ASTM F1068-90(2007)

(Specification)Standard Specification for Doors, Double, Gastight/Airtight, Individually Dogged, for Marine Use

Standard Specification for Doors, Double, Gastight/Airtight, Individually Dogged, for Marine Use

ABSTRACT

This specification covers the principal dimensions and the mechanical requirements for manufacturing individually dogged, airtight/gastight double doors of steel and aluminum construction for personnel access through bulkheads, complete with frames, intended to maintain the structural and the air and gas tightness integrity of the bulkheads.

SCOPE

1.1 This specification, to be used in conjunction with Specification F 1073, covers the principal dimensions and the mechanical requirements for manufacturing steel and aluminum individually dogged, airtight/gastight double doors for personnel access through bulkheads, complete with frames, intended to maintain the structural and the air and gas tightness integrity of the bulkheads.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following precautionary caveat pertains only to the Test Methods portion, Section 6, of this specification: This standard does not purport to address the safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1068 −90(Reapproved 2007) An American National Standard

Standard Specification for

Doors, Double, Gastight/Airtight, Individually Dogged, for

Marine Use

This standard is issued under the fixed designation F1068; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.3 Military Standards:

MIL-R-900 Rubber Gasket Material, 45 Durometer Hard-

1.1 This specification, to be used in conjunction with

ness

Specification F1073, covers the principal dimensions and the

MIL-C-81706 Coating, Aluminum and Aluminum Alloys

mechanical requirements for manufacturing steel and alumi-

MIL-P-24441 Epoxy-Polyamide Paint

num individually dogged, airtight/gastight double doors for

DoD-STD-2138 Metal Sprayed Coating System for Corro-

personnel access through bulkheads, complete with frames,

sion Protection

intended to maintain the structural and the air and gas tightness

TT-E-490 Enamel, Silicone Alkyd Copolymer, Semi-Gloss,

integrity of the bulkheads.

Exterior

1.2 The values stated in inch-pound units are to be regarded

ZZ-R-765 Rubber, Silicone

as the standard. The values given in parentheses are for

information only.

3. Ordering Information

1.3 The following precautionary caveat pertains only to the

3.1 Ordering for doors under this specification shall include

Test Methods portion, Section 6, of this specification:This

the following:

standard does not purport to address the safety concerns

3.1.1 Material of doors,

associated with its use. It is the responsibility of the user of this

3.1.2 Nominal and ASTM designations, fixed lights or no

standard to establish appropriate safety and health practices

lights,

and determine the applicability of regulatory limitations prior

3.1.3 Quantity, and

to use.

3.1.4 Location of active and inactive panels.

3.2 Inspection and acceptance of doors shall be agreed upon

2. Referenced Documents

between the purchaser and the supplier.

2.1 ASTM Standards:

A36/A36M Specification for Carbon Structural Steel

4. Construction, Shape, and Dimensions

A131/A131M Specification for Structural Steel for Ships

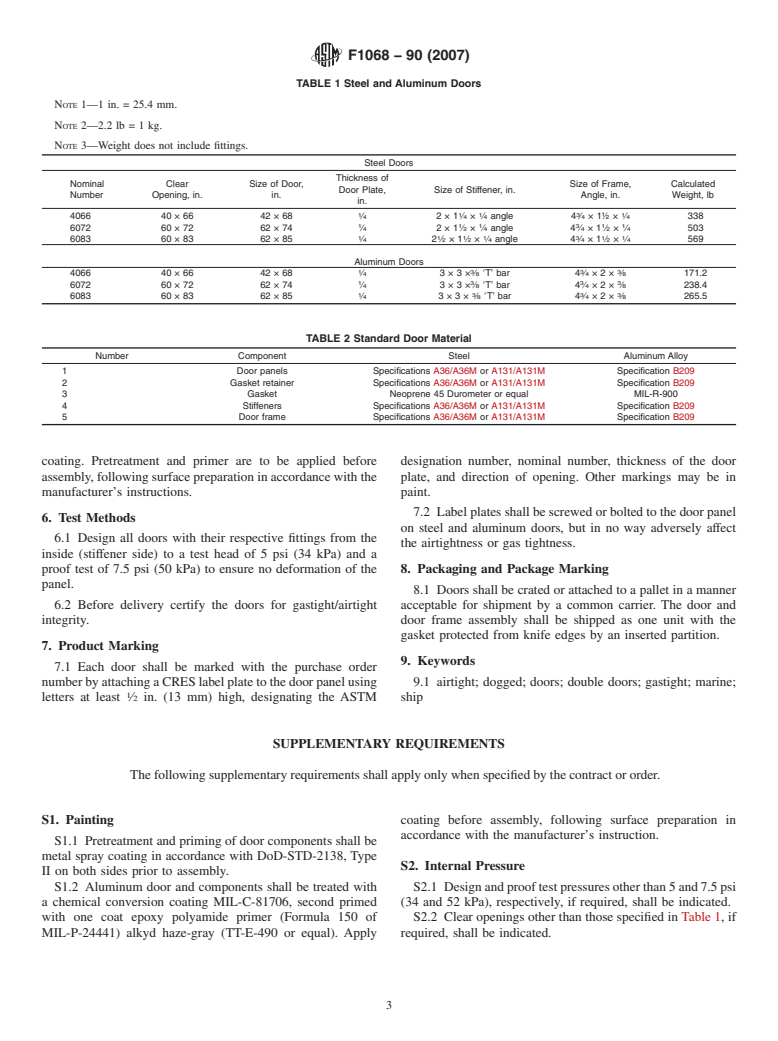

4.1 The construction, shape, and clear opening dimensions

B209 Specification for Aluminum and Aluminum-Alloy

shall be as shown in Fig. 1 and Table 1; in addition, they shall

Sheet and Plate

conform to the following requirements:

F1073 Specification for Door Fittings, for Watertight

4.1.1 Door frames shall be supplied as indicated in Fig. 1.

/Gastight /Airtight, Weathertight, and Non-Tight Doors,

The corner radius inside of door frame shall be 8 in. (203 mm).

for Marine Use

4.1.2 Dogs shall be located on the door panels unless

2.2 ABS Standard:

otherwise specified.

Rules for Building and Classing Steel Vessels

4.1.3 The doors shall be fitted with dogs, hinges, hasp and

staple assemblies, grab handles, label plates, and hook assem-

blies.

This specification is under the jurisdiction of ASTM Committee F25 on Ships

4.1.4 The position of the grab handles shall be located at the

and Marine Technology and is the direct responsibility of Subcommittee F25.03 on

Outfitting and Deck Machinery.

center of the height of each door panel.

Current edition approved Dec. 1, 2007. Published January 2008. Originally

4.1.5 The components shall be attached to the steel doors.

approved in 1987. Last previous edition approved in 2003 as F1068 – 90 (2003).

Components shall be attached to aluminum doors by either

DOI: 10.1520/F1068-90R07.

welding or bolting.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Available from American Bureau of Shipping (ABS), ABS Plaza, 16855 Available from Standardization Documents, Order Desk, Bldg. 4, Section D,

Northchase Dr., Houston, TX 77060, http://www.eagle.org. 700 Robbins Ave., Philadelphia, PA 19111-5094, ATTN: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1068 − 90 (2007)

NOTE 1—1 in. = 25.4 mm.

FIG. 1 Typical Double-Door Details

4.1.6 The material of standard door components shall be as 5.2 Pretreatment and priming of door components shall be

given in Table 2. as follows:

4.1.7 Welding shall be done in accordance with ABS Rules 5.2.1 Steel door and components, except component No. 3,

for Building and Classing Steel Vessels. are to be coated with inorganic zinc rich primer, SSPC Paint 20

Type I-C, at 1.5 to 3.0 mils (MDFT), both sides, before

5. Workmanship, Finish, and Appearance

assembly, following surface preparation in accordance with the

5.1 All sharp and ragged edges shall be ground flush and manufacturer’s instructions.

removed for personnel protection. 5.2.2 Aluminum door and components, except component

5.1.1 The door panels, upon completion, shall be straight No. 3, are to be pretreated with vinyl wash p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.