ASTM E28-18

(Test Method)Standard Test Methods for Softening Point of Resins Derived from Pine Chemicals and Hydrocarbons, by Ring-and-Ball Apparatus

Standard Test Methods for Softening Point of Resins Derived from Pine Chemicals and Hydrocarbons, by Ring-and-Ball Apparatus

SIGNIFICANCE AND USE

3.1 In general, with materials of these types, softening does not take place at a definite temperature. As the temperature rises, these materials gradually change from brittle or exceedingly thick and slow-flowing materials to softer and less viscous liquids. For this reason, the determination of the softening point must be made by a fixed, arbitrary, and closely defined method if the results obtained are to be comparable.

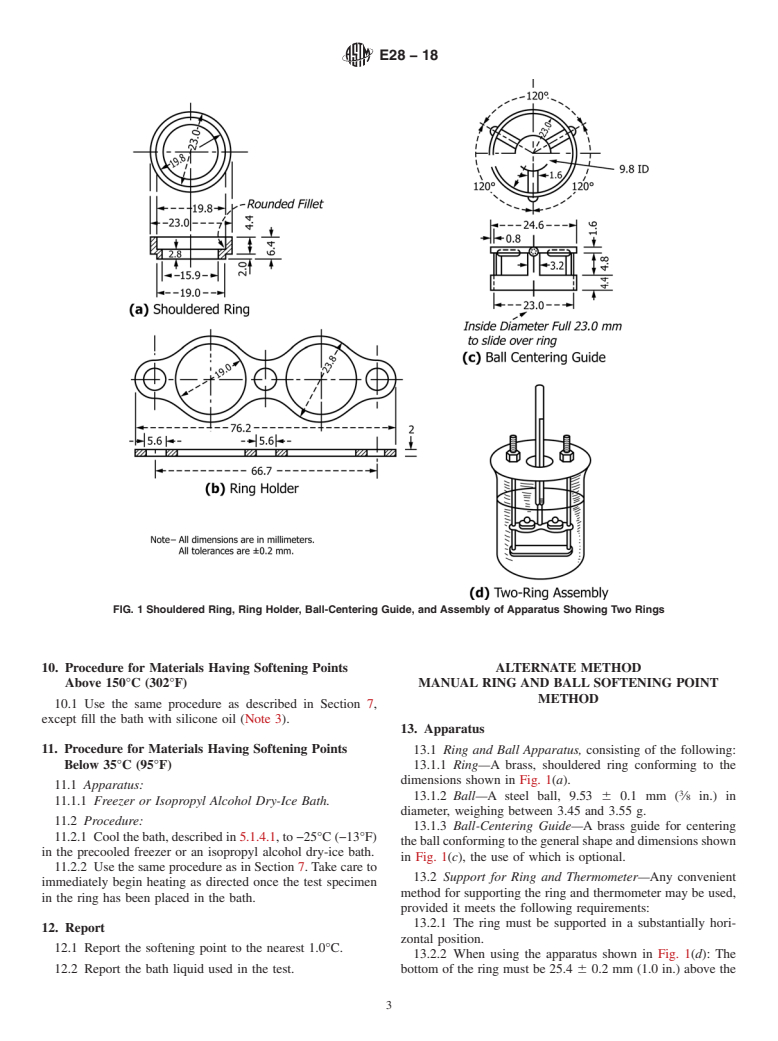

3.2 In these test methods, the softening point is defined as the temperature at which a disk of the sample held within a horizontal ring is forced downward a distance of 25.4 mm (1 in.) under the weight of a steel ball as the sample is heated at 5°C/min in a water, glycerin, silicone oil, ethylene glycol/water or glycerin/water bath.

3.3 The automatic method was chosen to be the reference method because a round robin demonstrated that it gave more precise results than the manual method.

SCOPE

1.1 These test methods are intended for determining the softening point of resins (including rosin and terpene resins) and similar materials by means of the ring-and-ball apparatus.

Note 1: For testing asphalts, tars, and pitches, see Test Method D36.

1.1.1 Test method using the automated ring and ball softening point apparatus is the reference method and the test method using the manual ring and ball method is an alternative method.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E28 − 18

Standard Test Methods for

Softening Point of Resins Derived from Pine Chemicals and

1

Hydrocarbons, by Ring-and-Ball Apparatus

ThisstandardisissuedunderthefixeddesignationE28;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope ASTM Test Methods

E691Practice for Conducting an Interlaboratory Study to

1.1 These test methods are intended for determining the

Determine the Precision of a Test Method

softening point of resins (including rosin and terpene resins)

and similar materials by means of the ring-and-ball apparatus.

3. Significance and Use

NOTE 1—For testing asphalts, tars, and pitches, see Test Method D36.

3.1 In general, with materials of these types, softening does

1.1.1 Test method using the automated ring and ball soften- not take place at a definite temperature. As the temperature

ingpointapparatusisthereferencemethodandthetestmethod rises, these materials gradually change from brittle or exceed-

usingthemanualringandballmethodisanalternativemethod. ingly thick and slow-flowing materials to softer and less

viscous liquids. For this reason, the determination of the

1.2 The values stated in SI units are to be regarded as the

softening point must be made by a fixed, arbitrary, and closely

standard. The values given in parentheses are for information

defined method if the results obtained are to be comparable.

only.

3.2 In these test methods, the softening point is defined as

1.3 This standard does not purport to address all of the

the temperature at which a disk of the sample held within a

safety concerns, if any, associated with its use. It is the

horizontal ring is forced downward a distance of 25.4 mm

responsibility of the user of this standard to establish appro-

(1in.) under the weight of a steel ball as the sample is heated

priate safety, health, and environmental practices and deter-

at 5°C/min in a water, glycerin, silicone oil, ethylene glycol/

mine the applicability of regulatory limitations prior to use.

water or glycerin/water bath.

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

3.3 The automatic method was chosen to be the reference

ization established in the Decision on Principles for the

method because a round robin demonstrated that it gave more

Development of International Standards, Guides and Recom-

precise results than the manual method.

mendations issued by the World Trade Organization Technical

4. Sample Preparation

Barriers to Trade (TBT) Committee.

4.1 Preparation of Sample by the Pour Method:

2. Referenced Documents

4.1.1 This procedure is suitable for materials that can be

2

heated and poured without adverse effects on the softening

2.1 ASTM Standards:

point.

D36TestMethodforSofteningPointofBitumen(Ring-and-

4.1.2 Select a sample representative of the material to be

Ball Apparatus)

tested.Thesampleshouldconsistofflakes,pastilles,orfreshly

E1Specification for ASTM Liquid-in-Glass Thermometers

broken lumps free of oxidized surfaces. Avoid inclusion of

E177Practice for Use of the Terms Precision and Bias in

finely divided material or dust.

4.1.3 Selectaquantityatleasttwicethatnecessarytofillthe

1

These test methods are under the jurisdiction of ASTM Committee D01 on desired number of rings, and melt it immediately in a clean

Paint and Related Coatings, Materials, and Applications and are the direct

container, using an oven, hot plate, sand bath or oil bath to

responsibility of Subcommittee D01.34 on Pine Chemicals and Hydrocarbon

prevent local overheating. Take care to avoid incorporating air

Resins.

bubbles in the sample. Melt the sample completely, but do not

CurrenteditionapprovedJuly1,2018.PublishedJuly2018.Originallyapproved

in 1936. Last previous edition approved in 2014 as E28– 14. DOI: 10.1520/E0028-

heat it above a temperature necessary to pour the material

18.

readily. The time from the beginning of heating to the pouring

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

of the sample should not exceed 15 min.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E28−18

NOTE 2—For materials that may be heat sensitive, continuously inert

6.2 Ring—A brass, shouldered ring conforming to the di-

the flask containin

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E28 − 14 E28 − 18

Standard Test Methods for

Softening Point of Resins Derived from Pine Chemicals and

1

Hydrocarbons, by Ring-and-Ball Apparatus

This standard is issued under the fixed designation E28; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 These test methods are intended for determining the softening point of resins (including rosin and terpene resins) and similar

materials by means of the ring-and-ball apparatus.

NOTE 1—For testing asphalts, tars, and pitches, see Test Method D36.

1.1.1 Test method using the automated ring and ball softening point apparatus is the reference method and the test method using

the manual ring and ball method is an alternative method.

1.1.2 Test method using the manual ring and ball softening point apparatus is an alternative method.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D36 Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus)

E1 Specification for ASTM Liquid-in-Glass Thermometers

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Significance and Use

3.1 In general, with materials of these types, softening does not take place at a definite temperature. As the temperature rises,

these materials gradually change from brittle or exceedingly thick and slow-flowing materials to softer and less viscous liquids.

For this reason, the determination of the softening point must be made by a fixed, arbitrary, and closely defined method if the results

obtained are to be comparable.

3.2 In these test methods, the softening point is defined as the temperature at which a disk of the sample held within a horizontal

ring is forced downward a distance of 25.4 mm (1 in.) under the weight of a steel ball as the sample is heated at 5°C/min in a water,

glycerin, silicone oil, ethylene glycol/water or glycerin/water bath.

3.3 The automatic method was chosen to be the reference method because a round robin demonstrated that it gave more precise

results than the manual method.

1

These test methods are under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and are the direct responsibility of

Subcommittee D01.34 on Pine Chemicals and Hydrocarbon Resins.

Current edition approved July 1, 2014July 1, 2018. Published August 2014July 2018. Originally approved in 1936. Last previous edition approved in 20092014 as E28 – 99

(2009).E28 – 14. DOI: 10.1520/E0028-14.10.1520/E0028-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E28 − 18

4. Sample Preparation

4.1 Preparation of Sample by the Pour Method:

4.1.1 This procedure is suitable for materials that can be heated and poured without adverse effects on the softening point.

4.1.2 Select a sample representative of the material to be tested. The sample should consist of flakes, pastilles, or freshly broken

lumps free of oxidized surfaces. Avoid inclusion of finely divided material or dust.

4.1.3 Select a quantity at least twice that necessary to fill the d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.