ASTM D7559/D7559M-09(2020)

(Test Method)Standard Test Method for Determining Pressure Decay of Inflatable Restraint Cushions

Standard Test Method for Determining Pressure Decay of Inflatable Restraint Cushions

SIGNIFICANCE AND USE

5.1 This test method may be used for product development and design, production validation, manufacturing process control, lot acceptance, or for a combination thereof.

5.2 The rate of inflation in this method does not attempt to mimic that of an actual cushion deployment, nor is it intended to subject the cushion to the dynamic loads, stress, and temperatures during such an event. It is also recognized that the compressed air used for this tests may not leak through the cushion at the same rate as the gas or mixture of gasses typically used in cushion inflators. Rather this method is intended to give a relative indication of the pressure holding ability of the cushion.

5.3 The internal volume and internal design of cushions varies greatly. This test method is most useful when comparing data from cushions of the same design and volume. This test method does not provide any data concerning the volume of gas leaking from the bag. At certain higher levels of the initial internal pressure, this test method will irreversibly damage the cushion and change its leakage properties for future testing or for commercial use. The damage to the bag is dependent on the design or shape of a specific bag and the type of coating applied. It is the responsibility of the supplier and/or purchaser to determine if the parameters under which a cushion is tested will be destructive and render the cushion unfit for future use

5.4 Within the limits of variance expressed in Section 12, this test method is useful for design and production validation and may be suitable for incorporation in a cushion specification or for lot acceptance testing of commercial shipments.

SCOPE

1.1 This test method is intended to determine the ability of an inflatable restraint cushion to retain air pressure at elevated pressures for a specified time interval.

1.2 Procedures and apparatus other than those stated in this test method may be used by agreement of purchaser and supplier, provided the specific deviations from the standard acknowledged in the report.

1.3 The results of this test method should not be used to predict the actual internal pressure decay of a cushion during a deployment.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7559/D7559M −09 (Reapproved 2020)

Standard Test Method for

Determining Pressure Decay of Inflatable Restraint

Cushions

This standard is issued under the fixed designation D7559/D7559M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method is intended to determine the ability of

D6799 Terminology Relating to Inflatable Restraints

an inflatable restraint cushion to retain air pressure at elevated

pressures for a specified time interval.

3. Terminology

1.2 Procedures and apparatus other than those stated in this

3.1 For all terminology relating to D13.20, Inflatable

test method may be used by agreement of purchaser and

restraints, refer to Terminology D6799.

supplier, provided the specific deviations from the standard

3.1.1 The following terms are relevant to this standard:

acknowledged in the report.

deployment; inflatable restraint.

1.3 The results of this test method should not be used to

3.2 For all other terms related to textiles, see Terminology

predict the actual internal pressure decay of a cushion during a

D123.

deployment.

4. Summary of Test Method

1.4 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

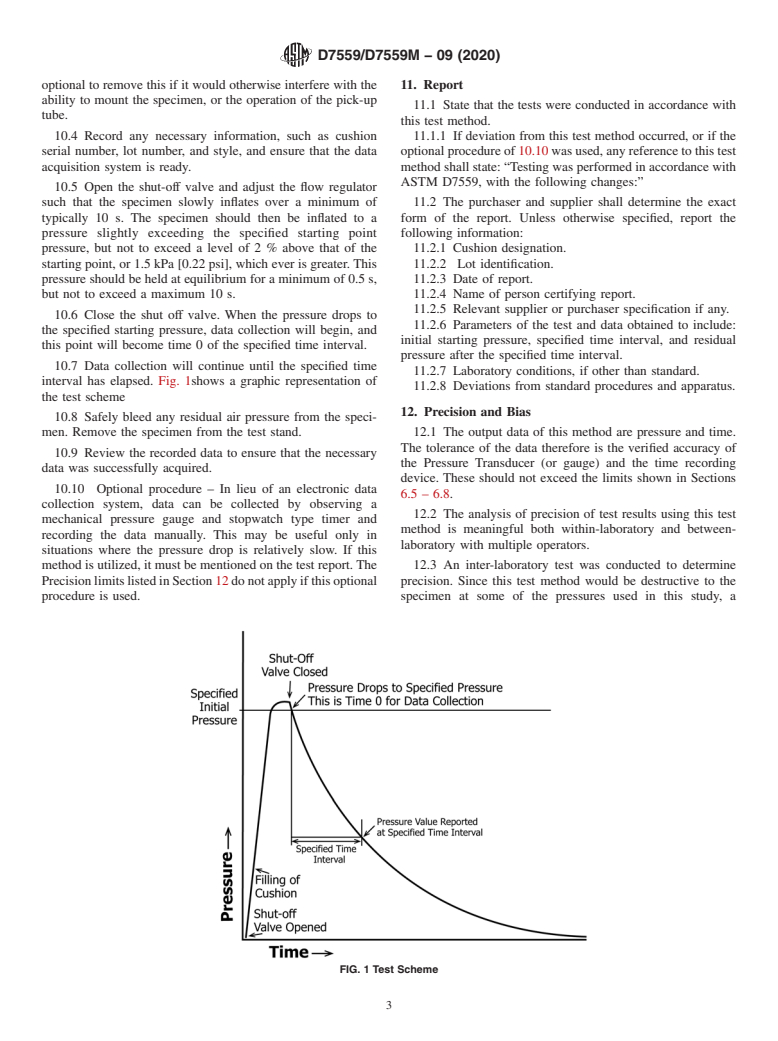

4.1 After inflation with air to a specific initial internal

each system may not be exact equivalents; therefore, each

pressure, an inflatable restraint cushion is tested to for its

system shall be used independently of the other. Combining

abilitytoretainaspecifiedresidualpressure(allowingforsome

values from the two systems may result in non-conformance

pressure loss) over a specified time period.

with the standard.

4.2 An inflatable restraint cushion is mounted onto a test

1.5 This standard does not purport to address all of the

stand that allows for the inflation of the cushion to a specified

safety concerns, if any, associated with its use. It is the

initial internal pressure. After the air supply is discontinued,

responsibility of the user of this standard to establish appro-

instrumentation measures and records internal pressure drop

priate safety, health, and environmental practices and deter-

over time.

mine the applicability of regulatory limitations prior to use.

4.3 Cushion internal pressure versus time data is recorded

1.6 This international standard was developed in accor-

and compared to allowable limits agreed upon by the purchaser

dance with internationally recognized principles on standard-

and supplier.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

5. Significance and Use

mendations issued by the World Trade Organization Technical

5.1 This test method may be used for product development

Barriers to Trade (TBT) Committee.

and design, production validation, manufacturing process

control, lot acceptance, or for a combination thereof.

2. Referenced Documents

5.2 The rate of inflation in this method does not attempt to

2.1 ASTM Standards:

mimic that of an actual cushion deployment, nor is it intended

D123 Terminology Relating to Textiles

to subject the cushion to the dynamic loads, stress, and

temperaturesduringsuchanevent.Itisalsorecognizedthatthe

compressed air used for this tests may not leak through the

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

and are the direct responsibility of Subcommittee D13.20 on Inflatable Restraints.

cushion at the same rate as the gas or mixture of gasses

Current edition approved Feb. 1, 2020. Published February 2020. Originally

typically used in cushion inflators. Rather this method is

approved as D7559/D7559M-09. Last previous edition approved in 2014 as

intended to give a relative indication of the pressure holding

D7559/D7559M-09(2014). DOI: 10.1520/D7559_D7559M-09R20.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or ability of the cushion.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.3 The internal volume and internal design of cushions

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. varies greatly.This test method is most useful when comparing

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7559/D7559M − 09 (2020)

data from cushions of the same design and volume. This test recorded must have an accuracy of 61 %. It is optional that

method does not provide any data concerning the volume of this system can initiate the filling of the bag and the closure of

gas leaking from the bag. At certain higher levels of the initial the shut-off valve.

internal pressure, this test method will irreversibly damage the

6.8 Manual Timer (stopwatch), optional, suitable for manu-

cushion and change its leakage properties for future testing or

ally observing elapsed time. This must have an accuracy of 61

for commercial use.The damage to the bag is dependent on the

%.

design or shape of a specific bag and the type of coating

6.9 Filter requirements, data sampling rate, transducer fre-

applied. It is the responsibility of the supplier and/or purchaser

quency response, and amplifier frequency response shall be

to determine if the parameters under which a cushion is tested

such that the overall accuracy of the data acquisition system

will be destructive and render the cushion unfit for future use

shall be within 61 %. The significant figures of the recorded

5.4 Within the limits of variance expressed in Section 12,

data of time and pressure, along with the timing increment

this test method is useful for design and production validation

should be agreed upon by the purchaser and supplier.

andmaybesuitableforincorporationinacushionspecification

or for lot acceptance testing of commercial shipments.

7. Sampling

7.1 The Cushion Pressure Decay Test at certain test param-

6. Apparatus

eters and pressures is a destructive test and therefore necessi-

6.1 Air Supply Source, capable of filling the cushion to the

tates sampling procedures if used in conjunction with lot

specified pressure, with a flow rate capable of maintaining the

acceptance.

specified pressure at equilibrium. Typically the pressure used

for testing the cushion will not exceed 200 kPa [29 psi], nor 7.2 The determination of lot size and sampling plan shall be

will the flow exceed 1500 L/min [53 CFM]. The air source agreed to by purchaser and supplier.

shouldbeequippedwithaninlinefilter,shutoffvalve,andflow

7.3 One cushion assembly is a test specimen.

regulator. Care should be taken to trap out excess moisture or

oil from the compressed air source.

8. Equipment Calibration

6.2 Shut Off Valve, capable of being actuated either manu-

8.1 For inflatable restraints, all test equipment used in

ally or remotely by an electrical signal.

accordance with this test method shall be certified for calibra-

6.3 Mounting Fixture, capable of allowing a sealed attach-

tion annually using gages that are traceable to the National

ment of the cushion to the air supply source, the shut off valve,

Institute of Science and Technology (NIST) or other national

and instrumentation to monitor the pressure decay during the

standards laboratory. The test parameters of the equipment

test. It should contain a pressure pickup tube. It shall be in an

shall be tested within the operating ranges covered in the

orientation that allows free expansion of the cushion geometry.

cushion specification or equivalent document.

It should have sufficient safety shielding and isolation for

operator protection during the test. The clamping device that

9. Conditioning

attaches the opening of the cushion to the filling tube fixture

9.1 Conditioning of specimens and conducting of the testing

should be designed to properly fit the opening of the cushion,

in the standard atmosphere for testing textiles is desirable, but

provide a secure mechanical attachment, and prevent gas

not required. It is recognized that conditions of the air from the

leakage.

compressed air source used to inflate the specimen will not be

6.4 PickupTube,mountedcoaxiallyinsidefillingtubeofthe

controlled, even though care should be taken to filter the air

mounting fixture. One end should extend inside the cushion at

and trap out any excessive moisture or compressor oils.

minimum of 25 mm [1 in.] beyond the clamping device. The

9.2 Testing can be conducted in, or specimens conditioned

other end should

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.