ASTM D3308-97

(Specification)Standard Specification for PTFE Resin Skived Tape

Standard Specification for PTFE Resin Skived Tape

SCOPE

1.1 This specification covers skived tape in thicknesses from 0.013 to 6.35 mm (0.0005 to 0.250 in.) manufactured by skiving (Note 1) from PTFE resin molding and extrusion materials.

Note 1—Skiving is the process of continuously shaving a film on a lathe from the outer surface to the core of a molded cylindrical tube of material.

Note 2—Abbreviations have been approved from Terminology D 1600.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following hazard caveat pertains only to the test method portion, Section 8, of this specification:This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 3—This specification and ISO 13000-1 and ISO/FDIS 13000-2 differ in approach or detail, and data obtained using either may not be technically equivalent.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3308 – 97 An American National Standard

Standard Specification for

PTFE Resin Skived Tape

This standard is issued under the fixed designation D 3308; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 882 Test Methods for Tensile Properties of Thin Plastic

Sheeting

1.1 This specification covers skived tape in thicknesses

D 1389 Methods for Dielectric Proof-Voltage Testing of

from 0.013 to 6.35 mm (0.0005 to 0.250 in.) manufactured by

Thin Solid Electrical Insulating Materials

skiving (Note 1) from PTFE resin molding and extrusion

D 1505 Test Method for Density of Plastics by the Density-

materials.

Gradient Technique

NOTE 1—Skiving is the process of continuously shaving a film on a

D 1600 Terminology for Abbreviated Terms Relating to

lathe from the outer surface to the core of a molded cylindrical tube of

4 3

Plastics Microtensile Specimens

material.

D 1898 Practice for Sampling of Plastics

NOTE 2—Abbreviations have been approved from Terminology

D 3892 Practice for Packaging/Packing of Plastics

D 1600.

D 4894 Specification for Polytetrafluoroethylene (PTFE)

1.2 The values stated in inch-pound units are to be regarded

Granular Molding and Ram Extrusion Materials

as the standard. The values given in parentheses are for

E 691 Practice for Conducting an Interlaboratory Study to

information only.

Determine the Precision of a Test Method

1.3 The following hazard caveat pertains only to the test

2.2 ISO Standards:

method portion, Section 7, of this specification: This standard

ISO/FDIS 13000-1 Plastics—Polytetrafluorethylene

does not purport to address all of the safety concerns, if any,

(PTFE) Semi-Finished Products Part 1: Requirements and

associated with its use. It is the responsibility of the user of this

Designation

standard to establish appropriate safety and health practices

ISO/FDIS 13000-2 Plastics—Polytetrafluorethylene

and determine the applicability of regulatory limitations prior

(PTFE) Semi-Finished Products Part 2: Preparation of

to use.

Specimens and Determination of Properties

NOTE 3—This specification and ISO/FDIS 13000-1 and ISO/FDIS

3. Classification

13000-2 differ in approach or detail, and data obtained using either may

not be technically equivalent.

3.1 This specification covers four types of PTFE resin

skived tape:

2. Referenced Documents

3.1.1 Type I—Premium; normally used for exacting electri-

2.1 ASTM Standards:

cal, mechanical, or chemical applications.

D 149 Test Methods for Dielectric Breakdown Voltage and

3.1.2 Type II—General purpose; for electrical, mechanical,

Dielectric Strength of Solid Electrical Insulating Materials

and chemical applications not requiring premium material.

at Commercial Power Frequencies

3.1.3 Type III—Commercial; for non-critical chemical,

D 374 Test Methods for Thickness of Solid Electrical Insu-

electrical, and mechanical applications.

lation

3.1.4 Type IV—Utility; having no electrical requirements,

D 618 Practice for Conditioning Plastics and Electrical

and with mechanical properties at lower level.

Insulating Materials for Testing

3.2 Types I, II, III, and IV may be subdivided into two

D 638 Test Method for Tensile Properties of Plastics

grades according to the base resin used as follows:

D 792 Test Method for Specific Gravity (Relative Density)

3.2.1 Grade 1—Made only from virgin resin.

and Density of Plastics by Displacement

3.2.2 Grade 2—May be made using reprocessed resin, or a

mixture of virgin and reprocessed resin.

This specification is under the jurisdiction of ASTM Committee D-20 on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

Materials (Section D20.15.12). Annual Book of ASTM Standards, Vols 08.01 and 08.04.

Current edition approved Nov. 10, 1997. Published April 1998. Originally Annual Book of ASTM Standards, Vol 08.02.

published as D 3308 – 74. Last previous edition D 3308 – 91a. Annual Book of ASTM Standards, Vol 14.02.

2 7

Annual Book of ASTM Standards, Vol 10.02. Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book o ASTM Standards, Vol 08.01. Floor, New York, NY 10036.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 3308

TABLE 1 Width Tolerances for Skived Tape

3.3 A one-line system may be used to specify materials

covered by this specification. The system uses predefined cells Width Tolerance

to refer to specific aspects of this specification, asillustrated

mm in. mm in.

below:

12.7 0.5 −0, +0.51 −0, +0.020

25.4 1 −0, +0.64 −0, +0.025

Specification

50.8 2 −0, +0.89 −0, +0.035

Standard Number : Type : Grade : Class : Special

76.2 3 −0, +0.89 −0, +0.075

Block : : : : Notes

152.4 6 −0, +1.91 −0, +0.125

304.8 12 −0, +3.18 −0, +0.250

:::::

609.6 24 −0, +6.35 −0, +0.250

–––––––––––– ––– ––– ––– –––––,

Example: Specification D 3308 – 97 I 2 . “Oil”

For this example, the line callout would be: Specification

6. Number of Tests and Retests

D 3308 – 97,I2, Oil and would specify a skived tape that has all

6.1 One set of test specimens as prescribed in Section 7

of the properties listed for that Type and Grade, in the

shall be considered sufficient for testing each batch. The

appropriate specified properties, tables, or both, in the specifi-

average result of the specimens shall conform to the require-

cation identified. A comma is used as the separator between the

ments of this specification.

Standard number and the Type. Separators are not needed

between the Type and Grade, because they are, in turn, Roman

numerals and Arabic digits. Provision for “Special Notes” is

TABLE 2 Thickness Tolerances for Skived Tape

included so that other information can be provided when

Thickness Tolerance

required. This example would be premium PTFE tape noting

mm in. mm in.

that the dielectric strength is to be done in oil. When Special

0.013 to 0.025 0.0005 to 0.001 60.0025 60.0001

Notes are used, they should be preceded by a comma.

0.028 to 0.048 0.0011 to 0.0019 60.008 60.0003

0.051 to 0.076 0.002 to 0.003 60.008 60.0003

4. Physical Requirements

0.089 to 0.25 0.0035 to 0.010 60.013 60.0005

0.28 to 0.38 0.011 to 0.015 60.026 60.0010

4.1 The tape shall be made from unpigmented PTFE resin.

0.41 to 1.02 0.016 to 0.040 60.038 60.0015

4.2 The length and width of the roll shall be as agreed upon

1.04 to 1.55 0.041 to 0.061 60.127 60.0050

1.58 to 3.18 0.062 to 0.125 60.13 60.0050

between the purchaser and the seller. Width tolerances shall be

>3.18 >0.125 60.254 60.010

in accordance with Table 1.

4.3 The melting point for all types of tape shall be 327 6

10°C (621 6 18°F).

7. Test Methods

4.4 The thickness tolerances for skived tape shall be as

shown in Table 2.

7.1 The properties enumerated in this specification shall be

4.5 Tensile strength and elongation shall meet the require-

determined in accordance with the following test methods:

ments shown in Table 3.

7.1.1 Conditioning—For those tests where conditioning is

4.6 The requirements for specific gravity shall be as shown

required, condition the test specimens in accordance with

in Table 3.

Procedure A of Practice D 618 for a period of at least 4 h prior

4.7 The minimum required values for dielectric strength S

to test. If the test material has been exposed to temperatures

(V/mil), shall be computed for applicable thicknesses of below 20°C within 24 h prior to test, the conditioning shall be

materials in accordance with the following formulas, where t is

for at least 24 h.

the thickness of the tape in mils.

Type I: S 5 1000 20/t

=

TABLE 3 Mechanical Requirements for Skived Tape

Type II: S 5 840 20/t

=

A

Tensile Strength, min

Elongation, Specific

Type III: S 5 500 20/t

= Type

min,% Gravity

MPa psi

Type IV: No requirement for dielectric strength

I 27.58 4000 300 2.14 to 2.19

4.8 The number of permissible electrical flaws shall be as

II 19.31 2800 200 2.14 to 2.19

agreed between the purchaser and the seller.

III 11.00 1600 75 2.14 min

IV 9.66 1400 50 2.14 min

5. Sampling

A

Tape 6.35 mm ( ⁄4 in.) or wider.

5.1 Unless agreed upon between the purchaser and the

seller, the materials shall be sampled in accordance with the

7.1.2 Test Conditions—Conduct tests at the standard labo-

sampling procedure prescribed in Practice D 1898. Adequate

ratory temperature of 23 6 2°C (70 to 77°F). The maintenance

statistical sampling shall be considered an acceptable alterna-

of constant humidity is not necessary. In reference cases, the

tive. A lot shall consist of all tape that is part of one

standard atmosphere, 50 6 5 % relative humidity, shall apply.

manufacturer’s production made from the same nominal raw

7.1.3 Thickness—Measure thickness in accordance with

material under the same conditions, and designed to meet the

Method A of Test Methods D 374.

same specifications. A lot shall not exceed 24 h.

7.1.4 Melting Point—Determine the melting point on one

specimen in accordance with the test method stated in Speci-

See the ASTM Form and Style Manual. Available from ASTM Headquarters. fication D 4894.

D 3308

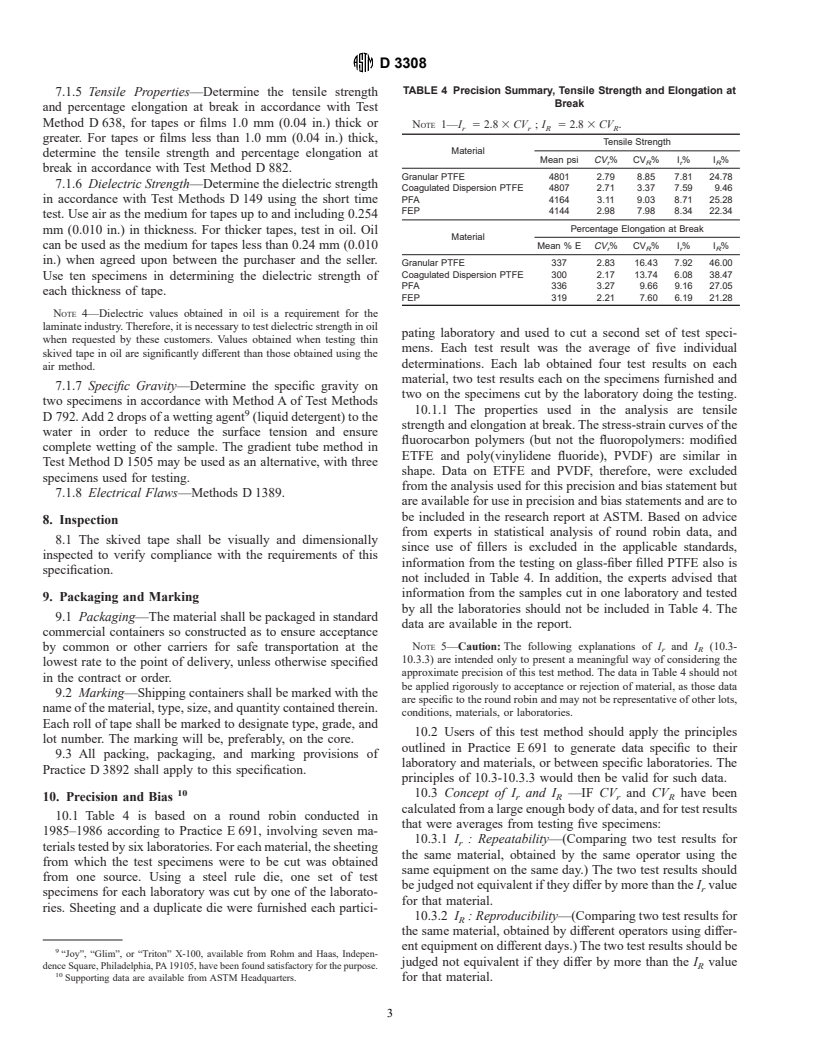

TABLE 4 Precision Summary, Tensile Strength and Elongation at

7.1.5 Tensile Properties—

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.