ASTM D6395-99

(Test Method)Standard Test Method for Flatwise Flexural Impact Resistance of Rigid Plastics

Standard Test Method for Flatwise Flexural Impact Resistance of Rigid Plastics

SCOPE

1.1 The resistance of plastics to breakage by flexural shock may be determined by test methods such as those contained in Test Method D 256. Specimens used in those test methods feature a milled notch to promote brittle fracture. The test specimens are struck by a pendulum with the depth dimension parallel to the direction of pendulum swing. This test method is differentiated from the others by its application to the assessment of the affect on impact resistance of changes in the surface of specimens resulting from weathering or other exposure. In this test method, specimens are struck by a pendulum with the depth dimensions perpendicular to the direction of pendulum swing. Test Method D 5420 may also be used to conduct testing of weathered or exposed specimens. This test method is differentiated from Gardner Impact by the smaller size of the specimens, which may result in substantially higher productivity of accelerated weathering instruments. Additionally, this test method provides multiple data from a single specimen for characterization of within specimen variability.

1.2 This test method describes the determination of the resistance of rigid plastic strip specimens to breakage or permanent deformation when one end of the specimen is subjected to an impact upon its wide face while the other end of the specimen is firmly clamped.

1.3 This test method is applicable to specimens of 1.60 mm (0.0625 in.) thickness. However, the limits of applicability of the test are not sharply defined, and specimens having other dimensions may frequently be used. For specimens of thicknesses other than 1.60 mm (0.0625 in.) the ratio of the distance between the top of the clamp and the centerline of the rounded striking edge to the specimen thickness must be 2.5 + or - 0.1.

1.4 This test method measures the relative impact resistance of samples having approximately the same thickness. Normalization of the impact resistance to unit cross-sectional area only partly compensates for the effects of specimen thickness variation because, at the fixed cantilever length, the ratio of shear stress to tensile stress in bending increases with thickness, and the importance of these effects in contributing to the energy absorbed is greater for ductile than for brittle failure.

1.5 This test method is used primarily as a means of assessing, for a series of samples, changes relative to a control due to some treatment such as weathering or exposure to active environments. It has been particularly useful as a sensitive indicator fo the development of surface cracks or a brittle surface. The existence or formation of cracks in an inherently brittle surface produces marked lowering of impact strength when the surface is the one subjected to tension in the test.

1.6 This test method is not generally applicable to materials such as elastomers or nonrigid plastics in which there is no fracture, permanent deforamation, or other change due to yielding in flexure. However, it may be disirable to test such materials as file samples to establish reference points when the test is applied as described in 1.5.

1.7 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1-There is no equivalent or similar ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6395–99

Standard Test Method for

Flatwise Flexural Impact Resistance of Rigid Plastics

This standard is issued under the fixed designation D 6395; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope ness, and the importance of these effects in contributing to the

energy absorbed is greater for ductile than for brittle failure.

1.1 The resistance of plastics to breakage by flexural shock

1.5 This test method is used primarily as a means of

may be determined by test methods such as those contained in

assessing, for a series of samples, changes relative to a control

Test Method D 256. Specimens used in those test methods

due to some treatment such as weathering or exposure to active

feature a milled notch to promote brittle fracture. The test

environments. It has been particularly useful as a sensitive

specimens are struck by a pendulum with the depth dimension

indicator of the development of surface cracks or a brittle

parallel to the direction of pendulum swing.This test method is

surface. The existence or formation of cracks in an inherently

differentiated from the others by its application to the assess-

brittle surface produces marked lowering of impact strength

ment of the affect on impact resistance of changes in the

when that surface is the one subjected to tension in the test.

surface of specimens resulting from weathering or other

1.6 This test method is not generally applicable to materials

exposure. In this test method, specimens are struck by a

such as elastomers or nonrigid plastics in which there is no

pendulum with the depth dimension perpendicular to the

fracture, permanent deformation, or other change due to

direction of pendulum swing.Test Method D 5420 may also be

yielding in flexure. However, it may be desirable to test such

used to conduct testing of weathered or exposed specimens.

materials as file samples to establish reference points when the

This test method is differentiated from Gardner Impact by the

test is applied as described in 1.5.

smallersizeofthespecimens,whichmayresultinsubstantially

1.7 The values stated in SI units are to be regarded as the

higher productivity of accelerated weathering instruments.

standard. The values given in parentheses are for information

Additionally, this test method provides multiple data from a

only.

single specimen for characterization of within specimen vari-

1.8 This standard does not purport to address all of the

ability.

safety concerns, if any, associated with its use. It is the

1.2 This test method describes the determination of the

responsibility of the user of this standard to establish appro-

resistance of rigid plastic strip specimens to breakage or

priate safety and health practices and determine the applica-

permanent deformation when one end of the specimen is

bility of regulatory limitations prior to use.

subjected to an impact upon its wide face while the other end

of the specimen is firmly clamped.

NOTE 1—There is no equivalent or similar ISO standard.

1.3 This test method is applicable to specimens of 1.60 mm

2. Referenced Documents

(0.0625 in.) thickness. However, the limits of applicability of

the test are not sharply defined, and specimens having other

2.1 ASTM Standards:

dimensions may frequently be used. For specimens of thick-

D 256 Test Method for Determining the Pendulum Impact

nesses other than 1.60 mm (0.0625 in.) the ratio of the distance

Resistance of Notched Specimens of Plastics

between the top of the clamp and the centerline of the rounded

D 618 Practice for Conditioning Plastics and Electrical

striking edge to the specimen thickness must be 2.5 6 0.1.

Insulating Materials for Testing

1.4 This test method measures the relative impact resistance

D 883 Terminology Relating to Plastics

of samples having approximately the same thickness. Normal-

D 5420 Test Method for Impact Resistance of Flat, Rigid

izationoftheimpactresistancetounitcross-sectionalareaonly

Plastic Specimen by Means of a Striker Impacted by a

partly compensates for the effects of specimen thickness

Falling Weight (Gardner Impact)

variation because, at the fixed cantilever length, the ratio of

D 5947 Test Methods for Physical Dimensions of Solid

shear stress to tensile stress in bending increases with thick-

Plastic Specimens

ThistestmethodisunderthejurisdictionofASTMCommitteeD-20onPlastics

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties. Annual Book of ASTM Standards, Vol 08.01.

Current edition approved March 10, 1999. Published June 1999. Annual Book of ASTM Standards, Vol 08.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6395

3. Terminology 5. Interferences

5.1 Use of an improper shim will result in test values either

3.1 Definitions used in this test method are in accordance

with Terminology D 883. too large or too small depending upon whether the shim in use

is too short or too long.

5.2 Orientation and molded-in stresses due to flow and

4. Significance and Use

cooling history result in variation in properties within injection

4.1 The flatwise flexural impact test is a test in which the

molded specimen, especially at the ends and at the gate region.

kinetic energy lost by a moving pendulum during impact is

The effects of such variations can be minimized by avoiding

used to determine the energy to break or deform a test

tests close to the gate or the ends of the specimen.

specimen.

5.3 The clearance between the pendulum and the clamp as

4.2 The standard Izod test apparatus as described in Test

the pendulum passes the clamp at its closest point during a test

MethodD 256isretrofittedwithclampingjaws,whichholdthe

significantly affects the results of this test. If the specimen

test specimen such that the flat face of the specimen is struck

thickness is greater than about one half of the clearance, a large

by the pendulum during a test.

energy loss due to friction occurs in ductile specimens. The

4.3 The pendulum shall be a standard Izod pendulum as

ratio of shear to surface tensile stress increases and the nature

described in Test Method D 256. It shall be capable of

of failure may change abruptly over a narrow range of

delivering an energy of 2.71 6 0.14J (2.00 6 0.10 ft.-lbf).

specimenthickness.Theclearanceisdictatedbytheratioofthe

Except as detailed in 10.5 this basic pendulum shall be used

distance between the pendulum nose centerline and the clamp

with all specimens that extract less than 85 % of the available

top to the specimen thickness (2.56 0.1). The movable jaw

energy. Higher energy pendulums or a basic pendulum to

face and fixed jaw face set used for the thickness of specimen

which weights are added to increase its available energy shall

being tested shall either be of proper dimensions for this ratio

be used with specimens that require more energy to break. A

or be adjustable in design to allow the ratio to be achieved.

series of energy levels such that each has twice the energy of

5.4 The use of excessive clamping force may induce

thenextlighteronewillbefoundconvenient.Thestrikingnose

stresses in test specimens causing variation in test results.

of the pendulum shall contact one of the flat faces of the

specimen at a specified distance above the clamp edge. The

6. Apparatus

ratio of the distance between the top of the clamp and the

6.1 Testing Machine—The testing machine shall consist of

centerline of the rounded striking edge to the specimen

the standard Izod test instrument as detailed in Test Method

thickness shall be 2.5 6 0.1.

D 256 but with a modified clamping arrangement. Figs. 1-3

4.4 The type of failure of each specimen tested shall be

illustrate typical clamping arrangements applicable to some

assigned one of the following categories:

instruments. Other clamping arrangements may be used pro-

Complete Break (C) —A break in which the specimen is

vided that they maintain the specified ratio of the distance

separated into two or more pieces.

between the top of the clamp and the centerline of the

HingeBreak(H)—Anearly complete break in which there is

pendulum nose to the specimen thickness (2.5 6 0.1). Other

little or no spring back when the free end is bent or displaced.

arrangements must also provide uniform clamping along the

Partial Break (P)—An incomplete break in which fracture

clampedlengthofthespecimenandpositionthespecimensuch

extends through at least 50 % of the specimen thickness, and

that when the pendulum is freely hanging, the striking edge is

such that the free end can be bent with relatively little effort yet

within 0.2 % of full scale of touching the front face of the

has considerable spring back.

specimen as required by Test Method D 256. As indicated by

Nonbreak (N)—A result where there is no fracture or the

these figures, the specimen clamp faces may be bolted or

fracture extends less than 50 % of the specimen thickness.

otherwise firmly attached to the existing Izod fixed and

4.5 The value of this impact test is to determine the change

movable jaws. To avoid compromising the instrument’s capa-

in impact properties that may result from a material having

bility for Izod testing, using either a dedicated set of fixed and

been exposed to one or a series of environments, such as

movable Izod jaws or clamping faces mounted in such a way

weathering at different intervals or different intensities when

as to not alter the existing Izod jaws is recommended.

these data are compared to a file sample exposed only to the

6.2 Specimen Clamp Faces—Special clamp faces (Fig. 2)

standard laboratory environment or other agreed upon condi-

for both the fixed and the movable jaws of the clamp shall be

tions.

used to clamp the test specimen flatwise with its long axis

4.6 The flatwise impact resistance is calculated as energy vertical and its thickness direction parallel to the direction of

absorbed per unit of cross-sectional area.

the pendulum swing. The clamp faces constitute a set. Some

dimensions within the set are dictated by the thickness of the

4.7 Before proceeding with this test method, reference

shouldbemadetothespecificationofthematerialbeingtested. specimen being tested and by the particular Izod instrument

being used. Fig. 2 provides the dimensions for clamp faces

Any test specimen preparation, conditioning, dimensions,

and/or testing parameters covered in the material specification when used with one type of Izod instrument to test 1.60 mm

(0.062 in.) thick specimen.

shall take precedence over those mentioned in this test method

except in cases where to do so would conflict with the purpose 6.2.1 For 1.60 mm (0.062 in.) thick specimens the distance

for conducting testing. If there are no material specifications, between the upper edge of the clamp and the striking nose of

then the default conditions apply. the pendulum is 4.0 mm (0.161 in.) providing a clearance

D6395

7. Sampling, Test Specimen, and Test Units

7.1 The standard test specimen shall have a rectangular

cross-section and an approximate length of 65 mm (2.5 in.).

Most specimens should be 12.7 mm (0.500 in.) wide by 1.60

mm (0.0625 in.) thick, but for some materials, such as those

which are glass reinforced, it may be desirable to use speci-

mens of other thicknesses. The specimens may be molded or

cut from flat sheet, but they shall be of uniform dimensions

within any given set.

7.2 Trim or sand off any protrusions that might interfere

with clamping or positioning the specimen in the instrument

clamps. Do not introduce notches or scratches in the test face

of the specimen.

7.3 Injection-molded specimens shall have at least 6 mm

(0.25 in.) cut from the end to be tested first so that when the

specimen is clamped in the testing machine, the clamp edge

willbenolessthan12mm(0.5in.)fromtheoriginalendofthe

specimen.Theclampedgeshallalsobeatleast6mm(0.25in.)

from a gate. Whenever this test is used for assessing aging

effects, cut off any portion of the test specimen end which has

not been uniformly exposed to the aging environment so that

the edge of the clamp will be at least 6 mm (0.25 in.) from the

unexposed region.

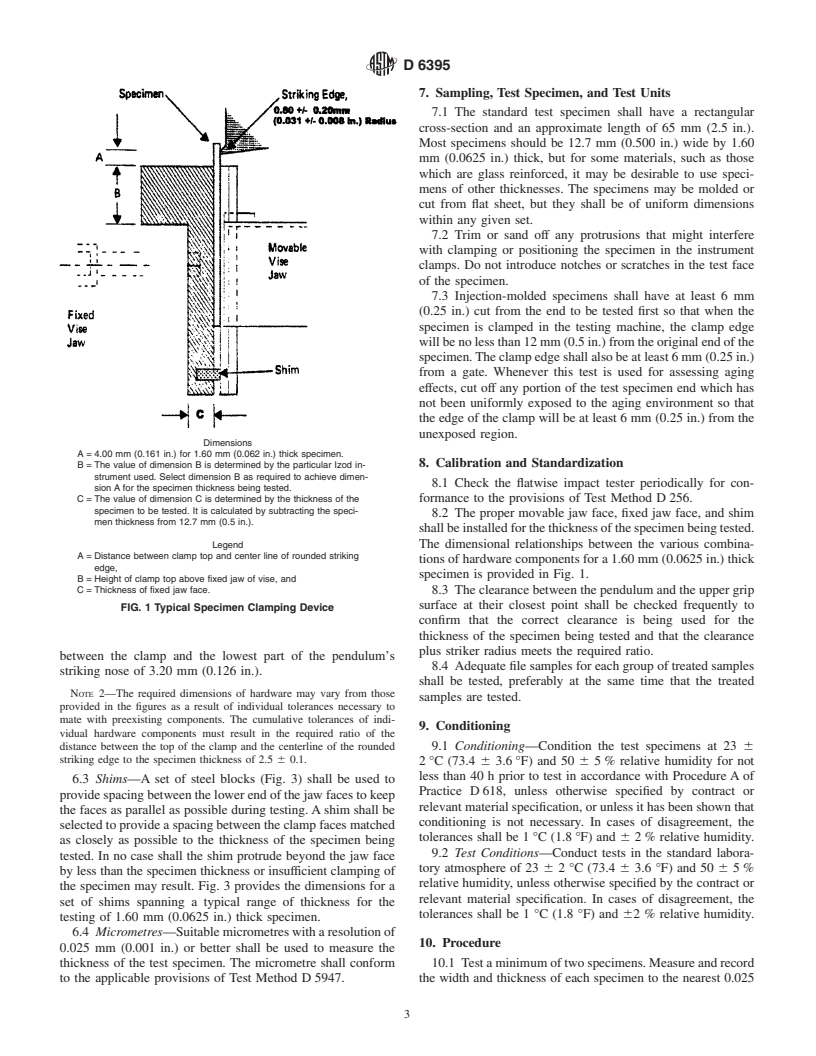

Dimensions

A = 4.00 mm (0.161 in.) for 1.60 mm (0.062 in.) thick specimen.

8. Calibration and Standardization

B = The value of dimension B is determined by the particular Izod in-

strument used. Select dimension B as required to achieve dimen-

8.1 Check the flatwise impact tester periodically for con-

sion A for the specimen thickness being tested.

C = The value of dimension C is determined by the thickness of the formance to the provisions of Test Method D 256.

specimen to be tested. It is calculated by subtracting the speci-

8.2 The proper movable jaw face, fixed jaw face, and shim

men thickness from 12.7 mm (0.5 in.).

shallbeinstalledforthethicknessofthespecimenbeingtested.

Legend The dimensional relationships between the various combina-

A = Distance between clamp top and center line of rounded striking

tions of hardware components for a 1.60 mm (0.0625 in.) thick

edge,

specimen is provided in Fig. 1.

B = Height of clamp top above fixed jaw of vise, and

C = Thickness of fixed jaw face. 8.3 The clearance between the pendulum and the upper grip

surface at their closest point shall be checked frequently to

FIG. 1 Typical Specimen Clamping Device

confirm that the correct clearance is being used for the

thickness of the specimen being tested and that the clearance

plus striker radius meets the required ratio.

between the clamp and the lowest part of the pendulum’s

8.4 Adequate file samples for each group of treated samples

striking nose of 3.20 mm (0.126 in.).

shall be tested, preferably at the same time that the treated

NOTE 2—The required dimensions of hardware may vary from those

samples are tested.

provided in the figures as a result of individual tolerances necessary to

mate with preexisting components. The cumulative tolerances of indi-

9. Conditioning

vidual hardware components must result in the required ratio of the

distance between the top of the clamp and the centerline of the rounded 9.1 Conditioning—Condition the test specimens at 23 6

striking edge to the specimen thickness of 2.5 6 0.1.

2 °C (73.4 6 3.6 °F) and 50 6 5 % relative humidity for not

less than 40 h prior to test in accordance with Procedure A of

6.3 Shims—A set of steel blocks (Fig. 3) shall be used to

Practice D 618, unless otherwise specified by contract or

provide spacing between the lower end of the jaw faces to keep

relevant material specification, or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.