ASTM D4870-99

(Test Method)Standard Test Method for Determination of Total Sediment in Residual Fuels

Standard Test Method for Determination of Total Sediment in Residual Fuels

SCOPE

1.1 This test method covers the determination of total sediment up to 0.40% m/m in residual fuel oils having a maximum viscosity of 55 cST (mm 2/S) at 100C. Some fuels can exceed the maximum filtration time specified in this test method due to factors other than the presence of significant quantities of insoluble organic or inorganic material. This test method can be used for the assessment of total sediment after regimes of fuel pretreatment designed to accelerate the aging process.

1.2 The values stated in acceptable SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements see Note 1, Note 2, and Annex A1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 4870 – 99

Designation: 375/99

Standard Test Method for

Determination of Total Sediment in Residual Fuels

This standard is issued under the fixed designation D 4870; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This test method has been approved by the sponsoring committees and accepted by the cooperating societies in accordance with

established procedures.

1. Scope 3. Terminology

1.1 This test method covers the determination of total 3.1 Definitions of Terms Specific to This Standard:

sediment up to 0.40 % m/m for distillate fuel oils containing 3.1.1 total sediment—the sum of the insoluble organic and

residual components and to 0.50 % m/m in residual fuel oils inorganic material that is separated from the bulk of the

having a maximum viscosity of 55 cSt (mm /s) at 100°C. Some residual fuel oil by filtration through a Whatman GF/A filter

fuels can exceed the maximum filtration time specified in this medium, and that is also insoluble in a predominantly paraf-

test method due to factors other than the presence of significant finic solvent.

quantities of insoluble organic or inorganic material. This test

4. Summary of Test Method

method can be used for the assessment of total sediment after

regimes of fuel pretreatment designed to accelerate the aging 4.1 A weighed quantity (10 g) of the oil sample is filtered

through the prescribed apparatus at 100°C. After solvent

process.

1.2 The values stated in acceptable SI units are to be washing and drying the total sediment on the filter medium is

weighed. The test is to be carried out in duplicate.

regarded as the standard.

1.3 This standard does not purport to address all of the

5. Significance and Use

safety concerns, if any, associated with its use. It is the

5.1 Appreciable amounts of sediment in a residual fuel oil

responsibility of the user of this standard to establish appro-

can cause fouling of facilities for handling, and give problems

priate safety and health practices and determine the applica-

in burner mechanisms. Sediment can accumulate in storage

bility of regulatory limitations prior to use. For specific hazard

tanks, on filter screens, or on burner parts, resulting in

statements see Note 1, Note 2, and Annex A1.

obstruction of the flow of oil from the tank to the burner.

2. Referenced Documents

6. Apparatus

2.1 ASTM Standards:

6.1 Filtration Apparatus, constructed of brass, with copper

D 362 Specification for Industrial Grade Toluene

steam coils attached, suitably supported above a vacuum flask

D 2880 Specification for Gas Turbine Fuel Oils

appropriately protected against the effects of implosion. See

D 4057 Practice for Manual Sampling of Petroleum and

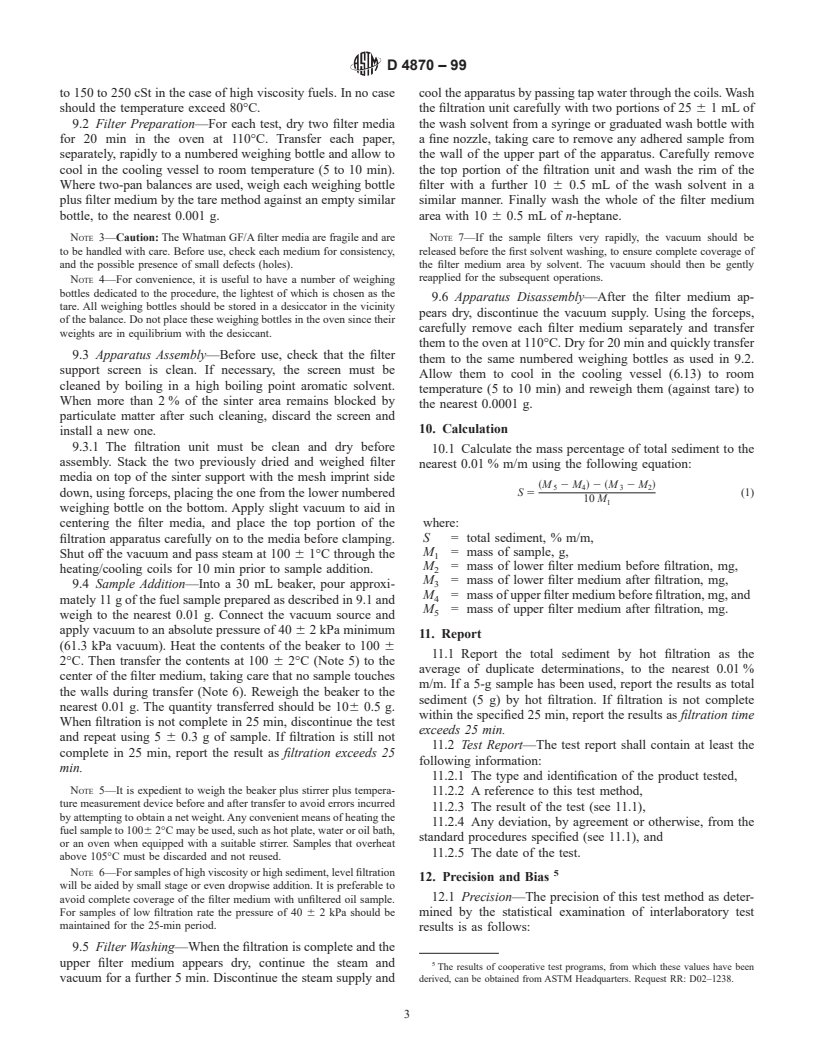

Figs. 1 and 2.

Petroleum Products

6.2 Thermometer, partial immersion type ranging from

D 4177 Practice for Automatic Sampling of Petroleum and

approximately 95 to 103°C. Maximum length 220 mm. Maxi-

Petroleum Products

mum graduation interval 0.5°C.

E 1 Specification for ASTM Thermometers

6.3 Oven, electric, capable of maintaining a temperature of

110 6 1°C. The oven should be capable of safely evaporating

the solvent without risk of fire.

This test method is under the jurisdiction of ASTM Committee D02 on

6.4 Stirring Rod, glass or PTFE approximately 150 by 3 mm

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

diameter.

D02.14 on Stability and Cleanliness of Liquid Fuels.

Current edition approved June 10, 1999. Published August 1999. Originally

6.5 Beaker, glass, 30 mL capacity, either squat form with lip

published as D 4870 – 88. Last previous edition D 4870 – 96.

or conical.

Annual Book of ASTM Standards, Vol 06.03.

3 6.6 Weighing Bottles, with ground glass stoppers, num-

Annual Book of ASTM Standards, Vol 05.02.

Annual Book of ASTM Standards, Vol 14.03. bered, 80 mm diameter by 40 mm.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4870–99

FIG. 1 Detail of Filtration Cell

6.15 Syringe or Graduated Wash Bottle, minimum capacity

25 mL, graduated in 0.5 mL increments.

6.16 Forceps, spade-ended.

7. Reagents and Materials

7.1 Normal Heptane, ASTM knock test grade, conforming

to the requirements of Specification D 2880.

NOTE 1—Warning: Flammable, vapor harmful if inhaled. See A1.1.

7.2 Toluene, conforming to Specification D 362.

NOTE 2—Warning: Flammable, vapor harmful. See A1.2.

7.3 Wash Solvent, consisting of 85 volume % n-heptane

FIG. 2 Arrangement of Filtration Apparatus

(7.1) and 15 volume % toluene (see 7.2).

6.7 Hotplate, electric.

8. Sampling

6.8 Steam Generator, to provide steam at 100 6 1°C.

8.1 Sample in accordance with Practice D 4057 or Practice

6.9 Vacuum Source, capable of providing the specified

D 4177.

vacuum.

6.10 Vacuum Gage, capable of measuring the specified

9. Procedure

vacuum.

6.11 Filter Medium, Whatman glass fiber filter medium, 9.1 Sample Preparation—Mix the whole sample, as re-

Grade GF/A, 47 mm diameter. ceived, thoroughly using a high speed mixer when practicable,

6.12 High Speed Mixer, any convenient type, minimum for 30 s. In all cases a sample taken on a glass or PTFE rod

speed 400 rpm. dipped to the bottom of the container must show a homoge-

6.13 Desiccator. neous appearance. For fuels with a high wax content (high pour

6.14 Cooling Vessel, a desiccator or other type of tightly point), or of very high viscosity, the sample must be heated

covered vessel for cooling the filter media before weighing. before stirring. The temperature must be either 15°C above the

The use of a drying agent is not recommended. pour point in the case of low viscosity fuels, or that equivalent

D4870–99

to 150 to 250 cSt in the case of high viscosity fuels. In no case cool the apparatus by passing tap water through the coils. Wash

should the temperature exceed 80°C. the filtration unit carefully with two portions of 25 6 1mLof

9.2 Filter Preparation—For each test, dry two filter media the wash solvent from a syringe or graduated wash bottle with

for 20 min in the oven at 110°C. Transfer each paper, a fine nozzle, taking care to remove any adhered sample from

separately, rapidly to a numbered weighing bottle and allow to the wall of the upper part of the apparatus. Carefully remove

cool in the cooling vessel to room temperature (5 to 10 min). the top portion of the filtration unit and wash the rim of the

Where two-pan balances are used, weigh each weighing bottle filter with a further 10 6 0.5 mL of the wash solvent in a

plus filter medium by the tare method against an empty similar similar manner. Finally wash the whole of the filter medium

bottle, to the nearest 0.001 g. area with 10 6 0.5 mL of n-heptane.

NOTE 3—Caution: The Whatman GF/A filter media are fragile and are NOTE 7—If the sample filters very rapidly, the vacuum should be

to be handled with care. Before use, check each medium for consistency, released before the first solvent washing, to ensure complete coverage of

and the possible presence of small defects (holes). the filter medium area by solvent. The vacuum should then be gently

reapplied for the subsequent operations.

NOTE 4—For convenience, it is useful to have a number of weighing

bottles dedicated to the procedure, the lightest of which is chosen as the

9.6 Apparatus Disassembly—After the filter medium ap-

tare. All weighing bottles should be stored in a desiccator in the vicinity

pears dry, discontinue the vacuum supply. Using the forceps,

of the balance. Do not place these weighing bottles in the oven since their

carefully remove each filter medium separately and transfer

weights are in equilibrium with the desiccant.

them to the oven at 110°C. Dry for 20 min and quickly transfer

9.3 Apparatus Assembly—Before use, check that the filter

them to the same numbered weighing bottles as used in 9.2.

support screen is clean. If necessary, the screen must be

Allow them to cool in the cooling vessel (6.13) to room

cleaned by boiling in a high boiling point aromatic solvent.

temperature (5 to 10 min) and reweigh them (against tare) to

When more than 2 % of the sinter area remains blocked by

the nearest 0.0001 g.

particulate matter after such cleaning, discard the screen and

10. Calculation

install a new one.

9.3.1 The filtration unit must be clean and dry before

10.1 Calculate the mass percentage of total sediment to the

assembly. Stack the two previously dried and weighed filter

nearest 0.01 % m/m using the following equation:

media on top of the sinter support with the mesh imprint side

~M 2 M ! 2 ~M 2 M !

5 4 3 2

down, using forceps, placing the one from the lower numbered S 5 (1)

10 M

weighing bottle on the bottom. Apply slight vacuum to aid in

centering the filter media, and place the top portion of the where:

filtration apparatus carefully on to the media before clamping. S = total sediment, % m/m,

M = mass of sample, g,

Shut off the vacuum and pass steam at 100 6 1°C through the

M = mass of lower filter medium before filtration, mg,

heating/cooling coils for 10 min prior to sample addition. 2

M = mass of lower filter medium after filtration, mg,

9.4 Sample Addition—Into a 30 mL beaker, pour approxi-

M = mass of upper filter medium before filtration, mg, and

mately 11 g of the fuel sample prepared as described in 9.1 and

M = mass of upper filter medium after filtration, mg.

weigh to the nearest 0.01 g. Connect the vacuum source and

apply vacuum to an absolute pressure of 40 6 2 kPa minimum

11. Report

(61.3 kPa vacuum). Heat the contents of the beaker to 100 6

11.1 Report the total sediment by hot filtration as the

2°C. Then transfer the contents at 100 6 2°C (Note 5) to the

average of duplicate determinations, to the nearest 0.01 %

center of the filter medium, taking care that no sample touches

m/m. If a 5-g sample has been used, report the results as total

the walls during transfer (Note 6). Reweigh the beaker to the

sediment (5 g) by hot filtration. If filtration is not complete

nearest 0.01 g. The quantity transferred should be 106 0.5 g.

within the specified 25 min, report the results as filtration time

When filtration is not complete in 25 min, discontinue the test

exceeds 25 min.

and repeat using 5 6 0.3 g of sample. If filtration is still not

11.2 Test Report—The test report shall contain at least the

complete in 25 min, report the result as filtration exceeds 25

following information:

min.

11.2.1 The type and identification of the product tested,

NOTE 5—It is expedient to weigh the beaker plus stirrer plus tempera-

11.2.2 A reference to this test method,

ture measurement device before and after transfer to avoid errors incurred

11.2.3 The result of the test (see 11.1),

by attempting to obtain a net weight. Any convenient means of heating the

11.2.4 Any deviation, by agreement or otherwise, from the

fuel sample to 1006 2°C may be used, such as hot plate, water or oil bath,

standard procedures specified (see 11.1), and

or an oven when equipped with a suitable stirrer. Samples that overheat

11.2.5 The date of the test.

above 105°C must be discarded and not reused.

NOTE 6—For samples of high viscosity or high sediment, level filtration 5

12. Precision and Bias

will be aided by small stage or even dropwise addition. It is preferable to

12.1 Precision—The precision of this test method as deter-

avoid complete coverage of the filter medium with unfiltered oil sample.

For samples of low filtration rate the pressure of 40 6 2 kPa should be mined by the statistical examination of interlaboratory test

maintained for the 25-min period.

results is as follows:

9.5 Filter Washing—When the filtration is complete and the

upper filter medium appears dry, continue the steam and

The results of cooperative test programs, from which these values have been

vacuum for a further 5 min. Discontinue the steam supply and derived, can be obtained from ASTM Headquarters. Request RR: D02–1238.

D4870–99

12.1.1 Repeatability—The difference between successive different laboratories on nominally identical test material

test results, expressed as the average of duplicate determina- would, in the long run, in the normal and correct operation of

the test method, exceed the following values only one case in

tions, obtained by the same operator with the same apparatus

twenty:

under constant operating conditions on identical test material,

would, in the long run, in the normal and correct operation of

R 5 0.294=x for residual fuels, and (4)

the test method, exceed the following values only in one case

R 5 0.174 x for distillate fuels containing

=

in twenty:

residual components (5)

r 5 0.089 x for residual fuels, and (2)

=

where x = the average of the test results, % m/m.

12.2 Bias—Since there is no accepted reference material

r 5 0.048 x for distillate fuels containing

=

residual components (3) suitable for determining the bias for the procedure in this test

method, bias cannot be determined.

where x = the average of the test results, % m/m.

13. Keywords

12.1.2 Reproducibility—The difference between two test

results, expressed as the average of duplicate determinations 13.1 ageing; fuel oils; hot filtration; residual fuel; sediment;

independently obtained by different operators operating in storage stability; total sediment

ANNEX

(Mandatory Information)

A1. PRECAUTIONARY STATEMENTS

A1.1 n-Heptane A1.2 Toluene

Keep away from heat, sparks, and open flame. Keep away from heat, sparks, and open flame.

Keep container closed. Keep container closed.

Use with adequate ventilation. Use with adequate ventilation.

Avoid prolonged breathing of vapor or spray mist. Avoid breathing of vapor or spray mist.

Avoid prolonged or repeated skin contact. Avoid prolonged or repeated skin contact.

APPENDIX

(Nonmandatory Information)

X1. PREDICTION OF TOTAL SEDIMENT IN RESIDUAL FUEL OILS

(STANDARD PROCEDURES FOR AGEING)

X1.1 Scope X1.3 Summary of Test Method

X1.1.1 This test method describes two procedures for evalu- X1.3.1 Procedure A for Thermal Ageing—A sample of

ating the sediment forming tendency of residual fuel oils residual fuel oil is aged at 100°C for 24 h.

during storage.

X1.3.2 Procedure B for Chemical Ageing—A sample of

residual fuel oil is diluted with hexadecane (cetane) and then

NOTE X1.1—Experience has shown that this test method can be

heated to 100°C for 1 h.

applicable to other fuel oils as well, but precision is unknown and

additional testing is required to determine that precision. X1.3.3 Following ageing by the above p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.