ASTM B597-92(1998)

(Practice)Standard Practice for Heat Treatment of Aluminum Alloys (Withdrawn 2002)

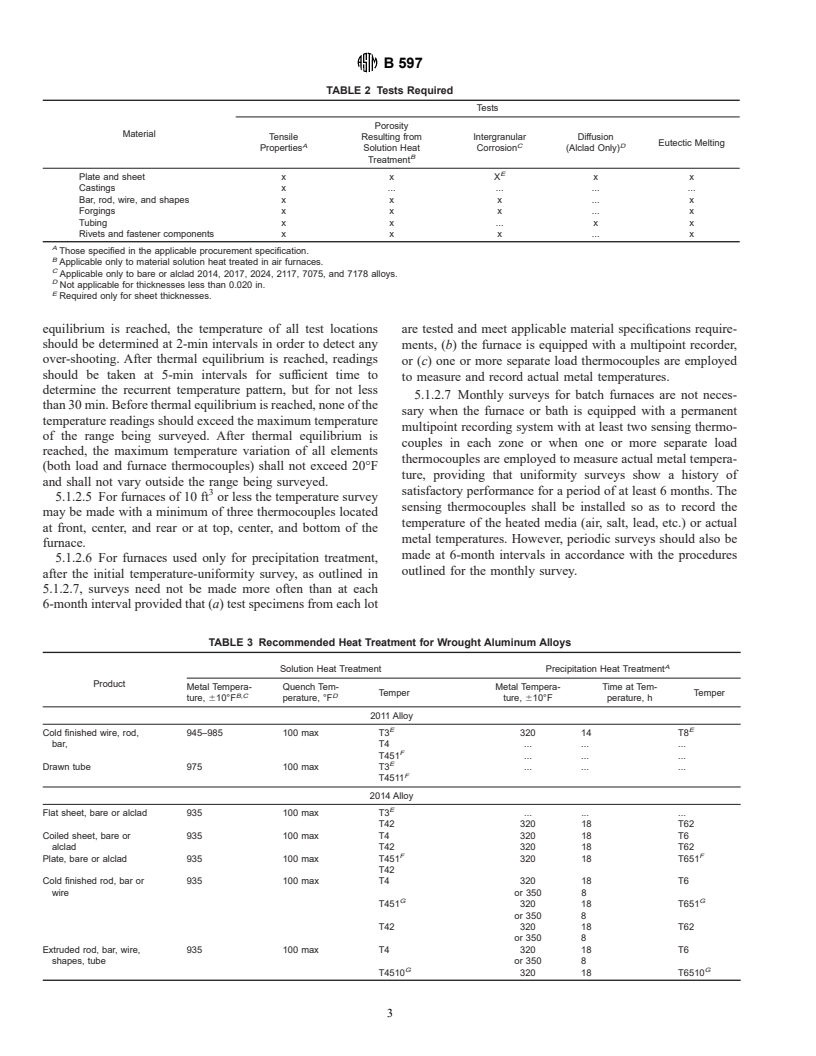

Standard Practice for Heat Treatment of Aluminum Alloys (Withdrawn 2002)

SCOPE

1.1 This practice is intended as an aid in establishing a suitable procedure for the heat treatment of aluminum alloys.

1.2 Times and temperatures appearing in the heat treatment tables are typical for various forms, sizes, and manufacturing methods and may not provide the optimum heat treatment for a specific item.

1.3 Some alloys in the 6XXX series may achieve the T4 temper by quenching from within the solution temperature range during or immediately following a hot working process, such as upon emerging from an extrusion die. Such alternatives to furnace heating and immersion quenching are indicated by footnote O, of the table for heat treatment of wrought aluminum alloys. However, this practice does not cover the requirements for a controlled press heat treatment. (A practice for press solution heat treatment of aluminum alloys is being developed.)

General Information

Standards Content (Sample)

Designation: B 597 – 92 (Reapproved 1998)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Practice for

1

Heat Treatment of Aluminum Alloys

This standard is issued under the fixed designation B 597; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * 3.1.1 The definitions relating to heat treatment of metals

appearing in Definitions E 44 are considered as applying to this

1.1 This practice is intended as an aid in establishing a

practice.

suitable procedure for the heat treatment of aluminum alloys.

1.2 Times and temperatures appearing in the heat treatment

4. Apparatus

tables are typical for various forms, sizes, and manufacturing

4.1 Aluminum alloys are usually heat treated in molten salt

methods and may not provide the optimum heat treatment for

baths or air chamber furnaces; however, lead baths, oil baths,

a specific item.

fluidized beds, or even superheated steam may be used in

1.3 Some alloys in the 6XXX series may achieve the T4

specific applications. However the use of uncontrolled heating

temper by quenching from within the solution temperature

is not permitted. Whichever heating means are employed,

range during or immediately following a hot working process,

careful evaluation is required to ensure that the alloy being heat

such as upon emerging from an extrusion die. Such alternatives

treated responds properly to heat treatment and is not damaged

to furnace heating and immersion quenching are indicated by

by overheating or by the heat treatment environment.

footnote K of the table for heat treatment of wrought aluminum

4.1.1 Salt Baths heat the work rapidly and uniformly. The

alloys. However, this practice does not cover the requirements

temperature of the bath can be closely controlled, an important

for a controlled press heat treatment. (A practice for press

consideration in solution heat treatment of wrought-aluminum

solution heat treatment of aluminum alloys is being devel-

alloys. Salt baths are not recommended for heat treatment of

oped.)

casting alloys. High-temperature oxidation of aluminum is not

2. Referenced Documents a problem in salt baths.

2.1 The following documents of the issue in effect on the

NOTE 1—Warning: Nitrate baths must not be used in the heat treatment

date of material purchase form a part of this specification to the

of 5xx.x series casting alloys because of a possible explosion.

extent referenced herein:

4.1.2 Air-Chamber Furnaces may be oil- or gas-fired or

2.2 ASTM Standards:

may be electrically heated. The atmosphere in air chamber

B 275 Practice for Codification of Certain Nonferrous Met-

furnaces must be controlled to prevent porosity resulting from

2

als and Alloys, Cast and Wrought

solution heat treatment. Furnace components that are signifi-

B 557 Test Methods of Tension Testing Wrought and Cast

cantly hotter than the metal should be suitably shielded for

2

Aluminum- and Magnesium-Alloy Products

metal less than 0.250 in. thick to prevent adverse radiation

E 44 Definitions of Terms Relating to Heat Treatment of

effects. The suitability of the atmosphere in an air-chamber

3

Metals

furnace can be demonstrated by determining by test that

2.3 American National Standard:

products processed in that furnace are substantially free of

H35.1 Alloy and Temper Designation Systems for Alumi-

porosity resulting from solution heat treatment.

4

num

NOTE 2—Porosity resulting from solution heat treatment may lower

mechanical properties and commonly causes blistering of the surface of

3. Terminology

the material. The condition is most likely in furnaces in which the products

3.1 Definitions:

of combustion contact the work, particularly if the gases are high in water

vapor or contain compounds of sulfur. In general, the high-strength

1 wrought alloys of the 2000 and 7000 series are most susceptible,

This recommended practice is under the jurisdiction of ASTM Committee B-7

particularly in the extruded form or as forgings, and casting alloys in the

on Light Metals and Alloys and is the direct responsibility of Subcommittee B07.03

300 series. Low-strength and alclad (two sides) alloys are practically

on Aluminum Alloy Wrought Products and Subcommittee B07.01 on Aluminum

Alloy Ingots and Castings. immune to this type of damage. Anodic films and proprietary heat-treat

Current edition approved January 15, 1992. Published March 1992. Originally

coatings are also useful in protecting against porosity resulting from

published as B 597 – 74. Last previous edition B 597 – 90.

solution heat treatment. Surface discoloration is a normal result of solution

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.