ASTM E2546-15(2023)

(Practice)Standard Practice for Instrumented Indentation Testing

Standard Practice for Instrumented Indentation Testing

SIGNIFICANCE AND USE

5.1 IIT Instruments are used to quantitatively measure various mechanical properties of thin coatings and other volumes of material when other traditional methods of determining material properties cannot be used due to the size or condition of the sample. This practice will establish the basic requirements for those instruments. It is intended that IIT based test methods will be able to refer to this practice for the basic requirements for force and displacement accuracy, reproducibility, verification, reporting, etc., that are necessary for obtaining meaningful test results.

5.2 IIT is not restricted to specific test forces, displacement ranges, or indenter types. This practice covers the requirements for a wide range of nano, micro, and macro (see ISO 14577-1) indentation testing applications. The various IIT instruments are required to adhere to the requirements of the practice within their specific design ranges.

SCOPE

1.1 This practice defines the basic steps of Instrumented Indentation Testing (IIT) and establishes the requirements, accuracies, and capabilities needed by an instrument to successfully perform the test and produce the data that can be used for the determination of indentation hardness and other material characteristics. IIT is a mechanical test that measures the response of a material to the imposed stress and strain of a shaped indenter by forcing the indenter into a material and monitoring the force on, and displacement of, the indenter as a function of time during the full loading-unloading test cycle.

1.2 The operational features of an IIT instrument, as well as requirements for Instrument Verification (Annex A1), Standardized Reference Blocks (Annex A2) and Indenter Requirements (Annex A3) are defined. This practice is not intended to be a complete purchase specification for an IIT instrument.

1.3 With the exception of the non-mandatory Appendix X4, this practice does not define the analysis necessary to determine material properties. That analysis is left for other test methods. Appendix X4 includes some basic analysis techniques to allow for the indirect performance verification of an IIT instrument by using test blocks.

1.4 Zero point determination, instrument compliance determination and the indirect determination of an indenter’s area function are important parts of the IIT process. The practice defines the requirements for these items and includes non-mandatory appendixes to help the user define them.

1.5 The use of deliberate lateral displacements is not included in this practice (that is, scratch testing).

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2546 − 15 (Reapproved 2023)

Standard Practice for

Instrumented Indentation Testing

This standard is issued under the fixed designation E2546; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

1.1 This practice defines the basic steps of Instrumented

1.8 This international standard was developed in accor-

Indentation Testing (IIT) and establishes the requirements,

dance with internationally recognized principles on standard-

accuracies, and capabilities needed by an instrument to suc-

ization established in the Decision on Principles for the

cessfully perform the test and produce the data that can be used

Development of International Standards, Guides and Recom-

for the determination of indentation hardness and other mate-

mendations issued by the World Trade Organization Technical

rial characteristics. IIT is a mechanical test that measures the

Barriers to Trade (TBT) Committee.

response of a material to the imposed stress and strain of a

shaped indenter by forcing the indenter into a material and

2. Referenced Documents

monitoring the force on, and displacement of, the indenter as a

2.1 ASTM Standards:

function of time during the full loading-unloading test cycle.

E3 Guide for Preparation of Metallographic Specimens

1.2 The operational features of an IIT instrument, as well as

E74 Practices for Calibration and Verification for Force-

requirements for Instrument Verification (Annex A1), Stan-

Measuring Instruments

dardized Reference Blocks (Annex A2) and Indenter Require-

E92 Test Methods for Vickers Hardness and Knoop Hard-

ments (Annex A3) are defined. This practice is not intended to

ness of Metallic Materials

be a complete purchase specification for an IIT instrument.

E177 Practice for Use of the Terms Precision and Bias in

1.3 With the exception of the non-mandatory Appendix X4,

ASTM Test Methods

this practice does not define the analysis necessary to deter-

E384 Test Method for Microindentation Hardness of Mate-

mine material properties. That analysis is left for other test

rials

methods. Appendix X4 includes some basic analysis tech-

E691 Practice for Conducting an Interlaboratory Study to

niques to allow for the indirect performance verification of an

Determine the Precision of a Test Method

IIT instrument by using test blocks.

E1875 Test Method for Dynamic Young’s Modulus, Shear

1.4 Zero point determination, instrument compliance deter- Modulus, and Poisson’s Ratio by Sonic Resonance

E1876 Test Method for Dynamic Young’s Modulus, Shear

mination and the indirect determination of an indenter’s area

function are important parts of the IIT process. The practice Modulus, and Poisson’s Ratio by Impulse Excitation of

Vibration

defines the requirements for these items and includes non-

mandatory appendixes to help the user define them.

2.2 American Bearing Manufacturers Association Stan-

dard:

1.5 The use of deliberate lateral displacements is not in-

ABMA/ISO 3290-1 Rolling Bearings- Balls-Part 1: Steel

cluded in this practice (that is, scratch testing).

Metal Balls

1.6 The values stated in SI units are to be regarded as

2.3 ISO Standards:

standard. No other units of measurement are included in this

ISO 14577-1, -2, -3, -4 Metallic Materials—Instrumented

standard.

Indentation Tests for Hardness and Material Properties

1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

This practice is under the jurisdiction of ASTM Committee E28 on Mechanical the ASTM website.

Testing and is the direct responsibility of Subcommittee E28.06 on Indentation Available from American Bearing Manufacturers Association (ABMA), 2025

Hardness Testing. M Street, NW Suite 800 Washington, DC 20036, http://www.americanbearings.org.

Current edition approved Sept. 1, 2023. Published September 2023. Originally

approved in 2007. Last previous edition approved in 2015 as E2546–15. DOI: Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/E2546-15R23. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2546 − 15 (2023)

ISO 376 Metallic Materials—Calibration of Force-Proving 3.1.8 refined area function, n—area function determined

Instruments for the Verification of Uniaxial Testing Ma- indirectly by a technique such as the one described in Appen-

chines dix X3.

3.1.9 test cycle, n—a series of operations at a single location

3. Terminology

on the test sample specified in terms of either applied test force

or displacement as a function of time.

3.1 Definitions of Terms Specific to This Standard:

3.1.9.1 Discussion—The test cycle may include any of the

3.1.1 contact stiffness, n—the instantaneous elastic response

following operations: approach of the indenter towards the test

of the material over the area of contact with the indenter.

sample, singular or multiple loading, dwell, and unloading

3.1.1.1 Discussion—Contact stiffness can be determined

cycles.

from the slope of line 3 in Fig. 1.

3.1.10 test data, n—for this practice it will consist, at the

3.1.2 force displacement curve, n—a common plot of the

minimum, of a set of related force/displacement/time data

force applied to an indenter and the resultant depth of penetra-

points.

tion.

3.1.2.1 Discussion—This plot is generated from data col-

3.1.11 zero point, n—the force-displacement-time reference

lected during the entire loading and unloading cycle. (See Fig.

point when the indenter first contacts the sample and the force

1.)

is zero.

3.1.11.1 Discussion—A course zero point is an approximate

3.1.3 indentation radius [a], n—the in-plane radius, at the

value used as part of an analysis to determine a refined value.

surface of the test piece, of the circular impression of an indent

created by a spherical indenter.

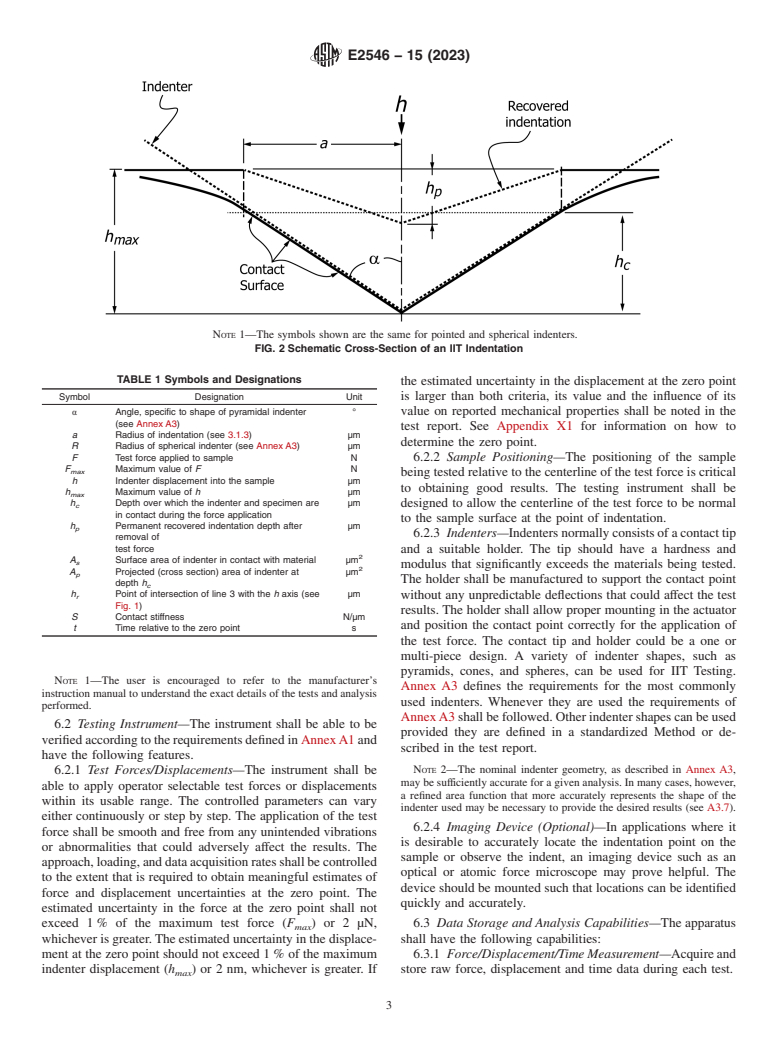

3.2 Indentation Symbols and Designations (see Fig. 2 and

3.1.3.1 Discussion—For non-circular impressions, the in-

Table 1):

dentation radius is the radius of the smallest circle capable of

enclosing the indentation. The indentation radius is normally 4. Summary of Practice

used as a guide for spacing of indentations.

4.1 This practice defines the details of the IIT test and the

3.1.4 indenter area function [Λ], n—mathematical function

requirements and capabilities for instruments that perform IIT

that relates the projected (cross-section) area of the indenter tip

tests. The necessary components are defined along with the

to the distance from the apex of the tip as measured along the

required accuracies required to obtain useful results. Verifica-

central axis.

tion methods are defined to insure that the instruments are

performing properly. It is intended that ASTM (or other) Test

3.1.5 instrument compliance, n—the flex or reaction of the

Methods will refer to this practice when defining different

load frame, actuator, stage, indenter, anvil, etc., that is the

calculations or algorithms that determine one or more material

result of the application of a test force to the sample.

characteristics that are of interest to the user.

3.1.6 instrumented indentation test (IIT), n—an indentation

test where the force applied to an indenter and the resultant

5. Significance and Use

displacement of the indenter into the sample are recorded

5.1 IIT Instruments are used to quantitatively measure

during the loading and unloading process for post test analysis.

various mechanical properties of thin coatings and other

3.1.7 nominal area function, n—area function determined

volumes of material when other traditional methods of deter-

from measurement of the gross indenter geometry.

mining material properties cannot be used due to the size or

condition of the sample. This practice will establish the basic

requirements for those instruments. It is intended that IIT based

test methods will be able to refer to this practice for the basic

requirements for force and displacement accuracy,

reproducibility, verification, reporting, etc., that are necessary

for obtaining meaningful test results.

5.2 IIT is not restricted to specific test forces, displacement

ranges, or indenter types. This practice covers the requirements

for a wide range of nano, micro, and macro (see ISO 14577-1)

indentation testing applications. The various IIT instruments

are required to adhere to the requirements of the practice within

their specific design ranges.

6. Apparatus

6.1 General—The force, displacement and time are simul-

taneously recorded during the full sequence of the test. An

analysis of the recorded data must be done to yield relevant

1. Increasing test force

information about the sample. When available, relevant ASTM

2. Removal of the test force

test methods for the analysis should be followed for compara-

3. Tangent to curve 2 at F

max

FIG. 1 IIT Procedure Shown Schematically tive results.

E2546 − 15 (2023)

NOTE 1—The symbols shown are the same for pointed and spherical indenters.

FIG. 2 Schematic Cross-Section of an IIT Indentation

TABLE 1 Symbols and Designations

the estimated uncertainty in the displacement at the zero point

Symbol Designation Unit is larger than both criteria, its value and the influence of its

α Angle, specific to shape of pyramidal indenter ° value on reported mechanical properties shall be noted in the

(see Annex A3)

test report. See Appendix X1 for information on how to

a Radius of indentation (see 3.1.3) μm

determine the zero point.

R Radius of spherical indenter (see Annex A3) μm

F Test force applied to sample N 6.2.2 Sample Positioning—The positioning of the sample

F Maximum value of F N

max

being tested relative to the centerline of the test force is critical

h Indenter displacement into the sample μm

to obtaining good results. The testing instrument shall be

h Maximum value of h μm

max

h Depth over which the indenter and specimen are μm designed to allow the centerline of the test force to be normal

c

in contact during the force application

to the sample surface at the point of indentation.

h Permanent recovered indentation depth after μm

p

6.2.3 Indenters—Indenters normally consists of a contact tip

removal of

test force

and a suitable holder. The tip should have a hardness and

A Surface area of indenter in contact with material μm

s

modulus that significantly exceeds the materials being tested.

A Projected (cross section) area of indenter at μm

p

The holder shall be manufactured to support the contact point

depth h

c

h Point of intersection of line 3 with the h axis (see μm

r without any unpredictable deflections that could affect the test

Fig. 1)

results. The holder shall allow proper mounting in the actuator

S Contact stiffness N/μm

and position the contact point correctly for the application of

t Time relative to the zero point s

the test force. The contact tip and holder could be a one or

multi-piece design. A variety of indenter shapes, such as

pyramids, cones, and spheres, can be used for IIT Testing.

NOTE 1—The user is encouraged to refer to the manufacturer’s

Annex A3 defines the requirements for the most commonly

instruction manual to understand the exact details of the tests and analysis

used indenters. Whenever they are used the requirements of

performed.

Annex A3 shall be followed. Other indenter shapes can be used

6.2 Testing Instrument—The instrument shall be able to be

provided they are defined in a standardized Method or de-

verified according to the requirements defined in Annex A1 and

scribed in the test report.

have the following features.

NOTE 2—The nominal indenter geometry, as described in Annex A3,

6.2.1 Test Forces/Displacements—The instrument shall be

may be sufficiently accurate for a given analysis. In many cases, however,

able to apply operator selectable test forces or displacements

a refined area function that more accurately represents the shape of the

within its usable range. The controlled parameters can vary

indenter used may be necessary to provide the desired results (see A3.7).

either continuously or step by step. The application of the test

6.2.4 Imaging Device (Optional)—In applications where it

force shall be smooth and free from any unintended vibrations

is desirable to accurately locate the indentation point on the

or abnormalities that could adversely affect the results. The

sample or observe the indent, an imaging device such as an

approach, loading, and data acquisition rates shall be controlled

optical or atomic force microscope may prove helpful. The

to the extent that is required to obtain meaningful estimates of

device should be mounted such that locations can be identified

force and displacement uncertainties at the zero point. The

quickly and accurately.

estimated uncertainty in the force at the zero point shall not

exceed 1 % of the maximum test force (F ) or 2 μN, 6.3 Data Storage and Analysis Capabilities—The apparatus

max

whichever is greater. The estimated uncertainty in the displace- shall have the following capabilities:

ment at the zero point should not exceed 1 % of the maximum 6.3.1 Force/Displacement/Time Measurement—Acquire and

indenter displacement (h ) or 2 nm, whichever is greater. If store raw force, displacement and time data during each test.

max

E2546 − 15 (2023)

6.3.2 Data Correction—When necessary, conversion of the als it is sufficient to locate the test at least six indent radii away

raw data defined in 6.3.1 to corrected force (F), displacement from such features; however, there are exceptions to this rule.

(h), and time (t) data as defined in 3.2. The conversion shall The measurements of elastic properties, for example, are

consider at least the following parameters: Zero point determi- significantly more sensitive and require greater spacing than

nation (see Appendix X1), instrument complian

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.