ASTM A683-05e1

(Specification)Standard Specification for Nonoriented Electrical Steel, Semiprocessed Types

Standard Specification for Nonoriented Electrical Steel, Semiprocessed Types

ABSTRACT

This specification covers the standard requirements for flat-rolled, nonoriented semiprocessed electrical steel intended primarily for commercial power frequency applications in magnetic devices. These electrical steels are low carbon, silicon-iron, or silicon-aluminum-iron alloys, and are classified according to core-loss. Unlike the fully processed electrical steels covered by ASTM A 677, the electrical steels in this specification require heat treatment by the user to develop the specified magnetic properties. The steels covered by this specification have a thickness of either 0.0185 in. (0.47 mm) or 0.025 in. (0.64 mm). For each thickness there are four core loss types. The core loss shall be determined following the use of a quality evaluation anneal listed in the specification. The core loss is determined using the Epstein test method at a test frequency of 60 Hz and a maximum flux density of 15 kG (1.5 T). Test methods to determine other required physical and mechanical properties are listed. Other typical magnetic and physical properties are listed for reference.

SCOPE

1.1 This specification covers the detailed requirements to which flat-rolled, nonoriented semiprocessed electrical steel shall conform.

1.2 This steel is produced to specified maximum core-loss values and is intended primarily for commercial power frequency (50- and 60-Hz) applications in magnetic devices. Desirable core-loss and permeability characteristics are developed through heat treatment by the user.

1.3 These nonoriented, semiprocessed electrical steels are low carbon, silicon-iron or silicon-aluminum-iron alloys containing up to about 2.5 % silicon and less than 1 % aluminum.

1.4 The values stated in customary (cgs-emu and inch-pound) units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: A683 – 05

Standard Specification for

1

Nonoriented Electrical Steel, Semiprocessed Types

This standard is issued under the fixed designation A683; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—The values statement (1.4) was corrected editorially in September 2006.

1. Scope A700 PracticesforPackaging,Marking,andLoadingMeth-

ods for Steel Products for Shipment

1.1 This specification covers the detailed requirements to

A719/A719M Test Method for Lamination Factor of Mag-

which flat-rolled, nonoriented semiprocessed electrical steel

netic Materials

shall conform.

A720/A720M Test Method for Ductility of Nonoriented

1.2 This steel is produced to specified maximum core-loss

Electrical Steel

values and is intended primarily for commercial power fre-

A971 Test Method for Measuring EdgeTaper and Crown of

quency (50- and 60-Hz) applications in magnetic devices.

Flat-Rolled Electrical Steel Coils

Desirable core-loss and permeability characteristics are devel-

A976 Classification of Insulating Coatings for Electrical

oped through heat treatment by the user.

Steels by Composition, Relative Insulating Ability and

1.3 These nonoriented, semiprocessed electrical steels are

Application

low carbon, silicon-iron or silicon-aluminum-iron alloys con-

taining up to about 2.5 % silicon and less than 1 % aluminum.

3. Terminology

1.4 The values stated in customary (cgs-emu and inch-

3.1 The terms and symbols used in this specification are

pound) units are to be regarded as standard. The values given

defined in Terminology A340.

in parentheses are mathematical conversions to SI units which

are provided for information only and are not considered

4. Classification

standard.

4.1 The nonoriented electrical steel types described by this

2. Referenced Documents specification are shown in Table 1.

2

2.1 ASTM Standards:

5. Ordering Information

A34/A34M Practice for Sampling and Procurement Testing

5.1 Orders for material under this specification shall include

of Magnetic Materials

as much of the following information as necessary to describe

A340 Terminology of Symbols and Definitions Relating to

the desired material adequately:

Magnetic Testing

5.1.1 ASTM specification number.

A343/A343M Test Method for Alternating-Current Mag-

5.1.2 Core-loss type number.

netic Properties of Materials at Power Frequencies Using

5.1.3 Surface coating type.

Wattmeter-Ammeter-VoltmeterMethodand25-cmEpstein

5.1.4 Thickness, width, and length (if in cut lengths instead

Test Frame

of coils).

A664 Practice for Identification of Standard Electrical Steel

5.1.5 Total weight of ordered item.

Grades in ASTM Specifications

5.1.6 Limitations in coil size or lift weights.

5.1.7 End Use—The user shall disclose as much pertinent

1

This specification is under the jurisdiction of ASTM Committee A06 on

information as possible about the intended application to

Magnetic Properties and is the direct responsibility of Subcommittee A06.02 on

enable the producer to provide material characteristics most

Material Specifications.

suitable for specific fabricating practices.

Current edition approved Aug. 15, 2005. Published August 2005. Originally

5.1.8 Special requirements or exceptions to the provisions

approved in 1974. Last previous edition approved in 1999 as A683/A683M – 99.

DOI: 10.1520/A0683-05E01.

of this specification.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6. Materials and Manufacture

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 6.1 Typical Melting and Casting:

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

A683 – 05

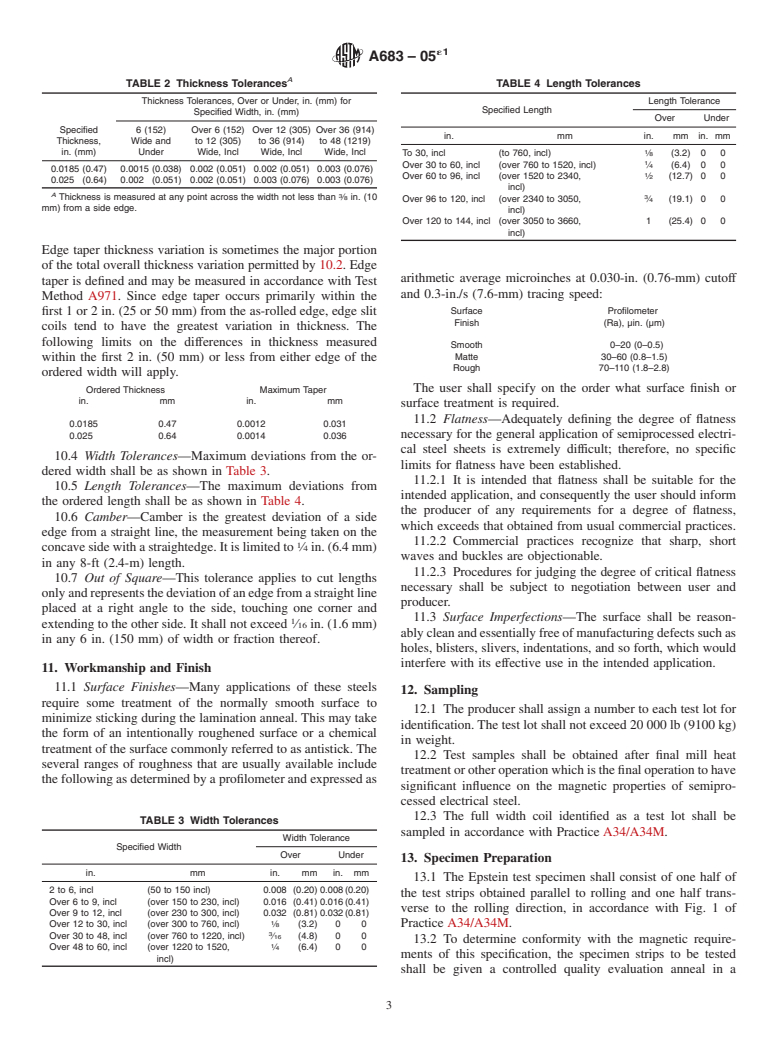

A B

TABLE 1 Core-Loss Types and Maximum Core Losses at a

7.3 Specific Exciting Power—The rms exciting power re-

C

Magnetic Flux Density of 15 kG (1.5 T) and 60 Hz of Quality

quired for the excitation of a particular type of electrical steel

D

Evaluation Annealed Epstein Specimens

is frequently useful to the user. Typical values of specific

0.0185-in. (0.47-mm) Thickness 0.025-in. (0.64-mm) Thickness

exciting power are given in Appendix X1.

Maximum Core Loss Maximum Core Loss

Core-Loss Core-Loss

Type Type

W/lb W/kg W/lb W/kg

8. Surface Insulation Characteristics

47S155 1.55 3.42 64S200 2.00 4.41

8.1 Unless otherwise specified, semiprocessed electrical

47S165 1.65 3.64 64S210 2.10 4.63

steels are supplied with a thin, tightly adherent surface oxide

47S175 1.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.