ASTM A1038-13e1

(Test Method)Standard Test Method for Portable Hardness Testing by the Ultrasonic Contact Impedance Method

Standard Test Method for Portable Hardness Testing by the Ultrasonic Contact Impedance Method

SIGNIFICANCE AND USE

4.1 The hardness of a material is a defined quantity having many scales and being dependent on the way the test is performed. In order to avoid the creation of a new method involving a new hardness scale, the UCI method converts into common hardness values, for example, HV, HRC, etc.

4.2 The UCI hardness test is a superficial determination, only measuring the hardness condition of the surface contacted. The results generated at a specific location do not represent the part at any other surface location and yield no information about the material at subsurface locations.

4.3 The UCI hardness test may be used on large or small components at various locations. It can be used to make hardness measurements on positions difficult to access, such as tooth flanks or roots of gears.

SCOPE

1.1 This test method covers the determination of comparative hardness values by applying the Ultrasonic Contact Impedance Method (UCI Method).

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: A1038 − 13

Standard Test Method for

Portable Hardness Testing by the Ultrasonic Contact

1

Impedance Method

This standard is issued under the fixed designation A1038; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Table 3 heading was corrected editorially in April 2016.

1. Scope* 3. Terminology

1.1 This test method covers the determination of compara-

3.1 Definitions:

tive hardness values by applying the Ultrasonic Contact

3.1.1 calibration—determination of the specific values of

Impedance Method (UCI Method).

the significant operating parameters of the UCI instrument by

comparisonwithvaluesindicatedbyastandardizedworkbench

1.2 The values stated in SI units are to be regarded as

hardness tester or by a set of certified reference test pieces.

standard. No other units of measurement are included in this

standard.

3.1.2 surface finish—all references to surface finish in this

1.3 This standard does not purport to address all of the

test method are defined as surface roughness (that is, Ra =

safety concerns, if any, associated with its use. It is the

average roughness value).

responsibility of the user of this standard to establish appro-

3.1.3 UCI hardness test—a hardness testing method using a

priate safety and health practices and determine the applica-

calibrated instrument by pressing a resonating rod with a

bility of regulatory limitations prior to use.

defined indenter, for example, a Vickers diamond, with a fixed

force against the surface of the part to be tested.

2. Referenced Documents

2

3.1.4 UCI method—Ultrasonic Contact Impedance, a hard-

2.1 ASTM Standards:

ness testing method developed by Dr. Claus Kleesattel in 1961

A370Test Methods and Definitions for Mechanical Testing

based on the measurement of the frequency shift of a resonat-

of Steel Products

ingrodcausedbytheessentiallyelasticnatureofthefinitearea

E10Test Method for Brinell Hardness of Metallic Materials

of contact between the indenter and the test piece during the

E18Test Methods for Rockwell Hardness of Metallic Ma-

penetration.

terials

E140Hardness Conversion Tables for Metals Relationship

3.1.5 verification—checking or testing the UCI instrument

Among Brinell Hardness, Vickers Hardness, Rockwell

to ensure conformance with this test method.

Hardness, Superficial Hardness, Knoop Hardness, Sclero-

scope Hardness, and Leeb Hardness

4. Significance and Use

E177Practice for Use of the Terms Precision and Bias in

4.1 The hardness of a material is a defined quantity having

ASTM Test Methods

many scales and being dependent on the way the test is

E384Test Method for Microindentation Hardness of Mate-

performed. In order to avoid the creation of a new method

rials

involving a new hardness scale, the UCI method converts into

E691Practice for Conducting an Interlaboratory Study to

common hardness values, for example, HV, HRC, etc.

Determine the Precision of a Test Method

4.2 The UCI hardness test is a superficial determination,

only measuring the hardness condition of the surface con-

1

This test method is under the jurisdiction of ASTM Committee A01 on Steel,

tacted. The results generated at a specific location do not

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

represent the part at any other surface location and yield no

A01.06 on Steel Forgings and Billets.

Current edition approved Nov. 1, 2013. Published March 2014. Originally

information about the material at subsurface locations.

approved in 2005. Last previous edition approved in 2010 as A1038–10a. DOI:

10.1520/A1038-13E01.

4.3 The UCI hardness test may be used on large or small

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

components at various locations. It can be used to make

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

hardnessmeasurementsonpositionsdifficulttoaccess,suchas

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. tooth flanks or roots of gears.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

A1038 − 13

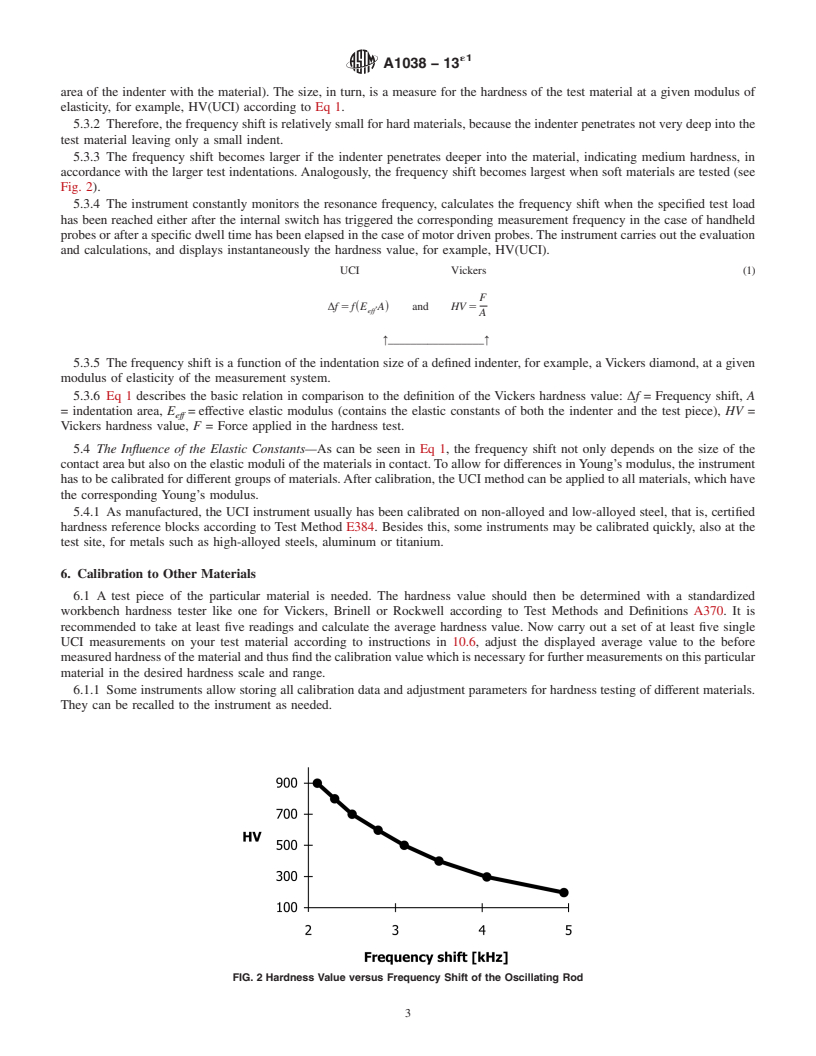

A. GENERAL DESCRIPTION OF INSTRUMENTS resonatingrod.Thisshiftisrelatedtothesizeoftheindentarea

AND TEST PROCEDURE FOR UCI HARDNESS (contact area of the indenter with the material). The size, in

TESTING turn,isameasureforthehardnessofthetestmaterialatagiven

modulus of elasticity, for example, HV(UCI) according to Eq

5. Apparatus

1.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: A1038 − 13 A1038 − 13

Standard Test Method for

Portable Hardness Testing by the Ultrasonic Contact

1

Impedance Method

This standard is issued under the fixed designation A1038; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Table 3 heading was corrected editorially in April 2016.

1. Scope*

1.1 This test method covers the determination of comparative hardness values by applying the Ultrasonic Contact Impedance

Method (UCI Method).

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

E10 Test Method for Brinell Hardness of Metallic Materials

E18 Test Methods for Rockwell Hardness of Metallic Materials

E140 Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness,

Superficial Hardness, Knoop Hardness, Scleroscope Hardness, and Leeb Hardness

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E384 Test Method for Microindentation Hardness of Materials

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions:

3.1.1 calibration—determination of the specific values of the significant operating parameters of the UCI instrument by

comparison with values indicated by a standardized workbench hardness tester or by a set of certified reference test pieces.

3.1.2 surface finish—all references to surface finish in this test method are defined as surface roughness (that is, Ra = average

roughness value).

3.1.3 UCI hardness test—a hardness testing method using a calibrated instrument by pressing a resonating rod with a defined

indenter, for example, a Vickers diamond, with a fixed force against the surface of the part to be tested.

3.1.4 UCI method—Ultrasonic Contact Impedance, a hardness testing method developed by Dr. Claus Kleesattel in 1961 based

on the measurement of the frequency shift of a resonating rod caused by the essentially elastic nature of the finite area of contact

between the indenter and the test piece during the penetration.

3.1.5 verification—checking or testing the UCI instrument to ensure conformance with this test method.

1

This test method is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.06

on Steel Forgings and Billets.

Current edition approved Nov. 1, 2013. Published March 2014. Originally approved in 2005. Last previous edition approved in 2010 as A1038 – 10a. DOI:

10.1520/A1038-13.10.1520/A1038-13E01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

A1038 − 13

4. Significance and Use

4.1 The hardness of a material is a defined quantity having many scales and being dependent on the way the test is performed.

In order to avoid the creation of a new method involving a new hardness scale, the UCI method converts into common hardness

values, for example, HV, HRC, etc.

4.2 The UCI hardness test is a superficial determination, only measuring the hardness condition of the surface contacted. The

results generated at a specific location do not represent the part at any other surface location and yield no information about the

material at subsurface locations.

4.3 The UCI hardness test may be used on large or small components at various locations. It can be used to make hardness

measurements on positions difficult to access, such as tooth flanks or roots of gears.

A. GE

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.