ASTM D922-23

(Specification)Standard Specification for Nonrigid Vinyl Chloride Polymer Tubing

Standard Specification for Nonrigid Vinyl Chloride Polymer Tubing

ABSTRACT

This specification covers three grades of nonrigid tubing of vinyl chloride polymer or its copolymers with other materials for use in electrical insulation. Clear transparent, black, white, yellow, green, blue, and red shall be considered standard colors. Colors other than these shall be considered special. Dimensional requirements to which tubing shall adhere are inside diameter, wall thickness, and commercial lengths. The tubing shall also conform to physical and electrical requirements, as follows: flammability; tensile strength; effect of elevated temperatures; ultimate elongation after immersion in oil; brittleness temperature; penetration resistance; volume resistivity; dielectric breakdown at high humidity; strain relief; and corrosive effect.

SCOPE

1.1 This specification covers nonrigid tubing of vinyl chloride polymer or its copolymers with other materials for use in electrical insulation in three grades, as follows:

1.1.1 Grade A—General-purpose.

1.1.2 Grade B—Low-temperature.

1.1.3 Grade C—High-temperature.

1.2 This standard and IEC-60684-3-100 to -105 address the same subject matter but differ in technical content.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D922 − 23

Standard Specification for

1

Nonrigid Vinyl Chloride Polymer Tubing

This standard is issued under the fixed designation D922; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* E176 Terminology of Fire Standards

2.2 IEC Standards:

1.1 This specification covers nonrigid tubing of vinyl chlo-

IEC-60684-3-100 to -105 Flexible insulating sleeving, Part

ride polymer or its copolymers with other materials for use in

3

3, Sheets 100 to 105: Extruded PVC sleeving

electrical insulation in three grades, as follows:

1.1.1 Grade A—General-purpose.

3. Terminology

1.1.2 Grade B—Low-temperature.

3.1 Definitions:

1.1.3 Grade C—High-temperature.

3.1.1 For definitions pertaining to electrical insulation, refer

1.2 This standard and IEC-60684-3-100 to -105 address the

to Terminology D1711.

same subject matter but differ in technical content.

3.1.2 For definitions pertaining to fire standards, refer to

Terminology E176.

1.3 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

4. Ordering Information

conversions to SI units that are provided for information only

4.1 Orders for material covered by this specification shall

and are not considered standard.

include the following:

1.4 This standard does not purport to address all of the

4.1.1 Grade of tubing,

safety concerns, if any, associated with its use. It is the

4.1.2 Size and color,

responsibility of the user of this standard to establish appro-

4.1.3 Total length in feet [or meters],

priate safety, health, and environmental practices and deter-

4.1.4 Length of cut pieces in inches [or centimeters], if any,

mine the applicability of regulatory limitations prior to use.

and

1.5 This international standard was developed in accor-

4.1.5 Amount of tubing on each spool or in each coil, if not

dance with internationally recognized principles on standard-

standard packaging with the supplier.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

5. Color

mendations issued by the World Trade Organization Technical

5.1 Clear transparent, black, white, yellow, green, blue, and

Barriers to Trade (TBT) Committee.

red shall be considered standard colors. Other colors shall be

considered special. The color desired shall be specified in the

2. Referenced Documents

purchase order.

2

2.1 ASTM Standards:

5.2 Conditioning:

D876 Test Methods for Nonrigid Vinyl Chloride Polymer

5.2.1 Unless otherwise specified, all testing for this standard

Tubing Used for Electrical Insulation

shall be conducted at 23 °C 6 5 °C (73 °F 6 9 °F) and a

D1711 Terminology Relating to Electrical Insulation

relative humidity of 50 % 6 10 % RH. All samples shall be

D3636 Practice for Sampling and Judging Quality of Solid

preconditioned at 23 °C 6 5 °C (73 °F 6 9 °F) and a relative

Electrical Insulating Materials

humidity of 50 % 6 10 % RH for a minimum of 30 minutes

prior to test.

1

This specification is under the jurisdiction of ASTM Committee D09 on

Electrical and Electronic Insulating Materials and is the direct responsibility of 6. Dimensional Requirements

Subcommittee D09.07 on Electrical Insulating Materials.

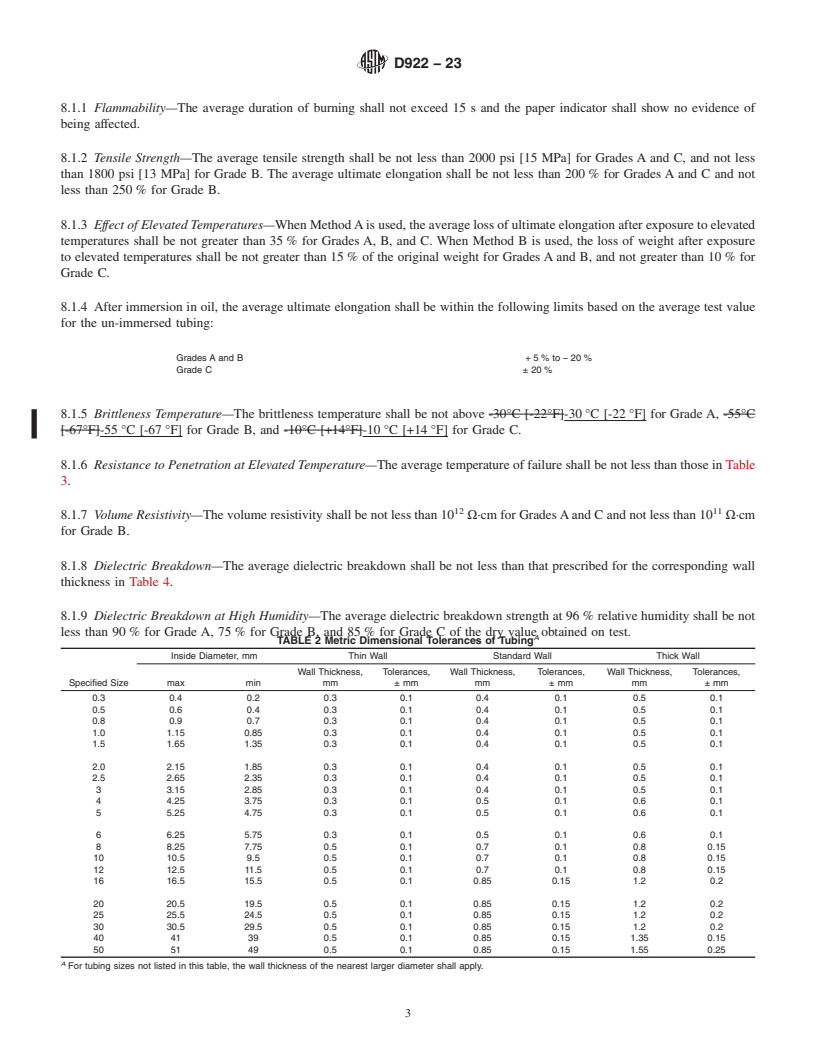

6.1 Inside Diameter—The inside diameter of the tubing

Current edition approved Feb. 1, 2023. Published February 2023. Originally

approved in 1947. Last previous edition approved in 2018 as D922 – 18. DOI: shall conform to the requirements prescribed in Table 1 or

10.1520/D0922-23.

Table 2.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D922 − 23

A,B

TABLE 1 Dimensional Tolerances of Tubing

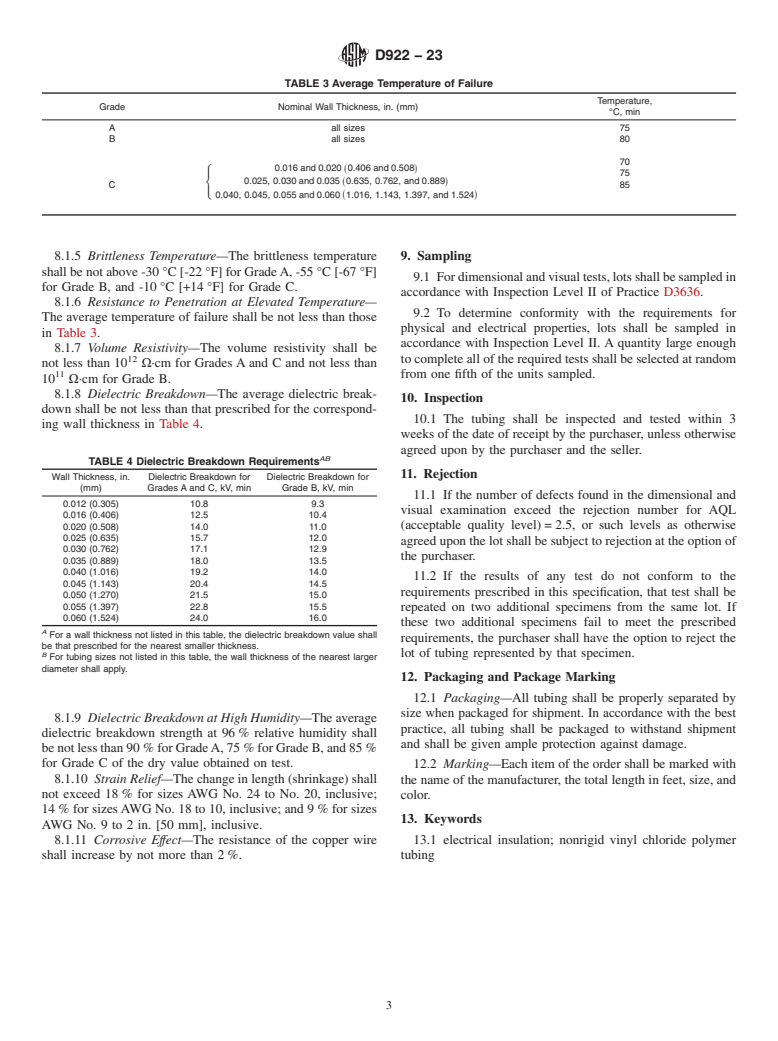

6.2 Wall Thickness—The wall thickness of the tubing shall

Inside Diameter, in. Wall Thickness

conform to the requirements prescribed in Table 1 or Table 2.

Tolerances,

Specified Size

Wall Thi

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D922 − 18 D922 − 23

Standard Specification for

1

Nonrigid Vinyl Chloride Polymer Tubing

This standard is issued under the fixed designation D922; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers nonrigid tubing of vinyl chloride polymer or its copolymers with other materials for use in electrical

insulation in three grades, as follows:

1.1.1 Grade A—General-purpose.

1.1.2 Grade B—Low-temperature.

1.1.3 Grade C—High-temperature.

1.2 This standard and IEC-60684-3-100 to -105 address the same subject matter but differ in technical content.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of

the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D876 Test Methods for Nonrigid Vinyl Chloride Polymer Tubing Used for Electrical Insulation

D1711 Terminology Relating to Electrical Insulation

1

This specification is under the jurisdiction of ASTM Committee D09 on Electrical and Electronic Insulating Materials and is the direct responsibility of Subcommittee

D09.07 on Electrical Insulating Materials.

Current edition approved May 1, 2018Feb. 1, 2023. Published May 2018February 2023. Originally approved in 1947. Last previous edition approved in 20112018 as

D922 – 11.D922 – 18. DOI: 10.1520/D0922-18. 10.1520/D0922-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D922 − 23

D3636 Practice for Sampling and Judging Quality of Solid Electrical Insulating Materials

E176 Terminology of Fire Standards

2.2 IEC Standards:

3

IEC-60684-3-100 to -105 Flexible insulating sleeving, Part 3, Sheets 100 to 105: Extruded PVC sleeving

3. Terminology

3.1 Definitions:

3.1.1 For definitions pertaining to electrical insulation, refer to Terminology D1711.

3.1.2 For definitions pertaining to fire standards, refer to Terminology E176.

4. Ordering Information

4.1 Orders for material covered by this specification shall include the following:

4.1.1 Grade of tubing,

4.1.2 Size and color,

4.1.3 Total length in feet [or metres],meters],

4.1.4 Length of cut pieces in inches [or centimetres],centimeters], if any, and

4.1.5 Amount of tubing on each spool or in each coil, if not standard packaging with the supplier.

5. Color

5.1 Clear transparent, black, white, yellow, green, blue, and red shall be considered standard colors. Other colors shall be

considered special. The color desired shall be specified in the purchase order.

5.2 Conditioning:

5.2.1 Unless otherwise specified, all testing for this standard shall be conducted at 23 6 5°C (73 6 9°F)23 °C 6 5 °C (73 °F 6

9 °F) and a relative humidity of 5050 % 6 10 % RH. All samples shall be preconditioned at 23 6 5°C (73 6 9°F)23 °C 6 5 °C

(73 °F 6 9 °F) and a relative humidity of 5050 % 6 10 % RH for a minimum of 3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.