification. This

3. Ordering Information

standarddoesnotpurporttoaddressallofthesafetyconcerns,

3.1 Ordersformaterialunderthisspecificationshallinclude

ifany,associatedwithitsuse.Itistheresponsibilityoftheuser

the following information:

of this standard to establish appropriate safety and health

3.1.1 Alloy, as indicated with UNS number,

practices and determine the applicability of regulatory limita-

3.1.2 Size,

tions prior to use.

3.1.3 Temper designation (Section 6),

2. Referenced Documents 3.1.4 Surface finish (Section 10),

3.1.5 Marking and packaging (Section 19), and

2.1 ASTM Standards:

3.1.6 Certification, if required. Please note that certification

D1971 Practices for Digestion of Samples for Determina-

should include traceability of the heat to the original manufac-

tion of Metals by Flame Atomic Absorption or Plasma

turer.

Emission Spectroscopy

E3 Methods of Preparation of Metallographic Specimens

4. Chemical Requirements

E8 TestMethodsforTensionTestingofMetallicMaterials

4.1 Each alloy shall conform to the requirements as to

E18 Test Methods for Rockwell Hardness and Rockwell

3 chemical composition prescribed in Table 1.

Superficial Hardness of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to

5. Surface Lubricants

Determine Conformance with Specifications

5.1 All lubricants used during cold-working operations,

E45 Practice for Determining the Inclusion Content of

3 such as drawing, rolling, or spinning, shall be capable of being

Steel

removed readily by any of the common organic degreasing

E92 Test Method for Vickers Hardness of Metallic Mate-

3 solvents.

rials

6. Temper

1 6.1 The desired temper of the material shall be specified in

This specification is under the jurisdiction of ASTM Committee F-1 on

the purchase order.

Electronics and is the direct responsibility of Subcommittee F01.03 on Metallic

Materials.

Current edition approved Jan. 10, 1999. Published March 1999. Originally

{1

published as F 1466–93. Last previous edition F 1466–93 .

2 5

Annual Book of ASTM Standards, Vol 11.01. Annual Book of ASTM Standards, Vol 03.05.

3 6

Annual Book of ASTM Standards, Vol 03.01. Annual Book of ASTM Standards, Vol 03.06.

4 7

Annual Book of ASTM Standards, Vol 14.02. Annual Book of ASTM Standards, Vol 10.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1466

TABLE 1 Chemical Requirements TABLE 3 Tensile Strength Requirements for Wire and Rod

Tensile Strength, ksi (MPa)

NOTE 1—Round observed or calculated values to the nearest unit in the

Temper

last right-hand place of figures used in expressing the limiting value, in UNS No. K94620

Designation

UNS No. K94630

(Nominal Values)

accordance with the rounding-off method of Practice E29.

A 85 (586) max 85 (586) max

Element UNS No. K94630 UNS No. K94620

B 85 to 105 (586 to 724) 85 to 100 (586 to 689)

A A

Iron, nominal remainder remainder

C 95 to 115 (655 to 793) 95 to 110 (655 to 758)

A A

Nickel, nominal 29 27

D 105 to 125 (724 to 862) 105 to 120 (724 to 827)

A A

Cobalt, nominal 17 25

E 125 (862) min 120 (827) min

Manganese, max 0.35 0.35

Silicon, max 0.15 0.15

Carbon, max 0.02 0.02

B B

Aluminum, max 0.01 0.01

8. Hardness

B B

Magnesium, max 0.01 0.01

B B

Zirconium, max 0.01 0.01

8.1 Deep-Drawing Temper—For deep drawing, the hard-

B B

Titanium, max 0.01 0.01

nessshallnotexceed82HRBformaterial0.100in.(2.54mm)

Copper, max 0.20 0.20

and less in thickness, and 85 HRB for material over 0.100 in.

Chromium, max 0.03 0.03

Molybdenum, max 0.06 0.06 inthicknesswhendeterminedinaccordancewithTestMethods

C C

Phosphorus, max 0.006 0.006

E18. See also Test Method E92 for Vickers Hardness Testing

C C

Sulfur, max 0.006 0.006

and tables in E 140.

A

Theiron,nickel,andcobaltrequirementsarenominalandmaybeadjustedby

8.2 Rolled and Annealed Tempers—Hardness tests when

themanufacturertomeettherequirementsforthecoefficientofthermalexpansion

as specified in 12.1. properlyappliedcanbeindicativeoftensilestrength.Hardness

B

The total of aluminum, magnesium, titanium, and zirconium shall not exceed

scales and ranges for these tempers, if desirable, shall be

0.04 %.

C negotiated between supplier and purchaser.

The total of phosphorus and sulfur shall not exceed 0.010. %.

9. Tensile Strength

6.2 Tube—Unless otherwise agreed upon between the sup-

9.1 Strip and Sheet:

plier or the manufacturer and the purchaser, these forms shall

9.1.1 Tensile strength shall be the basis for acceptance or

begivenafinalbrightannealbythemanufacturerandsupplied

rejection for the tempers given in Table 2 and shall conform

in the annealed temper.

with the requirements prescribed.

6.3 Strip and Sheet—These forms shall be supplied in one

9.1.2 Tension test specimens shall be taken so the longitu-

of the tempers given in Table 2 or in deep-drawing temper, as

dinalaxisisparalleltothedirectionofrollingandthetestshall

specified.

be performed in accordance with Test Methods E8.

6.4 Wire and Rod—These forms shall be supplied in one of

9.2 Wire and Rod:

the tempers given in Table 3 as specified. Unless otherwise

9.2.1 Tensile strength shall be the basis for acceptance or

specified, the material shall be bright annealed and supplied in

rejection for the tempers given inTable 3 and shall conform to

Temper A (annealed).

the requirements prescribed.

NOTE 1—For rod forms, air anneal, followed by centerless grinding to 9.2.2 The test shall be performed in accordance with Test

remove scale, is an acceptable alternate.

Methods E8.

7. Grain Size

10. Surface Finish

7.1 Strip and sheet for deep drawing shall have an average

10.1 The standard surface finishes available shall be those

grain size not larger thanASTM No. 5 (Note 2), and no more

resulting from the following operations:

than 10% of the grains shall be larger than No. 5 when

10.1.1 Hot rolling,

measured in accordance with Test Methods E112.

10.1.2 Forging,

10.1.3 Centerless grinding (rod),

NOTE 2—This corresponds to a grain size of 0.065 mm, or 16

grains/in. of image at 1003. 10.1.4 Belt polishing,

10.1.5 Cold rolling, and

7.2 Finer grain sizes for deep drawing quality shall be

10.1.6 Wire and rod drawing.

negotiated between user and supplier.

11. Inclusion Content

TABLE 2 Tensile Strength Requirements for Strip and Sheet

11.1 Wire, Rod, Bar, Strip and Sheet—These product forms

Tensile Strength, ksi (MPa)

shallbefreeofinclusions,cracks,blowholesandotherdefects

Temper Temper

UNS No. K94620

Designation Name

that are detrimental to the quality of subsequent product. The

UNS No. K94630

(Nominal Values)

maximum inclusion rating number shall be 2 for Inclusion

A annealed 82 max (565 max) 85 max (586 max)

Types,A, B, C and D in both the thin and heavy series shown

B ⁄4hard 75to90(517to 85 to 100 (586 to

in Plate I using Practice E45, Method A, Worst-Field Tech-

621) 689)

C half hard 85 to 100 (586 to 95 to 110 (655 to

nique.

689) 758)

D ⁄4 hard 95 to 110 (655 to 105 to 120 (724 to

NOTE 3—Thetestforinclusionsmaybeperformedonbilletsections.In

758) 827)

suchcases,thesamplesectionmustincluderegionsthatcorrespondtothe

E hard 100 min (689 min) 120 min (827 min)

top of the ingot.

F 1466

NOTE 4—Product section size information at which the inclusion NOTE 5—Asuggested etchant is a solution of three parts by volume of

ratings were taken should be included. concentrated hydrochloric acid and one part of concentrated nitric acid

saturated with cupric chloride (CuCl ·2H O). This etchant is more

2 2

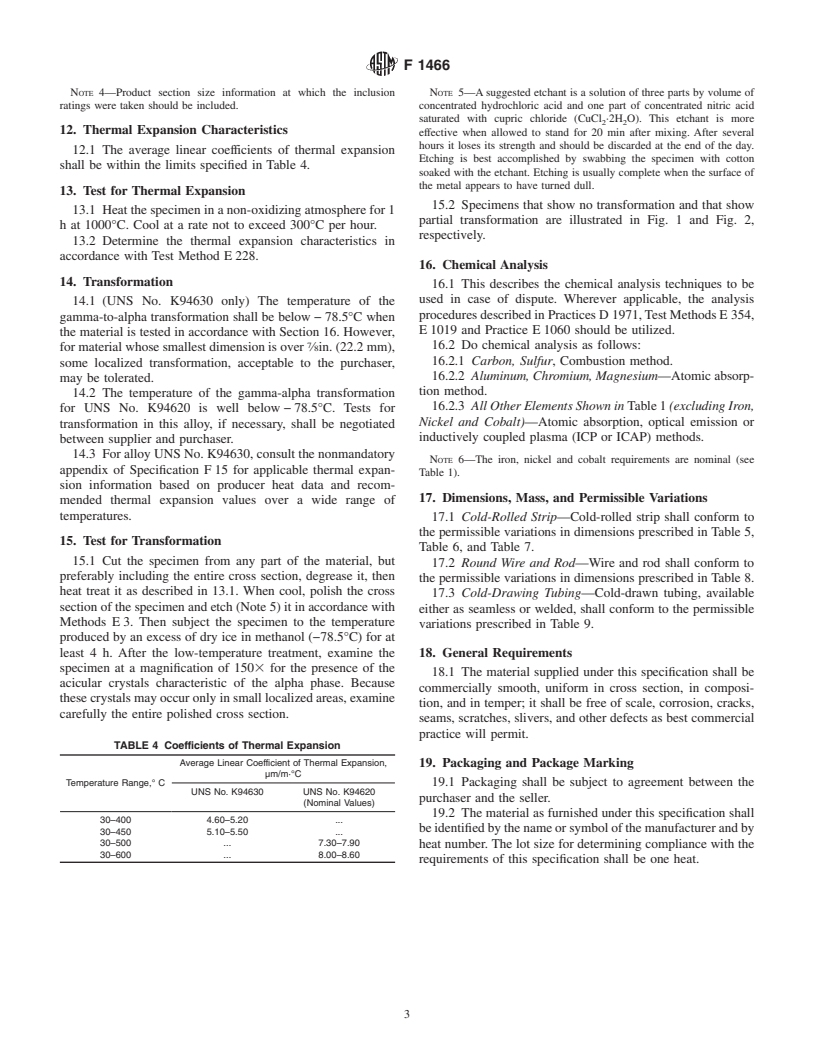

12. Thermal Expansion Characteristics

effective when allowed to stand for 20 min after mixing. After several

hours it loses its strength and should be discarded at the end of the day.

12.1 The average linear coefficients of thermal expansion

Etching is best accomplished by swabbing the specimen with cotton

shall be within the limits specified in Tab

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.