ASTM B604-91(1997)

(Specification)Standard Specification for Decorative Electroplated Coatings of Copper Plus Nickel Plus Chromium on Plastics

Standard Specification for Decorative Electroplated Coatings of Copper Plus Nickel Plus Chromium on Plastics

SCOPE

1.1 This specification covers the requirements for several grades and types of electrodeposited copper plus nickel plus chromium coatings on plateable plastic substrates where appearance, durability and resistance to thermal cycling are important to service performance. Five grades of coatings are provided to correlate with the service conditions under which each is expected to provide satisfactory performance.

1.2 This specification covers the requirements for coatings applied subsequent to the application of metal film by autocatalytic deposition or subsequent to the application of any strike coatings after autocatalytic deposition.

1.3 The following caveat pertains only to the test method portions of Section 6, Annex A1, and Appendixes X2, X3, and X4 of this specification. This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: B 604 – 91 (Reapproved 1997)

Standard Specification for

Decorative Electroplated Coatings of Copper Plus Nickel

Plus Chromium on Plastics

This standard is issued under the fixed designation B 604; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope B 532 Specification forAppearance of Electroplated Plastic

Surfaces

1.1 This specification covers the requirements for several

B 533 TestMethodforPeelStrengthofMetal-Electroplated

grades and types of electrodeposited copper plus nickel plus

Plastics

chromium coatings on plateable plastic substrates where ap-

B 556 Guide for Measurement of Thin Chromium Coatings

pearance, durability and resistance to thermal cycling are

by the Spot Test

important to service performance. Five grades of coatings are

B 567 Test Method for Measurement of Coating Thickness

provided to correlate with the service conditions under which

by the Beta Backscatter Method

each is expected to provide satisfactory performance.

B 568 Test Method for Measurement of Coating Thickness

1.2 This specification covers the requirements for coatings

by X-Ray Spectrometry

applied subsequent to the application of metal film by auto-

B 602 Test Method for Attribute Sampling of Metallic and

catalytic deposition or subsequent to the application of any

Inorganic Coatings

strike coatings after autocatalytic deposition.

B 659 Guide for Measuring Thickness of Metallic and

1.3 The following caveat pertains only to the test method

Inorganic Coatings

portions of Section 6,AnnexA1, andAppendix X2,Appendix

B 727 Practice for Preparation of Plastics Materials for

X3, andAppendix X4 of this specification. This standard does

Electroplating

not purport to address all of the safety concerns, if any,

B 764 Test Method for Simultaneous Thickness and Elec-

associated with its use. It is the responsibility of the user of this

trochemical Potential Determination of Individual Layers

standard to establish appropriate safety and health practices

in Multilayer Nickel Deposit (STEP Test)

and determine the applicability of regulatory limitations prior

D 1193 Specification for Reagent Water

to use.

E50 Practices for Apparatus, Reagents, and Safety Precau-

2. Referenced Documents tions for Chemical Analysis of Metals

2.1 ASTM Standards:

3. Terminology

B 368 Method for Copper-Accelerated Acetic Acid-Salt

3.1 Definitions:

Spray (Fog) Testing (CASS Test)

3.1.1 significant surfaces—those surfaces normally visible

B 487 Test Method for Measurement of Metal and Oxide

(directlyorbyreflection)thatareessentialtotheappearanceor

Coating Thicknesses by Microscopical Examination of a

2 serviceability of the article when assembled in normal position

Cross Section

or that can be the source of corrosion products that deface

B 489 Practice for Bend Test for Ductility of Electrodepos-

visible surfaces on the assembled article.

ited and Autocatalytically Deposited Metal Coatings on

Metals

4. Classification

B 504 Test Method for Measurement of Thickness of Me-

2 4.1 Five grades of coatings designated by service condition

tallic Coatings by the Coulometric Method

numbers and several types of coatings defined by classification

B 530 Test Method for Measurement of Coating Thick-

numbers are covered by this specification.

nesses by the Magnetic Method: Electrodeposited Nickel

4.2 Service Condition Number:

Coatings on Magnetic and Nonmagnetic Substrates

4.2.1 The service condition number indicates the severity of

exposure for which the grade of coating is intended, in

accordance with the following scale:

This specification is under the jurisdiction of ASTM Committee B-8 on

SC5—extended very severe

Metallic and Organic Coatings and is the direct responsibility of Subcommittee

B08.08.03 on Decorative Coatings.

Current edition approved May 15, 1991. Published October 1991. Originally

published as B 604 – 75. Last previous edition B 604 – 80. Annual Book of ASTM Standards, Vol 11.01.

2 4

Annual Book of ASTM Standards, Vol 02.05. Annual Book of ASTM Standards, Vol 03.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

B 604 – 91 (1997)

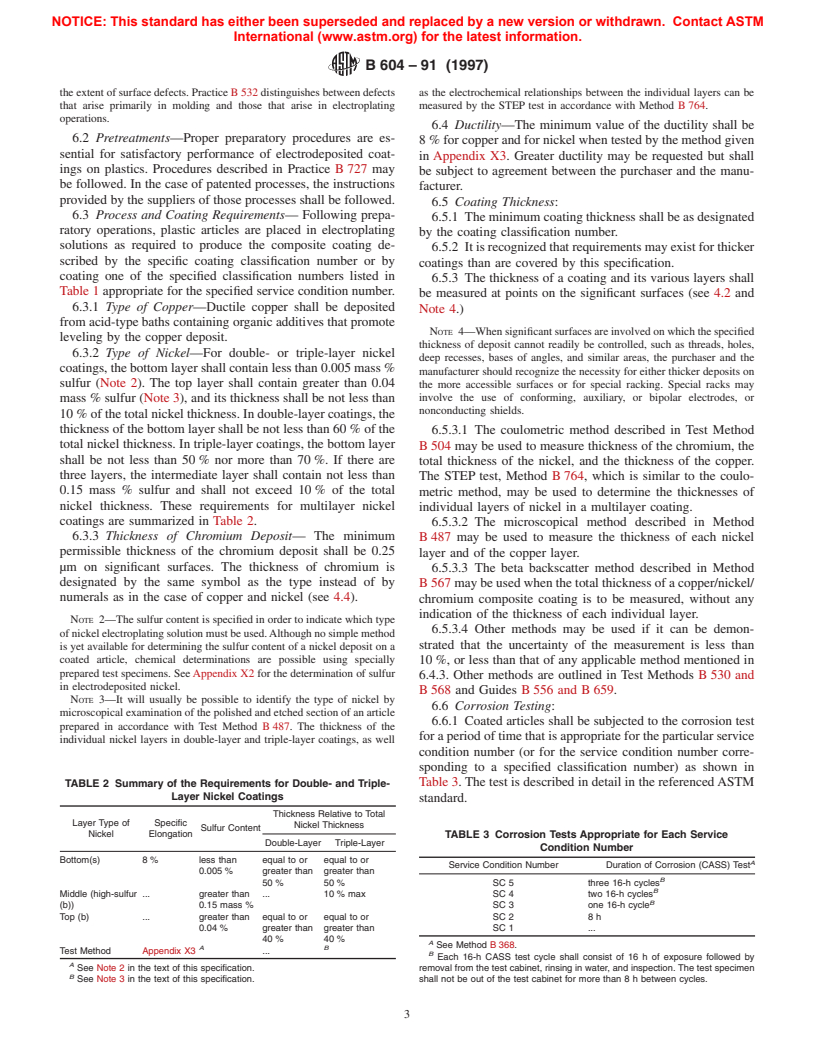

TABLE 1 Copper Plus Nickel Plus Chromium Coatings on

SC4—very severe

A

Plastic

SC3—severe

Service

Equivalent Nickel Thickness

SC2—moderate

Condition Classification Number

SC1—mild

µm mils (approx.)

Number

4.2.2 Service condition numbers are further defined in

SC 5 PL/Cu15a Ni30d Cr mc 30 1.2

AppendixX1wheretheyarerelatedtotheseverityofexposure

PL/Cu15a Ni30d Cr mp 30 1.2

SC 4 PL/Cu15a Ni30d Cr r 30 1.2

encountered by electroplated articles.

PL/Cu15a Ni25d Cr mc 25 1.0

4.3 Coating Classification Number— The coating classifi-

PL/Cu15a Ni25d Cr mp 25 1.0

cation number is a means of specifying the types and thick-

SC 3 PL/Cu15a Ni25d Cr r 25 1.0

PL/Cu15a Ni20d Cr mc 20 0.8

nesses of coatings appropriate for each grade and is comprised

PL/Cu15a Ni20d Cr mp 20 0.8

of the following:

SC 2 PL/Cu15a Ni15b Cr r 15 0.6

4.3.1 The symbol for the substrate (PL) indicating it is

PL/Cu15a Ni10b Cr mc 10 0.4

PL/Cu15a Ni10b Cr mp 10 0.4

plateable plastic, followed by a slash mark,

SC 1 PL/Cu15a Ni7b Cr r 7 0.3

4.3.2 The chemical symbol for copper (Cu),

A

The minimum copper thickness may be greater in some applications to meet

4.3.3 Anumbergivingtheminimumthicknessofthecopper

thermal cycling and other requirements.

coating in micrometres,

4.3.4 A lower-case letter designating the type of copper

5.1.3 The appearance required, for example, bright, dull, or

electrodeposit (see 4.4 and 6.3.1),

satin. Alternatively, samples showing the required finish or

4.3.5 The chemical symbol for nickel (Ni),

range of finish shall be supplied or approved by the purchaser.

4.3.6 Anumber giving the minimum thickness of the nickel

5.1.4 The significant surfaces, to be indicated on drawings

in micrometres,

of the parts, or by the provision of suitably marked specimens

4.3.7 A lower-case letter designating the type of nickel

(see 3.1).

electrodeposit (see 4.4 and 6.3.2),

5.1.5 The positions on significant surfaces for rack or

4.3.8 The chemical symbol for chromium (Cr), and

contact marks, where such marks are unavoidable (see 6.1.1).

4.3.9 A lower-case letter or letters designating the type of

5.1.6 The extent to which defects shall be tolerated on

chromium (see 4.4 and 6.3.3).

nonsignificant surfaces.

4.4 Symbols for Expressing Classification—The following

5.1.7 The ductility if other than the standard value (see 6.4).

lower-case letters shall be used in coating classification num-

5.1.8 The extent of tolerable surface deterioration after

bers to describe the types of coatings:

corrosion testing (see 6.6.3).

a — ductile copper deposited from acid-type baths

5.1.9 Sampling methods and acceptance levels (See Section

b — single-layer nickel deposited in the fully-bright condition

d — double- or triple-layer nickel coatings 7).

r — regular (that is, conventional) chromium

5.1.10 Whether thermal cycle and corrosion testing shall be

mc — microcracked chromium

conducted individually on separate specimens as described in

mp — microporous chromium

6.6 and 6.7, or sequentially using the same specimens as

4.5 Example of Complete Classification Number—A coat-

described in 6.8, and whether the specimens shall be un-

ing on plastic comprising 15 µm minimum ductile acid copper

mounted or mounted in a manner simulating assembly when

plus 15 µm minimum double-layer nickel plus 0.25 µm

these tests are conducted.

minimum microporous chromium has the classification num-

5.2 The minimum values of the electrochemical potential

ber: PL/Cu15a Ni15d Cr mp.

differences between individual nickel layers as measured in

accordance with Method B 764 within the limits given in 6.10.

5. Ordering Information

5.1 When ordering articles to be electroplated in accordance

6. Product Requirements

with this standard, the purchaser shall state the following:

6.1 Visual Defects:

5.1.1 ASTM designation number.

6.1.1 The significant surfaces of the electroplated articles

5.1.2 Either the classification number of the specific coat-

shall be free of visible defects, such as blisters, pits, roughness,

ing required (see 4.3) or the substrate material and the service

cracks, and uncoated areas, and shall not be stained or

condition number denoting the severity of the conditions it is

discolored. On articles where a visible contact mark is un-

required to withstand (see 4.2). If the service condition number

avoidable, its position shall be specified by the purchaser. The

is quoted and not the classification number, the manufacturer is

electroplated article shall be free of damage and clean.

free to supply any of the types of coatings designated by the

6.1.2 Defects in the surface of the molded plastic, such as

classification number corresponding to the service condition

cold shots, ejection marks, flash, gate marks, parting lines,

number, as given in Table 1. On request, the manufacturer

splay and others, may adversely affect the appearance and

shall inform the purchaser of the classification number of the

performance of coatings applied thereto despite the observance

coating applied.

of the best electroplating practice.Accordingly, the electroplat-

er’s responsibility for defects in the coating resulting from the

“Performance of Decorative Electrodeposited Copper-Nickel-Chromium Coat-

plastic-molding operation shall be waived (Note 1).

ings on Plastics” is a final report on programs conducted by ASTM and ASEP to

NOTE 1—To minimize problems of this type, the specifications cover-

evaluate the coating classification numbers. A copy of the report has been filed at

ASTM Headquarters as RR B-8-1003. ing the items to be electroplated should contain appropriate limitations on

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

B 604 – 91 (1997)

the extent of surface defects. Practice B 532 distinguishes between defects as the electrochemical relationships between the individual layers can be

that arise primarily in molding and those that arise in electroplating measured by the STEP test in accordance with Method B 764.

operations.

6.4 Ductility—The minimum value of the ductility shall be

6.2 Pretreatments—Proper preparatory procedures are es-

8 % for copper and for nickel when tested by the method given

sential for satisfactory performance of electrodeposited coat-

in Appendix X3. Greater ductility may be requested but shall

ings on plastics. Procedures described in Practice B 727 may

be subject to agreement between the purchaser and the manu-

be followed. In the case of patented processes, the instructions

facturer.

provided by the suppliers of those processes shall be followed.

6.5 Coating Thickness:

6.3 Process and Coating Requirements— Following prepa-

6.5.1 The minimum coating thickness shall be as designated

ratory operations, plastic articles are placed in electroplating

by the coating classification number.

solutions as required to produce the composite coating de-

6.5.2 Itisrecognizedthatrequirementsmayexistforthicker

scribed by the specific coating classification number or by

coatings than are covered by this specification.

coating one of the specified classification numbers listed in

6.5.3 The thickness of a coating and its various layers shall

Table 1 appropriate for the specified service condition number.

be measured at points on the significant surfaces (see 4.2 and

6.3.1 Type of Copper—Ductile copper shall be deposited

Note 4.)

from acid-type baths containing organic additives that promote

NOTE 4—Whensignificantsurfacesareinvolvedonwhichthespecified

leveling by the copper deposit.

thickness of deposit cannot readily be controlled, such as threads, holes,

6.3.2 Type of Nickel—For double- or triple-layer nickel

deep recesses, bases of angles, and similar areas, the purchaser and the

coatings, the bottom layer shall contain less than 0.005 mass %

manufacturer should recognize the necessity for either thicker deposits on

sulfur (Note 2). The top layer shall contain greater than 0.04 the more accessible surfaces or for special racking. Special racks may

involve the use of conforming, auxiliary, or bipolar electrodes, or

mass % sulfur (Note 3), and its thickness shall be not less than

nonconducting shields.

10 % of the total nickel thickness. In double-layer coatings, the

thickness of the bottom layer shall be not less than 60 % of the

6.5.3.1 The coulometric method described in Test Method

total nickel thickness. In triple-layer coatings, the bottom layer

B 504 may be used to measure thickness of the chromium, the

shall be not less than 50 % nor more than 70 %. If there are

total thickness of the nickel, and the thickness of the copper.

three layers, the intermediate layer shall contain not less than

The STEP test, Method B 764, which is similar to the coulo-

0.15 mass % sulfur and shall not exceed 10 % of the total

metric method, may be used to determine the thicknesses of

nickel thickness. These requirements for multilayer nickel

individual layers of nickel in a multilayer coating.

coatings are summarized in Table 2.

6.5.3.2 The microscopical method described in Method

6.3.3 Thickness of Chromium Deposit— The minimum

B 487 may be used to measure the thickness of each nickel

permissible thickness of the chromium deposit shall be 0.25

layer and of the copper layer.

µm on significant surfaces. The thickness of chromium is

6.5.3.3 The beta backscatter method described in Method

designated by the same symbol as the type instead of by

B 567 may be used when the total thickness of a copper/nickel/

numerals as in the case of copper and nickel (see 4.4).

chromium composite coating is to be measured, without any

indication of the thickness of each individual layer.

NOTE 2—The sulfur content is specified in order to indicate which type

6.5.3.4 Other methods may be used if it can be demon-

ofnickelelectroplatingsolutionmustbeused.Althoughnosimplemethod

strated that the uncertainty of the measurement is less than

is yet available for determining the sulfur content of a nickel deposit on a

coated article, chemical determinations are possible using specially 10 %, or less than that of any applicable method mentioned in

prepared test specimens. SeeAppendix X2 for the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.