ASTM D6188-97

(Test Method)Standard Test Method for Viscosity of Cellulose by Cuprammonium Ball Fall

Standard Test Method for Viscosity of Cellulose by Cuprammonium Ball Fall

SCOPE

1.1 This test method describes the procedure for estimating the molecular weight of cellulose by determining the viscosity of cuprammonium (CuAm) solutions of cellulosic materials, such as wood pulp, cotton and cotton linters. This test method is suitable for rapid, routine testing of large numbers of samples with accuracy and precision. This test method updates and extends the procedure reported by the American Chemical Society (ACS).

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6188 – 97

Standard Test Method for

Viscosity of Cellulose by Cuprammonium Ball Fall

This standard is issued under the fixed designation D 6188; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope ized water. Samples are either squeezed or pressed to 20 to

40 % consistency as necessary, then passed through a picker.

1.1 This test method describes the procedure for estimating

4.2 The wet pulp sample is dried with air whose maximum

the molecular weight of cellulose by determining the viscosity

temperature is 120°C and weighed under conditions that cause

of cuprammonium (CuAm) solutions of cellulosic materials,

the specified quantity of sample to be obtained. The weighed

such as wood pulp, cotton, and cotton linters. This test method

sample is placed in a glass 120-mL (4-oz) bottle, steel shot are

is suitable for rapid, routine testing of large numbers of

added, a vacuum is pulled on the bottle, and 97 mL of

samples with high accuracy and precision. This test method

cuprammonium solution are added to the bottle. The bottle is

updates and extends the procedure reported by the American

placed on a shaker to mix and dissolve the pulp sample in the

Chemical Society (ACS) .

CuAm solution.

1.2 The values stated in SI units are to be regarded as the

4.3 The dissolved sample is transferred to a glass viscosity

standard. The values given in parentheses are for information

tube. The tube is mounted vertically with a bright light behind

only.

the tube. A special glass bead (see 7.13) is dropped into the

1.3 This standard does not purport to address all of the

center of the solution in the tube. The time is measured in

safety concerns, if any, associated with its use. It is the

seconds (s) for the glass bead to pass between two marks on the

responsibility of the user of this standard to establish appro-

tube which are 20 cm apart. This time (s) is the uncorrected “as

priate safety and health practices and determine the applica-

is” cuprammonium ball fall viscosity. The temperature of the

bility of regulatory limitations prior to use.

solution is determined, and the correction factor for this

2. Referenced Documents

temperature is multiplied by the uncorrected viscosity of the

sample. This gives the “as is” cuprammonium ball fall viscos-

2.1 ASTM Standards:

ity value.

D 1193 Specification for Reagent Water

4.4 The “as is” viscosity value for the sample size used is

D 1695 Terminology of Cellulose and Cellulose Deriva-

converted to the 2.50-g ACS viscosity by the equations

tives

provided in 14.4. The viscosity is reported in “ACS seconds”.

D 438 Specification for Glasses in Laboratory Apparatus

5. Significance and Use

3. Terminology

5.1 This test method is suitable for use as a rapid control test

3.1 This standard terminology of cellulose and cellulose

for pulp manufacture or for careful determination of the

derivatives, see Terminology D 1695.

viscometric molecular weight of purified cotton or wood

4. Summary of Test Method

derived pulps.

5.2 This test method is applicable over a very large range of

4.1 An in-process or finished product sample is taken. All

cellulose molecular weights because seven sample sizes are

cooking and bleaching chemicals must be washed out of

defined. (Sample weights are reduced as cellulose molecular

in-process samples. Dry samples are wetted with demineral-

weight increases.)

5.3 Cotton and high molecular weight pulps may be difficult

to dissolve.

This test method is under the jurisdiction of ASTM Committee D-1 on Paint

and Related Coatings, Materials, and Applications and is the direct responsibility of

NOTE 1—Caution: This test method is only valid if the sample dis-

Subcommittee D01.36 on Cellulose and Cellulose Derivatives.

solves completely without gels.

Current edition approved Nov. 10, 1997. Published April 1998.

Carver et al., “A Standard Method for Determining the Viscosity of Cellulose

6. Interferences

in Cuprammonium Hydroxide,” Industrial and Engineering Chemistry, Analytical

Edition, Vol 1, No 1, 1929, pp. 49-51.

6.1 High temperature drying of pulp causes a reduction in

Annual Book of ASTM Standards, Vol 11.01.

viscosity. Therefore, limit the maximum temperature of the air

Annual Book of ASTM Standards, Vol 6.03.

Annual Book of ASTM Standards, Vol 14.02. used to dry the sample to 120°C and the maximum drying time

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D6188–97

TABLE 2 Effect of Volume Errors on Viscosity Error

to 20 min to keep viscosity loss to a minimum. All in-process

samples must be washed to remove cooking and bleaching Volume Percent Viscosity Error

chemicals, because the presence of chemicals while drying will

Error, (mL) Low Volume High Volume

increase viscosity loss.

1 4.0 3.9

6.2 The weight of sample used with this test method is

2 8.2 7.6

5 21.8 17.9

critical. The effect of incorrect sample weight on viscosity is

10 48.3 32.6

shown in Table 1.

6.2.1 If the pulp sample is properly weighed but a small

amount fails to dissolve, the viscosity will be incorrect by at

TABLE 3 Temperature Correction Factors

least the percentage of the sample that failed to dissolve.

Temperature Correction Factor

6.3 The volume of cuprammonium solution used is also

Error, °C Low Temperature High Temperature

critical. The effect of incorrect volume on viscosity is shown in

1 0.971 1.030

Table 2.

2 0.943 1.061

6.4 Use the temperature correction factors given in Table 3

3 0.915 1.093

4 0.888 1.126

to correct the cuprammonium viscosities to 25°C, assuming

5 0.863 1.159

that a 1°C increase causes a 3 % decrease in the measured

viscosity of the solution. Correction for temperatures off by

more than 5°C is not recommended. Samples should be

retested, ensuring than the CuAm solution is within tempera-

ture limits.

7. Apparatus

7.1 Testing Laboratory, maintained at 25 6 2°C.

7.2 Picker, suitable for shredding pulp without damaging it.

The picker must have provisions that permit sample remaining

after picking is completed to be blown out with compressed air.

7.3 Drier, suitable for pulp sample that dries the pulp with

hot air whose temperature is never permitted to get higher that

120°C.

7.4 Analytical Balance, capable of weighing to 60.001 g.

7.5 Bottles, wide mouth, glass, for use with an approxi-

mately No. 5 rubber stopper, and with a capacity of at least 120

mL (4 oz). The type of bottle must be selected such that it is

suitable for dissolving pulps in cuprammonium solution as

specified in this test method.

7.6 Steel Balls, chrome alloy, Grade 25, 3.2-mm (1/8-in.)

diameter.

7.7 Automatic Pipet, special made, capable of delivering

97 6 1 mL of CuAm solution, which is part of the cupram-

monium solution filling system (see Fig. 1).

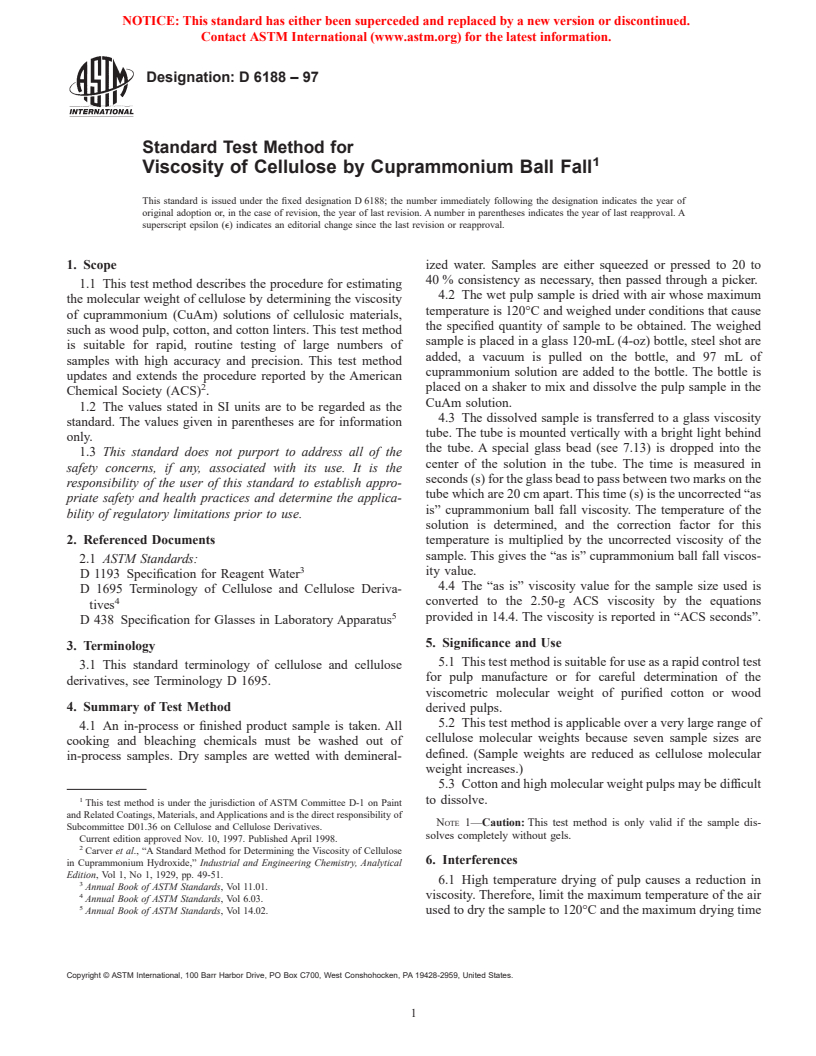

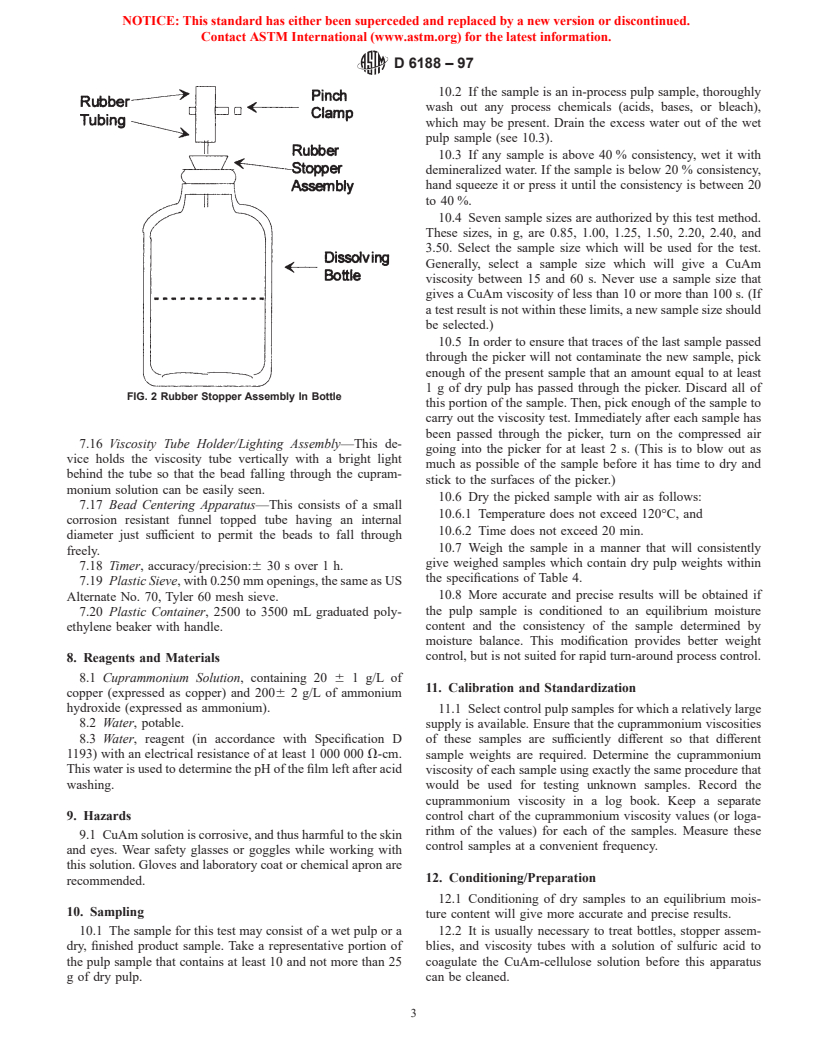

7.8 Rubber Stopper Assembly (see Fig. 2).

FIG. 1 Solution Filling System

7.9 Vacuum Source, capable of pulling a vacuum of 686 mm

Hg.

7.10 Shaker, capable of shaking bottles of cuprammonium 7.12 Viscosity Tube, specially made (see Fig. 4).

solution containing pulp. The shaker is to hold the bottles in a

7.13 Glass Viscosity Beads, for ACS cuprammonium vis-

horizontal position, and its design and operation should be such cosity determination. These beads are to be ground to a

that in-process pulps will be completely dissolved after 20 min

diameter that causes the viscosity of each second of bead fall

of shaking.

time in cuprammonium-cellulose solution to equal 22 cP. (This

7.11 Transfer Assembly, for transferring the will mean that a sample that has a bead fall time of 10 s will

cuprammonium-cellulose solution from the bottle to the vis-

have a viscosity of 220 cP, and a sample that has a bead fall

cosity tube (see Fig. 3). time of 50 s will have a viscosity of 1100 cP). Since the density

of various shipments of glass beads will vary somewhat, the

TABLE 1 Effect of Weight Errors on Viscosity Error

diameter of the beads will have to be varied to compensate for

Pulp Weight Percent Viscosity Error

the variation in the density of the glass. Generally the beads

Error, % Underweight Overweight

will be about 3.3 mm in diameter, and they will weigh about

1 3.8 3.9 0.046 g.

2 7.4 8.0

7.14 Moisture Balance—Apparatus to determine the dry

5 17.4 21.1

weight of cellulose.

10 31.8 45.6

7.15 pH Meter.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D6188–97

10.2 If the sample is an in-process pulp sample, thoroughly

wash out any process chemicals (acids, bases, or bleach),

which may be present. Drain the excess water out of the wet

pulp sample (see 10.3).

10.3 If any sample is above 40 % consistency, wet it with

demineralized water. If the sample is below 20 % consistency,

hand squeeze it or press it until the consistency is between 20

to 40 %.

10.4 Seven sample sizes are authorized by this test method.

These sizes, in g, are 0.85, 1.00, 1.25, 1.50, 2.20, 2.40, and

3.50. Select the sample size which will be used for the test.

Generally, select a sample size which will give a CuAm

viscosity between 15 and 60 s. Never use a sample size that

gives a CuAm viscosity of less than 10 or more than 100 s. (If

a test result is not within these limits, a new sample size should

be selected.)

10.5 In order to ensure that traces of the last sample passed

through the picker will not contaminate the new sample, pick

enough of the present sample that an amount equal to at least

1 g of dry pulp has passed through the picker. Discard all of

FIG. 2 Rubber Stopper Assembly In Bottle

this portion of the sample. Then, pick enough of the sample to

carry out the viscosity test. Immediately after each sample has

been passed through the picker, turn on the compressed air

7.16 Viscosity Tube Holder/Lighting Assembly—This de-

going into the picker for at least 2 s. (This is to blow out as

vice holds the viscosity tube vertically with a bright light

much as possible of the sample before it has time to dry and

behind the tube so that the bead falling through the cupram-

stick to the surfaces of the picker.)

monium solution can be easily seen.

10.6 Dry the picked sample with air as follows:

7.17 Bead Centering Apparatus—This consists of a small

10.6.1 Temperature does not exceed 120°C, and

corrosion resistant funnel topped tube having an internal

10.6.2 Time does not exceed 20 min.

diameter just sufficient to permit the beads to fall through

10.7 Weigh the sample in a manner that will consistently

freely.

give weighed samples which contain dry pulp weights within

7.18 Timer, accuracy/precision:6 30sover1h.

the specifications of Table 4.

7.19 Plastic Sieve, with 0.250 mm openings, the same as US

10.8 More accurate and precise results will be obtained if

Alternate No. 70, Tyler 60 mesh sieve.

the pulp sample is conditioned to an equilibrium moisture

7.20 Plastic Container, 2500 to 3500 mL graduated poly-

content and the consistency of the sample determined by

ethylene beaker with handle.

moisture balance. This modification provides better weight

control, but is not suited for rapid turn-around process control.

8. Reagents and Materials

8.1 Cuprammonium Solution, containing 20 6 1 g/L of

11. Calibration and Standardization

copper (expressed as copper) and 2006 2 g/L of ammonium

hydroxide (expressed as ammonium). 11.1 Select control pulp samples for which a relatively large

8.2 Water, potable.

supply is available. Ensure that the cuprammonium viscosities

8.3 Water, reagent (in accordance with Specification D of these samples are sufficiently different so that different

1193) with an electrical resistance of at least 1 000 000 V-cm. sample weights are required. Determine the cuprammonium

This water is used to determine the pH of the film left after acid

viscosity of each sample using exactly the same procedure that

washing. would be used for testing unknown samples. Record the

cuprammonium viscosity in a log book. Keep a separate

9. Hazards control chart of the cuprammonium viscosity values (or loga-

rithm of the values) for each of the samples. Measure these

9.1 CuAm solution is corrosive, and thus harmful to the skin

control samples at a convenient frequency.

and eyes. Wear safety glasses or goggles while working with

this solution. Gloves and laboratory coat or chemical apron are

12. Conditioning/Preparation

recommended.

12.1 Conditioning of dry samples to an equilibrium mois-

10. Sampling

ture content will give more accurate and precise results.

10.1 The sample for this test may consist of a wet pulp or a 12.2 It is usually necessary to treat bottles, stopper assem-

dry, finished product sample. Take a representative portion of blies, and viscosity tubes with a solution of sulfuric acid to

the pulp sample that contains at least 10 and not more than 25 coagulate the CuAm-cellulose solution before this apparatus

g of dry pulp. can be cleaned.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D6188–97

FIG. 3 Solution Transfer Assembly In Bottle

NOTE 2—Caution: It is very important that this apparatus be thor-

this may result in the loss of several millilitres of the measured

oughly washed to remove all of the sulfuric acid before it is dried. If there

97 mL of CuAm solution that was supposed to have been

is a small amount of sulfuric acid remaining on the surface of any

added to the bottle.)

apparatus when it dries, a thin film of sulfuric acid will remain on the

13.5 Place a hose clamp on the rubber hose on the stopper

surface of the apparatus.

assembly to prevent air from entering the bottle (see Fig. 2),

13. Procedure

and disconnect the hose on the stopper assembly from the

filling assembly. Place the bottle in the shaker so that the bottle

13.1 Carry out the following operations in a room main-

tained at 25 6 2°C (77 6 3.6°F). is in a horizontal position, and shake for 25 6 3 min. Stop the

13.2 This test method defines clean, dry bottles; clean, dry

shaker and remove the bottle. Observe the bottle to see if there

stopper assemblies; and clean, dry viscosity tubes as ones that is any indication of undissolved material in the solution. If

ap

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.