ASTM F986-86(2004)

(Specification)Standard Specification for Suction Strainer Boxes

Standard Specification for Suction Strainer Boxes

ABSTRACT

This specification covers the design and material requirements as well as the construction strainer boxes used in ships' bilges and other tank locations requiring trash protection for suction pipes and pumps. Materials covered by this specification are Types 1 and 2 strainer boxes, which shall be manufactured free of defects, burrs, and sharp edges, and with dimensions conforming to the requirements specified. The strainer boxes shall be hot galvanized after fabrication.

SCOPE

1.1 This specification covers the design, materials, and construction of strainer boxes for use in ships' bilges and other such tank locations that require trash protection for suction pipes and pumps.

1.2 This specification covers pipe sizes from NPS 1½ through NPS 16 (see Note 1). Note 1—The dimensionless designator NPS (nominal pipe size) has been substituted in this specification for such traditional terms as "nominal diameter," "size," and "nominal size."

1.3 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 986 – 86 (Reapproved 2004)

Standard Specification for

Suction Strainer Boxes

This standard is issued under the fixed designation F 986; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

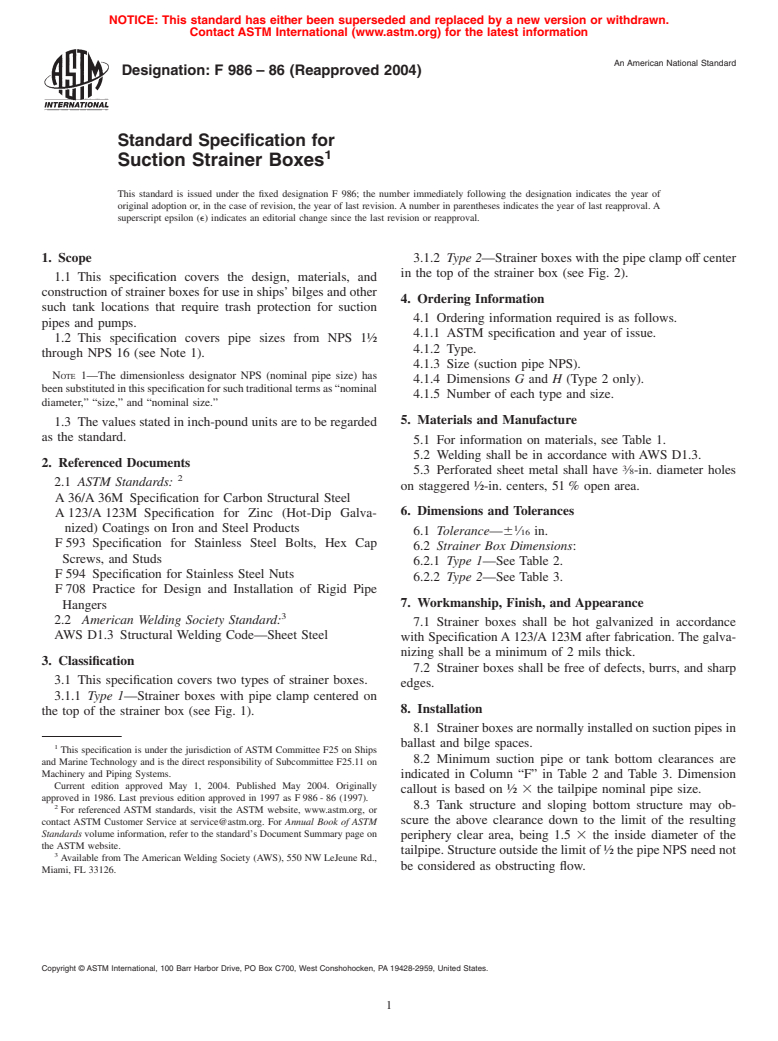

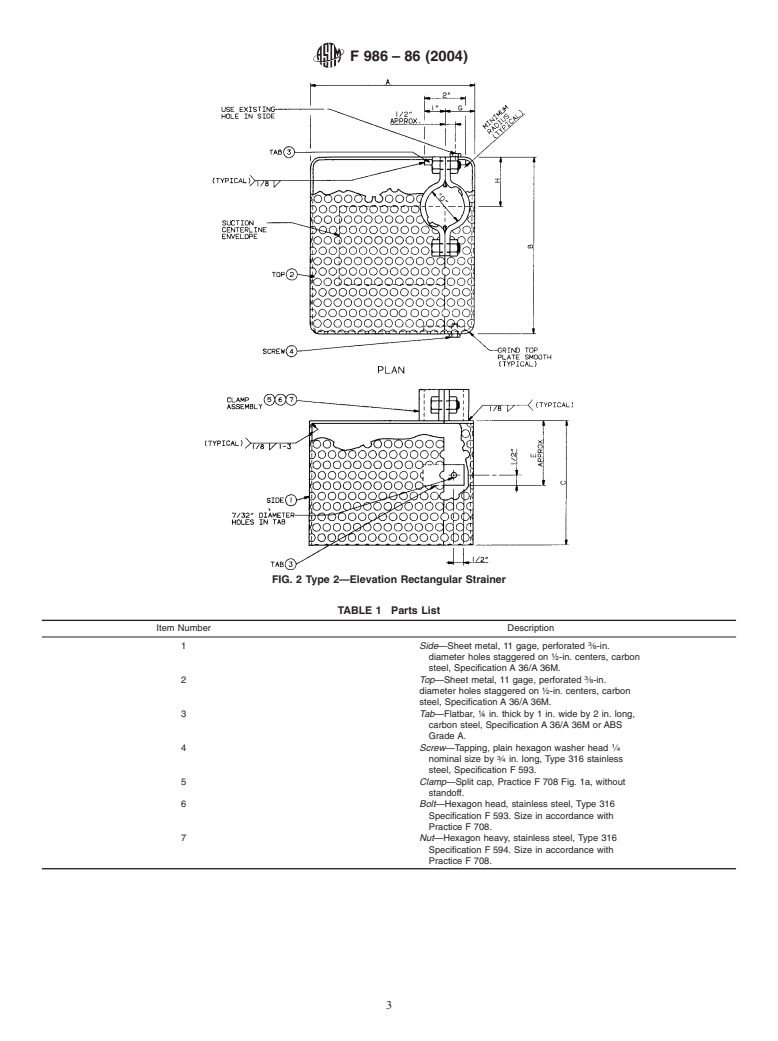

1. Scope 3.1.2 Type 2—Strainer boxes with the pipe clamp off center

in the top of the strainer box (see Fig. 2).

1.1 This specification covers the design, materials, and

constructionofstrainerboxesforuseinships’bilgesandother

4. Ordering Information

such tank locations that require trash protection for suction

4.1 Ordering information required is as follows.

pipes and pumps.

4.1.1 ASTM specification and year of issue.

1.2 This specification covers pipe sizes from NPS 1½

4.1.2 Type.

through NPS 16 (see Note 1).

4.1.3 Size (suction pipe NPS).

NOTE 1—The dimensionless designator NPS (nominal pipe size) has

4.1.4 Dimensions G and H (Type 2 only).

beensubstitutedinthisspecificationforsuchtraditionaltermsas“nominal

4.1.5 Number of each type and size.

diameter,” “size,” and “nominal size.”

5. Materials and Manufacture

1.3 The values stated in inch-pound units are to be regarded

as the standard.

5.1 For information on materials, see Table 1.

5.2 Welding shall be in accordance with AWS D1.3.

2. Referenced Documents

5.3 Perforated sheet metal shall have ⁄8-in. diameter holes

2.1 ASTM Standards:

on staggered ½-in. centers, 51% open area.

A36/A36M Specification for Carbon Structural Steel

6. Dimensions and Tolerances

A 123/A 123M Specification for Zinc (Hot-Dip Galva-

nized) Coatings on Iron and Steel Products

6.1 Tolerance—6 ⁄16 in.

F593 Specification for Stainless Steel Bolts, Hex Cap

6.2 Strainer Box Dimensions:

Screws, and Studs

6.2.1 Type 1—See Table 2.

F594 Specification for Stainless Steel Nuts

6.2.2 Type 2—See Table 3.

F708 Practice for Design and Installation of Rigid Pipe

7. Workmanship, Finish, and Appearance

Hangers

2.2 American Welding Society Standard:

7.1 Strainer boxes shall be hot galvanized in accordance

AWS D1.3 Structural Welding Code—Sheet Steel

with SpecificationA123/A123M after fabrication. The galva-

nizing shall be a minimum of 2 mils thick.

3. Classification

7.2 Strainer boxes shall be free of defects, burrs, and sharp

3.1 This specification covers two types of strainer boxes.

edges.

3.1.1 Type 1—Strainer boxes with pipe clamp centered on

8. Installation

the top of the strainer box (see Fig. 1).

8.1 Strainerboxesarenormallyinstalledonsuctionpipesin

ballast and bilge spaces.

This specification is under the jurisdiction ofASTM Committee F25 on Ships

8.2 Minimum suction pipe or tank bottom clearances are

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

Machinery and Piping Systems.

indicated in Column “F” in Table 2 and Table 3. Dimension

Current edition approved May 1, 2004. Published May 2004. Originally

callout is based on ½ 3 the tailpipe nominal pipe size.

approved in 1986. Last previous edition approved in 1997 as F986-86 (1997).

2 8.3 Tank structure and sloping bottom structure may ob-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

scure the above clearance down to the limit of the resulting

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

periphery clear area, being 1.5 3 the inside diameter of the

the ASTM website.

tailpipe.Structureoutsidethelimitof½thepipeNPSneednot

Available from TheAmerican Welding Society (AWS), 550 NW LeJeune Rd.,

be considered as obstructing flow.

Miami, FL 33126.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 986 – 86 (2004)

NOTE 1—Tab location to suit p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.