ASTM F563-00

(Specification)Standard Specification for Wrought Cobalt-20Nickel-20Chromium-3.5Molybdenum-3.5Tungsten-5Iron Alloy for Surgical Implant Applications (UNS R30563) (Withdrawn 2005)

Standard Specification for Wrought Cobalt-20Nickel-20Chromium-3.5Molybdenum-3.5Tungsten-5Iron Alloy for Surgical Implant Applications (UNS R30563) (Withdrawn 2005)

SCOPE

1.1 This specification covers the requirements for a wrought cobalt-20nickel-20chromium-3.5molybdenum-3.5tungsten-5 iron alloy in the form of bars, wires, and forgings used for the manufacture of surgical implants.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

WITHDRAWN RATIONALE

This specification covers the requirements for a wrought cobalt-20nickel-20chromium-3.5molybdenum-3.5tungsten-5 iron alloy in the form of bars, wires, and forgings used for the manufacture of surgical implants.

Formerly under the jurisdiction of Committee F04 on Medical and Surgical Materials and Devices, this specification was withdrawn in March 2005 because it has been determined that the alloy is no longer being used for surgical implant applications.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation: F 563 – 00

Standard Specification for

Wrought Cobalt-20Nickel-20Chromium-3.5Molybdenum-

3.5Tungsten-5Iron Alloy for Surgical Implant Applications

(UNS R30563)

This standard is issued under the fixed designation F 563; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

1. Scope ISO 5832-8 Implant for Surgery—Metallic Materials—Part

8: Wrought Cobalt-Nickel-Chromium-Tungsten-Iron Al-

1.1 This specification covers the requirements for a wrought

loy

cobalt-20nickel-20chromium-3.5molybdenum-3.5tungsten-5

2.4 ASQ Stamdard:

iron alloy in the form of bars, wires, and forgings used for the

Cl Specification of General Requirements for a Quality

manufacture of surgical implants.

Program

1.2 The values stated in inch-pound units are to be regarded

as the standard. The SI units given in parentheses are for

3. Ordering Information

information only.

3.1 Inquiries and orders for material under this specification

2. Referenced Documents shall include the following information:

3.1.1 Quantity (weight or number of pieces),

2.1 ASTM Standards:

3.1.2 Condition (4.1),

A 751 Test Methods, Practices, and Terminology for

3.1.3 Finish (4.2),

Chemical Analysis of Steel Products

3.1.4 Mechanical properties (if applicable, for special con-

E8 TestMethodsforTensionTestingofMetallicMaterials

ditions) (7.1),

E18 Test Methods for Rockwell Hardness and Rockwell

3.1.5 Applicable dimensions, including size, thickness,

Superficial Hardness of Metallic Materials

width, and length (exact, random, multiples), or print number,

E92 Test Method for Vickers Hardness of Metallic Mate-

3.1.6 Special tests, and

rials

3.1.7 Supplementary requirements (if applicable),

E112 Test Methods for Determining Average Grain Size

3.1.8 Product uniformity, and

E 140 HardnessConversionTablesforMetals(Relationship

3.1.9 Additional tests or inspections, supplementary com-

Among Brinell Hardness, Vickers Hardness, Rockwell

positionlimits,ifany,asrequiredbythemanufacturingprocess

Hardness, Rockwell Superficial Hardness, Knoop Hard-

and intended application, and other supplementary require-

ness, and Scleroscope Hardness)

ments.

E 354 Test Methods for Chemical Analysis of High-

Temperature, Electrical, Magnetic, and Other Similar Iron,

4. Materials and Manufacture

Nickel, and Cobalt Alloys

4.1 Condition:

2.2 Aerospace Material Specification:

4.1.1 Bar and wire shall be furnished to the implant manu-

AMS 2269 Chemical Check Analysis Limits Wrought

5 facturer as specified, in the annealed, medium hard, hard, or,

Nickel Alloys and Cobalt Alloys

for special applications, extra hard condition, depending on the

2.3 ISO Standard:

degree of cold work and aging treatment, if any.

4.1.2 Forgingshallbefurnishedtotheimplantmanufacturer

This specification is under the jurisdiction of ASTM Committee F04 on

as specified, in the forged or forged and solution heattreated

Medical and Surgical Materials and Devices, and is the direct responsibility of

and aged condition.

Subcommittee F04.12 on Metallurgical Materials.

Current edition approved November 10, 2000. Published January 2001. Origi-

nally published as F 563 – 78. Last previous edition F 563 – 95.

Annual Book of ASTM Standards, Vol 01.01.

3 6

Annual Book of ASTM Standards, Vol 03.01. Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 03.05. Floor, New York, NY 10036.

5 7

Available from Society of Automotive Engineers, 400 Commonwealth Drive, Available from American Society for Quality, 161 West Wisconsin Ave.,

Warrendale, PA 15096. Milwaukee, WI 53203.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

F563–00

A

TABLE 2 Product Analysis Tolerances

4.2 Finish—Surface finish shall be as specified and required

by the subsequent manufacturing process and the intended Tolerances over the max (upper limit) or under the min

Element

(lower limit), %, Mass/Mass

application, if pertinent.

Carbon 0.01

Manganese 0.03

5. Chemical Composition

Sulfur 0.003

5.1 The heat analysis shall conform to the requirements as

Silicon 0.03

Chromium 0.25

to chemical composition specified in Table 1. The product

Molybdenum 0.10

analysis tolerances shall conform to the requirements pre-

Tungsten 0.15

scribed in Table 2.

under min over max

Nickel 0.20 0.25

5.1.1 Requirements for the major and minor elemental

Titanium 0.03 0.07

constituents are listed in Table 1. Also listed are important

Iron 0.07 0.10

residual elements.Analysis for elements not listed inTable 1 is

A

Refer to AMS 2269.

not required to verify compliance with this specification.

5.2 For referee purposes, Test Methods E 354E 354 shall be

6.2 The grain size shall be No. 5 or finer, based on the

used.

appropriate chart of Test Methods E 112E112.

5.3 Methods and practices relating to chemical analysis

required by this specification shall be in accordance with Test

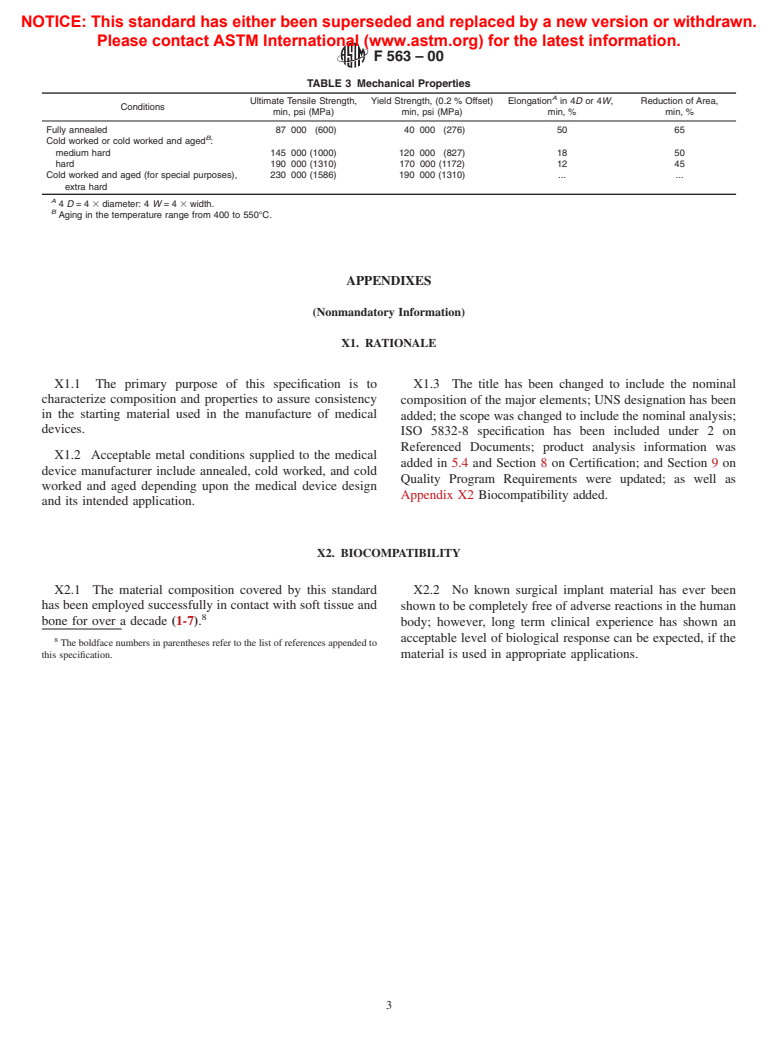

7. Mechanical Requirements

Methods A 751A 751.

7.1 The material shall conform to the appropriate minimum

5.4 Product Analysis—Product analysis tolerances do not

mechanical properties specified in Table 3. Test Methods

broaden the specified heat analysis requirements, but cover

E8E8 shall apply.

variations between laboratories in the measurement of chemi-

7.2 When desired, hardness limits may be specified. Test

cal content. The manufacturer shall not ship material that is

Methods E 18 or E 92E 18E 92 and Standard Tables

outside the limits specified in Table 1. Product analysis limits

E140E 140 shall be used. Hardness determination of cold-

shall be as specified in Table 2.

worked material shall be made on a product cross section,

5.4.1 The product analysis is either for the purpose of

midway between the center and the surface, if the cross section

verifying the composition of a heat or lot or to determine

si

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.