ASTM F1005-91(2019)

(Practice)Standard Practice for HVAC Duct Shapes; Identification and Description of Design Configuration

Standard Practice for HVAC Duct Shapes; Identification and Description of Design Configuration

SIGNIFICANCE AND USE

3.1 Standard nomenclature shall be used to facilitate communication between designers, suppliers, and users of HVAC ventilation ductwork components.

3.2 Standard design parameters shall be used to define ventilation ductwork shapes.

3.3 Standard variables for design parameters (see 2.2) are useful in writing CAD/CAM software for automatic fabrication of ventilation ductwork shapes.

SCOPE

1.1 This practice covers the identification of design configurations and descriptive nomenclature for sheetmetal HVAC ductwork shapes frequently used in shipbuilding. This practice also covers parametric dimensions of these shapes. (See Table 1.)

1.2 This practice does not cover the location of seams or joints within a shape or the method of joining shapes together.

1.3 Since this practice is not measurement sensitive, it is applicable whether inch-pound or SI metric dimensions are used.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F1005 −91 (Reapproved 2019) An American National Standard

Standard Practice for

HVAC Duct Shapes; Identification and Description of Design

Configuration

This standard is issued under the fixed designation F1005; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.1.5 offset, n—fitting that changes the location of the duct

with the line of the duct remaining parallel.

1.1 This practice covers the identification of design configu-

2.1.6 ogee, n—a smoothly curved type of offset. The inside

rations and descriptive nomenclature for sheetmetal HVAC

curve of each end is tangent to the outside curve of the other

ductwork shapes frequently used in shipbuilding. This practice

end.

also covers parametric dimensions of these shapes. (See Table

1.)

2.1.7 radius corner, n—cross section that is generally

rectangular, but with the corners softened to a radius.

1.2 This practice does not cover the location of seams or

joints within a shape or the method of joining shapes together. 2.1.8 rectangular, n—rectangular or square cross section.

2.1.9 reducer, n—a fitting that changes the size but not the

1.3 Since this practice is not measurement sensitive, it is

cross-section type of duct.

applicable whether inch-pound or SI metric dimensions are

used.

2.1.10 round, n—circular cross section.

1.4 This standard does not purport to address all of the

2.1.11 short axis of flat oval, n—curved so that the flat sides

safety concerns, if any, associated with its use. It is the

of the flat oval correspond to the curve.

responsibility of the user of this standard to establish appro-

2.1.12 splitter, n—internal part of some elbows and offsets;

priate safety, health, and environmental practices and deter-

sometimes required in diverging transitions. Used to provide

mine the applicability of regulatory limitations prior to use.

more uniform velocity and distribution of air flow.The number

1.5 This international standard was developed in accor-

and location of splitters is determined by calculation or from a

dance with internationally recognized principles on standard-

nomograph.

ization established in the Decision on Principles for the

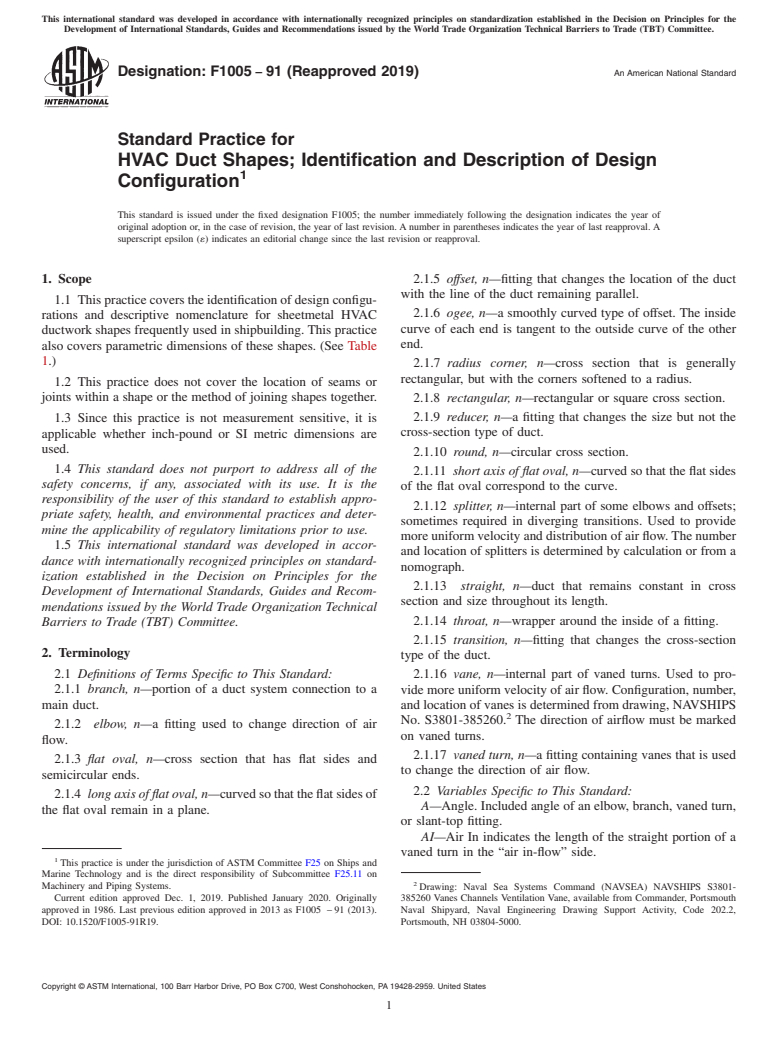

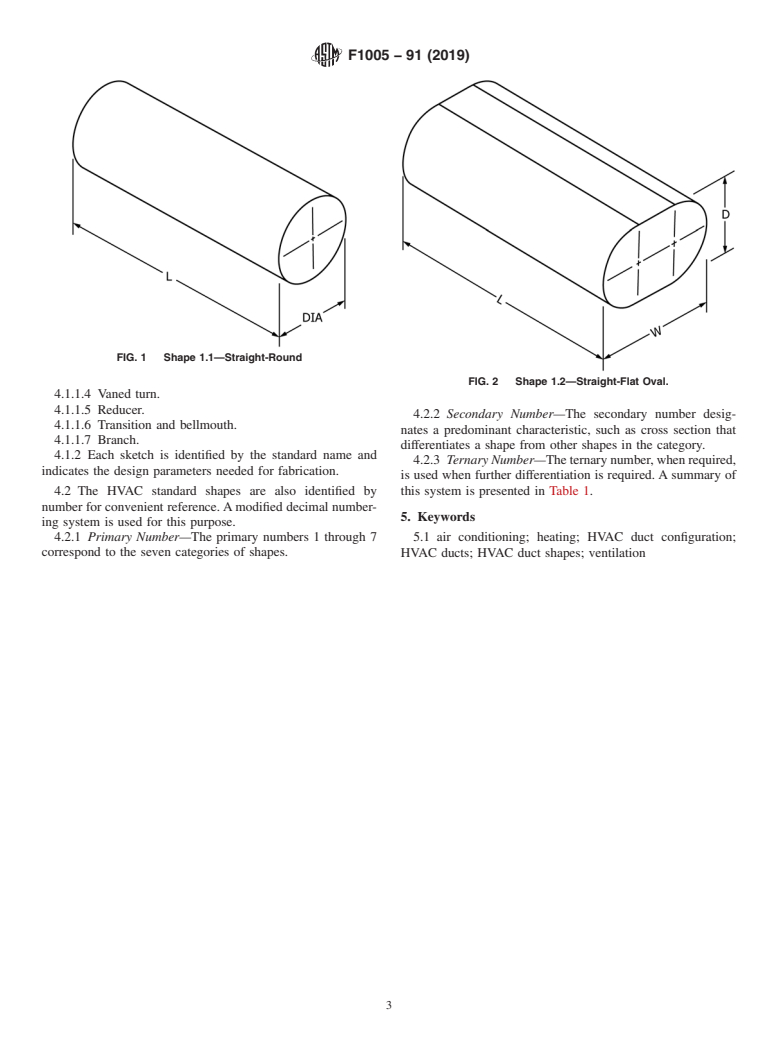

2.1.13 straight, n—duct that remains constant in cross

Development of International Standards, Guides and Recom-

section and size throughout its length.

mendations issued by the World Trade Organization Technical

2.1.14 throat, n—wrapper around the inside of a fitting.

Barriers to Trade (TBT) Committee.

2.1.15 transition, n—fitting that changes the cross-section

2. Terminology

type of the duct.

2.1 Definitions of Terms Specific to This Standard:

2.1.16 vane, n—internal part of vaned turns. Used to pro-

2.1.1 branch, n—portion of a duct system connection to a vide more uniform velocity of air flow. Configuration, number,

main duct. and location of vanes is determined from drawing, NAVSHIPS

No. S3801-385260. The direction of airflow must be marked

2.1.2 elbow, n—a fitting used to change direction of air

on vaned turns.

flow.

2.1.17 vaned turn, n—a fitting containing vanes that is used

2.1.3 flat oval, n—cross section that has flat sides and

to change the direction of air flow.

semicircular ends.

2.2 Variables Specific to This Standard:

2.1.4 longaxisofflatoval,n—curvedsothattheflatsidesof

A—Angle. Included angle of an elbow, branch, vaned turn,

the flat oval remain in a plane.

or slant-top fitting.

AI—Air In indicates the length of the straight portion of a

vaned turn in the “air in-flow” side.

This practice is under the jurisdiction of ASTM Committee F25 on Ships and

Marine Technology and is the direct responsibility of Subcommittee F25.11 on

Machinery and Piping Systems. Drawing: Naval Sea Systems Command (NAVSEA) NAVSHIPS S3801-

Current edition approved Dec. 1, 2019. Published January 2020. Originally 385260 Vanes Channels Ventilation Vane, available from Commander, Portsmouth

approved in 1986. Last previous edition approved in 2013 as F1005 – 91 (2013). Naval Shipyard, Naval Engineering Drawing Support Activity, Code 202.2,

DOI: 10.1520/F1005-91R19. Portsmouth, NH 03804-5000.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1005−91 (2019)

TABLE 1 HVAC Standard Nomenclature and Numbering System

1.1—Major length of a Y branch.

1. Straight: 1.2—Minor length of a Y branch.

1.1 Straight-round

O—Offset in one direction.

1.2 Straight-flat oval

R—Radius of a bellmouth.

1.3 Straight-rectangular

2. Offset: RC—Radius corner.

2.1 Offset-round

RV1—Radius of first splitter at V extension.

2.2.1 Offset-flat oval-long axis

RV2—Radius of second splitter at V extension.

2.2.2 Offset-flat oval-short axis

2.3.1 Offset-rectangular-without splitters

RV3—Radius of third splitter at V extension.

2.3.2 Offset-rectangular-with splitters

RZ1—Radius of first splitter at Z extension.

2.4.1 Offset-ogee-without splitters

RZ2—Radius of second splitter at Z extension.

2.4.2 Offset-ogee-with splitters

2.5.1 Offset-rectangular reducing-without RZ3—Radius of third splitter at Z extension.

splitters

R1—Radius of first splitter.

2.5.2 Offset-rectangular reducing-with splitters

R2—Radius of second splitter.

3. Elbow:

3.1 Elbow-round

R3—Radius of third splitter.

3.2.1 Elbow-flat oval-long axis

S1—Distance of first splitter from the outside curve of an

3.2.2 Elbow-flat oval-short axis

ogee offset.

3.3.1 Elbow-rectangular-without splitters

3.3.2 Elbow-rectangular-with splitters

S2—Distance of second splitter from the outside curve of

3.4.1 Elbow-rectangular reducing-without

an ogee offset.

splitters

S3—Distance of third splitter from the outside curve of an

3.4.2 Elbow-rectangular reducing-with splitters

3.5.1 Elbow-rectangular transition-without

ogee offset.

splitters

TR—Throat radius is the radius of the inside surface of an

3.5.2 Elbow-rectangular transition-with splitters

elbow or offset. Normally TR is equal to the width (of a

4. Vaned Turn:

4.1 Vaned turn

rectangular elbow).

5. Reducer:

TR1—Major throat radius of a reducing offset.

5.1 Reducer-round

TR2—Minor throat radius of a reducing offset.

5.2 Reducer-flat oval

5.3 Reducer-rectangular

V—Extension on one end of a part, opposite from Z.

6. Transition and Bellmouth:

W—Width of a part.

6.1 Transition-flat oval to round

WB—Width of a branch.

6.2 Transition-rectangular to round

6.3 Transition-rectangular to flat oval

W1—Major width of a part.

6.4 Transition-rectangular to radius corner

W2—Minor width of a part.

6.5 Transition-radius corner to flat oval

X+—Offsetofatransitionorreducertowardtherightalong

6.6.1 Bellmouth-round

6.6.2 Bellmouth-rectangular

the X axis, looking down from above.

7. Branch:

X−—Offset of a transition or reducer toward the left along

7.1.1 Branch-round-on equal diameter round

the X axis, looking down from above.

7.1.2 Branch-round-on larger diameter round

7.1.3 Branch-round-on round reducer

Y+—Offset of a transition or reducer toward the top of the

7.1.4 Branch-round-on rectangular straight

Y axis, looking down from above.

7.1.5 Branch-round-on rectangular reducer

Y−—Offset of a transition or reducer toward the bottom of

7.1.6 Branch-round “Y”

7.1.7 Branch-rectangular to round-“Y”

the Y axis, looking down from above.

7.2.1 Branch-rectangular-on rectangular straight

Z—Extension on one end of a part, oppos

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.