ASTM F1466-20

(Specification)Standard Specification for Iron-Nickel-Cobalt Alloys for Metal-to-Ceramic Sealing Applications

Standard Specification for Iron-Nickel-Cobalt Alloys for Metal-to-Ceramic Sealing Applications

ABSTRACT

This specification covers the property requirements and corresponding test methods for two iron-nickel-cobalt alloys in the forms of wire, rod, bar, strip, sheet, and tubing, intended primarily for brazed metal-to-ceramic seals with alumina ceramics, for vacuum electronic applications. The two alloys covered here are UNS K94630 that contains nominally 29 % nickel, 17 % cobalt, and 53 % iron, and UNS K94620 that contains nominally 27 % nickel, 25 % cobalt and 48 % iron. When tested, the alloys shall comply to specified requirements for chemical composition, surface finish, temper, grain size, tensile strength, hardness, inclusion content, thermal expansion, transformation, and dimensions.

SCOPE

1.1 This specification covers two iron-nickel-cobalt alloys, the former, (UNS No. K94630), containing nominally 29 % nickel, 17 % cobalt, and 53 % iron, the latter, (UNS No. K94620), nominally 27 % nickel, 25 % cobalt and 48 % iron, in the forms of wire, rod, bar, strip, sheet, and tubing, intended primarily for brazed metal-to-ceramic seals with alumina ceramics, for vacuum electronic applications. Unless otherwise indicated, all articles apply to both alloys.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.3 The following hazard caveat pertains only to the test method portion, Sections 14 and 16 of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F1466 −20

Standard Specification for

Iron-Nickel-Cobalt Alloys for Metal-to-Ceramic Sealing

1

Applications

This standard is issued under the fixed designation F1466; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E3Guide for Preparation of Metallographic Specimens

E8Test Methods for Tension Testing of Metallic Materials

1.1 This specification covers two iron-nickel-cobalt alloys,

[Metric] E0008_E0008M

the former, (UNS No. K94630), containing nominally 29%

E18Test Methods for Rockwell Hardness of Metallic Ma-

nickel, 17% cobalt, and 53% iron, the latter, (UNS No.

terials

K94620), nominally 27% nickel, 25% cobalt and 48% iron,

E29Practice for Using Significant Digits in Test Data to

in the forms of wire, rod, bar, strip, sheet, and tubing, intended

Determine Conformance with Specifications

primarily for brazed metal-to-ceramic seals with alumina

E45Test Methods for Determining the Inclusion Content of

ceramics,forvacuumelectronicapplications.Unlessotherwise

Steel

indicated, all articles apply to both alloys.

E92Test Methods for Vickers Hardness and Knoop Hard-

1.2 The values stated in SI units are to be regarded as

ness of Metallic Materials

standard. The values given in parentheses after SI units are

E112Test Methods for Determining Average Grain Size

provided for information only and are not considered standard.

E140Hardness Conversion Tables for Metals Relationship

1.3 The following hazard caveat pertains only to the test Among Brinell Hardness, Vickers Hardness, Rockwell

method portion, Sections 14 and 16 of this specification. This

Hardness, Superficial Hardness, Knoop Hardness, Sclero-

standarddoesnotpurporttoaddressallofthesafetyconcerns, scope Hardness, and Leeb Hardness

ifany,associatedwithitsuse.Itistheresponsibilityoftheuser

E228Test Method for Linear Thermal Expansion of Solid

of this standard to establish appropriate safety, health, and Materials With a Push-Rod Dilatometer

environmental practices and determine the applicability of

E354 Test Methods for Chemical Analysis of High-

regulatory limitations prior to use. Temperature,Electrical,Magnetic,andOtherSimilarIron,

1.4 This international standard was developed in accor-

Nickel, and Cobalt Alloys

dance with internationally recognized principles on standard-

E1019Test Methods for Determination of Carbon, Sulfur,

ization established in the Decision on Principles for the Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt

Development of International Standards, Guides and Recom-

Alloys by Various Combustion and Inert Gas Fusion

mendations issued by the World Trade Organization Technical Techniques

Barriers to Trade (TBT) Committee.

E1601Practice for Conducting an Interlaboratory Study to

Evaluate the Performance of an Analytical Method

2. Referenced Documents

3. Ordering Information

2

2.1 ASTM Standards:

3.1 Ordersformaterialunderthisspecificationshallinclude

D1971Practices for Digestion of Water Samples for Deter-

the following information:

minationofMetalsbyFlameAtomicAbsorption,Graphite

3.1.1 Alloy, as indicated with UNS number,

Furnace Atomic Absorption, Plasma Emission

3.1.2 Size,

Spectroscopy, or Plasma Mass Spectrometry

3.1.3 Temper designation (Section 6),

3.1.4 Surface finish (Section 10),

1

This specification is under the jurisdiction of ASTM Committee F01 on

3.1.5 Marking and packaging (Section 19), and

Electronics and is the direct responsibility of Subcommittee F01.03 on Metallic

3.1.6 Certification, if required. Please note that certification

Materials, Wire Bonding, and Flip Chip.

should include traceability of the heat to the original manufac-

Current edition approved Sept. 1, 2020. Published September 2020. Originally

approved in 1993. Last previous edition approved in 2015 as F1466–99 (2015). turer.

DOI: 10.1520/F1466-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 4. Chemical Requirements

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1 Each alloy shall conform to the requirements as to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. chemical composition prescribed in Table 1.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

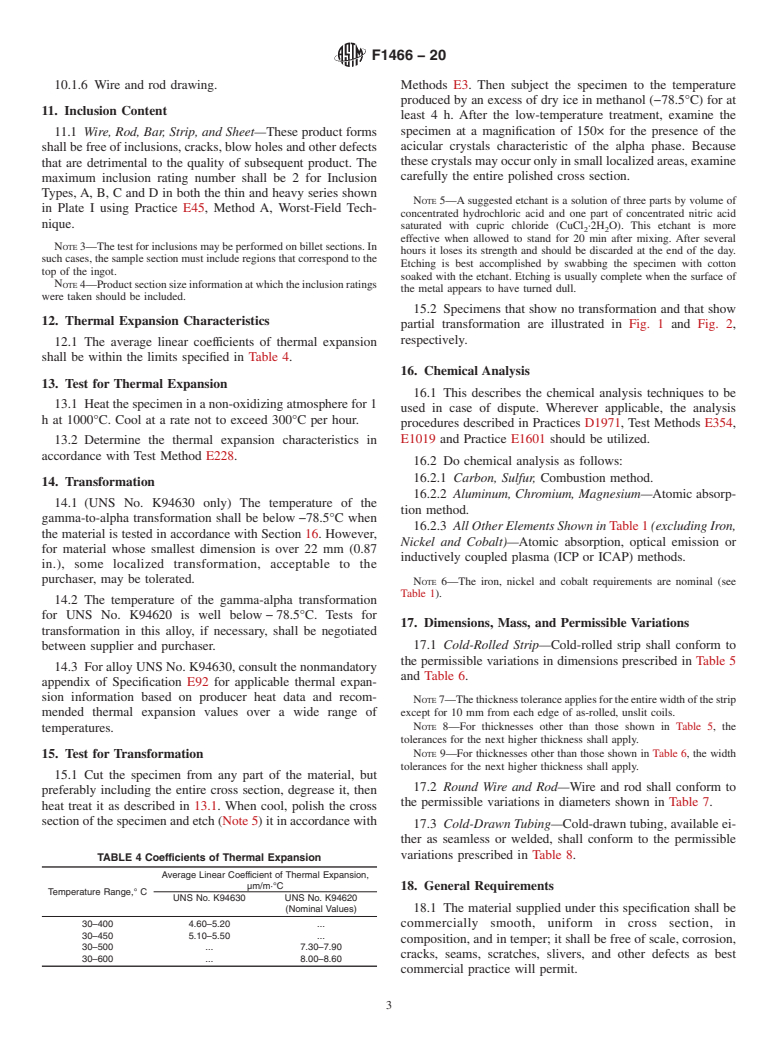

F1466−20

TABLE 1 Chemical Requirements TABLE 3 Tensile Strength Requirements for Wire and Rod

Tensi

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1466 − 99 (Reapproved 2015) F1466 − 20

Standard Specification for

Iron-Nickel-Cobalt Alloys for Metal-to-Ceramic Sealing

1

Applications

This standard is issued under the fixed designation F1466; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers two iron-nickel-cobalt alloys, the former, (UNS No. K94630), containing nominally 29 % nickel,

17 % cobalt, and 53 % iron, the latter, (UNS No. K94620), nominally 27 % nickel, 25 % cobalt and 48 % iron, in the forms of wire,

rod, bar, strip, sheet, and tubing, intended primarily for brazed metal-to-ceramic seals with alumina ceramics, for vacuum

electronic applications. Unless otherwise indicated, all articles apply to both alloys.

1.2 The values stated in inch-poundSI units are to be regarded as standard. The values given in parentheses are mathematical

conversions to after SI units that are provided for information only and are not considered standard.

1.3 The following hazard caveat pertains only to the test method portion, Sections 14 and 16 of this specification.This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D1971 Practices for Digestion of Water Samples for Determination of Metals by Flame Atomic Absorption, Graphite Furnace

Atomic Absorption, Plasma Emission Spectroscopy, or Plasma Mass Spectrometry

E3 Guide for Preparation of Metallographic Specimens

E8 Test Methods for Tension Testing of Metallic Materials [Metric] E0008_E0008M

E18 Test Methods for Rockwell Hardness of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E45 Test Methods for Determining the Inclusion Content of Steel

E92 Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials

E112 Test Methods for Determining Average Grain Size

E140 Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness,

Superficial Hardness, Knoop Hardness, Scleroscope Hardness, and Leeb Hardness

E228 Test Method for Linear Thermal Expansion of Solid Materials With a Push-Rod Dilatometer

1

This specification is under the jurisdiction of ASTM Committee F01 on Electronics and is the direct responsibility of Subcommittee F01.03 on Metallic Materials, Wire

Bonding, and Flip Chip.

Current edition approved July 1, 2015Sept. 1, 2020. Published October 2015September 2020. Originally approved in 1993. Last previous edition approved in 20102015

as F1466F1466 – 99 (2015).– 99(2010). DOI: 10.1520/F1466-99R15.10.1520/F1466-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

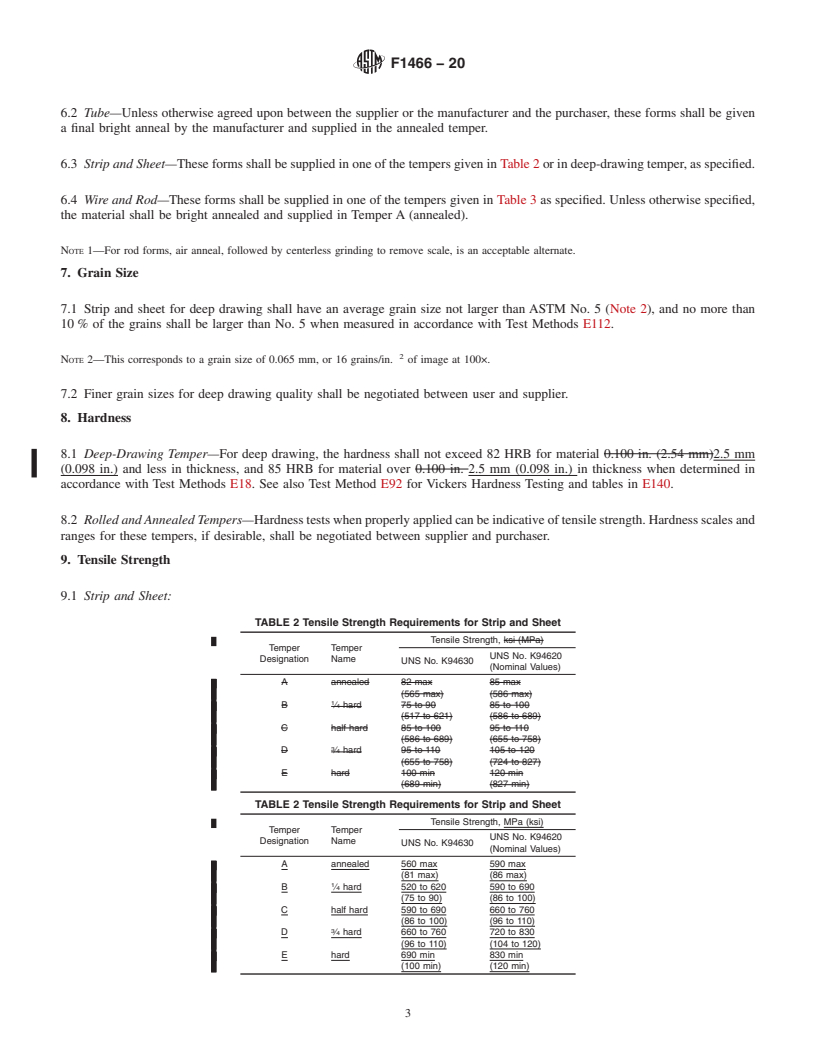

F1466 − 20

E354 Test Methods for Chemical Analysis of High-Temperature, Electrical, Magnetic, and Other Similar Iron, Nickel, and

Cobalt Alloys

E1019 Test Methods for Determination of Carbon, Sulfur, Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt Alloys by

Various Combustion and Inert Gas Fusion Techniques

E1060E1601 Practice for Interlaboratory Testing of Spectrochemical Methods of AnalysisConducting an Interlaboratory Study

to Evaluate the Performance of an Analytical Method (Withdrawn 1997)

3. Ordering Information

3.1 Orders for material under this specification shall include the following information:

3.1.1 Alloy, as indicated with UNS number,

3.1.2 Size,

3.1.3 Temper designation (Section 6),

3.1.4 Surfa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.