ASTM E2358-04

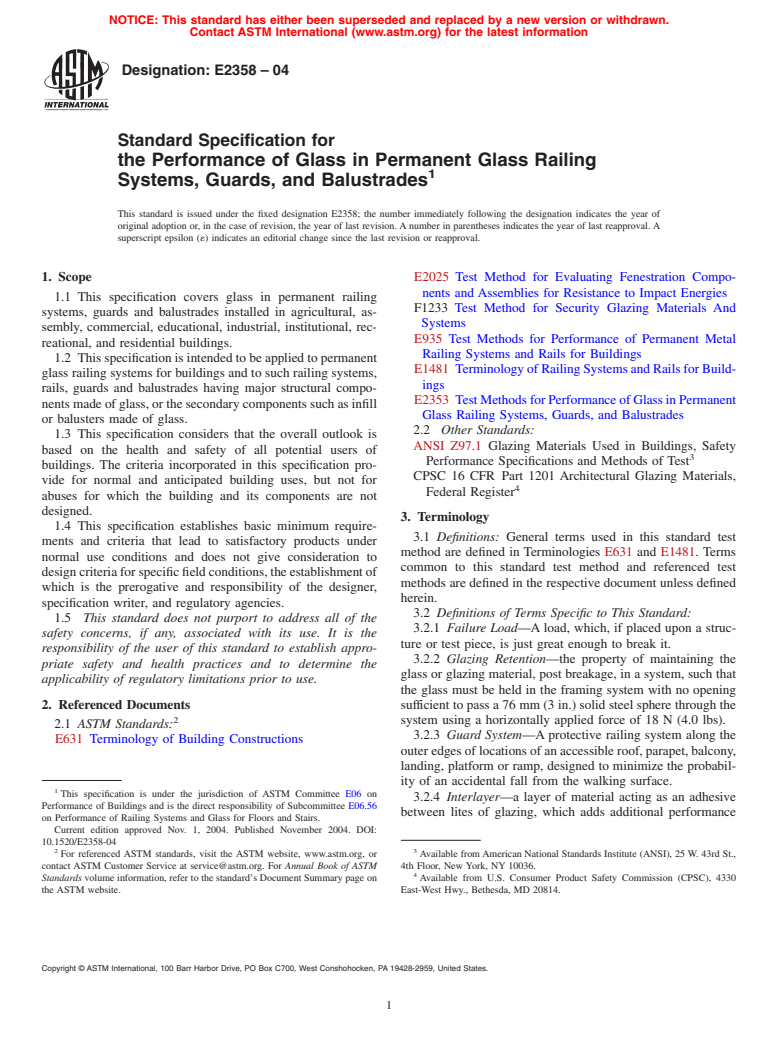

(Specification)Standard Specification for the Performance of Glass in Permanent Glass Railing Systems, Guards, and Balustrades

Standard Specification for the Performance of Glass in Permanent Glass Railing Systems, Guards, and Balustrades

ABSTRACT

This specification covers the classification, design and performance requirements, and test methods for glass in permanent railing systems, guards, and balustrades installed in agricultural, assembly, commercial, educational, industrial, institutional, recreational, and residential buildings. This specification considers that the overall outlook is based on the health and safety of all potential users of buildings, and establishes the basic minimum requirements and criteria that lead to satisfactory products under normal and anticipated building uses, and not for abuses for which the building and its components are not designed. Also, this specification does not give consideration to design criteria for specific field conditions, the establishment of which is the prerogative and responsibility of the designer, specification writer, and regulatory agencies.

SCOPE

1.1 This specification covers glass in permanent railing systems, guards and balustrades installed in agricultural, assembly, commercial, educational, industrial, institutional, recreational, and residential buildings.

1.2 This specification is intended to be applied to permanent glass railing systems for buildings and to such railing systems, rails, guards and balustrades having major structural components made of glass, or the secondary components such as infill or balusters made of glass.

1.3 This specification considers that the overall outlook is based on the health and safety of all potential users of buildings. The criteria incorporated in this specification provide for normal and anticipated building uses, but not for abuses for which the building and its components are not designed.

1.4 This specification establishes basic minimum requirements and criteria that lead to satisfactory products under normal use conditions and does not give consideration to design criteria for specific field conditions, the establishment of which is the prerogative and responsibility of the designer, specification writer, and regulatory agencies.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2358 – 04

Standard Specification for

the Performance of Glass in Permanent Glass Railing

Systems, Guards, and Balustrades

This standard is issued under the fixed designation E2358; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E2025 Test Method for Evaluating Fenestration Compo-

nents and Assemblies for Resistance to Impact Energies

1.1 This specification covers glass in permanent railing

F1233 Test Method for Security Glazing Materials And

systems, guards and balustrades installed in agricultural, as-

Systems

sembly, commercial, educational, industrial, institutional, rec-

E935 Test Methods for Performance of Permanent Metal

reational, and residential buildings.

Railing Systems and Rails for Buildings

1.2 Thisspecificationisintendedtobeappliedtopermanent

E1481 TerminologyofRailingSystemsandRailsforBuild-

glass railing systems for buildings and to such railing systems,

ings

rails, guards and balustrades having major structural compo-

E2353 TestMethodsforPerformanceofGlassinPermanent

nentsmadeofglass,orthesecondarycomponentssuchasinfill

Glass Railing Systems, Guards, and Balustrades

or balusters made of glass.

2.2 Other Standards:

1.3 This specification considers that the overall outlook is

ANSI Z97.1 Glazing Materials Used in Buildings, Safety

based on the health and safety of all potential users of

Performance Specifications and Methods of Test

buildings. The criteria incorporated in this specification pro-

CPSC 16 CFR Part 1201 Architectural Glazing Materials,

vide for normal and anticipated building uses, but not for

Federal Register

abuses for which the building and its components are not

designed.

3. Terminology

1.4 This specification establishes basic minimum require-

3.1 Definitions: General terms used in this standard test

ments and criteria that lead to satisfactory products under

method are defined in Terminologies E631 and E1481. Terms

normal use conditions and does not give consideration to

common to this standard test method and referenced test

designcriteriaforspecificfieldconditions,theestablishmentof

methods are defined in the respective document unless defined

which is the prerogative and responsibility of the designer,

herein.

specification writer, and regulatory agencies.

3.2 Definitions of Terms Specific to This Standard:

1.5 This standard does not purport to address all of the

3.2.1 Failure Load—A load, which, if placed upon a struc-

safety concerns, if any, associated with its use. It is the

ture or test piece, is just great enough to break it.

responsibility of the user of this standard to establish appro-

3.2.2 Glazing Retention—the property of maintaining the

priate safety and health practices and to determine the

glass or glazing material, post breakage, in a system, such that

applicability of regulatory limitations prior to use.

the glass must be held in the framing system with no opening

2. Referenced Documents sufficient to pass a 76 mm (3 in.) solid steel sphere through the

2 system using a horizontally applied force of 18 N (4.0 lbs).

2.1 ASTM Standards:

3.2.3 Guard System—A protective railing system along the

E631 Terminology of Building Constructions

outeredgesoflocationsofanaccessibleroof,parapet,balcony,

landing, platform or ramp, designed to minimize the probabil-

ity of an accidental fall from the walking surface.

This specification is under the jurisdiction of ASTM Committee E06 on

3.2.4 Interlayer—a layer of material acting as an adhesive

Performance of Buildings and is the direct responsibility of Subcommittee E06.56

between lites of glazing, which adds additional performance

on Performance of Railing Systems and Glass for Floors and Stairs.

Current edition approved Nov. 1, 2004. Published November 2004. DOI:

10.1520/E2358-04

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036.

Standards volume information, refer to the standard’s Document Summary page on Available from U.S. Consumer Product Safety Commission (CPSC), 4330

the ASTM website. East-West Hwy., Bethesda, MD 20814.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2358 – 04

attributes to the finished product, for example: impact resis- 4.1.1.4 For balconies in public-assembly buildings, the

tance, solar control, and acoustical insulation. required railing height in front of the first row of fixed seats

3.2.5 Lite—a term for a single pane (or piece) of glass or shall be reduced to 660 mm (26 in.) provided adequate safety

other glazing material. is established by the design and approved by the authority

3.2.6 Stile—one of the upright structural members of a havingjurisdiction;however,itshallbeaminimumof910mm

frame or a framework of bars (36 in.) at aisle ends and a minimum of 1070 mm (42 in.)

where aisle steps are perpendicular to the railing system.

4. Design Requirements

4.1.2 Handrails and Stair-rail Systems

4.1 Railing Height 4.1.2.1 In corridors, ramp, walkways, and enclosed stair-

4.1.1 Guardrail Systems: ways having a slope of at least 1 in 20, the height of the

4.1.1.1 The fabricated height of a guardrail system, mea- handrail of the stair-rail system, measured from its top surface

sured from its top surface to the finished floor level, shall be at to the finished floor level or tread-nose line, shall be not less

least 1070 mm (42 in.). When variation in the evenness of the than 860 mm (34 in.) nor more than 970 mm (38 in.). When a

finished floor will result in any individual height measurement stair-rail system is higher than 970 mm (38 in.), a separate

of the installed guardrail system to be less than 1040 mm (41 handrail shall be installed at a height of not less than 860 mm

(34 in.) nor more than 970 mm (38 in.).

in.),thefabricatedheightoftheentireguardrailsystemshallbe

increased accordingly. 4.1.2.2 Where required and in childcare and educational

facilities serving children under the age of 12 years, a second

4.1.1.2 Within an individual dwelling unit, the required

railing height shall be permitted to be reduced as allowed by separate handrail shall be permitted to be installed at a

mounting height of 610 mm to 710 mm (24 in. to 28 in.). The

the governing jurisdiction.

4.1.1.2.1 Where the vertical distance between adjacent fin- vertical clearance between the handrails shall be at least 230

mm (9 in.).

ished floor levels is less than 1830 mm (72 in.), the height of

the guardrail system shall be at least 810 mm (32 in) (Fig. 1). 4.1.3 Transfer Rails Systems—where transfer rail systems

are to be installed, such as in toilets and bathrooms, the

When variation in the evenness of the finished floor results in

any individual height measurement of the installed guardrail required height, measured from its top surface to the finished

floor level, shall not be less than 760 mm (30 in) nor more than

system less than 790 mm (31 in), the fabricated height of the

entire guardrail system shall be increased accordingly. 860 mm (34 in.).

4.1.1.2.2 Where the vertical distance between adjacent fin- 4.2 Railing System Penetration

ishedfloorlevelsisaminimumof1830mm(72in.),theheight 4.2.1 Various members of the railing system, such as balus-

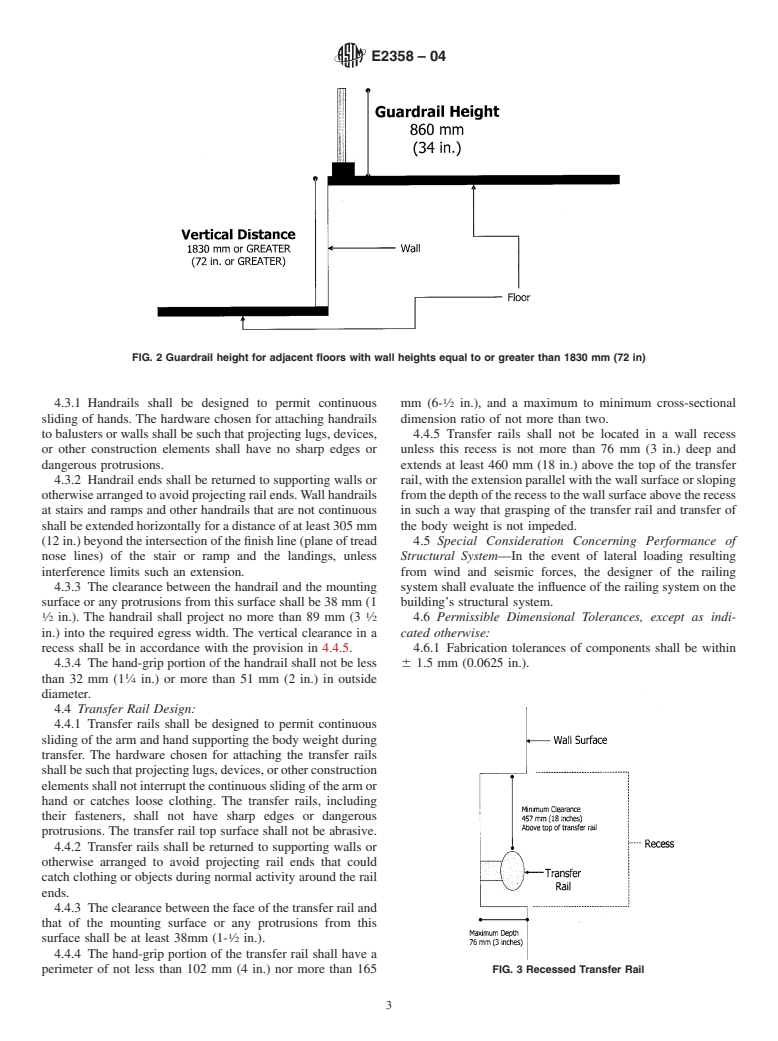

shall be a minimum of 860 mm (34 in.) (Fig. 2). When ters, screens, wire mesh, or scrolls, shall be arranged in such a

variations in the evenness of the finished floor results in way that a sphere, 76 mm (3 in) in diameter cannot be passed

individual height measurements of the installed guardrail through any opening in the system.

system less than 840 mm (33 in.), the fabricated height of the 4.2.2 Toe boards shall be provided in areas where tools and

guardrail system shall be increased accordingly. other objects could be dislodged and fall on occupants below.

4.1.1.3 Inpublicassembly,elementaryschool,andmultiple- The top of the toe board shall not be less than 102 mm (4 in)

family buildings where the vertical distance between stair and andthebottomnotmorethan12mm( ⁄2in.)abovetheaverage

adjacentfloorlevelsismorethan6100mm(20ft),therequired finished level at the line of the vertical supports of the railing

height of the top of the railing above the finished floor system.

including any variation shall be at least 1220 mm (48 in.). 4.3 Handrail Design:

FIG. 1 Guardrail height for adjacent floors with wall heights up to but not including 1830 mm (72 in).

E2358 – 04

FIG. 2 Guardrail height for adjacent floors with wall heights equal to or greater than 1830 mm (72 in)

4.3.1 Handrails shall be designed to permit continuous mm (6- ⁄2 in.), and a maximum to minimum cross-sectional

sliding of hands. The hardware chosen for attaching handrails dimension ratio of not more than two.

to balusters or walls shall be such that projecting lugs, devices, 4.4.5 Transfer rails shall not be located in a wall recess

or other construction elements shall have no sharp edges or unless this recess is not more than 76 mm (3 in.) deep and

dangerous protrusions. extends at least 460 mm (18 in.) above the top of the transfer

4.3.2 Handrail ends shall be returned to supporting walls or rail, with the extension parallel with the wall surface or sloping

otherwisearrangedtoavoidprojectingrailends.Wallhandrails fromthedepthoftherecesstothewallsurfaceabovetherecess

at stairs and ramps and other handrails that are not continuous in such a way that grasping of the transfer rail and transfer of

shallbeextendedhorizontallyforadistanceofatleast305mm the body weight is not impeded.

(12in.)beyondtheintersectionofthefinishline(planeoftread 4.5 Special Consideration Concerning Performance of

nose lines) of the stair or ramp and the landings, unless Structural System—In the event of lateral loading resulting

interference limits such an extension. from wind and seismic forces, the designer of the railing

4.3.3 The clearance between the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.